Beruflich Dokumente

Kultur Dokumente

Mill - Drive Gearbox Input Pinion Shaft Failure

Hochgeladen von

JyesthaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mill - Drive Gearbox Input Pinion Shaft Failure

Hochgeladen von

JyesthaCopyright:

Verfügbare Formate

Problem Statement: Poor life & frequent failure of Sag Mill drive gearbox input pinion shaft at Mines.

Observations: The above problem was studied in detail and following observations were made: It was reported that in last three years, total 3 input pinion shafts of the main mill drive gearbox have failed and the failed pinion shafts gave ~12 months life (refer plate -1 & 2). The speed rating of the gearbox is 1470/232.59 and it was designed for a service life factor of 1.92. Department confirmed that each failure was reported to OEM via emails but from OEM no satisfactory answer for the failures of input pinion shaft was given as a result every time the failed shaft was replaced with available spare shaft and the problem reappeared after sometime. It was observed that all three failures of input pinion shaft took place from the same location i.e. the position where pinion is mounted on the pinion shaft (refer plate -2, rough sketch). Clear beach marks (progressive lines) were observed on the fractured surface of both failed shafts. The beach marks covers around 90% of the fractured surface area and is an indication of unidirectional fatigue mode failure (refer plate 3 & 4). The instantaneous zone area (final fracture area) was found very small ~10% of the fractured surface area indicates that the designer has taken sufficient service factor during designing. It also indicates that the failure slowly propagated across the fatigue zone, and then very rapidly crossed the instantaneous zone (refer plate-3&4). It was observed that in all the failed pinion shafts, the surface of the pinion shaft had peeled off along its circumference i.e. spalling, which is an indication of failure due to high surface hardness. Moreover, presence of beach marks in the failed surface (in spalling area) indicate that the failure took place in fatigue mode and originates from the keyway fillet radius due to severe stress concentration (refer plate - 3 & 4)

Recommendations: Above observations suggest that the component failed due to rotating bending fatigue under low nominal load and severe stress concentration created due to high surface hardness (improper heat treatment) and sharp fillet radius in the keyway at the location of failure. This aspect may be checked at OEM end.

Page 1 of 6

Use of 42CrMo4V IS:5517, Class 4 forging material (volume hardened & tempered) i.e. En19 could be explored, which will definitely give better fatigue life under present operating conditions. Include suitable fillet radius (R1 to R1.6) to avoid stress raiser and better fatigue life in the drawing.

Page 2 of 6

SAG Mill Drive Gearbox Input Pinion Shaft Failure (Plate-1)

INPUT PINION SHAFT

FAILURE LOCATION

G. A. drawing of the Mill drive gearbox

Photographs of the failed input pinion shaft (Feb. 2007)

Page 3 of 6

SAG Mill Drive Gearbox Input Pinion Shaft Failure (Plate-2)

The broken input pinion shaft (May 2008)

FAILURE LOCATION

Rough sketch of the failed input pinion shaft

Page 4 of 6

SAG Mill Drive Gearbox Input Pinion Shaft Failure (Plate-3)

SPALLING OF THE SURFACE IS AN INDICATION OF HIGH SURFACE HARDNESS

Side view of one of the failed input pinion shaft

SMALL INSTANTANEOUS ZONE AREA IS AN IDICATION THAT THE SHAFT FAILED UNDER NOMINAL LOAD

ORIGIN

Beach marks is a clear indication of fatigue failure

Book photograph of a fatigue failure

Page 5 of 6

SAG Mill Drive Gearbox Input Pinion Shaft Failure (Plate-4)

ORIGIN

BEACH MARKS

ONCE AGAIN SPALLING OF THE SURFACE (MATEL CHIPS CAME OUT) IS AN INDICATION OF HIGH SURFACE HARDNESS OR IMPROPER HEAT TREATMET DURING MANUFACTURING.

Side view of second failed input pinion shaft

INSTANTANEOUS ZONE

Beach marks & small instantaneous area is a clear indication of shaft failure under nominal bending fatigue mode

Page 6 of 6

Das könnte Ihnen auch gefallen

- Longwall Mining at Shallow Depth of Cover in IndiaVon EverandLongwall Mining at Shallow Depth of Cover in IndiaNoch keine Bewertungen

- Drilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsVon EverandDrilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsBewertung: 5 von 5 Sternen5/5 (1)

- Failure Analysis of Sheared Shaft of A Brine Recycle Pump...Dokument12 SeitenFailure Analysis of Sheared Shaft of A Brine Recycle Pump...Pd RarNoch keine Bewertungen

- Failure Analysis of An Outer MainDokument3 SeitenFailure Analysis of An Outer Mainaspul62Noch keine Bewertungen

- Service Bulletin RTA-46Dokument12 SeitenService Bulletin RTA-46Christopher Garcia100% (1)

- Exemplary Hot Kiln Alignment ReportDokument82 SeitenExemplary Hot Kiln Alignment ReportsamihakhanNoch keine Bewertungen

- BHCS34749 Q2 - 2020 - Radial - Rub - Centrifugal - Compressor - R3Dokument8 SeitenBHCS34749 Q2 - 2020 - Radial - Rub - Centrifugal - Compressor - R3Maria Gabriela MalloneyNoch keine Bewertungen

- Failure Analysis of A Helical GearDokument7 SeitenFailure Analysis of A Helical Geartheerapat patkaewNoch keine Bewertungen

- TIL 1304 3 - 9th Stage Stator Casing Hook Fit CrackingDokument4 SeitenTIL 1304 3 - 9th Stage Stator Casing Hook Fit CrackinghernangNoch keine Bewertungen

- Contoh Schedule RepairDokument17 SeitenContoh Schedule RepairUdoy LahNoch keine Bewertungen

- Examination of A Failed Fan Blade Rolls Royce RB 211 Trent 892 Turbo Fan EngineDokument21 SeitenExamination of A Failed Fan Blade Rolls Royce RB 211 Trent 892 Turbo Fan EnginePDDELUCANoch keine Bewertungen

- 27 MW Steam Turbine Blade Failure Case HistoryDokument23 Seiten27 MW Steam Turbine Blade Failure Case HistoryPablo Scott100% (1)

- 4-Spalling Investigation of Connecting RodDokument10 Seiten4-Spalling Investigation of Connecting RodHakimNoch keine Bewertungen

- 1 Exemplary Technical Report 2012 PDFDokument99 Seiten1 Exemplary Technical Report 2012 PDFMKPashaPashaNoch keine Bewertungen

- 1 Exemplary Technical Report 2012Dokument99 Seiten1 Exemplary Technical Report 2012MKPashaPashaNoch keine Bewertungen

- Failure Analysis of Coal Pulverizer Mill PDFDokument12 SeitenFailure Analysis of Coal Pulverizer Mill PDFHendraNoch keine Bewertungen

- Failure Analysis of Twin Screw Extruder Shaft: Technicalarticle-Peer-ReviewedDokument8 SeitenFailure Analysis of Twin Screw Extruder Shaft: Technicalarticle-Peer-ReviewedluisNoch keine Bewertungen

- Coke Drum Anchor Bolt FailuresDokument7 SeitenCoke Drum Anchor Bolt FailuresmirekwaznyNoch keine Bewertungen

- Propeller CrackDokument22 SeitenPropeller CrackArdhika Hermigo100% (1)

- Engineering Failure Analysis: Xiao-Lei Xu, Zhi-Wei YuDokument11 SeitenEngineering Failure Analysis: Xiao-Lei Xu, Zhi-Wei YusobhanNoch keine Bewertungen

- Crankshaft Failure Due To Fatigue-ADokument7 SeitenCrankshaft Failure Due To Fatigue-Aaschutsehay0123Noch keine Bewertungen

- Report Gundriling AAMAstakhovDokument27 SeitenReport Gundriling AAMAstakhovGyörgy Murvai100% (1)

- Method Statement For Field Erection Storage TanksDokument29 SeitenMethod Statement For Field Erection Storage TanksTee Klong Rung100% (1)

- Failure Analysis of A Leak Off Oil Pipe From Injection Valves of An Off Shore Operating Diesel Engine - 2007 - Engineering Failure Analysis PDFDokument13 SeitenFailure Analysis of A Leak Off Oil Pipe From Injection Valves of An Off Shore Operating Diesel Engine - 2007 - Engineering Failure Analysis PDFAPINoch keine Bewertungen

- M2010051in-Mcb - Rolling Suggestions PDFDokument42 SeitenM2010051in-Mcb - Rolling Suggestions PDFthaivinhtuyNoch keine Bewertungen

- Paper Falla Por FluenciaDokument8 SeitenPaper Falla Por FluenciaJuan Diego Ospina FlorezNoch keine Bewertungen

- Failure Analysis On Diesel-Engine Valve SpringsDokument7 SeitenFailure Analysis On Diesel-Engine Valve SpringsReza FebriNoch keine Bewertungen

- Measurement Manual: Procedure For Rocking Test (Wear Mearsurement) in Slewing Bearing For Marine CraneDokument6 SeitenMeasurement Manual: Procedure For Rocking Test (Wear Mearsurement) in Slewing Bearing For Marine CranePaul Lucian Ventel100% (5)

- Engineering Failure Analysis: Saharash Khare, O.P. Singh, K. Bapanna Dora, C. SasunDokument10 SeitenEngineering Failure Analysis: Saharash Khare, O.P. Singh, K. Bapanna Dora, C. SasunBima SorayaNoch keine Bewertungen

- Analysis of Process Fan Failure & Bearing Housing Case - StudyDokument16 SeitenAnalysis of Process Fan Failure & Bearing Housing Case - Studytylerdurdane100% (1)

- Construction File Jet GroutingDokument38 SeitenConstruction File Jet GroutingCarlos Manuel Alvarez Nogueira0% (1)

- Operational Evaluation of Piston Ring WearDokument10 SeitenOperational Evaluation of Piston Ring WearDarmawan PutrantoNoch keine Bewertungen

- Solid Particle Erosion and Mechanical DamageDokument5 SeitenSolid Particle Erosion and Mechanical DamageCarlos ToscanoNoch keine Bewertungen

- Failure Analysis: Integrally Geared Compressor Cracked ImpellerDokument35 SeitenFailure Analysis: Integrally Geared Compressor Cracked ImpellerAbdulrahman AlkhowaiterNoch keine Bewertungen

- Engine Base & BlockDokument47 SeitenEngine Base & Blockkr_abhijeet7235658750% (2)

- Failure Analysis of A 1990 Mazda Miata Crankshaft and Timing Pulley BoltDokument12 SeitenFailure Analysis of A 1990 Mazda Miata Crankshaft and Timing Pulley BoltKhan Mohammed Ameen Mohammed SageerNoch keine Bewertungen

- 72 50 02Dokument6 Seiten72 50 02alvaro lemosNoch keine Bewertungen

- Studyof Frequent Failuresof Pressure Rollerat Sinter Plant PGDokument20 SeitenStudyof Frequent Failuresof Pressure Rollerat Sinter Plant PGJoão PedroNoch keine Bewertungen

- SL98-356 B&W Service LetterDokument14 SeitenSL98-356 B&W Service LetterkamalNoch keine Bewertungen

- Pump Monitoring: Parts and Areas That Should Be Monitored For Efficient ProductivityDokument56 SeitenPump Monitoring: Parts and Areas That Should Be Monitored For Efficient ProductivityKim Howard CastilloNoch keine Bewertungen

- Soft Torque System (Paper) - OME Paper 112Dokument18 SeitenSoft Torque System (Paper) - OME Paper 112Odion Ikhajiagbe100% (1)

- PoleAttachmentCracking MooreDokument8 SeitenPoleAttachmentCracking MooreSirish ShresthaNoch keine Bewertungen

- Class 2 OralsDokument26 SeitenClass 2 Oralssahilpawar100% (1)

- Checklist RigDokument104 SeitenChecklist RigKiryaki Francis100% (2)

- Bearing InspectionDokument20 SeitenBearing InspectionMoustapha SeyeNoch keine Bewertungen

- B&W S60MC M.E Ahead and Astern Changing Function InabilityDokument3 SeitenB&W S60MC M.E Ahead and Astern Changing Function InabilityRani NoumanNoch keine Bewertungen

- Failure Analysis of Air Cooled Conden 2014 Case Studies in Engineering FailuDokument7 SeitenFailure Analysis of Air Cooled Conden 2014 Case Studies in Engineering FailuMeccbellNoch keine Bewertungen

- GRABON - Tribological Characteristics of One-Process and Two-Process Cylinder Liner Honed Surface Under Reciprocating Sliding ConditionsDokument11 SeitenGRABON - Tribological Characteristics of One-Process and Two-Process Cylinder Liner Honed Surface Under Reciprocating Sliding ConditionsSilvaNoch keine Bewertungen

- Design and Optimization of Crankpin - A ReviewDokument7 SeitenDesign and Optimization of Crankpin - A ReviewMaiman LatoNoch keine Bewertungen

- Premature Bearing FailuresDokument21 SeitenPremature Bearing FailuresArup Das100% (1)

- The Effect of Rotor Blade Thickness and Surface Finish On The Erformance of A Small Axial Flow TurbineDokument16 SeitenThe Effect of Rotor Blade Thickness and Surface Finish On The Erformance of A Small Axial Flow TurbinePeter IjaramendiNoch keine Bewertungen

- Coal Mine Modeling Problem 2020Dokument14 SeitenCoal Mine Modeling Problem 2020Harold Leòn CadenasNoch keine Bewertungen

- RTA-46 Cracks in ColumnDokument12 SeitenRTA-46 Cracks in ColumnCatalin CataNoch keine Bewertungen

- 501 F Rotor OverhaulDokument3 Seiten501 F Rotor OverhaulmacrespoNoch keine Bewertungen

- Failure Analysis of A Gearbox of A Conveyor Belt: Technicalarticle-Peer-ReviewedDokument7 SeitenFailure Analysis of A Gearbox of A Conveyor Belt: Technicalarticle-Peer-RevieweddouglasncamiloNoch keine Bewertungen

- Calciner Coal PfisterDokument12 SeitenCalciner Coal Pfistermalek.anas.omar2022Noch keine Bewertungen

- Lectura Problemas de CTDokument19 SeitenLectura Problemas de CTAlexVillagómezJacomeNoch keine Bewertungen

- Gluzman - Turbine Bearing Wiped On CoastdownDokument18 SeitenGluzman - Turbine Bearing Wiped On CoastdownArzu AkarNoch keine Bewertungen

- API-653 Tank Inspection Sample ReportDokument19 SeitenAPI-653 Tank Inspection Sample Reportツ ツ93% (15)

- Roaster Bed Fusion After Power FailureDokument2 SeitenRoaster Bed Fusion After Power FailureJyesthaNoch keine Bewertungen

- HSM - Gamma Ray Measuring House Bearing FailureDokument6 SeitenHSM - Gamma Ray Measuring House Bearing FailureJyesthaNoch keine Bewertungen

- Right Steps To World Class ManufacturingDokument13 SeitenRight Steps To World Class ManufacturingJyesthaNoch keine Bewertungen

- HGP - Field TrippingDokument2 SeitenHGP - Field TrippingJyesthaNoch keine Bewertungen

- ZINC Plant AnimationDokument10 SeitenZINC Plant AnimationJyesthaNoch keine Bewertungen

- FP IgniterDokument13 SeitenFP IgniterDavid AlexanderNoch keine Bewertungen

- Summer Training ProgramDokument21 SeitenSummer Training ProgramAyan BorgohainNoch keine Bewertungen

- C Rollway PDFDokument16 SeitenC Rollway PDFoxonoerNoch keine Bewertungen

- Comparative Cost Analysis - MechanicalDokument1 SeiteComparative Cost Analysis - MechanicalRayley Daven SusiNoch keine Bewertungen

- Grand Vitara 2010Dokument191 SeitenGrand Vitara 2010Fernando OrtizNoch keine Bewertungen

- Development of A Device For Brazing Copper Pipes in HVAC InstallationsDokument8 SeitenDevelopment of A Device For Brazing Copper Pipes in HVAC InstallationsJournal of Interdisciplinary PerspectivesNoch keine Bewertungen

- Iveco Daily Euto 4 Repair Manual Mechanical Electric and Electronic 2006 2009Dokument20 SeitenIveco Daily Euto 4 Repair Manual Mechanical Electric and Electronic 2006 2009marcia100% (46)

- A Seminar Report On Water Cooled ChillerDokument15 SeitenA Seminar Report On Water Cooled ChillerSudip Sharma100% (3)

- Cat Needle Valve11Dokument13 SeitenCat Needle Valve11Nilesh MistryNoch keine Bewertungen

- Safety in Welding and CuttingDokument33 SeitenSafety in Welding and CuttingBhavya ShuklaNoch keine Bewertungen

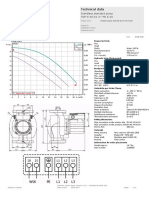

- BOMBAS PRIMARIAS - Data - Sheet - TOP-S - 40 - 10 - 3 - PN - 6 - 10Dokument1 SeiteBOMBAS PRIMARIAS - Data - Sheet - TOP-S - 40 - 10 - 3 - PN - 6 - 10Sebastian FuentesNoch keine Bewertungen

- HMC 080Dokument12 SeitenHMC 080Mohamed ElmakkyNoch keine Bewertungen

- 2.3.2 TensileTesting SIMDokument4 Seiten2.3.2 TensileTesting SIMRaymond NguyenNoch keine Bewertungen

- Flexible Grouted ClampDokument14 SeitenFlexible Grouted ClampMiroslav AleksicNoch keine Bewertungen

- Blowout PreventerDokument8 SeitenBlowout PreventerLaminus DZNoch keine Bewertungen

- EG1109 Lectures 10-12Dokument61 SeitenEG1109 Lectures 10-12Steven KuaNoch keine Bewertungen

- Spun PilesDokument2 SeitenSpun Pileshoetapea100% (1)

- Exercise # 1.1Dokument1 SeiteExercise # 1.1iamniczdejzNoch keine Bewertungen

- Operacion de Sistemas Power Shift - D4EDokument6 SeitenOperacion de Sistemas Power Shift - D4ERenato LicettiNoch keine Bewertungen

- Pump ListDokument20 SeitenPump ListPHAM PHI HUNG100% (1)

- 2017 Book MechanicsAndThermodynamics PDFDokument459 Seiten2017 Book MechanicsAndThermodynamics PDFLuis Muñoz Riquelme100% (1)

- Planer (Motor) (R921805375) (18 - ) (24 - ) - (S - N 341000655 & Above, 231611101 & Above, 721700342 & Above, 231711101 & Above) - PlanerDokument3 SeitenPlaner (Motor) (R921805375) (18 - ) (24 - ) - (S - N 341000655 & Above, 231611101 & Above, 721700342 & Above, 231711101 & Above) - PlanerPedro Alfonso PerezNoch keine Bewertungen

- CO2 Storage Tank Product Manual Ws PDFDokument34 SeitenCO2 Storage Tank Product Manual Ws PDFrafik1995Noch keine Bewertungen

- AOS Voltex Hybrid Electric Heat Pump English CANXE50004 - 1015Dokument2 SeitenAOS Voltex Hybrid Electric Heat Pump English CANXE50004 - 1015Pat AuffretNoch keine Bewertungen

- GPG216 Energy Saving in The Filtration and Drying of Compressed AirDokument31 SeitenGPG216 Energy Saving in The Filtration and Drying of Compressed AirIppiNoch keine Bewertungen

- SLC-D Cyclone PreheaterDokument55 SeitenSLC-D Cyclone PreheaterAdnan Nawaz100% (2)

- NPCP Chapter 6Dokument6 SeitenNPCP Chapter 6Cristian OmacNoch keine Bewertungen

- Ficha Cat Excavadorahidraulica 324DLDokument32 SeitenFicha Cat Excavadorahidraulica 324DLAnthony Arturo Mestiza SalinasNoch keine Bewertungen

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDokument1 SeiteField Welding Inspection Checklist: Wisconsin Department of TransportationDele TedNoch keine Bewertungen