Beruflich Dokumente

Kultur Dokumente

U412 - 2 Hour

Hochgeladen von

maher58Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

U412 - 2 Hour

Hochgeladen von

maher58Copyright:

Verfügbare Formate

BXUV.

U412 - Fire Resistance Ratings - ANSI/UL 263

http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpag...

BXUV.U412 Fire Resistance Ratings - ANSI/UL 263

Page Bottom

Design/System/Construction/Assembly Usage Disclaimer

Authorities Having Jurisdiction should be consulted in all cases as to the particular requirements covering the installation and use of UL Listed or Classified products, equipment, system, devices, and materials. Authorities Having Jurisdiction should be consulted before construction. Fire resistance assemblies and products are developed by the design submitter and have been investigated by UL for compliance with applicable requirements. The published information cannot always address every construction nuance encountered in the field. When field issues arise, it is recommended the first contact for assistance be the technical service staff provided by the product manufacturer noted for the design. Users of fire resistance assemblies are advised to consult the general Guide Information for each product category and each group of assemblies. The Guide Information includes specifics concerning alternate materials and alternate methods of construction. Only products which bear UL's Mark are considered as Classified, Listed, or Recognized.

Fire Resistance Ratings - ANSI/UL 263

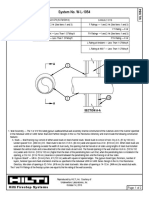

See General Information for Fire Resistance Ratings - ANSI/UL 263 Design No. U412 March 23, 2009 Nonbearing Wall Rating 2 HR.

1. Floor and Ceiling Runner (Not Shown) 25 MSG (min) galv steel 1 in. high, return legs 1-5/8 in. wide (min), attached to floor and ceiling with fasteners 24 in. OC max. 1A. Framing Members* Floor and Ceiling Runners (Not shown) As an alternate to Item 1 - Channel shaped, min. 1-5/8 in. wide, attached to floor and ceiling with fasteners 24 in. OC. max. SCAFCO STEEL STUD MANUFACTURING CO Type SUPREME Framing System

1B. Framing Members - Floor and Ceiling Runner* Not shown - In lieu of Item 1 For use with Item 2B, proprietary channel shaped runners, 1-1/4 in. deep by 1-5/8 in. wide fabricated from min 0.0200 in. thick galv steel, attached to floor and ceiling with fasteners spaced 24 in. OC max. MARINO\WARE A DIV OF WARE INDUSTRIES INC Viper20S Track, Viper20D Track

2. Steel Studs 1-5/8 in. wide (min), 1-1/4 in. legs, 1/4 in. return, formed of 25 MSG (min) galv steel max stud

1 of 4

3/25/2009 2:08 PM

BXUV.U412 - Fire Resistance Ratings - ANSI/UL 263

http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpag...

spacing 24 in. OC. Studs to be cut 3/4 in. less than assembly height. 2A. Framing Members* Steel Studs As an alternate to Item 2 - Channel shaped studs, min. 1-5/8 in. wide, spaced a max of 24 in. OC. Studs to be cut 3/4 in. less than assembly height. SCAFCO STEEL STUD MANUFACTURING CO Type SUPREME Framing System

2B. Framing Members - Metal Studs* Not shown - In lieu of Item 2 For use with Item 1B, proprietary channel shaped steel studs, 1-1/4 in. deep by 1-5/8 in. wide fabricated from min 0.0200 in. thick galv steel. Studs 3/4 in. less in lengths than assembly heights. MARINO\WARE A DIV OF WARE INDUSTRIES INC Viper20S, Viper20D

3. Batts and Blankets* (Optional) Mineral wool or glass fiber batts, partially or completely filling stud cavity. Fasten each batt to wallboard base layer with a min 9/16 in. long staple. Use five staples for each 4 ft long piece. Drive one staple in the center of each piece and a staple at each corner, approx 3 in. from edges. See Batts and Blankets (BZJZ) category for names of manufacturers. 3A. Fiber, Sprayed* As an alternate to Batts and Blankets (Item 3) Spray applied cellulose insulation material. The fiber is applied with water to completely fill the enclosed cavity in accordance with the application instructions

supplied with the product. Nominal dry density of 3.0 lb/ft3. Alternate application method: The fiber is applied with U.S. Greenfiber LLC Type AD100 hot melt adhesive at a nominal ratio of one part adhesive to 6.6 parts fiber to completely fill the enclosed cavity in accordance with the application instructions supplied with the product. Nominal dry density of 2.5 lb/ft3.

U S GREENFIBER L L C Cocoon2 Stabilized or Cocoon-FRM (Fire Rated Material)

3B. Fiber, Sprayed* As an alternate to Batts and Blankets (Item 3) and Item 3A - Spray applied cellulose insulation material. The fiber is applied with water to interior surfaces in accordance with the application instructions supplied with the product. Applied to completely fill the enclosed cavity. Minimum dry density of 4.3 pounds per cubic ft. NU-WOOL CO INC Cellulose Insulation

4. Gypsum Board* 1/2 in. thick. Wallboard applied vertically in two layers. (Laminated System) Inner layer attached to studs with 1 in. long Type S steel screws spaced 24 in. O.C. along vertical edges and 24 in. O.C. in the field. Outer layer laminated to inner layer with joint compound, applied with a notched spreader producing continuous beads of compound about 3/8 in. in diameter, spaced not greater than 2 in. O.C. Joints of laminated outer layer offset 12 in. from inner layer joints. Outer layer wallboard attached to inner layer with 1-1/2 in. long Type G steel screws spaced 24 in. O.C. along edges and center line of each sheet.

2 of 4

3/25/2009 2:08 PM

BXUV.U412 - Fire Resistance Ratings - ANSI/UL 263

http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpag...

Optional, (Direct Attached System) Wallboard applied vertically in two layers. Inner layer attached to studs with 1 in. long Type S steel screws spaced 24 in. O.C. in the field and along the vertical edges. Outer layer attached to the studs over the inner layer with 1-5/8 in. long Type S steel screws spaced 12 in. O.C. in the field, along the vertical edges, and to the floor and ceiling runners. Joints of screw-attached outer layer offset from inner layer joints. Optional, (Direct Attached System) Inner layer wallboard applied vertically, outer layer wallboard applied horizontally. Inner layer attached to studs with 1 in. Type S steel screws spaced 24 in. O.C. along vertical edges and in the field. Outer layer attached to the studs over the inner layer with 1-5/8 in. long Type S steel screws spaced 12 in. OC in the field, along the vertical edges, and to the floor and ceiling runners. Outer layer secured to inner layer wallboard with 1-1/2 in. long Type G steel screws located midway between studs and 1 in. from the horizontal joint. Outer layer wallboard joints covered with joint tape and min two coats of joint compound, and screw heads covered with min two coats of joint compound. As an alternate, nom 3/32 in. thick gypsum veneer plaster may be applied to the entire surface of Classified veneer baseboard. Joints reinforced. AMERICAN GYPSUM CO Types AG-C.

CERTAINTEED GYPSUM INC Type FRPC, ProRoc Type C.

CERTAINTEED GYPSUM CANADA INC ProRoc Type C.

CANADIAN GYPSUM COMPANY Type C, IP-X2, IPC-AR or WRC.

GEORGIA-PACIFIC GYPSUM L L C Types 5, C, , DAP, DA.

LAFARGE NORTH AMERICA INC Type LGFC-C, LGFC-C/A.

NATIONAL GYPSUM CO Types FSK-C, FSW-G, FSW-C, FSMR-C.

PABCO BUILDING PRODUCTS L L C, DBA PABCO GYPSUM Type PG-C.

PANEL REY S A Type PRC

TEMPLE-INLAND FOREST PRODUCTS CORP Type TG-C.

UNITED STATES GYPSUM CO Type C, IP-X2, IPC-AR or WRC.

USG MEXICO S A DE C V Type C, IP-X2, IPC-AR or WRC.

4A. Gypsum Board* (As an alternate to Item 4) 5/8 in. thick. Two layers installed by any method as described in Item 4. NATIONAL GYPSUM CO Type FSMR-C.

*Bearing the UL Classification Mark Last Updated on 2009-03-23

Questions?

Notice of Disclaimer

Page Top

Copyright 2009 Underwriters Laboratories Inc. The appearance of a company's name or product in this database does not in itself assure that products so identified have been manufactured under UL's Follow-Up Service. Only those products bearing the UL Mark should be considered to be Listed and covered under

3 of 4

3/25/2009 2:08 PM

BXUV.U412 - Fire Resistance Ratings - ANSI/UL 263

http://database.ul.com/cgi-bin/XYV/template/LISEXT/1FRAME/showpag...

UL's Follow-Up Service. Always look for the Mark on the product. UL permits the reproduction of the material contained in the Online Certification Directory subject to the following conditions: 1. The Guide Information, Designs and/or Listings (files) must be presented in their entirety and in a non-misleading manner, without any manipulation of the data (or drawings). 2. The statement "Reprinted from the Online Certifications Directory with permission from Underwriters Laboratories Inc." must appear adjacent to the extracted material. In addition, the reprinted material must include a copyright notice in the following format: "Copyright 2009 Underwriters Laboratories Inc."

4 of 4

3/25/2009 2:08 PM

Das könnte Ihnen auch gefallen

- D 1761 - 88 R00 - Rde3njeDokument13 SeitenD 1761 - 88 R00 - Rde3njeAnonymous 6SHxUn1xd10% (1)

- VSTEP DH Su PhamDokument285 SeitenVSTEP DH Su PhamPhát Lợi Nguyễn VưuNoch keine Bewertungen

- Technical Data Sheet Avikote Av 650 R PDFDokument2 SeitenTechnical Data Sheet Avikote Av 650 R PDFCIAKNoch keine Bewertungen

- FireProofing SpecificationDokument10 SeitenFireProofing SpecificationSalman ShaikhNoch keine Bewertungen

- BXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqDokument4 SeitenBXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqEmanuel Ciprian CiucurNoch keine Bewertungen

- GEN ED Math B S2017 Ans Key PDFDokument6 SeitenGEN ED Math B S2017 Ans Key PDFednalyn75% (4)

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDokument4 SeitenXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamNoch keine Bewertungen

- X854Dokument10 SeitenX854RimNoch keine Bewertungen

- J718Dokument4 SeitenJ718Gatot KeceNoch keine Bewertungen

- FireproofingDokument3 SeitenFireproofingarki_emmanNoch keine Bewertungen

- Chartek 1709 Ul Xr625 NuevaDokument3 SeitenChartek 1709 Ul Xr625 NuevaAndres LopezNoch keine Bewertungen

- GAP Guidelines: Fireproofing For Hydrocarbon Fire ExposuresDokument7 SeitenGAP Guidelines: Fireproofing For Hydrocarbon Fire ExposuresAlbert GuiNoch keine Bewertungen

- C892Dokument5 SeitenC892dinhtung2210Noch keine Bewertungen

- Y710Dokument2 SeitenY710RimNoch keine Bewertungen

- Cafco Fendolite Mii Application Guidelines PDFDokument23 SeitenCafco Fendolite Mii Application Guidelines PDFTanmay GorNoch keine Bewertungen

- Pew 105.04 (P)Dokument174 SeitenPew 105.04 (P)Raj BindasNoch keine Bewertungen

- Seoul, Korea: Estimation SheetDokument6 SeitenSeoul, Korea: Estimation SheetHRK65Noch keine Bewertungen

- 10-1 PaintDokument5 Seiten10-1 PaintdetteheartsNoch keine Bewertungen

- Finishing Materials & Cladding: Industrial InsulationDokument19 SeitenFinishing Materials & Cladding: Industrial InsulationTariq Latif SaeedNoch keine Bewertungen

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Dokument3 SeitenDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerNoch keine Bewertungen

- Chartek 1709 SDSDokument2 SeitenChartek 1709 SDSJOHN100% (1)

- Mechanical Insulation - Types and MaterialsDokument9 SeitenMechanical Insulation - Types and Materialssowman tungNoch keine Bewertungen

- Fire Protection Systems Chapter X Proposed OutlineDokument23 SeitenFire Protection Systems Chapter X Proposed OutlineEslam ElsayedNoch keine Bewertungen

- Salt ContaminationDokument8 SeitenSalt Contaminationabdayub100% (1)

- 09 Samss 098Dokument3 Seiten09 Samss 098Cherukunnon JubuNoch keine Bewertungen

- Phenoline 1205 PDS 9-06 PDFDokument2 SeitenPhenoline 1205 PDS 9-06 PDFttr_1947Noch keine Bewertungen

- Coating Personnel Id FormatDokument1 SeiteCoating Personnel Id FormatShabbar Abbas MalikNoch keine Bewertungen

- CF5012 Firetex FX5120 DFT Sherwin-WilliamsDokument7 SeitenCF5012 Firetex FX5120 DFT Sherwin-WilliamsRony Ruiz100% (1)

- Fire Protective Coatings - An OverviewDokument1 SeiteFire Protective Coatings - An OverviewdantranzNoch keine Bewertungen

- 18B. Protegol UR 32.55R Data SheetDokument3 Seiten18B. Protegol UR 32.55R Data SheetClarkFedele27Noch keine Bewertungen

- Interseal 670HS+Br+EngDokument2 SeitenInterseal 670HS+Br+Engrajauae2008100% (1)

- General: Insulated Aluminium CladdingDokument5 SeitenGeneral: Insulated Aluminium Claddingeccos3338Noch keine Bewertungen

- Data Sheet: Elcometer 142 ISO 8502-3 Dust Tape Test KitDokument2 SeitenData Sheet: Elcometer 142 ISO 8502-3 Dust Tape Test KitDavid Frizt SiregarNoch keine Bewertungen

- Masterseal 620 TdsDokument3 SeitenMasterseal 620 TdsEmil MemmedovNoch keine Bewertungen

- Section 07810 Applied FireproofingDokument4 SeitenSection 07810 Applied FireproofingMØhãmmed ØwięsNoch keine Bewertungen

- Thermal Ceramics - Marine - and - OffshoreDokument6 SeitenThermal Ceramics - Marine - and - OffshoremubeennavazNoch keine Bewertungen

- Underground Insulation Specification Data SheetDokument2 SeitenUnderground Insulation Specification Data Sheetadoptvn100% (1)

- Hempel Galvosil 1570019840Dokument2 SeitenHempel Galvosil 1570019840Jj OredinaNoch keine Bewertungen

- Insulation MoMDokument13 SeitenInsulation MoMMehthabNoch keine Bewertungen

- 2.naima Ci PPT Final PDFDokument14 Seiten2.naima Ci PPT Final PDFMuhammad AsifNoch keine Bewertungen

- Specification For Coating SteelDokument28 SeitenSpecification For Coating SteelSaud PathiranaNoch keine Bewertungen

- Investigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorDokument6 SeitenInvestigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorNsidibe Michael Etim100% (1)

- Saudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 MechDokument2 SeitenSaudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 Mechpookkoya thangalNoch keine Bewertungen

- 001CorrosionArticleAntiCorrosionTechWEIQ PDFDokument3 Seiten001CorrosionArticleAntiCorrosionTechWEIQ PDFJACK100% (1)

- SSPC Paint System RecommendationsDokument3 SeitenSSPC Paint System RecommendationsJayesh2281Noch keine Bewertungen

- Pts Ip Paint SystemDokument51 SeitenPts Ip Paint SystemshiqinmkNoch keine Bewertungen

- Standard Colour List PDFDokument1 SeiteStandard Colour List PDFKumarNoch keine Bewertungen

- Coating Standards PDFDokument5 SeitenCoating Standards PDFHanuman RaoNoch keine Bewertungen

- Mfy 003Dokument4 SeitenMfy 003Le TuanNoch keine Bewertungen

- Insulation Rfi Control RecordDokument1.353 SeitenInsulation Rfi Control RecordJoseph DarwinNoch keine Bewertungen

- Carboguard 1209: Selection & Specification DataDokument4 SeitenCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- W L 1054Dokument2 SeitenW L 1054shama093Noch keine Bewertungen

- Method Statement-KccDokument10 SeitenMethod Statement-KccSyerifaizal Hj. Mustapha100% (1)

- FTI Tech AdvancedCladdingPreInsulationSystemsDokument5 SeitenFTI Tech AdvancedCladdingPreInsulationSystemseoseos12Noch keine Bewertungen

- CIP 1 Preparation GuideDokument10 SeitenCIP 1 Preparation GuideSabrina RodriguezNoch keine Bewertungen

- Fireproofing Brochure (US)Dokument8 SeitenFireproofing Brochure (US)Ramesh PrabhakarNoch keine Bewertungen

- ICorr Insulation InspectorDokument31 SeitenICorr Insulation Inspector22238.spoNoch keine Bewertungen

- BXUV.P204 Fire Resistance Ratings - ANSI/UL 263Dokument5 SeitenBXUV.P204 Fire Resistance Ratings - ANSI/UL 263AlexNoch keine Bewertungen

- BXUV.P264 Fire Resistance Ratings - ANSI/UL 263Dokument5 SeitenBXUV.P264 Fire Resistance Ratings - ANSI/UL 263AlexNoch keine Bewertungen

- P739Dokument7 SeitenP739brauliosopasNoch keine Bewertungen

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionVon EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNoch keine Bewertungen

- Tuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDokument7 SeitenTuguegarao Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceNenbon NatividadNoch keine Bewertungen

- CSE PricelistDokument13 SeitenCSE PricelistShiela BautistaNoch keine Bewertungen

- Specifications Ipo Cardboard PackagingDokument55 SeitenSpecifications Ipo Cardboard PackagingCure Shot100% (1)

- Familiya Graphika Wholesale Pricelist 2023..Dokument19 SeitenFamiliya Graphika Wholesale Pricelist 2023..ginojezzamae21Noch keine Bewertungen

- Surgical Accessory Products: Surgical Selection, Solutions & ValueDokument36 SeitenSurgical Accessory Products: Surgical Selection, Solutions & ValueDennis ChenNoch keine Bewertungen

- Procurement Service Depot: PricelistDokument5 SeitenProcurement Service Depot: PricelistLito GarinNoch keine Bewertungen

- 02.07.2021 Stock TakeDokument2.918 Seiten02.07.2021 Stock TakeBENAYA TAMBENGINoch keine Bewertungen

- Activity 6.3 Functional Analysis AutomobloxDokument3 SeitenActivity 6.3 Functional Analysis Automobloxapi-450114937Noch keine Bewertungen

- Samsung CLX-9352 User ManualDokument265 SeitenSamsung CLX-9352 User ManualRed CristianNoch keine Bewertungen

- 2021 PPMP - Mooe - FinalDokument39 Seiten2021 PPMP - Mooe - FinalKimscey Yvan DZ SulitNoch keine Bewertungen

- Tre550 Stapler EnglishDokument5 SeitenTre550 Stapler EnglishEugenio TerreroNoch keine Bewertungen

- Cetak Soal Tugas - Sistem Informasi Pembelajaran (SIP) SMA Kusuma Bangsa Palemba 5Dokument4 SeitenCetak Soal Tugas - Sistem Informasi Pembelajaran (SIP) SMA Kusuma Bangsa Palemba 5Gora Marondos Kayara SaragihNoch keine Bewertungen

- Basic Operator Troubleshooting and Maintenance Guide For Ricoh CopiersDokument22 SeitenBasic Operator Troubleshooting and Maintenance Guide For Ricoh Copierschrisban35100% (3)

- 2022-04-12 Inner Finisher-H1 Partscatalog EDokument51 Seiten2022-04-12 Inner Finisher-H1 Partscatalog Emichael ourdanNoch keine Bewertungen

- Tuguegarao List of Common-Use Supplies and EquipmentDokument13 SeitenTuguegarao List of Common-Use Supplies and EquipmentNenbon NatividadNoch keine Bewertungen

- DC 250 Error CodesDokument40 SeitenDC 250 Error CodeskirubaspeedNoch keine Bewertungen

- 7500 SDokument13 Seiten7500 SAmr H Fadl HNoch keine Bewertungen

- Troubleshooting Guide: Multifunctional Digital Color SystemsDokument120 SeitenTroubleshooting Guide: Multifunctional Digital Color SystemsIgor IgorNoch keine Bewertungen

- ISSA2013Ed CabinStores v100 Часть190Dokument2 SeitenISSA2013Ed CabinStores v100 Часть190Александр ВласовNoch keine Bewertungen

- Ticket: CruiseDokument4 SeitenTicket: CruisejuniorrachelNoch keine Bewertungen

- 550-560-570 User Guide en-EN PDFDokument274 Seiten550-560-570 User Guide en-EN PDFjanam_sweetNoch keine Bewertungen

- Paper Christmas DecorationsDokument6 SeitenPaper Christmas DecorationsLa RadmilaNoch keine Bewertungen

- BakemonogatariDokument89 SeitenBakemonogatariluna_96Noch keine Bewertungen

- Finisher l1 IR1600 SMDokument171 SeitenFinisher l1 IR1600 SMremote controlNoch keine Bewertungen

- NC Purchasing and Supply Management Revised FinalDokument160 SeitenNC Purchasing and Supply Management Revised Finalrumbidzayiruwizhi9Noch keine Bewertungen

- Feasibility of Computer ShopDokument72 SeitenFeasibility of Computer ShopJoel O. Raborar80% (5)

- Edited TLE - Handicraft7 - 8 - Q1 - Mod3 - UnderstandRecyclingDokument32 SeitenEdited TLE - Handicraft7 - 8 - Q1 - Mod3 - UnderstandRecyclingLanie QuintuaNoch keine Bewertungen