Beruflich Dokumente

Kultur Dokumente

Dry Blend Scale Up

Hochgeladen von

zedd06Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dry Blend Scale Up

Hochgeladen von

zedd06Copyright:

Verfügbare Formate

AAPS PharmSciTech , 2000; 1 (3) article 26 (http://www.pharmscitech.

com/)

Dry Blending Process Scale-up for a Very Low Dose Drug Candidate

Submitted: May 10, 2000; Accepted: August 28, 2000

Lei-Shu Wu*, Josephine Pang, Jian-Ge Chen, and Munir A. Hussain

DuPont Pharmaceuticals Company, Wilmington, DE

INTRODUCTION DMP 543 is a pharmacologically

potent compound intended for the potential treatment of Alzheimers disease. DMP 543, 10,10-bis(2-fluoro-4pyridinylmethyl)-9(10H)-anthracenone, is poorly water soluble (2.6 g/mL at ~22 C) and is soluble in methanol and ethanol. DMP 543 contains no ionizable moiety in the pH range of 2-9.2 and exhibits a melting peak at 171 C by differential scanning calorimetric analysis. The drug is unstable in acidic solution. An extremely low strength (0.025-mg capsule with 0.02% drug load in the formulation) was used in clinical studies. Because of the low dose, content uniformity is a major concern in the process development. Proper blending and prevention of segregation, especially when wet granulation is not feasible and powder is cohesive, are required for a successful processing. Particle size distribution, particle shape, surface charge, and cohesiveness of materials have an impact on the mobility of particles and surface adherence to a carrier excipient. The use of a carrier that forms a structured powder with the micronized drug substance adhering on the carriers surface is critical for a successful formulation and process for a low-dose drug [1]. Electrostatic attraction occurs with particles having a diameter no larger than 2 m, and Van der Waal forces play a role between particles with a diameter less than 50 m [2,3]. In addition to the drug substance, the current formulation includes lactose monohydrate (a diluent), sodium starch glycolate (a disintegrant), and magnesium stearate (a lubricant). Because of stability reasons, a wet granulation process for this potent compound was not an option unless stabilizing agents were added. Therefore, a dry blending process was pursued. In this report, the optimized scaled-up blending process and product evaluation results are presented.

EXPERIMENTAL

MATERIALS

Micronized DMP 543 drug substance was manufactured by DuPont Pharmaceuticals at the Deep Water facility in New Jersey. The excipients included lactose monohydrate (Spray Dried 316, Foremost Farms USA, Rothschild, WI), sodium starch glycolate (Explotab , Penwest Pharmaceuticals, Patterson, NY), magnesium stearate ( Mallinckrodt, Cheaterfield, MO), and white opaque #2 and #3 capsules (Capsugel, Greenwood, SC). Milli-Q water (Millipore Corp, Milford, MA) was used for preparing the dissolution medium and the high-performance liquid chromatography (HPLC) mobile phase. HPLC-grade acetonitrile, reagent-grade phosphoric acid 85%, and reagent-grade sodium phosphate, monobasic, monohydrate (all from EM, Gibbstown, NJ) were used in the preparation of the mobile phase for HPLC analysis. Whatman 0.45 m PVDF (Hydrophilic Polyvinylidine Fluoride membrane) filters (Whatman Science, Ann Arbor, MI) were used for sample filtration.

EQUIPMENT

The following tools and equipment were used during the developmental stage: glass mortar and pestle, Patterson-Kelly Blend Master 8-qt V-Blender, Patterson-Kelly 1-cu-ft and 2-cu-ft V-Blenders (Patterson-Kelley, East Stroudsburg, PA), Gallay Blender 113L (Gallay Containers & Systems LTD, Birmingham, UK), Turbula Shaker/Mixer Model T2C *)Corresponding Author: Lei-Shu Wu, PhD. , Experimental Station, E400/1241, P.O. Box 80400 , Wilmington, DE, 198800400; e-mail: lei-shu.wu@dupontpharma.com

KEYWORDS Dry Blending Process, Low Strength,

Process Scale-up, Carrier

(Willy A. Bachofen AG, Maschinenfabrik, Germany), Zanasi ZA5 Capsule Filler (Nuova Zanasi IMA Group, Ozzano Emilia, Italy), Bosch 400 Ccapsule Filler (Bosch, Waiblingen, Germany), Se-Jong SF-30 Capsule Filler (Se-Jong Machinaery Co LTD, Kyoungki-Do, Korea), and JEOL JSM 840 Scanning Electron Microscope (Japanese Electron Optics Laboratories, Tokyo, Japan).

Process

Geometric mixing of the drug substance and lactose monohydrate in various sizes of mixer/blenders was used for the dry blending process. A small fraction of lactose (0.4%-4% of total lactose) was triturated in a mortar and pestle, and then mixed with the drug substance in a glass bottle using a turbular mixer. The drug to triturated lactose ratios were 1:99 to 5:95, depending on the batch size. The 400-g blend mixed using turbular mixer was then transferred from the glass bottle to an 8-qt V-blender with I-bar installed. The glass bottle was rinsed with fresh lactose 4 times. The lactose rinses and fresh lactose were then geometrically blended with the initial pre-blend in the 8-qt V-blender. The second pre-blend from the 8-qt Vblender was transferred to either a 1-cu-ft V-blender, a 2-cu-ft V-blender, or a 113-L Gallay tote bin, depending on the batch size (10-, 20-, or 50-kg, respectively). The 8-qt V-blender was rinsed 4 times with lactose. Again, the lactose rinses and fresh lactose were geometrically blended with the second pre-blend. The final blend was encapsulated after the disintegrant and lubricant were blended in.

FORMULATION

The capsule formulation for different product strengths is given in Table 1. Table 1. DMP 543 Capsule Formulations, 0.025- and 0.1mg Strengths Ingredient 0.025-mg 0.1-mg Strength Strength Amount (%) Amount (%)

0.021 97.23 2.00 0.75 100.00 120 mg #3 0.042 97.21 2.00 0.75 100.00 240 mg #2

DMP 543 Lactose monohydrate, NF Sodium starch glycolate, NF Magnesium stearate, NF Total Fill weight Capsule size

1A

2%-9% excess of drug was added to the formulation. 2A 2% excess of drug was added to the formulation.

Sampling

The final powder blend (1 to 3 times unit dose) was sampled using a thief from 10 different locations (5 from top, 3 from middle, and 2 from bottom) of a Vblender for blending uniformity test for a 10-kg and a 20-kg batch size. The final powder blend (1 to 3 times unit dose) was removed from 12 different locations (from 4 segments of top, middle, and bottom sections) of a Galley tote bin for a 50-kg batch size. Ten even fractions of capsules were collected throughout the encapsulation process per batch. One capsule was arbitrarily removed from each fraction of collected capsules for the content uniformity test.

Lactose monohydrate (~97%) was used as a bulking agent, sodium starch glycolate was used as a disintegrant, and magnesium stearate served as a lubricant.

Selection of Mixing Method and Bottle Type for Pre-Blend

The effect of the mixing method for the pre-blend of DMP 543 and lactose, at a ratio of 1 to 200, on the potency and content uniformity of the capsules was examined using trituration in a glass mortar and pestle, and turbular mixing in a plastic bottle or a glass bottle. The number of lactose rinses required to minimize the drug loss to the bottles was investigated using methanol to extract the drug from the bottles after 2 and 4 lactose rinses.

Scanning Electron Microscopy

Scanning electron microscopy was conducted by mounting the sample on a sample holder and sputter coated with gold/palladium prior to examination, using JEOL JSM 840.

Assay and Degradation Determination

Capsules were extracted in aliquots of an acetonitrile/water mixture (50:50, vol/vol) for 30 minutes. After extraction, samples were centrifuged and/or filtered with 0.45 m Whatman PVDF filters for HPLC analysis. HPLC was performed on a system including a programmable pump (Waters 510 HPLC pump system, Waters, Milford, MA), an autosampler (WatersTM 717 Plus, Waters, Milford, MA), a variable wavelength UV absorbance detector (Spectroflow 757, Waters, Milford, MA) set at 260 nm, a Hewlett Packard Zorbax C8 (25 cm x 4.6 mm) column (Hewlett Packard, Valley Forge, PA), and a column oven (Waters, Milford, MA) at 35C. An isocratic method was used for assay, using a mixture of acetonitrile, pH 4.6, 10 mmol sodium phosphate buffer (60:40, vol/vol) as a mobile phase at a flow rate of 1.0 mL/min. A gradient method was used for degradants determination. Mobile phase A (10 mmol sodium phosphate buffer) and mobile phase B (acetonitrile:water, 70:30, vol/vol) at a flow rate of 1.5 mL/min were used. The results were obtained using a data acquisition and analysis program ( ultichrom software, VG Instruments, M Altrincham, UK).

value of only 75%. More drug was recovered from the glass bottle (B, Table 2) than from the plastic bottle (A, Table 2) after the lactose-rinsed bottles were subjected to the methanol extraction. This suggests that the drug loss to the plastic bottle was not recoverable by methanol, although the drug substance was freely soluble in methanol. It is possible that, because of the hydrophobic nature of DMP 543, the drug dissolved in methanol was then irreversibly sorbed to the plastic material. Furthermore, only 0.4% of drug was lost to the walls of the glass bottle, and a complete recovery of the drug was achieved provided the glass bottle was subjected to 4 lactose rinses (C, Table 2). Therefore, a total of 4 lactose rinses to the glass bottle were selected in the pre-blending step. Table 2. Drug Recovery From Different Types of Bottles by Solvent Extraction of a 0.025-mg Strength Capsule Batch, Type of Bottle

A, Plastic bottle B, Glass bottle C, Glass bottle

% Recovered

0.24 2.4 0.4

No. of Lactose Rinses

2 2 4

Assay (%)

74.71 96.21 108.12

1A 6% excess of drug was added in this batch (0.48-kg size). A 2-qt V-

blender was used after turbular mixing. 2A 9% excess of drug was added in this batch (10-kg size). An 8-qt Vblender was used after turbular mixing

RESULTS AND DISCUSSION

Blending of the drug substance and lactose at a ratio of 1 to 200 in a glass mortar and pestle followed by multiple rinses with lactose resulted in capsules with 100% potency. Because this method is not practical for large-scale manufacturing, turbular mixing in different types of bottles was examined. Also, because the DMP 543 dose is very low, full recovery after pre-blending of lactose and drug substance is very critical. Pre-blending of lactose and DMP 543 in a glass bottle followed by 2 rinses of the bottle with lactose resulted in capsules with a 96% potency. However, pre-blending in a plastic bottle using turbular mixing followed by 2 rinses of the bottle with lactose resulted in a capsule assay

When scaling up to batch size larger than 10 kg, it was found that using a small amount of triturated lactose (0.4%-2% of total lactose) enhanced its carrier efficiency. As shown in Table 3, the low assay value of batch D was probably due to some drug substance concentrated in a certain portion of blend that was not sampled for assay (the 10 samples tested representing 0.012% of the entire batch). Batch E was prepared by mixing the drug with a small fraction of triturated lactose that distributed the cohesive drug substance better, and this resulted in an accountable potency, although the content uniformity was still not acceptable (Table 3). Effectively, with lactose triturated and turbular mixing time extended from 20 to 30 minutes, batch F resulted in an excellent content uniformity with a 100% accountable potency and a small RSD (0.9%, Table 3).

1a

1b

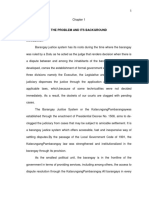

Figure 1. Scanning electron microscope photomicrographs of a placebo powder blend (1a) and an active powder blend (1b) at 3000X magnification with 10 m reference scale provided.

The initial powder blend was then transferred to an 8-qt V-blender for the next step of geometric blending. It was found that 3 lactose rinses of the V-blender prevented drug loss to the processing container. Approximately 3.3% and 0.4% of drug was recovered in the first and third lactose rinses, respectively. Table 3. Effect of Trituration and Turbular Mixing Time on Content Uniformity of a 10-kg Batch Size of a 0.025-mg Strength Capsule Process Parameters

Batch Step 1: Step 2: Step 3: Step 4: Assay no. Trituration Turbular 8-qt V- 1-cu-ft V- 1 Mean Mixing Blending Blending RSD, % (min) Time Time (n=10) 2 2 D 20 93.9 2.7 2 2 E lactose 20 108.1 14.7 2 2 F lactose 30 109.6 0.9

1The

Scanning electron microscopy of placebo and active blends (Figures 1a and 1b) of a 10-kg batch size showed that the drug evenly distributed on the surface of the lactose. Further scale-up using a 2-cuft V-blender or a 113-L tote bin instead of a 1-cu-ft V-blender at Step 4 (Table 3) was conducted. Results for a 20-kg batch of 0.025-mg strength capsules and a 50-kg batch of 0.1-mg strength are shown in Table 4. Acceptable content uniformity with RSD 2.2% and 1.6%, respectively, was obtained. Table 4. Results of Chemical Tests for Two Scale-up Batches1 Test 0.025-mg 0.1-mg Capsule Capsule 20-kg 50-kg Batch Batch Size Size

Content uniformity of 101.5 1.3% (n=10) 101.8 0.5% (n=12) powder blend Content uniformity of 101.1 2.2% (n=10) 103.8 1.2% (n=10) capsules Composite for initial 101.7 1.0% (n=3) 102.2 1.6% (n=3) release Related substance (RS) Individual RS: Individual RS: <0.1%Total RS: <0.1%Total RS: <0.1% <0.1%

1A

drug overage in these batches was 9%. 2The blending time for all three batches was the same (16 minutes and 18 minutes for step 3 and step, respectively).

2% excess of drug was added to the formulation.

In conclusion, using a dry blending process for a very low dose drug is feasible provided that the preblending is carefully designed and other process parameters are optimized. Triturated lactose served as an excellent de-agglomerating carrier for micronized, cohesive drug substance at the initial mixing step. This effectively facilitated the distribution of the drug evenly onto the surface of the remaining lactose. A successful scale-up to a 50-kg batch size was demonstrated using this blending process.

ACKNOWLEDGEMENT

We appreciate Raymond Meade in the Preclinical Pharmacology Group for conducting scanning electron microscopy.

REFERENCES

1. Egermann H, Kemptner J, Pichler E. Effects of interparticulate interactions on mixing homogeneity. Drug Dev Ind Pharm. 1985;11:663-676. 2. Hiestand EN. Powder: particle interactions. J Pharm Sci. 1966;55:1325-1343. 3. Staniforth JN, Rees JE. Electrostatic charge interactions in ordered powder mixes. J Pharm Pharmacol. 1982;34:69-76.

Das könnte Ihnen auch gefallen

- Formulasi Sediaan FarmasiDokument11 SeitenFormulasi Sediaan FarmasiKukuh PermadiNoch keine Bewertungen

- Experiment No:: Object/AimDokument9 SeitenExperiment No:: Object/AimSudeep KothariNoch keine Bewertungen

- Salbutamol Sulphate-Ethylcellulose Microparticles: Formulation and In-Vitro Evaluation With Emphasis On Mathematical ApproachesDokument8 SeitenSalbutamol Sulphate-Ethylcellulose Microparticles: Formulation and In-Vitro Evaluation With Emphasis On Mathematical ApproachesThiiwiie'thiiwiie PrathiiwiieNoch keine Bewertungen

- LoperAmid 1Dokument5 SeitenLoperAmid 1Hemma KusumaningrumNoch keine Bewertungen

- Research Article Fast Disintegrating Combination Tablets of Omeprazole and DomperidoneDokument9 SeitenResearch Article Fast Disintegrating Combination Tablets of Omeprazole and DomperidoneMuhamad Nur ArifinNoch keine Bewertungen

- Acetazolamide PPT@Dokument39 SeitenAcetazolamide PPT@SREEDHAR ATTLANoch keine Bewertungen

- Aloe Vera GelDokument8 SeitenAloe Vera GelUday MahajanNoch keine Bewertungen

- My Research PaperDokument10 SeitenMy Research PaperMamta AroraNoch keine Bewertungen

- 61032-Hardik SoniDokument8 Seiten61032-Hardik SoniAparna PathakNoch keine Bewertungen

- 4.kalpana ArticleDokument5 Seiten4.kalpana ArticleBaru Chandrasekhar RaoNoch keine Bewertungen

- VygfDokument6 SeitenVygfDyla FaradhylaNoch keine Bewertungen

- Solid Dispersion ........Dokument31 SeitenSolid Dispersion ........Rishikesh ChakorNoch keine Bewertungen

- DesloratadineDokument6 SeitenDesloratadineEliza TelamianaNoch keine Bewertungen

- Cucumber MucilageDokument18 SeitenCucumber Mucilagesaicharan88417Noch keine Bewertungen

- Formulasi Dan Optimasi Basis Krim Tipe A/M Dan Aktivitas Antioksidan Daun Cempedak (Artocarpus Champeden Spreng)Dokument9 SeitenFormulasi Dan Optimasi Basis Krim Tipe A/M Dan Aktivitas Antioksidan Daun Cempedak (Artocarpus Champeden Spreng)ElfiaNeswitaNoch keine Bewertungen

- Editorajpcr,+32 AJPCR 35690 RADokument9 SeitenEditorajpcr,+32 AJPCR 35690 RAtaikhoan217Noch keine Bewertungen

- Effect of Mode of Addition of Disintegrants On Dissolution of Model Drug From Wet Granulation TabletsDokument9 SeitenEffect of Mode of Addition of Disintegrants On Dissolution of Model Drug From Wet Granulation TabletsIka YulianaNoch keine Bewertungen

- Captopril FloatingDokument6 SeitenCaptopril FloatingMira TjakkuduNoch keine Bewertungen

- 2018 Article 99Dokument10 Seiten2018 Article 99IIrsandi JohanNoch keine Bewertungen

- Novel Binary Itraconazole-Skimmed Milk Solid Dispersion: Preparation and EvaluationDokument10 SeitenNovel Binary Itraconazole-Skimmed Milk Solid Dispersion: Preparation and Evaluationmunishahuja17Noch keine Bewertungen

- Antioxidant, Antimicrobial Activity andDokument7 SeitenAntioxidant, Antimicrobial Activity andDidi Haryo TistomoNoch keine Bewertungen

- Orange PeelDokument5 SeitenOrange Peellalit4u78Noch keine Bewertungen

- Natamycin 6Dokument6 SeitenNatamycin 6Ευαγγελία ΘεοχάρηNoch keine Bewertungen

- Jurnal Internasional Fisika DasarDokument8 SeitenJurnal Internasional Fisika DasarTiya TululiNoch keine Bewertungen

- Available Online Through Dissolution Enhancement of Atorvastatin Calcium by Nanosuspension TechnologyDokument4 SeitenAvailable Online Through Dissolution Enhancement of Atorvastatin Calcium by Nanosuspension TechnologyChandarana ZalakNoch keine Bewertungen

- Design and Characterization of Zaltoprofen Nanosuspension by Precipitation MethodDokument8 SeitenDesign and Characterization of Zaltoprofen Nanosuspension by Precipitation Methodsunaina agarwalNoch keine Bewertungen

- Experiment KumudDokument8 SeitenExperiment KumudSudeep KothariNoch keine Bewertungen

- Formulation and Characterization of Papaya Leaf GelDokument6 SeitenFormulation and Characterization of Papaya Leaf GelTutorial BEMNoch keine Bewertungen

- A C A D e M I C S C I e N C e SDokument5 SeitenA C A D e M I C S C I e N C e SlovehopeNoch keine Bewertungen

- Miconazole Nitrate From EmulgelDokument6 SeitenMiconazole Nitrate From Emulgelasit_m100% (1)

- Ahmad Kirom Masruri - A3Dokument13 SeitenAhmad Kirom Masruri - A3Kang ZerefNoch keine Bewertungen

- Development and Validation of Novel Hydrotropic Solubilization Method For Spectrophotometric Determination of Halofantrine in Pure and Solid Dosage Form Nwodo NJ, Nnadi CO and Nnadi KIDokument6 SeitenDevelopment and Validation of Novel Hydrotropic Solubilization Method For Spectrophotometric Determination of Halofantrine in Pure and Solid Dosage Form Nwodo NJ, Nnadi CO and Nnadi KIHabibur RahmanNoch keine Bewertungen

- Formulation and Evaluation of Controlled Release Ocular Inserts of Betaxolol HydrochlorideDokument5 SeitenFormulation and Evaluation of Controlled Release Ocular Inserts of Betaxolol HydrochlorideIOSR Journal of PharmacyNoch keine Bewertungen

- Cap EsiDokument12 SeitenCap EsiducngoctrinhNoch keine Bewertungen

- 11 ArticleDokument10 Seiten11 ArticleBaru Chandrasekhar RaoNoch keine Bewertungen

- Quantitative Analysis and Purity Evaluation of Medroxyprogesterone Acetate by HPLCDokument12 SeitenQuantitative Analysis and Purity Evaluation of Medroxyprogesterone Acetate by HPLCLeonardo GiraldoNoch keine Bewertungen

- JPSR 03110106Dokument9 SeitenJPSR 03110106sunilpdNoch keine Bewertungen

- EnalaprilDokument6 SeitenEnalaprilPerli DuNoch keine Bewertungen

- Spectrometric Dissolution Method For Dabigatran Etexilate Mesylate CapsulesDokument14 SeitenSpectrometric Dissolution Method For Dabigatran Etexilate Mesylate CapsulesVinod ChoudharyNoch keine Bewertungen

- Primo GelDokument10 SeitenPrimo Gelandika adikaraNoch keine Bewertungen

- Extraction of Polysaccharide Polymer From Dioscorea Trifida and Evaluation As A Tablet BinderDokument6 SeitenExtraction of Polysaccharide Polymer From Dioscorea Trifida and Evaluation As A Tablet BinderMurali Krishna ReddyNoch keine Bewertungen

- 22 PDFDokument7 Seiten22 PDFWidya Dwi Arini100% (1)

- Lactulose SpctroDokument4 SeitenLactulose SpctroDr-Asad RazaNoch keine Bewertungen

- Formulation, Development and Evalution of An Immediate Release Tablet of MethotrexateDokument22 SeitenFormulation, Development and Evalution of An Immediate Release Tablet of MethotrexateDarlianaMelloSouzaNoch keine Bewertungen

- Formulation and Evaluation of Sustained Release Sodium Alginate Microbeads of CarvedilolDokument8 SeitenFormulation and Evaluation of Sustained Release Sodium Alginate Microbeads of CarvedilolDelfina HuangNoch keine Bewertungen

- Design and Evaluation of Matrix Tablets of Diltiazem HydrochlorideDokument9 SeitenDesign and Evaluation of Matrix Tablets of Diltiazem HydrochlorideSiva PrasadNoch keine Bewertungen

- IJPR 2010 2 (4) 62-66 SRIKANTH-corrected ResearchDokument5 SeitenIJPR 2010 2 (4) 62-66 SRIKANTH-corrected ResearchkbnarkhedeNoch keine Bewertungen

- Formulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression MethodDokument5 SeitenFormulation and Evaluation of Voglibose Mouth Dissolving Tablets by Direct Compression Methodanto_pharma7784Noch keine Bewertungen

- Kinetic Study of The in Vitro Release andDokument24 SeitenKinetic Study of The in Vitro Release andEpha Lumban GaolNoch keine Bewertungen

- Alkaloid Isolation 1.1 GeneralDokument15 SeitenAlkaloid Isolation 1.1 GeneralKiki QqsNoch keine Bewertungen

- Hydrate Formation Wet Granulation Taylor LSDokument11 SeitenHydrate Formation Wet Granulation Taylor LSDaniel Mateo OrtizNoch keine Bewertungen

- FormulationDevelopment GemcitabineHCl DryPowder For IntravenousInfusionDokument16 SeitenFormulationDevelopment GemcitabineHCl DryPowder For IntravenousInfusionDo Thanh HoanNoch keine Bewertungen

- GSCBPS 2019 0082Dokument17 SeitenGSCBPS 2019 0082mwdhtirahNoch keine Bewertungen

- Project PPT YugeshDokument57 SeitenProject PPT Yugeshyugesh shresthaNoch keine Bewertungen

- 9 To 11 FinalDokument19 Seiten9 To 11 FinalSusmita GhoshNoch keine Bewertungen

- Formulation and Evaluation of Diclofenac Sodium Matrix Tablets Using Abelmoschus Esculentusmucilage As A PolymerDokument6 SeitenFormulation and Evaluation of Diclofenac Sodium Matrix Tablets Using Abelmoschus Esculentusmucilage As A Polymerpbs4yvxjndNoch keine Bewertungen

- 6.UV EplerenoneDokument7 Seiten6.UV EplerenoneBaru Chandrasekhar RaoNoch keine Bewertungen

- Experimental approaches to Biopharmaceutics and PharmacokineticsVon EverandExperimental approaches to Biopharmaceutics and PharmacokineticsNoch keine Bewertungen

- Practical Handbook of Pharmaceutical Chemistry for M.PharmVon EverandPractical Handbook of Pharmaceutical Chemistry for M.PharmNoch keine Bewertungen

- Foundations For Our Faith Ministries: Home Introduction and Bible Study IndexDokument16 SeitenFoundations For Our Faith Ministries: Home Introduction and Bible Study Indexzedd06Noch keine Bewertungen

- Crystailization of APIDokument7 SeitenCrystailization of APIzedd06Noch keine Bewertungen

- HACC 797guideDokument15 SeitenHACC 797guidezedd06Noch keine Bewertungen

- Guidance For Industry: Q8, Q9, and Q10 Questions and AnswersDokument16 SeitenGuidance For Industry: Q8, Q9, and Q10 Questions and Answerszedd06Noch keine Bewertungen

- Multicultural Dance WebquestDokument3 SeitenMulticultural Dance Webquestapi-398534676Noch keine Bewertungen

- What Is A Null Hypothesis8Dokument6 SeitenWhat Is A Null Hypothesis8a d100% (1)

- MPT CvtsDokument42 SeitenMPT CvtsSudarshan100% (1)

- Laboratory Turnaround TimeDokument17 SeitenLaboratory Turnaround TimeNicole HoNoch keine Bewertungen

- Service Management: Operations, Strategy, Information Technology Seventh EditionDokument8 SeitenService Management: Operations, Strategy, Information Technology Seventh EditionHeri NovriyandiNoch keine Bewertungen

- Creswell 2005 Literature ReviewDokument5 SeitenCreswell 2005 Literature Reviewaflsiosbe100% (1)

- Coherent Modeling and Forecasting of Mortality Patterns ForDokument14 SeitenCoherent Modeling and Forecasting of Mortality Patterns ForAldair BsNoch keine Bewertungen

- Internship Report - Aishwarya Sharma - 2Dokument42 SeitenInternship Report - Aishwarya Sharma - 2aishwaryaNoch keine Bewertungen

- Assignment # 2 - Literature Review of Behavioral IntentionDokument14 SeitenAssignment # 2 - Literature Review of Behavioral Intentionapi-3719928100% (1)

- HYDRO 2019 Curnis-Bronzetti-Sayah PaperDokument24 SeitenHYDRO 2019 Curnis-Bronzetti-Sayah PaperFrancisco GurzovNoch keine Bewertungen

- Godisnjak Annual Review 2015 2016Dokument233 SeitenGodisnjak Annual Review 2015 2016Beta ElizabetaNoch keine Bewertungen

- Full-Blown Thesis ReviewDokument2 SeitenFull-Blown Thesis ReviewRamil Gofredo100% (2)

- Automotive EngineeringDokument3 SeitenAutomotive EngineeringRoshan Shanmughan100% (1)

- Application of The BIM Method in Sustainable ConstructionDokument72 SeitenApplication of The BIM Method in Sustainable ConstructionAnge Basile Diawara TshivumdaNoch keine Bewertungen

- Assignment/ Tugasan: BBRS4103 Marketing Research January Semester 2022Dokument15 SeitenAssignment/ Tugasan: BBRS4103 Marketing Research January Semester 2022Zaidi Bin Ishak0% (2)

- AStudyon Dataminingtechniquestoimprovestudentsperformancein Higher EducationDokument7 SeitenAStudyon Dataminingtechniquestoimprovestudentsperformancein Higher Educationddol36899Noch keine Bewertungen

- DepEd Baguio City - Research ManualDokument45 SeitenDepEd Baguio City - Research ManualMYRA SHIMEATH D. LAGARTONoch keine Bewertungen

- How To Evaluate Journal Articles: Quality Research That Has Been Reviewed by ExpertsDokument2 SeitenHow To Evaluate Journal Articles: Quality Research That Has Been Reviewed by ExpertsCJ PrettyNoch keine Bewertungen

- Writing A Research Proposal PDFDokument2 SeitenWriting A Research Proposal PDFAnnie SNoch keine Bewertungen

- Thesis Feb4Dokument57 SeitenThesis Feb4Ralph CelesteNoch keine Bewertungen

- The Controller For Dohini Manufacturing Company Felt That The NumberDokument1 SeiteThe Controller For Dohini Manufacturing Company Felt That The NumberAmit PandeyNoch keine Bewertungen

- School Bayambang Nhs Grade Level Teacher John Adrian J. Malagotnot Learning Area Teaching Dates and Time JUNE 26-30,2017 QuarterDokument2 SeitenSchool Bayambang Nhs Grade Level Teacher John Adrian J. Malagotnot Learning Area Teaching Dates and Time JUNE 26-30,2017 QuarterAJ JMNoch keine Bewertungen

- Untitled PDFDokument6 SeitenUntitled PDFhayumbe08Noch keine Bewertungen

- Contact - Rizal Technological UniversityDokument9 SeitenContact - Rizal Technological UniversityChristopher BrownNoch keine Bewertungen

- The Euro and The CrisisDokument378 SeitenThe Euro and The CrisisFasie DragosNoch keine Bewertungen

- Transfer of Analytical Procedures 1224 Usp42 - NFDokument2 SeitenTransfer of Analytical Procedures 1224 Usp42 - NFMarcelo RigatuzoNoch keine Bewertungen

- Geography Form 4 SBADokument13 SeitenGeography Form 4 SBAJeff100% (1)

- Constructing Multiple Choice QuestionsDokument125 SeitenConstructing Multiple Choice QuestionsPamela Jane BateNoch keine Bewertungen

- RM SyllabusDokument4 SeitenRM SyllabuskoduruNoch keine Bewertungen

- Research ProposalDokument5 SeitenResearch ProposalPAUL THOMAS SAJITHNoch keine Bewertungen