Beruflich Dokumente

Kultur Dokumente

Introduction

Hochgeladen von

Chia Shee JinOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Introduction

Hochgeladen von

Chia Shee JinCopyright:

Verfügbare Formate

Introduction

Calorimetry is the science of measuring quantities of heat, as distinct from temperature. The instruments used for such measurements are known as calorimeters. The standard instruments for measuring calorific values of solid and liquid combustible samples are oxygen bomb calorimeters. The calorific value (heat of combustion) of a sample may be broadly defined as the number of heat units liberated by a unit mass of a sample when burned with oxygen in an enclosure of constant volume. In this reaction the sample and the oxygen are initially at the same temperature and the products of combustion are cooled to within a few degrees of the initial temperature; also the water vapour formed by the combustion is condensed to the liquid state. More specifically, the term calorific value (or heat of combustion) as measured in a bomb calorimeter denotes the heat liberated by the combustion of all carbon and hydrogen with oxygen to form carbon dioxide and water, including the heat liberated by the oxidation of other elements such as sulfur which may be present in the sample.

Objectives

At the end of this experiment students are able: 1. To obtain the calorific values of solids. 2. To demonstrate the working principles of an oxygen bomb calorimeter

Theory

Heats of combustions as determined in an oxygen bomb calorimeter are measured by a substitution procedure in which the heat obtained from the sample is compared with the heat obtained from combustion of a similar amount of benzoic acid or other standardizing material whose calorific value is known. These measurements are obtained by burning a representative sample in a high-pressure oxygen atmosphere within a metal pressure vessel or bomb. The energy released by this combustion is absorbed within the calorimeter and the resulting temperature change within the absorbing medium is noted. The heat of combustion of the sample is then calculated by multiplying the temperature rise in the calorimeter by a previously determined energy equivalent or heat capacity determined from previous tests with a standardizing material. Corrections must be applied to adjust these values for any heat transfer occurring in the calorimeter, as well as for any side reactions which are unique to the bomb combustion process. The net corrected temperature rise, t, is determined by:

where; tc = temperature at time c ta = temperature at time of firing r1 = rate (temperature units per minute) at which the temperature was rising during the 5-min period before firing r2 = rate (temperature units per minute) at which the temperature was rising during the 5-min period after time c. If the temperature was falling instead of rising after time c, r is negative and the quantity r(c-b) becomes positive and must be added when computing the corrected temperature rise a = time of firing b = time (to nearest 0.1 min) when the temperature reaches 60 percent of the total rise c = time at beginning of period (after the temperature rise) in which the rate of temperature change has become constant

The gross heat of combustion, Hg (cal/g) is then calculated from:

where; t = net corrected temperature rise e1 = correction in calories for heat of formation of nitric acid (HNO3) = 0 (assumed) e2 = correction in calories for heat of formation of sulfuric acid (H2SO4) = 0 (assumed) e3 = correction in calories for heat of combustion of fuse wire = 2.3 x (centimeters of fuse wire consumed in firing) m = mass of sample in grams W = energy equivalent of the calorimeter, determined under standardization (take as 2420 cal/C)

Specimens and Equipments

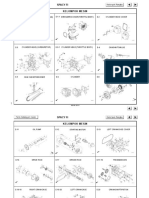

1. Oxygen combustion bomb 2. Oxygen bomb calorimeter 3. Fuel sample 4. Distilled water

5. Pellet press

Discussion Preparation of pellet sample: A pellet of the test fuel is prepared. One gram of solid is used approximately to do this. Then the pellet is weighted accurately and placed in the dish inside the bomb. Preparation of oxygen bomb: The bomb head is set on the provided support stand and fasten a 10-cm length of fuse wire between the two electrodes. The bomb head is moved carefully from the support stand to the bomb cylinder ensuring that the sample is not disturbed during the process. The bomb head is slide into cylinder and push it down as far as it will go (avoid twisting and leave the gas release valve open). The screw cap is set on the cylinder and turned it down firmly by hand to solid stop. The bomb is filled with approximately 30 atm of oxygen (follow instructions by demonstrator). Firing the bomb: 1. The calorimeter is filled with 2000grams (2 litres) of distilled water. 2. The bucket is set in the calorimeter. 3. The lifting handles are attached to the two holes in the side of the screw cap and partially lower the bomb in the water (handle the bomb carefully during this operation so that the sample will not be disturbed) 4. The two ignition lead wires are pushed into the terminal sockets on the bomb head. The wires are oriented away from the stirrer shaft so they do not become tangled in the stirring mechanism. 5. The bomb is lower completely into the water with its feet spanning the circular boss in the bottom if the bucket. The lifting handle is removed and shake any drops of water into the bucket and check for gas bubbles (if leaks are visible do not continue with the experiment and inform the demonstrator) 6. The cover is set in the jacket. The stirrer is turned by hand to be sure that it runs freely; then the drive belt is slipped onto the pulleys and the motor is started.

7. The stirrer is run for 5 minutes to reach equilibrium before starting a measured run. At the end of the 5-min period, time taking is commenced and the temperature is recorded every 20 seconds for duration of 5 minutes. 8. The calorimeter is stand back and the bomb is fired by pressing the ignition button and holding it down until the indicator light goes out. In any case, release the button within 5 seconds, regardless of the light. Caution: Do not have the head, hands or any parts of the body over the calorimeter when firing the bomb; and continue to stand clear for 30 seconds after firing. 9. The bucket temperature will start to rise within 20 seconds after firing. The temperature reading is continued to take every 20 seconds until the rate of temperature change becomes constant over a period of 5 minutes. 10. After the last temperature reading, the motor is stops, the belt is removed and the cover is lifted from the calorimeter. The thermometer is wiped and stirrer carefully with a clean cloth and the cover is set on the support stand. The bomb is lifted out of the bucket, the ignition leads are removed and the bomb is wiped with a clean towel. 11. The knurled knob is opened on the bomb head to release the gas pressure before attempting to remove the cap. This release should proceed slowly over a period of not less than one minute to avoid entrainment losses. After all pressure has been released, unscrew the cap; lift the head out of the cylinder and place it on the support stand. 12. All unburned pieces of the fuse wire is removed from the bomb electrodes; straighten them and their combined length is measured in centimeters. This length is subtracted from the initial length of 10 centimeters and this quantity is entered on the data sheet as the amount of wire burned. 13. The bomb is cleaned up and prepares it for the next run(s).

Results

Discussions 1. The assumptions make in this experiment are the correction in calories for heat of formation of nitric acid (HNO3) and correction in calories for heat of formation of

sulfuric acid (H2SO4) are assume to be zero and the weight of the sample is assume exactly equal to one gram for sample A and 15 grams for sample B. 2. The bomb calorimeter that Berthelot designed in 1880 measured the caloric value of fuels, and was applied to determining the thermal efficiency of a heat engine. A heat engine is a machine that absorbs heat at a high temperature, performs mechanical work, and as a result, gives off heat at a lower temperature. The FTT Scientific Oxygen Bomb calorimeter is an Isoperibolic calorimeter for determining gross calorific values of solid and liquid samples. The benefits by using this machine are complies to all major international standards requirements, high temperature measurement resolution and repeatability using platinum resistance thermometers and user friendly graphical interface and automatic temperature control and firing for ease of use. Besides, there are 2 reasons why the high pressure is used in bomb calorimeter. The first is that we need enough oxygen for a complete combustion in a very small volume. To do that the oxidant pressure must be high. The typical air ratios in a bomb calorimeter are between 4 and 9. The second reason is that we want to measure the high calorific value of a fuel. Thus the water produced from the combustion must be in liquid form. For a certain temperature, the higher the vapor pressure, the higher the liquid water percentage. So, the higher the total pressure (30 atm), the higher the partial vapor pressure.

Conclusion

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Series: Service ManualDokument10 SeitenSeries: Service Manualhasan siraitNoch keine Bewertungen

- INCAST 2008-109: Design and Development of An Indigenous 55 HP Wankel EngineDokument5 SeitenINCAST 2008-109: Design and Development of An Indigenous 55 HP Wankel EnginegauravamberkarNoch keine Bewertungen

- TS4065 McCloskeyDokument61 SeitenTS4065 McCloskeyOrlando Melipillan100% (1)

- Maples, Robert E.-Petroleum Refinery Process Economics-PennWell (2000)Dokument491 SeitenMaples, Robert E.-Petroleum Refinery Process Economics-PennWell (2000)janandcpcl100% (4)

- (23537779 - Production Engineering Archives) Electric Aircraft - Present and FutureDokument5 Seiten(23537779 - Production Engineering Archives) Electric Aircraft - Present and FuturekikiNoch keine Bewertungen

- BunkeringDokument10 SeitenBunkeringAnonymous UCveMQ100% (2)

- Fusibles Jetta 2001 2.0LDokument21 SeitenFusibles Jetta 2001 2.0LLuis Angel BarajasNoch keine Bewertungen

- Lesson 1Dokument14 SeitenLesson 1marpelNoch keine Bewertungen

- Parts Katalog Honda SpacyfiDokument76 SeitenParts Katalog Honda SpacyfiAgus PriyantoNoch keine Bewertungen

- CT150 CT165S (50Hz)Dokument3 SeitenCT150 CT165S (50Hz)M. ShaatNoch keine Bewertungen

- Tigra Af125baeDokument95 SeitenTigra Af125baeHeritiana Sylvain ANDRIANTSOANoch keine Bewertungen

- Engine - Presentation TAD 660, 760VEDokument13 SeitenEngine - Presentation TAD 660, 760VEAmr MohamedNoch keine Bewertungen

- Fuel Injection Pump Gear - RemoveDokument5 SeitenFuel Injection Pump Gear - RemoveedwinNoch keine Bewertungen

- IPS Parts Catalogue June 2016Dokument52 SeitenIPS Parts Catalogue June 2016ashielanieNoch keine Bewertungen

- SK331-8 SK350LC-8 AnzDokument16 SeitenSK331-8 SK350LC-8 AnzVishan100% (1)

- Lahore: University of Engneering and TechnologyDokument11 SeitenLahore: University of Engneering and TechnologyAB RafayNoch keine Bewertungen

- Service Manual - H21 23TX H23 25 TPXDokument265 SeitenService Manual - H21 23TX H23 25 TPXFlorin Stoian100% (2)

- Crankshaft Position SensorDokument9 SeitenCrankshaft Position SensorJam BabNoch keine Bewertungen

- Introduction of The Mercedes 0M651 EngineDokument58 SeitenIntroduction of The Mercedes 0M651 Enginejacksayshi100% (14)

- Understanding Crankshaft BalancingDokument5 SeitenUnderstanding Crankshaft BalancingVontrex DergonNoch keine Bewertungen

- World Cement 2017 03 BurnersDokument7 SeitenWorld Cement 2017 03 BurnersQuang Huy NguyễnNoch keine Bewertungen

- OM RT Flex84t D - Pulse - Lubrication - 2012 11 PDFDokument520 SeitenOM RT Flex84t D - Pulse - Lubrication - 2012 11 PDFsaw ba htooNoch keine Bewertungen

- Tata 407 Bs-Iii - 1Dokument184 SeitenTata 407 Bs-Iii - 1Niten Gupta100% (2)

- BD Project ProposalDokument21 SeitenBD Project ProposalMohammed Jowardhar50% (2)

- Briggs & Stratton Model 091200 Illustrated Parts ListDokument20 SeitenBriggs & Stratton Model 091200 Illustrated Parts Listb0beiiiNoch keine Bewertungen

- Motor Trend 2008-12Dokument189 SeitenMotor Trend 2008-12Gary Tasker100% (2)

- Pelton Turbine Erection ProcedureDokument91 SeitenPelton Turbine Erection Procedurebhanu prasad100% (1)

- Automatic Pneumatic Bumper and Break Actuation Before CollisionDokument41 SeitenAutomatic Pneumatic Bumper and Break Actuation Before Collisionpandi100% (2)