Beruflich Dokumente

Kultur Dokumente

Chapter VII

Hochgeladen von

Pruthvi RoyalOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Chapter VII

Hochgeladen von

Pruthvi RoyalCopyright:

Verfügbare Formate

CHAPTER-VII

SAFETY

STEEL AUTHORITY OF INDIA LIMITED There was overall improvement in the safety performance of the company during the year. The declining trend of all categories of accidents was maintained. Adequate emphasis was laid upon safety of human resources and assets of the Company along with production and productivity. Systematic approach to safety management was adopted through close monitoring of adherence to safety norms and procedures. RASHTRIYA ISPAT NIGAM LIMITED

Visakhapatnam Steel Plant is the first integrated Steel plant, which has implemented Occupational health & safety management system as per British Standards Institute specification and received OHSAS:18001 certificate from M/s BVQI in the presence of Minister of Industries, Govt. of Andhra Pradesh and Principal Secretary to Govt. of Andhra Pradesh, Labour, employment, training and factories Deptt.

Continuous efforts of all departments resulted in improvement of safety consciousness of employees. Refresher safety training is given to the regular employees. The contractor employees training was enriched by giving job

specific and site specific safety training at site by the zonal safety officer and engineer-in-charge before starting of the job in addition to normal training.

Status of safety activities are reviewed by top management on weekly as well as monthly basis. As a pro-active approach, special safety inspections were carried out in all major departments for identifying non-conformances (unsafeacts/unsafe-conditions) and the same were rectified. All accidents and incidents

were investigated and remedial measures were implemented. Round the clock monitoring was done by safety personnel during capital repairs of Sinter Plant, Blast Furnace, Steel Melting Shop, Light & Medium Merchant Mill, Wire Rod Mill & Medium & Merchant Structural Mill. Fire fighting facilities were inspected regularly and deficiencies were rectified. The central safety committee and 25 departmental safety committees discussed various safety issues and

recommendations of their committees were implemented.

High quality personal protective equipment, life safety shoes, helmets, FR coats, ear muffs, ear plugs, heat resistant face shields, water gel blankets, welders aprons, eye protective equipment, hand gloves of different varieties, skin paste, eye wash showers etc. were provided to employees.

Internal safety audits were conducted. External safety audit for the year 2001 was conducted by M/s P J Encon Services and recommendations of the reports were implemented. External safety audit for the year 2002 is being

conducted by M/s See-Tech Solutions, Nagpur.

Onsite emergency plan was implemented.

For testing the preparedness

of departments/plant, to fight against the emergencies, 12 departmental level fire mock drills were conducted every month and other mock drills were also conducted for meeting emergencies like gas leakage, electric shock, rescue etc. Two plant level mock drills were conducted during the year.

Road safety measures were implemented strictly. Special concrete road was laid in the heavy vehicle movement route. Printing and issue of bulletins, posters, safety hoarding, safety painting and safety messages, films in cable TV etc were taken up for safety promotion.

In connection with national safety day celebrations, many safety competitions like debate, essay, poster, slogan, songs/poem, quiz etc. were

conducted for employees and school children. Inter departmental safety and housekeeping competitions were also conducted.

Appreciating the receipt of OHSAS 18001 certificate, National safety council, Andhra Pradesh chapter and Government of Andhra Pradesh have awarded a trophy to RINL.

NATIONAL MINERAL DEVELOPMENT CORPORATION LIMITED In NMDC Vocational Training Centres are provided in each Project for imparting initial/ basic training for the new entrants. Every year 1/5th of the persons will be given refresher training. Apart from this special training and development

training is being given to the required persons. First aid and fire fighting training is being conducted regularly at the Projects. The other safety measures : In each mining project of NMDC, sufficient number of Workmen Inspectors were nominated / appointed for mining, mechanical and electrical installations as per statutory requirements. Safety Committees are formed in all the projects. Regular Safety Committee meetings are conducted once in a month. In the meetings Accident Analysis is being discussed and remedial measures are being implemented. Occupational Health Centres have been provided in all the Projects. Specialized training was given to Doctors in Occupational Health Safety Centres. All the periodical medical examination and other additional tests required under the statute are carried out in time schedule programme covering all the new recruitees, old employees on roll also one year before superannuation of the employee.

The number of fatal accidents during the year 2001-02 was two (2) in NMDC Mines. The number of serious injuries in all the mines of the Corporation was ten (10) during 02-03 (upto Dec.02).

KUDREMUKH IRON ORE COMPANY LIMITED A Safety Department is functioning effectively. The Company gives

utmost importance to occupational safety and health of the persons working in the Company. Workers' participation in Safety Management System is one of the important criteria adopted by the Company. Areawise Safety Committees are formed. Workers participation in these Safety Committees is ensured. Safety inspections are carried out regularly by the Safety Officer alongwith the Safety Committee Members and the safety points are discussed in the Safety Meetings held every month. In order to inculcate safety consciousness and to develop the human resources, various training programmes such as refresher training, training on first aid, training on positive work culture, awareness programmes on environment, quality and safety management system are conducted. Further, to increase the awareness of safety among the mining communities, safety campaign/propaganda is done by observing Mines Safety Week Celebrations every year under the guidance of Mines Safety Association, Karnataka. During the Mines Safety Week celebrations, various competitions are held at both Zonal Level and the State Level for the workers of different mines covered under Mines Safety Association, Karnataka. The Company has won several prizes both at Zonal and State level competitions.

MANGANESE ORE (INDIA) LTD. With the continuous depletion of near surface ore deposits, mining is progressively being extended to deeper horizons and extraction is increasingly done through deep under-ground working. This requires extra attention to be paid to various aspects viz. support system, ventilation and efficient filling of the voids arising out of extraction of ore. Continuos emphasis is laid on training of

employees. Mine working is regularly inspected by members of Pit Committees, Workman Inspectors, Safety Officers and General Manager (Safety). Safety Weeks are observed and exhibitions are held to inculcate safety habits to ensure safe working. Safety Committee meetings are regularly held during which any unsafe act committed/observed by any mine worker is discussed to avoid recurrence. The Company pays special attention to ensure safety of the mines and workforce employed therein. The company has The participated in Regional Safety Competition and has won 47 prizes. Injury Frequeny Rate for its Gumgaon Mine. FERRO SCRAP NIGAM LIMITED In order to create safety awareness among the employees, various training programmes are organised on safety through National Safety Council as well as other institutions. Apart from this, the Safety Day celebrations comprising of debate on safety are also held in all the units and corporate office, wherein the employees take part with full enthusiasm and the winners are given suitable prizes. There has not been any fatal accident during the year, and the frequency rate of accidents is only 0.56. MECON LIMITED MECON has design and consultancy offices and does not have any industrial unit. However, at project sites, all necessary safety related precautions are being taken and as a result, no accident has been reported during the year. HINDUSTAN STEEL CONSTRUCTION LIMITED (HSCL) HSCL has formulated safety code and adequate steps have been taken for its implementation.

company has received National Safety Award for the year 2000 for the Lowest

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

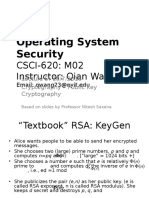

- CSCI 620 Lecture5Dokument14 SeitenCSCI 620 Lecture5Pruthvi RoyalNoch keine Bewertungen

- Operating System Security: CSCI-620: M02 Instructor: Qian WangDokument40 SeitenOperating System Security: CSCI-620: M02 Instructor: Qian WangPruthvi RoyalNoch keine Bewertungen

- CSCI 620 Lecture1Dokument30 SeitenCSCI 620 Lecture1Pruthvi RoyalNoch keine Bewertungen

- CSCI 620 Lecture10Dokument14 SeitenCSCI 620 Lecture10Pruthvi RoyalNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

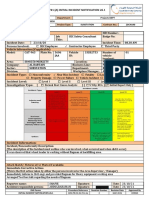

- ACCIDENT INCIDENT REPORT (Al Omran)Dokument2 SeitenACCIDENT INCIDENT REPORT (Al Omran)jonesNoch keine Bewertungen

- NEBOSH Questions 22.12.2012Dokument12 SeitenNEBOSH Questions 22.12.2012mohd100% (1)

- Lab MOP v2.8.4 Rectal SwabDokument3 SeitenLab MOP v2.8.4 Rectal SwabTriatmi HandayaniNoch keine Bewertungen

- Ohs-Pr-09-26-F01 (A) Initial Incident Notification 26.1Dokument2 SeitenOhs-Pr-09-26-F01 (A) Initial Incident Notification 26.1Shafie ZubierNoch keine Bewertungen

- Introduction To Amended PDRA GuidelinesDokument31 SeitenIntroduction To Amended PDRA GuidelinesCar Dilgopcen100% (1)

- Conplast SP550 - SDS23455 - 44Dokument6 SeitenConplast SP550 - SDS23455 - 44MR. MANTU DWIVEDINoch keine Bewertungen

- Safety Engineering: Devices and ProcessesDokument24 SeitenSafety Engineering: Devices and ProcesseszulNoch keine Bewertungen

- Fire and Safety in Edible Oil Industries To Be AdoptedDokument68 SeitenFire and Safety in Edible Oil Industries To Be AdoptedRushiram Reddy60% (5)

- Safety Data Sheet Photopolymer 3D Printer DAYLIGHT ResinDokument5 SeitenSafety Data Sheet Photopolymer 3D Printer DAYLIGHT ResinOSCAR AXEL VAZQUEZ COSMENoch keine Bewertungen

- Document Version: 3.0: Hazardous Areas Across The Entire Defence Estate Must Be Checked To Verify ComplianceDokument24 SeitenDocument Version: 3.0: Hazardous Areas Across The Entire Defence Estate Must Be Checked To Verify ComplianceramausNoch keine Bewertungen

- True Wash 75% Ethyl Alcohol Hand Sanitizer Gel: Safety Data SheetDokument14 SeitenTrue Wash 75% Ethyl Alcohol Hand Sanitizer Gel: Safety Data SheetWita Ferani KartikaNoch keine Bewertungen

- Rescue 1122 - WikipediaDokument11 SeitenRescue 1122 - WikipediaIshfaq AhmadNoch keine Bewertungen

- CV For Project Manager - EngineerDokument4 SeitenCV For Project Manager - EngineerShaikh IbrahimNoch keine Bewertungen

- Excavation and Shoring SH-2012-23eDokument5 SeitenExcavation and Shoring SH-2012-23eshamroz khan100% (1)

- ECE Laws PrelimsDokument47 SeitenECE Laws PrelimsYiesshana OnicanNoch keine Bewertungen

- A1 SITXWHS003 WorksheetsDokument10 SeitenA1 SITXWHS003 WorksheetsKomal SharmaNoch keine Bewertungen

- 1972 Manual Cary 5000Dokument44 Seiten1972 Manual Cary 5000VeGiNoch keine Bewertungen

- Offshore Oil and Gas Safety Review: Policy FrameworkDokument30 SeitenOffshore Oil and Gas Safety Review: Policy FrameworkRabeh BougouffaNoch keine Bewertungen

- Service Station Operator's Checklist: Guide For Service Station Operators Under The Work Health and Safety Act 2011Dokument5 SeitenService Station Operator's Checklist: Guide For Service Station Operators Under The Work Health and Safety Act 2011VijayKumar LokanadamNoch keine Bewertungen

- Vessel Safety Guide: Guidance For Offshore Renewable Energy DevelopersDokument26 SeitenVessel Safety Guide: Guidance For Offshore Renewable Energy DevelopersMuhammad Rusydi AlwiNoch keine Bewertungen

- Adwoc-17 HSE Rig Inspection at R-32 Oct 2014Dokument4 SeitenAdwoc-17 HSE Rig Inspection at R-32 Oct 2014Ricardo Hurtado HernándezNoch keine Bewertungen

- MDS-B-SPJ2 Series PDFDokument182 SeitenMDS-B-SPJ2 Series PDFFernando SabogalNoch keine Bewertungen

- Patient Safety 1, 2Dokument98 SeitenPatient Safety 1, 2salah salem100% (1)

- Hydrob FCDokument5 SeitenHydrob FCfivade5459Noch keine Bewertungen

- MSDS - FaslocHS - EN - InglesDokument8 SeitenMSDS - FaslocHS - EN - Inglescarlos_salas80Noch keine Bewertungen

- Finalized Assignment 1bDokument48 SeitenFinalized Assignment 1bNelson LeeNoch keine Bewertungen

- SDS Condat Sen 60Dokument4 SeitenSDS Condat Sen 60Ninh ChinhNoch keine Bewertungen

- g21 Choco Dream Slimming MsdsDokument3 Seiteng21 Choco Dream Slimming MsdsizaNoch keine Bewertungen

- Natpet MSDS V.4.1 H26ML Eng 2016Dokument6 SeitenNatpet MSDS V.4.1 H26ML Eng 2016sercanworkNoch keine Bewertungen

- WQ1454 Project Execution PlanDokument60 SeitenWQ1454 Project Execution PlanRAZANoch keine Bewertungen