Beruflich Dokumente

Kultur Dokumente

D40102 Connecting A 4 - 20ma Sensor To The Model 400

Hochgeladen von

Brian McMorrisOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

D40102 Connecting A 4 - 20ma Sensor To The Model 400

Hochgeladen von

Brian McMorrisCopyright:

Verfügbare Formate

Data Dolphin Tech Note

D40102

optinst.com viewdatanow.com datadolphin.com emailalarm.com

Connecting a 4 - 20mA sensor to the Model 400

Introduction

A wide variety of sensors available today have as their output a standard 4-20mA current signal. These

type of sensors include pressure transducers, temperature transmittters, level meters, flow meters and

many others. The following document covers the connection of a two, three, or four wire 4-20mA

sensor to a Model 400 precision input.

Shunt Resistors

Since the Model 400 datalogger reads and records voltages (and not current) on its precision inputs,

the output of a current signal device must be converted to a voltage. This is done with a precision

100Ω shunt resistor. A 100Ω resistor will, with a 4-20mA current source, produce voltages in the 0.4V

(4mA) to 2.0V (20mA) range. As an option, a 125Ω precision resistor can be used to produce voltages

in the 0.5V (4mA) to 2.5V (20mA) range. However, as 2.5V is the top of the input’s measurable voltage

scale, currents in excess 20mA will simply be read on the input as a full scale voltage when using a

125Ω shunt resistor.

Wiring and Connections

4-20mA sensing devices are available in two, three or four wire configurations. Where mentioned

below in the following sub-sections, “Switched VRAW ” is the second from the right terminal position on

the Model 400’s green plug-in power terminal connector (see “” below).

Figure 1: Power terminal connector

Two Wire

In the two-wire configuration, the V+/ Out+ wire is connected to the Model 400’s “Switched VRAW ”

terminal. The other wire of the sensor (V- / Out -) is connected to a precision input. In the diagram

shown in Figure 2, the sensor is connected to input 11. The shunt resistor is connected between the

input and Analog Common Ground (Alg. Comm.). During operation, the Model 400 will provide power

(equal to the power it is being powered with) to the “Switched VRAW ” terminal just prior to taking a

reading on its inputs to activate the sensor.

Optimum Instruments Inc. 1 of 4

#201, 3124 Parsons Road, Edmonton, AB, Canada, T6N 1L6

For more info call (780) 450-0591 or FAX (780) 440-2515 1000IE-09/03

Email: optimum@optinst.com

D40102

Switched VRAW

V+ / Out+

Two Wire

Sensor

V- / Out-

Input 11

Shunt Resistor

100

Analog

Common

Ground

Figure 2: Two wire sensor wiring diagram

Three Wire

With the three-wire version of the 4 – 20 mA sensor, the “V+” wire is connected to the Model 400’s

“Switched VRAW ” terminal. The sensor’s “Out+” wire is connected to the precision input on the Model

400 and the “V- / Out-“ wire is connected to the Analog Common Ground terminal (Alg. Comm.). Again,

the shunt resistor is connected between the Model 400’s precision input and ground to create the

measurable voltage for the input.

Switched VRAW

V+

Three

Wire Out + Input 11

Sensor

Shunt Resistor

V- / Out- 100

Analog

Common

Ground

Figure 3: Three wire sensor wiring diagram

Four Wire

A four-wire sensor will have the “V+” and “V-” wires connected to the “Switched VRAW ” terminal and the

Analog Common Ground terminal (Alg. Comm.) respectively. The other two wires will supply the 4-20

mA signal. The positive current signal wire (Out +) will connect to the Model 400’s precision input, and

the negative current signal wire (Out -) will connect to the analog common ground terminal (Alg.

Comm.). As above, the shunt resistor is connected between the Dolphin’s precision input and ground.

2 of 4 Connecting a 4 - 20mA sensor to the Model 400

D40102

Switched VRAW

V+ Out + Input 11

Four Wire Shunt Resistor

Sensor 100

Analog

Out - Common

V-

Ground

Figure 4: Four wire sensor wiring diagram

A bit about grounding

There are a few small differences with respect to the analog common ground terminal and the power

source ground terminal next to the “Switched VRAW” output. If high precision is desired from the 4-20mA

sensing device, and some noise is tolerable on the other input channels, use the analog common

ground terminal for grounding. On the other hand, if high precision is desired on all the other channels

and some imprecision (introduced by the Model 400 circuitry) is tolerable on the 4-20mA channel, then

it is suggested that you use the power source ground. In some cases, additional circuitry may be

required. If you are uncertain about the grounding requirements for your 4-20mA sensing device,

contact a technician at Optimum Instruments for more information.

How do I configure a Model 400 Input?

Once you have ensured that the 4-20 mA sensor is wired correctly to the Model 400, you will want to

enable and configure the input that the sensor is connected to by using the Data Dolphin software. As

an example, precision input 11 on the Model 400 has been correctly configured in the following

procedure to convert the current output from a temperature sensor (0 - 50°C) into a temperature

measurement, in degrees centigrade. Follow the example in the following procedure to configure the

Model 400’s input for your 4-20 mA sensor.

1. Power-up the Model 400 and the sensor. Connect your Model 400 to the serial port of your

computer, and load the Data Dolphin software on your computer, and establish a direct, on-site

connection to the Model 400 (see “Model 400 Software manual”).

2. Open the Dolphin Setup window by clicking the Setup button on the Model 400 software’s

toolbar.

3. Click on the “Precision Inputs” tab to view the Precision Inputs configuration page. Load the

precision input settings from the Model 400 into the Data Dolphin software by clicking on the

“Load from Dolphin” button. The Model 400 precision input settings should load into the

controls of the inputs sections on this page. If the settings did not load (the Status bar in the

Data Dolphin software reads “No response from data logger”) check your cable and power

connections and repeat this step

4. Now, determine which input you have connected the sensor to. Each section on this page

contains the configuration controls for a single precision input eg. The controls in the section

marked “Input 11” configure the Model 400’s precision input 11, marked “In + Alg 11” on its

screw terminal. Note that the settings for inputs 15-18 are displayed by clicking on the “Show

Inputs 15-18” button. Once you have determined which input you have connected your sensor

to, ensure that the input is enabled (the “On” checkbox has a check), and properly named (i.e.

“Temp 1”). The voltage range should be 2.5V, the “Rate” combo box should have 3 Hz

selected, and the type of scaling used should be linear equation.

Connecting a 4 - 20mA sensor to the Model 400 3 of 4

D40102

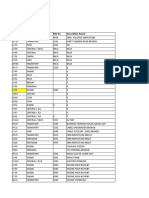

Figure 5: Precision input configuration

5. To calculate the final m and b values, open a spreadsheet in Microsoft Excel and enter the

depth and the corresponding input voltages into two separate columns. An example

spreadsheet is shown in below. These entries assume that the voltage read at the input, with a

100Ω resistor and the sensor at 0°C, is 0.4V. Also assumed is that when full scale temperature

(50°C) is applied to the sensor, it will output 20 mA, which will be read at the input as 2.0V

Figure 6: Slope and offset calculation with Excel

6. Click on the cell where you want the slope value to appear, and type the following into the

formula bar:

=SLOPE(<range of depth values>,<range of voltage values>)

The format for the range of depth and voltage values is in the spreadsheet formula format, such

as C3:C5, where C3 is the first cell in the range, and C5 is the last. Hit return, and the value

that appears in this cell is the final slope (m) value.

7. Finally, click on the cell where you want the offset value to appear, and enter the following

formula into the formula bar:

=INTERCEPT(<range of depth values>,<range of voltage values>)+ <distance from

depth sensor to the invert of pipe>

Hit the return button to calculate the offset (b).

8. Enter the slope (m) and offset (b) values into the textboxes as shown in step 4. Click the apply

button to program the input’s settings into the Model 400.

9. The Model 400 input is now correctly programmed for the 4-20 mA sensor. If possible, confirm

that the sensor is working correctly by exposing it to known conditions, and verifying its reading

in the Data Dolphin software’s Status window. In our example, this would correspond to

exposing our temperature sensor to a known temperature, and verifying that this temperature is

displayed in the Data Dolphin software’s Status window.

4 of 4 Connecting a 4 - 20mA sensor to the Model 400

Das könnte Ihnen auch gefallen

- AMS 2Q 2009 10K FilingDokument21 SeitenAMS 2Q 2009 10K FilingBrian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook May - 09Dokument2 SeitenBill Gross Investment Outlook May - 09Brian McMorris100% (2)

- Bill Gross Investment Outlook Jul - 09Dokument3 SeitenBill Gross Investment Outlook Jul - 09Brian McMorrisNoch keine Bewertungen

- ICVGR Proceedings ColorDokument571 SeitenICVGR Proceedings ColorBrian McMorris100% (2)

- Bill Gross Investment Outlook Aug - 09Dokument3 SeitenBill Gross Investment Outlook Aug - 09Brian McMorris100% (2)

- Bill Gross Investment Outlook Jun - 09Dokument3 SeitenBill Gross Investment Outlook Jun - 09Brian McMorris100% (2)

- Bill Gross Investment Outlook Jan - 09Dokument3 SeitenBill Gross Investment Outlook Jan - 09Brian McMorrisNoch keine Bewertungen

- JP Morgan JPM 10K 2008Dokument379 SeitenJP Morgan JPM 10K 2008Brian McMorris100% (1)

- GMO Ben Inker - Valuing Equities in An Economic Crisis - April 6 2009Dokument6 SeitenGMO Ben Inker - Valuing Equities in An Economic Crisis - April 6 2009Brian McMorris100% (1)

- GMO Grantham July 09Dokument6 SeitenGMO Grantham July 09rodmorleyNoch keine Bewertungen

- JP Morgan JPM Annual Report 2008Dokument240 SeitenJP Morgan JPM Annual Report 2008Brian McMorrisNoch keine Bewertungen

- 2008 AR Letter To ShareholdersDokument28 Seiten2008 AR Letter To Shareholdersfwallstreet100% (1)

- Microsoft MSFT Annual Report 2008Dokument56 SeitenMicrosoft MSFT Annual Report 2008Brian McMorrisNoch keine Bewertungen

- GGP 10-K Annual Report Filing 12-31-08Dokument142 SeitenGGP 10-K Annual Report Filing 12-31-08Brian McMorrisNoch keine Bewertungen

- GGP 8K Bankruptcy Filing 04-16-09Dokument8 SeitenGGP 8K Bankruptcy Filing 04-16-09Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Dec - 02Dokument5 SeitenBill Gross Investment Outlook Dec - 02Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Apr - 09Dokument4 SeitenBill Gross Investment Outlook Apr - 09Brian McMorrisNoch keine Bewertungen

- Still River Systems in MIT Tech Review 9-5-2006Dokument3 SeitenStill River Systems in MIT Tech Review 9-5-2006Brian McMorrisNoch keine Bewertungen

- Microsoft MSFT Annual Report 2008Dokument56 SeitenMicrosoft MSFT Annual Report 2008Brian McMorrisNoch keine Bewertungen

- Ams 10K 2006Dokument74 SeitenAms 10K 2006Brian McMorrisNoch keine Bewertungen

- Ams 10K 2008Dokument80 SeitenAms 10K 2008Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Aug - 01Dokument4 SeitenBill Gross Investment Outlook Aug - 01Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Aug - 02Dokument5 SeitenBill Gross Investment Outlook Aug - 02Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Oct - 02Dokument5 SeitenBill Gross Investment Outlook Oct - 02Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Nov - 02Dokument5 SeitenBill Gross Investment Outlook Nov - 02Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Sep - 02Dokument8 SeitenBill Gross Investment Outlook Sep - 02Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Feb - 02Dokument5 SeitenBill Gross Investment Outlook Feb - 02Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook May - 02Dokument8 SeitenBill Gross Investment Outlook May - 02Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Jul - 02Dokument4 SeitenBill Gross Investment Outlook Jul - 02Brian McMorrisNoch keine Bewertungen

- Bill Gross Investment Outlook Apr - 02Dokument5 SeitenBill Gross Investment Outlook Apr - 02Brian McMorrisNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Multi Channel Gas Detector Receiver: GTC-200A SeriesDokument2 SeitenMulti Channel Gas Detector Receiver: GTC-200A Seriesjames darrel LaraNoch keine Bewertungen

- Maintenance PlanDokument2 SeitenMaintenance PlanMuneeb QayyumNoch keine Bewertungen

- Billing For Electrical Works 03-28-23Dokument3 SeitenBilling For Electrical Works 03-28-23ʞǝǝs Uǝ ƎpıɥNoch keine Bewertungen

- 2015 Frigidaire Laundry Center Service ManualDokument195 Seiten2015 Frigidaire Laundry Center Service ManualRiks GarcesNoch keine Bewertungen

- XEnergy Light Cat enDokument97 SeitenXEnergy Light Cat enCris_eu09Noch keine Bewertungen

- Electrical System IDokument191 SeitenElectrical System IMsRody2009Noch keine Bewertungen

- Configuración de Fase Kubota j119Dokument1 SeiteConfiguración de Fase Kubota j119Julio MendozaNoch keine Bewertungen

- Cables and ConnectorsDokument4 SeitenCables and ConnectorsFik BestNoch keine Bewertungen

- MCD 310Dokument52 SeitenMCD 310PatNoch keine Bewertungen

- Conventional Fire Alarm Control Panel: Model: CK1004, CK1008, CK1016Dokument2 SeitenConventional Fire Alarm Control Panel: Model: CK1004, CK1008, CK1016SanrasniNoch keine Bewertungen

- Gauge Blocks: Length StandardDokument40 SeitenGauge Blocks: Length Standardaraha21Noch keine Bewertungen

- 5-12 HSVS MOD-B Radial DoorDokument62 Seiten5-12 HSVS MOD-B Radial Doornardo_ing100% (5)

- Series R1E02 General Description Technical Information: Pressure Relief ValvesDokument3 SeitenSeries R1E02 General Description Technical Information: Pressure Relief Valvesshahrol effendy rodziNoch keine Bewertungen

- Membrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Dokument7 SeitenMembrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Mila CalderónNoch keine Bewertungen

- Electrical Data: General Data:: Data Sheet For Three-Phase Squirrel-Cage-MotorsDokument1 SeiteElectrical Data: General Data:: Data Sheet For Three-Phase Squirrel-Cage-MotorsSalih Ahmed ObeidNoch keine Bewertungen

- Sag582136600 AgDokument99 SeitenSag582136600 Agphu pham quocNoch keine Bewertungen

- Patch Cord FibraDokument2 SeitenPatch Cord FibrajoquinNoch keine Bewertungen

- Technical Note 5: Samsung (Starting Signal Injector)Dokument19 SeitenTechnical Note 5: Samsung (Starting Signal Injector)Producto DigitalNoch keine Bewertungen

- DC9-48-60-24-8C-EV: Installation InstructionsDokument28 SeitenDC9-48-60-24-8C-EV: Installation InstructionsBeto RNoch keine Bewertungen

- Pt. Rea Kaltim Plantations Central Enginering Services List Part Direct UserDokument98 SeitenPt. Rea Kaltim Plantations Central Enginering Services List Part Direct Usertechnical trainer 011cNoch keine Bewertungen

- PL1000E Install Guide REHS2362-00Dokument20 SeitenPL1000E Install Guide REHS2362-00Teguhprabowo CenaNoch keine Bewertungen

- Critical Wear Areas & Vacuum Test Locations: Upper Valve Body - U760E ShownDokument4 SeitenCritical Wear Areas & Vacuum Test Locations: Upper Valve Body - U760E ShownДенис ЕфрахимNoch keine Bewertungen

- Kyb Conmat CP30Dokument55 SeitenKyb Conmat CP30Bhomesh Kumawat100% (1)

- Atos - VV Prop TN6 DHZO e TN 10 DKZORDokument6 SeitenAtos - VV Prop TN6 DHZO e TN 10 DKZORNkma Borges100% (1)

- Simbologia y Muestra de PLanos Electricos y ElectronicosDokument13 SeitenSimbologia y Muestra de PLanos Electricos y ElectronicosCristóbalGuzmánNoch keine Bewertungen

- WDS Spencer FranklinDokument52 SeitenWDS Spencer FranklinGeo BuzatuNoch keine Bewertungen

- ZS65 40 200 5 5Dokument5 SeitenZS65 40 200 5 5Karthikeyan VisvakNoch keine Bewertungen

- Module 8 - Electrical LayoutDokument36 SeitenModule 8 - Electrical LayoutMargarette ManaloNoch keine Bewertungen

- SUN Series Autoclave (Class B) : Operation ManualDokument14 SeitenSUN Series Autoclave (Class B) : Operation ManualLamer HassenNoch keine Bewertungen

- Single Acting Cylinder: Manual-SA PN CylinderDokument3 SeitenSingle Acting Cylinder: Manual-SA PN CylindermehtahemalNoch keine Bewertungen