Beruflich Dokumente

Kultur Dokumente

ASME Listado

Hochgeladen von

juma1987Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASME Listado

Hochgeladen von

juma1987Copyright:

Verfügbare Formate

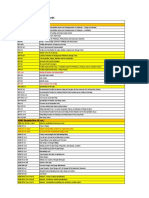

ASME - American Society of Mechanical Engineers

ASME B1.1 Unified Inch Screw Threads ASME B1.20.1 Pipe Threads, General Purpose (Inch) ASME B16.5 Pipe Flanges and Flanged Fittings ASME B16.10 Face-to-Face and End-to-End Dimension of Valves ASME B16.11 Forged Fittings, Socket Welding and Threaded ASME B16.20 Metallic Gaskets for Pipe Flanges, Ring Joint, Spiral Wound, and Jacketed ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges ASME B16.24 Cast Copper Alloy Pipe Flanges and Flanged Fittings ASME B16.25 Butt-welding Ends ASME B16.28 Wrought Steel Butt-welding Short Radius Elbows and Returns ASME B16.34 Valves - Flanged, Threaded, and Welding End ASME B18.2.1 Square and Hex Bolts and Screws (inch series) ASME B31.3 Process Piping ASME B31.5 Refrigeration Piping and Heat Transfer Components ASME B36.10 Welded and Seamless Wrought Steel Pipe

ASME Boiler & Pressure Vessel Code

Section I Rules for Construction of Power Boilers Section II Part A Ferrous Material Specifications Section II Part B Nonferrous Material Specifications Section II Part C Specification for Welding Rods, Electrodes, and Filler Metals Section II Part D Properties (Metric) Section V Nondestructive Examination Section VI Recommended Rules for the Care and Operation of Heating Boilers Section VII Recommended Guidelines for the Care of Power Boilers Section VIII Div 1 Rules for Construction of Pressure Vessels Section VIII Div 2 Alternative Rules for Construction of Pressure Vessels Section VIII Div 3 Alternative Rules for Construction of High Pressure Vessels Section IX Welding and Brazing Qualifications

AGMA - American Gear Manufacturers Association

AGMA 207.06 Tooth Proportions for Fine-Pitch Involute Spur and Helical Gears AGMA 420.04 Practice for Enclosed Speed Reducers or Increasers Using Spur, Helical, Herringbone and Spiral Bevel Gears AGMA 908.B89 Geometry Factors for Determining the Pitting Resistance and Bending Strength of Spur, Helical and Herringbone Gear Teeth AGMA 6010.F97 Standard for Spur, Helical, Herringbone and Bevel Enclosed Drives

API - American Petroleum Institute

API 500 Recommended Practice for Classification of Locations for Electrical Installations at Petroleum Facilities Classified as Class 1, Division1 and Division 2

API 510 Pressure Vessel Inspection Code: Maintenance Inspection, Rating, Repair, and Alteration API 520 Sizing, Selection, and Installation of Pressure Relieving Devices in Refineries API 551 Process Measurement Instrumentation API 581 Risk-Based Inspection Base Resource Document API 589 Fire Test for Evaluation of Valve Stem Packing API 598 Valve Inspection and Testing

AWS - American Welding Society AWS D1.1 Structural Welding Code - Steel

Das könnte Ihnen auch gefallen

- Valve StandardsDokument22 SeitenValve StandardsKlubowoloya110% (1)

- List of International Standards: API Standards Block (25 Nos.)Dokument4 SeitenList of International Standards: API Standards Block (25 Nos.)Siva baalan100% (1)

- Code and Standards List - 2014Dokument42 SeitenCode and Standards List - 2014amirrulasyraf100% (2)

- Piping Standard and Specification For Piping Material PresentationDokument62 SeitenPiping Standard and Specification For Piping Material PresentationDuy Hiệp LâmNoch keine Bewertungen

- Normas Mas Comunes Usadas en ProyectosDokument11 SeitenNormas Mas Comunes Usadas en ProyectosAlvaro Gutiérrez TrocheNoch keine Bewertungen

- No. Doc No: Description API ProductsDokument2 SeitenNo. Doc No: Description API ProductsInChy Rencarnation PoseidonNoch keine Bewertungen

- StandardsDokument4 SeitenStandardsrania hammamiNoch keine Bewertungen

- Welding, Brazing and Soldering of Piping GuidelinesDokument28 SeitenWelding, Brazing and Soldering of Piping GuidelinesMunir RasheedNoch keine Bewertungen

- Codes and Standards DocumentDokument4 SeitenCodes and Standards DocumentOvaisNoch keine Bewertungen

- Norsok L001Dokument2 SeitenNorsok L001Walid Labidi50% (2)

- ASME STANDARDS LISTDokument6 SeitenASME STANDARDS LISTCorjan TerblancheNoch keine Bewertungen

- Codes and Standards: ASME B31 Piping CodesDokument44 SeitenCodes and Standards: ASME B31 Piping CodesMuthukumar ThangaiahNoch keine Bewertungen

- List of StandardsDokument3 SeitenList of Standardssumant.c.singh1694Noch keine Bewertungen

- Codes TableDokument2 SeitenCodes TablejesamsonNoch keine Bewertungen

- Valve StandardsDokument14 SeitenValve StandardskandhasamykarthickNoch keine Bewertungen

- 04 Samss 002 PDFDokument8 Seiten04 Samss 002 PDFnadeem shaikhNoch keine Bewertungen

- Codes & Standards For Natural GasDokument13 SeitenCodes & Standards For Natural Gasharikrishnanpd3327Noch keine Bewertungen

- Bakhrabad Siddhirganj Pipeline Project Piping / Equipment Piping Design CriteriaDokument16 SeitenBakhrabad Siddhirganj Pipeline Project Piping / Equipment Piping Design CriteriaIbad AlamNoch keine Bewertungen

- Process Engineering StandardsDokument8 SeitenProcess Engineering Standardssal143100% (1)

- Valve StandardsDokument5 SeitenValve StandardsSingaravel GanesanNoch keine Bewertungen

- Piping Codes List of Piping Codes Is HereDokument8 SeitenPiping Codes List of Piping Codes Is Hereabidaliabid1Noch keine Bewertungen

- 1 Engg DBD PP 010Dokument19 Seiten1 Engg DBD PP 010sanketNoch keine Bewertungen

- ANSI Valve StandardDokument5 SeitenANSI Valve StandardsandystaysNoch keine Bewertungen

- ASME piping, fittings, valves, pumps, boilers standards guideDokument4 SeitenASME piping, fittings, valves, pumps, boilers standards guideengrmakramNoch keine Bewertungen

- Standards For RefineryDokument11 SeitenStandards For RefinerykknanduriNoch keine Bewertungen

- Valve StandardsDokument15 SeitenValve StandardsabduNoch keine Bewertungen

- Piping NoteDokument9 SeitenPiping NoteSanal SNoch keine Bewertungen

- 903-10004-SPC-M-001 Piping Material SpecificationDokument15 Seiten903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaNoch keine Bewertungen

- Design Codes & StandardsDokument21 SeitenDesign Codes & StandardsJay Omana50% (2)

- Steel Piping SpecificationDokument28 SeitenSteel Piping Specificationfelixrich100% (2)

- 04 SAMSS 001 Gate ValvesDokument12 Seiten04 SAMSS 001 Gate Valves권상우Noch keine Bewertungen

- Piping Codes and StandardsDokument21 SeitenPiping Codes and StandardsZa Yon100% (1)

- Piping Codes and Standards - The Piping Engineering BlogDokument5 SeitenPiping Codes and Standards - The Piping Engineering BlogSalman KhanNoch keine Bewertungen

- American Welding Society StandardsDokument2 SeitenAmerican Welding Society StandardsGeorge Nicolaides100% (1)

- American National Standards Institute - STD LISTDokument15 SeitenAmerican National Standards Institute - STD LISTRajesh ChoudharyNoch keine Bewertungen

- Standards and Specifications: ANSI (American National Standards Institute)Dokument5 SeitenStandards and Specifications: ANSI (American National Standards Institute)norhazarudinNoch keine Bewertungen

- Volime II of II Mechanical Piping-GAILDokument245 SeitenVolime II of II Mechanical Piping-GAILBathi Hari PrasadNoch keine Bewertungen

- Project Standard Specification: Fuel Oil Piping 15191 - Page 1/6Dokument6 SeitenProject Standard Specification: Fuel Oil Piping 15191 - Page 1/6adel rihanaNoch keine Bewertungen

- Active Standard ASTM A694 / A694M: Steel StandardsDokument3 SeitenActive Standard ASTM A694 / A694M: Steel Standardshemant_solanki78940% (1)

- 1.06 A Piping Codes & StandardsDokument31 Seiten1.06 A Piping Codes & StandardsSumedh Singh100% (2)

- Algunas Normas y Estándares de Aplicación IndustrialDokument6 SeitenAlgunas Normas y Estándares de Aplicación Industrialoluseun_adediranNoch keine Bewertungen

- General Q and ADokument10 SeitenGeneral Q and AmohamedqcNoch keine Bewertungen

- 01 Samss 010Dokument11 Seiten01 Samss 010biplabpal2009Noch keine Bewertungen

- ASME and API piping, pump, valve, and equipment standardsDokument2 SeitenASME and API piping, pump, valve, and equipment standardsAhmed Shaban KotbNoch keine Bewertungen

- Auxiliary Piping SpecificationDokument11 SeitenAuxiliary Piping SpecificationZubair RaoofNoch keine Bewertungen

- SpecificationsDokument7 SeitenSpecificationsMarine SleimanNoch keine Bewertungen

- C Anadian Institute of Steel Construction, Canadian Paint Manufac TurDokument7 SeitenC Anadian Institute of Steel Construction, Canadian Paint Manufac Turmuthuswamy77Noch keine Bewertungen

- Piping Systems 0508 PDFDokument31 SeitenPiping Systems 0508 PDFJade JavierNoch keine Bewertungen

- Astm f1387Dokument28 SeitenAstm f1387kswaghmareNoch keine Bewertungen

- PipingDokument21 SeitenPipingsubashNoch keine Bewertungen

- Codes and StandardsDokument1 SeiteCodes and StandardsSuresh MechNoch keine Bewertungen

- List of Standards & Their Usage: SL - No. DecriptionDokument8 SeitenList of Standards & Their Usage: SL - No. DecriptionSumeet MahajanNoch keine Bewertungen

- ANSI Valve StandardsDokument19 SeitenANSI Valve Standardsdevadoss kishoreNoch keine Bewertungen

- Pages From Cvh99Dokument16 SeitenPages From Cvh99Paraschiv AlexandruNoch keine Bewertungen

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsVon EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- All-in-One Manual of Industrial Piping Practice and MaintenanceVon EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceBewertung: 5 von 5 Sternen5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyVon EverandPipeline and Energy Plant Piping: Design and TechnologyBewertung: 5 von 5 Sternen5/5 (2)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsVon EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNoch keine Bewertungen

- Highway Cargo TanksDokument36 SeitenHighway Cargo Tanksjuma1987Noch keine Bewertungen

- Blackmer Performance Curves CRL 1.25 To 4 InchDokument2 SeitenBlackmer Performance Curves CRL 1.25 To 4 Inchjuma1987Noch keine Bewertungen

- TankTel - Quick Start GuideDokument14 SeitenTankTel - Quick Start Guidejuma1987Noch keine Bewertungen

- Magnetel Instructions 115-820Dokument6 SeitenMagnetel Instructions 115-820juma1987Noch keine Bewertungen

- Filtro de Línea 285-SS-01Dokument1 SeiteFiltro de Línea 285-SS-01juma1987Noch keine Bewertungen

- CO2 Safety ManualDokument51 SeitenCO2 Safety ManualKrishna YadavNoch keine Bewertungen

- CO2 Safety ManualDokument51 SeitenCO2 Safety ManualKrishna YadavNoch keine Bewertungen

- D Fire Extinguisher: Technical SpecificationDokument1 SeiteD Fire Extinguisher: Technical Specificationjuma1987Noch keine Bewertungen

- Kee+Safety +Safety+Barrier+SolutionDokument4 SeitenKee+Safety +Safety+Barrier+Solutionjuma1987Noch keine Bewertungen

- Yokogawa FX1000Dokument7 SeitenYokogawa FX1000juma1987Noch keine Bewertungen

- 320D & 320D L Excavator Hydraulic System SchematicDokument15 Seiten320D & 320D L Excavator Hydraulic System SchematicchanlinNoch keine Bewertungen

- Rolled Alloy ElectrodesDokument12 SeitenRolled Alloy ElectrodesradenmuhaiminNoch keine Bewertungen

- DT60-DT70S (50 HZ)Dokument3 SeitenDT60-DT70S (50 HZ)Md ShNoch keine Bewertungen

- Cadworx Cadworx Cadworx Cadworx Syllabus Syllabus Syllabus SyllabusDokument6 SeitenCadworx Cadworx Cadworx Cadworx Syllabus Syllabus Syllabus SyllabusSelvaNoch keine Bewertungen

- Gas-Liquid Separators Sizing Parameter - Campbell Tip of The MonthDokument18 SeitenGas-Liquid Separators Sizing Parameter - Campbell Tip of The MonthsterlingNoch keine Bewertungen

- Thermal Breakage and Impact Strength of Tempered GlassDokument7 SeitenThermal Breakage and Impact Strength of Tempered GlassMartinBalanagNoch keine Bewertungen

- Technical Description MPPUDokument10 SeitenTechnical Description MPPUNinaNoch keine Bewertungen

- Basic Motor Technical + Safe Area MotorsDokument74 SeitenBasic Motor Technical + Safe Area MotorsmayureshrmahajanNoch keine Bewertungen

- Shear & Diagonal Tension in BeamsDokument15 SeitenShear & Diagonal Tension in BeamsS. M. ZAHIDUR RAHMAN 1301129Noch keine Bewertungen

- Positioning Strain Gages To Monitor Bending, Axial, Shear, and Torsional LoadsDokument2 SeitenPositioning Strain Gages To Monitor Bending, Axial, Shear, and Torsional LoadsPrakash VasudevanNoch keine Bewertungen

- Mercedes-Benz Tractor HeadDokument9 SeitenMercedes-Benz Tractor HeadRudi KurniawanNoch keine Bewertungen

- Piping Drawings Basics: Mr. T. N. GopinathDokument39 SeitenPiping Drawings Basics: Mr. T. N. Gopinathhirenkumar patel100% (1)

- Chapter 2 P H Diagram Analysis Refrigerant Flow DiagiaramDokument20 SeitenChapter 2 P H Diagram Analysis Refrigerant Flow DiagiaramMyo Kyaw KyawNoch keine Bewertungen

- PC2000-8 Shop ManualDokument1.348 SeitenPC2000-8 Shop ManualPeetNoch keine Bewertungen

- QUY150C 150t Crawler Crane BrochureDokument59 SeitenQUY150C 150t Crawler Crane BrochureliftNoch keine Bewertungen

- Thermography ReportDokument9 SeitenThermography ReportsandrositohangNoch keine Bewertungen

- Sae J 765 (1990-10) Crane Load Stability Test Code PDFDokument8 SeitenSae J 765 (1990-10) Crane Load Stability Test Code PDFAdrianNoch keine Bewertungen

- Difference Between Spillback and Minimum Circulation Line - Google SearchDokument1 SeiteDifference Between Spillback and Minimum Circulation Line - Google SearchGourav KumarNoch keine Bewertungen

- Dehumidifcation and CoolingDokument3 SeitenDehumidifcation and CoolingWaleed A. ShreimNoch keine Bewertungen

- AGTE Theory 1 Chapter 1Dokument41 SeitenAGTE Theory 1 Chapter 1Abush NigussieNoch keine Bewertungen

- VRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonDokument55 SeitenVRF Technical Data Book Highlights Key Specs (38k-61k BTU, 3-4.5 TonFred BensimonNoch keine Bewertungen

- Is Schrodinger EquationDokument3 SeitenIs Schrodinger EquationSpirosKoutandosNoch keine Bewertungen

- Strengthening Mechanisms ExplainedDokument74 SeitenStrengthening Mechanisms ExplainedRyan TorresNoch keine Bewertungen

- Eaton 420 PartsDokument16 SeitenEaton 420 PartsF Labio Alex100% (1)

- Retrofit BMBS InstructionsDokument3 SeitenRetrofit BMBS InstructionsPradipta SahooNoch keine Bewertungen

- 032 Aeroplane Performance (JAA ATPL Theory)Dokument429 Seiten032 Aeroplane Performance (JAA ATPL Theory)dforceman0% (1)

- Bobcat 843 Service Repair Manual PDFDokument520 SeitenBobcat 843 Service Repair Manual PDFservimaquinados plazas sas56% (9)

- FINNPOWER P Series Manual PDFDokument33 SeitenFINNPOWER P Series Manual PDFMaulanna Ibrohiim50% (2)

- ElectricianSemIICITSQB PDFDokument82 SeitenElectricianSemIICITSQB PDFmarvin2008Noch keine Bewertungen

- Repair Stuck Grease Pumps EX2600-7Dokument7 SeitenRepair Stuck Grease Pumps EX2600-7TLK ChannelNoch keine Bewertungen