Beruflich Dokumente

Kultur Dokumente

Lecture 2 - Master Location Plan

Hochgeladen von

Ameen ZennOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lecture 2 - Master Location Plan

Hochgeladen von

Ameen ZennCopyright:

Verfügbare Formate

2.0 MASTER LOCATION PLAN 2.1 PLANT SITE LOCATION 2.1.

1 Planning of Palm Oil Mill Before constructing palm oil mill, planning and selection of the propose mill site is become very important. It is a very good approach if this planning is made during planting stage to avoid wasting of cost for unnecessary clearing the planted palms tree for the construction of mill. However this always not the case as most of the mills has also been constructed upon decision of site after estate is ready. The criteria for determining the suitability of a site for a mill are As follows a) Must be near to reliable water source/ water supply b) Relatively high and solid ground c) Located centrally within the reach of estates d) Easy accessibility e) Transportation of FFB to Mill Gate f) Transportation of product from the mill g) Soil condition h) Land topography flat or undulating i) General infrastructure Main government road/ Access road/ water treatment cost/ telephone lines etc. j) Regulations from Local Authority/ sensitivity of the nearby area/ restrictions. 2.1.2 Planning and Selection of Site

a) b) c) d) e) f) g) 2.2.2

Propose location of the mill with respect to overall plantations area Area of mills building and mills compound Area of effluent treatment plant, ETP Area of raw water storage pond Water sources and water intake access Area for executives, staffs and workers quarters Roads and accessibility

Feasibility Study

2.2.2.1 The planning which includes feasibility study must be well ahead before decision to construct oil mill is implemented. Feasibility study is normally undertaken by an experience consultant OR engineer who posses extensive experience in palm oil mill design. Feasibility study will normally focus on the followings:

2.2.2.1.1 2.2.2.1.2 2.2.2.1.3 2.2.2.1.4 2.2.2.1.5 2.2.3

Supply of the raw material, i.e. FFB Projection Selection & Location of the site Capacity of Mill and economic of scale Financial Implication i.e. capital investment and payback years Environmental Issues

Crop Projection

2.2.3.1 Sizes of plantations, planted or to be planted 2.2.3.2 The planting time/years 2.2.3.3 The time of yielding 2.2.3.4 The appropriate Yield 2.2.4 Planning of required Mill Capacity

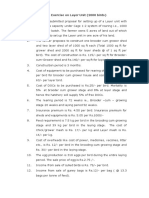

2.2.4.1 Determining of oil mill capacity from FFB Projection. 2.2.4.2 Mill capacity should capable to handle peak months ffb at approximately 12.5% of the annual crop and on 25 days/month @ 20hrs/day 2.2.4.3 Milling capacity is given by the basic mathematic Capacity, T = Q / (D x H) Where; T is in Ton/Hour Q is peak month FFB in Ton D is number of day per month H is the operating hours per day Palm oil mill normally runs on two shifts or three shifts per day. There are some mill which run on two and a half shift per day i.e. two shifts workers employed and during peak crops the mill will run overtime to process all the FFB. For sizing the capacity of palm oil mills, the following operating hours can be used i.e. 8 hrs per shift or 16 hrs for two shift. For overtime processing hours first shift will work extra 4 hours from their normal 8 hours working and second shift will continue to work another 4 hours addition to their normal 8 hours work.

Another factor that should be considered is the No of working day per year or per month. The company used figure is 300 working days per year or 25 days per month. 2.2.5 Location of Site The criteria for determining the suitability of a site for a mills are as follows 2.2.5.1 Strategically located within all the ffb supplying estates. 2.2.5.2 Near the water sources 2.2.5.3 Relatively high and solid ground 2.2.5.4 Easy Access for raw material and final product transportation process 2.2.5.5 To consider and obtaining the followings information a) b) c) d) e) f) Transportation of FFB to Mill Gate Transportation of Product from the mill Water source / Water supply Land Topography Flat or Undulating Soil Condition from soil test report General Infrastructure Main Road/Access road/water treatment cost/Telephone lines etc. g) Regulations from Local Authority/sensitivity of the nearby area / restrictions. 2.2.6 Capital Expenditure Projections

2.2.6.1 This an important aspect of a feasibility study 2.2.6.2 Total capital investment and operation cost over a certain period (ex: 15 years) 2.2.6.3 To shows profit / Internal Rate of Return/ Payback period 2.2.6.4 To established prospect of income from the oil mill project 2.2.6.5 To be prepared during feasibility study is conducted 2.2.6.6 To clearly indicate disbursement of such big capital expenditure and payback period over a certain number of years 2.2.6.7 To determine return on investment and at what year the project will be in the green

2.2.7

Environmental Issues The feasibility study should also seriously look into the environment impact of setting up the mill project. The rationale behind this is the effects of environment issues can last for generations as well as the human welfare as a whole. Such issues like water, air, noise pollution are becoming more and more stringent and recommendations to construct a mill should give more in depth considerations to these environment issues.

Das könnte Ihnen auch gefallen

- 2.0 SDPA - Palm Oil Mill ProjectDokument19 Seiten2.0 SDPA - Palm Oil Mill ProjectAmeen Zenn100% (1)

- 1.0 IntroductionDokument38 Seiten1.0 IntroductionAmeen ZennNoch keine Bewertungen

- FFB Crop ForecastDokument6 SeitenFFB Crop ForecastAmeen ZennNoch keine Bewertungen

- Processing Station - Part 1 (Mpob HQ 21711)Dokument56 SeitenProcessing Station - Part 1 (Mpob HQ 21711)Ameen Zenn100% (2)

- Calcul Conveioare SurubDokument2 SeitenCalcul Conveioare SurubgvisanNoch keine Bewertungen

- Material Balance (A)Dokument5 SeitenMaterial Balance (A)Ameen Zenn50% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- MidtermDokument30 SeitenMidtermRona CabuguasonNoch keine Bewertungen

- Factors That Shape A Child's Self-ConceptDokument17 SeitenFactors That Shape A Child's Self-ConceptJaylou BernaldezNoch keine Bewertungen

- 173 RevDokument131 Seiten173 Revmomo177sasaNoch keine Bewertungen

- Dax CowartDokument26 SeitenDax CowartAyu Anisa GultomNoch keine Bewertungen

- Tales From The SSRDokument48 SeitenTales From The SSRBrad GlasmanNoch keine Bewertungen

- How To Cite Legal Materials PDFDokument2 SeitenHow To Cite Legal Materials PDFNadine AbenojaNoch keine Bewertungen

- Eternal Generation What Is Eternal Generation?Dokument2 SeitenEternal Generation What Is Eternal Generation?Jake DavilaNoch keine Bewertungen

- Principles of PR Measurement 0 PDFDokument15 SeitenPrinciples of PR Measurement 0 PDFVisai_kitasNoch keine Bewertungen

- Case Exercise On Layer Unit (2000 Birds)Dokument2 SeitenCase Exercise On Layer Unit (2000 Birds)Priya KalraNoch keine Bewertungen

- A Tuna ChristmasDokument46 SeitenA Tuna ChristmasMark100% (3)

- 2016-10-26 Memo Re Opposition To MTDDokument64 Seiten2016-10-26 Memo Re Opposition To MTDWNYT NewsChannel 13Noch keine Bewertungen

- Time ClockDokument21 SeitenTime ClockMarvin BrunoNoch keine Bewertungen

- I YOU HE SHE IT WE YOU They: Personal Pronouns in Your Language (In Limba Ta)Dokument1 SeiteI YOU HE SHE IT WE YOU They: Personal Pronouns in Your Language (In Limba Ta)Alina SardariuNoch keine Bewertungen

- Oxford University Colleges' ProfilesDokument12 SeitenOxford University Colleges' ProfilesAceS33Noch keine Bewertungen

- The Officers of Bardwell Company Are Reviewing The ProfitabilityDokument1 SeiteThe Officers of Bardwell Company Are Reviewing The ProfitabilityAmit PandeyNoch keine Bewertungen

- Double JeopardyDokument5 SeitenDouble JeopardyDeepsy FaldessaiNoch keine Bewertungen

- Career Oriented ProfileDokument3 SeitenCareer Oriented ProfileSami Ullah NisarNoch keine Bewertungen

- Ict: Advantages & Disadvantages: Presentation PlanDokument11 SeitenIct: Advantages & Disadvantages: Presentation PlanLe FleauNoch keine Bewertungen

- ЛексикологіяDokument2 SeitenЛексикологіяQwerty1488 No nameNoch keine Bewertungen

- Resume: Md. Saiful IslamDokument2 SeitenResume: Md. Saiful IslamSaiful IslamNoch keine Bewertungen

- HirarchaddonDokument5 SeitenHirarchaddonawe_emNoch keine Bewertungen

- BPM at Hindustan Coca Cola Beverages - NMIMS, MumbaiDokument10 SeitenBPM at Hindustan Coca Cola Beverages - NMIMS, MumbaiMojaNoch keine Bewertungen

- Multicast VLAN CommandsDokument8 SeitenMulticast VLAN CommandsRandy DookheranNoch keine Bewertungen

- Assignment 10Dokument2 SeitenAssignment 10Kristina KittyNoch keine Bewertungen

- Boone Pickens' Leadership PlanDokument2 SeitenBoone Pickens' Leadership PlanElvie PradoNoch keine Bewertungen

- Gyges RingDokument1 SeiteGyges RingCYRINE HALILINoch keine Bewertungen

- Dreaded Homework Crossword ClueDokument9 SeitenDreaded Homework Crossword Clueafnahsypzmbuhq100% (1)

- SJDM Es Smepa Board 2020-2021Dokument5 SeitenSJDM Es Smepa Board 2020-2021Loreto Capitli MoralesNoch keine Bewertungen

- Causes of The Fall of Rome 1Dokument8 SeitenCauses of The Fall of Rome 1api-334241910Noch keine Bewertungen

- Fachhochschule Südwestfalen: We Create MomentumDokument45 SeitenFachhochschule Südwestfalen: We Create MomentumSha EemNoch keine Bewertungen