Beruflich Dokumente

Kultur Dokumente

Below The Hook Lifting Devices

Hochgeladen von

Ali Al-KhalilOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Below The Hook Lifting Devices

Hochgeladen von

Ali Al-KhalilCopyright:

Verfügbare Formate

Below the Hook Lifting Devices Author: Peter Cooke Corporate Trainer for Columbus McKinnon A below-the-hook lifter

is a device that operates independently from cranes, hoists, trolleys and carrier hooks. Devices such as spreader beams, c-hooks, pallet lifters, grabs, plate clamps and sheet lifters offer a way to attach load to hoist as well as hold, protect, control and orient the load. Selecting the proper below the hook lifter for the job and knowing its limitations is critical. They are designed to make your work easier but, like any good rigging tool, they must be properly used. The latest version of ASME B30.20 should be obtained and reviewed. ASME B30.20 is the safety standard for below the hook lifting devices. It covers markings, construction, installation, inspection, testing, maintenance and operation of below the hook lifting devices. Lifting devices may contain slings, hooks, rigging hardware and lifting attachments covered by other ASME standards. Why choose a below the hook lifter over slings or conventional rigging? Below the hook lifters allow you to properly support long loads. A load handled with slings alone may have a tendency to slip or slide. Can provide lower headroom between load and hoist. Slings require more height between attachment points and hoist hook. This is useful for facilities with very low ceiling height or for lifting large loads. Handles equipment without damage. Many sling hook ups can cause edge damage to load and slings They can be customer designed or easily adapted in the field by attaching or repositioning components to suit many operations. Simplifies and speeds up repetitive lifting operations. They are a fast, direct method of attachment. They replace time consuming improvisations required with slings and chains. Often times, improvising can lead to unsafe rigging practices. Camlok Vertical Plate A combination of both slings and rigging hardware are often used to make Clamp a safe lift. Can help eliminate rigging at dangerous shallow angles (30 degrees or less) thus reducing tremendous tension imposed on slings and load. It is not recommended to rig below a 30 degree angle. If you find this is happening, chances are you need a below the hook lifting device to assist with the lift. ASME B30.20 has gone through some radical changes regarding design and construction of below the hook lifting devices. The revised ASME B30.20-2006 was issued on January 16, 2007. The effective date to be in compliance with the revised standard was January 16, 2008. The standard now says that below the hook lifting devices shall be designed to ASME BTH-1-2005. ASME BTH-1 addresses only design requirements. As such, this standard should be used in conjunction with ASME B30.20, which addresses safety requirements. ASME BTH-1 does not replace ASME B30.20. It is not the intent of ASME BTH-1 standard to require retrofitting of existing lifting devices. Per ASME, although always implied, this provision now explicitly states that

the design of below the hook lifting devices is the responsibility of a qualified person. This requirement has been established in recognition of the impact that the performance of a lifting device has on workplace safety, the complexity of the design process, and the level of knowledge and training required to competently design lifting devices. BTH-1-2005 is very technical and I can not sum it up in a few brief sentences. There are options for service class and design categories that manufactures can design to depending on frequency of use and the type of loading see by the lifter. Below the hook manufactures have been designing their lifters to new BTH-1 design category B: where loading can be unpredictable and environmental conditions are either severe or not defined.

Required markings per ASME: Manufactures name serial number, lifter weight (if over 100 lbs), cold current amps (when applicable), rated voltage (if applicable), rated load, ASME BTH-1 Design category (January 2008) ASME BTH-1 Service Class. (January 2008) Warning labels (basically the dos and donts of rigging).

Cady Lifters Pallet Lifter

Inspection (per ASME) An every lift inspection by the operator is required (no documentation) A minimum of a yearly inspection with documentation for normal service. Heavy service requires an inspection semiannually with documentation. Severe service requires a quarterly inspection with documentation. Operation (per ASME) Below-the-hook lifting devices shall be operated only by trained, designated persons. Qualifications (per ASME) Training is required The operator shall demonstrate the ability to operate the lifter as instructed before assuming responsibility for using the lifer. The operator training requires knowledge of basic rigging practices. Most revised ASME standards are requiring training for material handling equipment. (Rigging)

Cady Lifters Steel Coil Lifter

The following is a brief general checklist to check if your below the hook lifter meets the ASME B30.20 standard. Is the lifter clearly marked on two sides with the rated load capacity?

Is there a nameplate or other permanent marking displaying the following: Manufactures name serial number, lifter weight (if over 100 lbs), cold current amps (when applicable), rated voltage (if applicable), rated load, ASME BTH-1 Design category (January 2008) ASME BTH-1 Sevice Class. (January 2008) Warning labels (basically the dos and donts of rigging)

Cady Lifters Low Headroom Beam

Are there engineering calculations and a bill of material showing that the lifter was designed and construction by a qualified person according to ASME B30.20? Do you perform a minimum of a yearly inspection for normal service on each lifter, including inspection of all welds, wear of components, and deformation or other defects? Note: an operator shall perform a visual inspection of the lifter before every lift. Do you have a certificate of conformance and/or a proof test certificate for each lifter stating that the lifter meets ASME B30.20? Note: This is only a general guideline, users should obtain a full copy of ASME B30.20 to review full details of this standard. If you failed to check all the boxes above, your lifter may not meet ASME B30.20 and may be a potential safety hazard. You need to take immediate action to insure your lifter meets this specification. Cady Lifters of Columbus McKinnon can answer or assist you with your below the hook lifting requirements. Columbus McKinnon manufactures a broad line of material handling products for use in a wide range of markets around the world. Primary products include hoists, lifting chain, overhead crane systems and below-the-hook attachments. The company has a rich 135-year history, and many of the brands are the most recognized in the world. Products from Columbus McKinnon are used to lift, position, and secure loads in hundreds of industries including fabrication, food processing, mining, forestry, entertainment, trucking, utility, and defense to name only a few.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

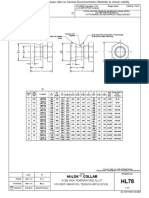

- HL78Dokument2 SeitenHL78Renato WatanabeNoch keine Bewertungen

- Stock-LedMax - XLSX 0Dokument96 SeitenStock-LedMax - XLSX 0Emidio CostaNoch keine Bewertungen

- 1732 1989 Reff2019Dokument6 Seiten1732 1989 Reff2019FAHAD KHANNoch keine Bewertungen

- Territory ManagementDokument12 SeitenTerritory ManagementShruti Suman MiddhaNoch keine Bewertungen

- ELCOSeal Installation GuidelinesDokument12 SeitenELCOSeal Installation GuidelinesEdgarNoch keine Bewertungen

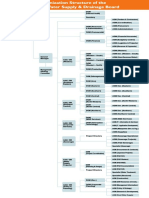

- Organization Structure of NWSDBDokument1 SeiteOrganization Structure of NWSDBSurangaG0% (2)

- Dynamics NAV Inventory Cost Restoration WhitepaperDokument9 SeitenDynamics NAV Inventory Cost Restoration WhitepaperAndrea DjunaidyNoch keine Bewertungen

- Syed Mazhar CV 250913Dokument8 SeitenSyed Mazhar CV 250913Anwar SultanNoch keine Bewertungen

- 911 Tragedy & Treason 2nd Ed 6.1Dokument183 Seiten911 Tragedy & Treason 2nd Ed 6.1Michael TreisNoch keine Bewertungen

- Value Analysis and Value Engineering in Material ManagementDokument12 SeitenValue Analysis and Value Engineering in Material ManagementKarthik Soundarajan100% (1)

- Design Resistance: HST HST-R HST-HCR HST HST-R HST-HCRDokument1 SeiteDesign Resistance: HST HST-R HST-HCR HST HST-R HST-HCRМилан БурсаћNoch keine Bewertungen

- Six Sigma Through Poka-Yoke: A Navigation Through Literature ArenaDokument13 SeitenSix Sigma Through Poka-Yoke: A Navigation Through Literature Arenaprabhulean14Noch keine Bewertungen

- Concerning Contribution of Beneficiary Parties To The Cost of Contracts of Roads and Public TransportDokument24 SeitenConcerning Contribution of Beneficiary Parties To The Cost of Contracts of Roads and Public TransportCharles Fernandes100% (1)

- How to Renew Car Registration in RiyadhDokument4 SeitenHow to Renew Car Registration in RiyadhterramocoNoch keine Bewertungen

- Field Notice / Site Instruction: Project Ref. Field Order No. Location Date Contractor Time Copies ToDokument3 SeitenField Notice / Site Instruction: Project Ref. Field Order No. Location Date Contractor Time Copies ToCMGroupDavaoGrainTerminal Archen TechNoch keine Bewertungen

- Te Mecanica U-BoltDokument2 SeitenTe Mecanica U-BoltJuan carlos santos jimenezNoch keine Bewertungen

- PROC-G-001 Procedure To Ensure Impartiality, Independence and Confidentiality.Dokument6 SeitenPROC-G-001 Procedure To Ensure Impartiality, Independence and Confidentiality.Emily BrockNoch keine Bewertungen

- Man PowerDokument54 SeitenMan PowerMuhaidirNoch keine Bewertungen

- 12 Ton Fixed Height Tripod Jack Business Jets: Model 7212BDokument4 Seiten12 Ton Fixed Height Tripod Jack Business Jets: Model 7212BGenaire LimitedNoch keine Bewertungen

- Birdair Tensotherm Brochure - 2014Dokument4 SeitenBirdair Tensotherm Brochure - 2014Angel ReyesNoch keine Bewertungen

- Environmental Health and Safety Management System (HSMS) For Micro, Small and Medium Scale IndustriesDokument62 SeitenEnvironmental Health and Safety Management System (HSMS) For Micro, Small and Medium Scale IndustriesAlton LeeNoch keine Bewertungen

- D1-NOSPI-22-085: Engr. Lord Patrick S. Rodriguez Meralco - BatangasDokument1 SeiteD1-NOSPI-22-085: Engr. Lord Patrick S. Rodriguez Meralco - BatangasSenrick MedranoNoch keine Bewertungen

- The Ajax Project Rubys PPT MGMT 505Dokument12 SeitenThe Ajax Project Rubys PPT MGMT 505ABHINAV KADAMNoch keine Bewertungen

- Certificate of ComplianceDokument3 SeitenCertificate of ComplianceNeil100% (1)

- Petrothene NA214000Dokument1 SeitePetrothene NA214000Julio GarcíaNoch keine Bewertungen

- Target Costing and Total Life Cycle CostingDokument14 SeitenTarget Costing and Total Life Cycle CostingImelda HotmariaNoch keine Bewertungen

- Numerical, Wind Tunnel, and On Track Study of Monash 2002 Aero PackageDokument13 SeitenNumerical, Wind Tunnel, and On Track Study of Monash 2002 Aero PackageZizo StarkNoch keine Bewertungen

- CIS Security Metrics v1.0.0Dokument90 SeitenCIS Security Metrics v1.0.0Sendy Radiana SaktiNoch keine Bewertungen

- B02-S05 Rev 3 Sep 2017 Design, Fabri and Inst of GratingsDokument9 SeitenB02-S05 Rev 3 Sep 2017 Design, Fabri and Inst of Gratings15150515715Noch keine Bewertungen

- ISO Tolerances For Holes (ISO 286-2) - 400mm To 3150 MMDokument2 SeitenISO Tolerances For Holes (ISO 286-2) - 400mm To 3150 MMchubee94Noch keine Bewertungen