Beruflich Dokumente

Kultur Dokumente

58.process Costing

Hochgeladen von

mercatuzOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

58.process Costing

Hochgeladen von

mercatuzCopyright:

Verfügbare Formate

PROCESS COSTI NG

Process costing is an accounting methodology that traces and accumulates direct costs, and allocates indirect costs of a manufacturing process. Costs are assigned to products, usually in a large batch, which might include an entire month's production. Eventually, costs have to be allocated to individual units of product. It assigns average costs to each unit, and is the opposite extreme of Job costing which attempts to measure individual costs of production of each unit. Process costing is usually a significant chapter.

Process costing is a type of operation costing which is used to ascertain the cost of a product at each process or stage of manufacture. CIMA defines process costing as "The costing method applicable where goods or services result from a sequence of continuous or repetitive operations or processes. Costs are averaged over the units produced during the period". Process costing is suitable for industries producing homogeneous products and where production is a continuous flow. A process can be referred to as the sub-unit of an organization specifically defined for cost collection purpose. The importance of process costing

Costing is an important process that many companies engage in to keep track of where their money is being spent in the production and distribution processes. Understanding these costs is the first step in being able to control them. It is very important that a company chooses the appropriate type of costing system for their product type and industry. One type of costing system that is used in certain industries is process costing that varies from other types of costing (such as job costing) in some ways. In Process costing unit costs are more like averages, the process-costing system requires less bookkeeping than does a job-order costing system. So, a lot of companies prefer to use process-costing system. When process costing is applied?

Process costing is appropriate for companies that produce a continuous mass of like units through series of operations or process. Also, when one order does not affect the production process and a standardization of the process and product exists. However, if there are

significant differences among the costs of various products, a process costing system would not provide adequate product-cost information. Costing is generally used in such industries such as petroleum, coal mining, chemicals, textiles, paper, plastic, glass, and food. Reasons for use

Companies need to allocate total product costs to units of product for the following reasons: A company may manufacture thousands or millions of units of product in a given period of time. Products are manufactured in large quantities, but products may be sold in small quantities, sometimes one at a time (automobiles, loaves of bread), a dozen or two at a time (eggs, cookies), etc. Product costs must be transferred from Finished Goods to Cost of Goods Sold as sales are made. This requires a correct and accurate accounting of product costs per unit, to have a proper matching of product costs against related sales revenue. Managers need to maintain cost control over the manufacturing process. Process costing provides managers with feedback that can be used to compare similar product costs from one month to the next, keeping costs in line with projected manufacturing budgets. A fraction-of-a-cent cost change can represent a large dollar change in

overall profitability, when selling millions of units of product a month. Managers must carefully watch per unit costs on a daily basis through the production process, while at the same time dealing with materials and output in huge quantities. Materials part way through a process (e.g. chemicals) might need to be given a value, process costing allows for this. By determining what cost the part processed material has incurred such as labour or overhead an "equivalent unit" relative to the value of a finished process can be calculated.

Process cost procedures

There are four basic steps in accounting for Process cost:

Summarize the flow of physical units of output. Compute output in terms of equivalent units.

Summarize total costs to account for and Compute equivalent unit costs. Assign total costs to units completed and to units in ending work in process inventory.

Questions: 1) What is process costing? 2) When do we apply process costing? 3) What is the difference between job costing and process costing?

Source

: wikipedia

Compiled by Harikrishnan R S harikrishnanrsmalayam@gmail.com 0 9446461475

Das könnte Ihnen auch gefallen

- Process Costing of Sugar IndustryDokument30 SeitenProcess Costing of Sugar Industrymeera bhanushali67% (24)

- 20221218145704D6181 - Datar - 17e - Accessible - Fullppt - 18 - Process Costing WeightedDokument27 Seiten20221218145704D6181 - Datar - 17e - Accessible - Fullppt - 18 - Process Costing WeightedMateus AriatamaNoch keine Bewertungen

- Chapter 041Dokument248 SeitenChapter 041abeNoch keine Bewertungen

- Process Costing of Sugar IndustryDokument30 SeitenProcess Costing of Sugar Industrymeera bhanushali67% (24)

- Process Costing 1Dokument10 SeitenProcess Costing 1msadhanani3922Noch keine Bewertungen

- Introduction To Process CostingDokument29 SeitenIntroduction To Process Costingshersudsher67% (3)

- Process costing allocates indirect costs to productsDokument4 SeitenProcess costing allocates indirect costs to productsHarish PrajapatNoch keine Bewertungen

- Process CostingDokument12 SeitenProcess CostingPranesh KhambeNoch keine Bewertungen

- Proses Costing and Job Order CostingDokument9 SeitenProses Costing and Job Order CostingNefvi Desqi AndrianiNoch keine Bewertungen

- Process Costing ControlDokument7 SeitenProcess Costing Controlvijayadarshini vNoch keine Bewertungen

- Zahid AssignmentDokument5 SeitenZahid AssignmentJinnath JumurNoch keine Bewertungen

- Process CostingDokument23 SeitenProcess CostingDawn Juliana AranNoch keine Bewertungen

- Project On Process CostingDokument38 SeitenProject On Process CostingViraj Balsara78% (9)

- Process AccountDokument37 SeitenProcess Accountsneha9121100% (1)

- Acctg201 ProcessCostingLectureNotesDokument24 SeitenAcctg201 ProcessCostingLectureNotesSophia Marie Eredia FerolinoNoch keine Bewertungen

- Job-Order Costing Versus Process CostingDokument6 SeitenJob-Order Costing Versus Process CostingArnin OwonNoch keine Bewertungen

- Pinto - (18100072-Managerial 12th Batch)Dokument7 SeitenPinto - (18100072-Managerial 12th Batch)Takibul HasanNoch keine Bewertungen

- Process Costing System ExplainedDokument35 SeitenProcess Costing System ExplainedkoligautamiNoch keine Bewertungen

- AdvantagesDokument6 SeitenAdvantagesAqsa_afridi0062Noch keine Bewertungen

- Process CostingDokument27 SeitenProcess CostingAashika ShahNoch keine Bewertungen

- System Design-Job Order CostingDokument38 SeitenSystem Design-Job Order CostingAbuShahidNoch keine Bewertungen

- Process Costing..Dokument26 SeitenProcess Costing..Priyal Shah40% (5)

- Process Costing vs. Job CostingDokument11 SeitenProcess Costing vs. Job CostingRhea Royce CabuhatNoch keine Bewertungen

- Chapter_4_Process_Costing_Rework_Scrap_Spoilage_Joint_Product_2015Dokument17 SeitenChapter_4_Process_Costing_Rework_Scrap_Spoilage_Joint_Product_2015Amha SeyoumNoch keine Bewertungen

- Process Costing ExplainedDokument28 SeitenProcess Costing Explainedbhavinpoldiya0% (1)

- Kaduna State University: PGD in AccountingDokument12 SeitenKaduna State University: PGD in AccountingPAUL TIMMYNoch keine Bewertungen

- Process CostingDokument6 SeitenProcess CostingNibu Raj SNoch keine Bewertungen

- Cost Accounting1Dokument18 SeitenCost Accounting1Dishank KukrejaNoch keine Bewertungen

- Process Costing Vs Job CostingDokument2 SeitenProcess Costing Vs Job CostingRhea Royce CabuhatNoch keine Bewertungen

- Process CostingDokument43 SeitenProcess Costingjinalshah21097946Noch keine Bewertungen

- Methods Costing Explained Job Batch Contract ProcessDokument21 SeitenMethods Costing Explained Job Batch Contract ProcessRupesh Shinde100% (1)

- Process CostingDokument29 SeitenProcess CostingAshish Lakwani100% (4)

- Management AccountingDokument246 SeitenManagement AccountingsaraNoch keine Bewertungen

- Chap 4 CMADokument18 SeitenChap 4 CMAsolomonaauNoch keine Bewertungen

- Operation CostingDokument5 SeitenOperation CostingAshmanur RhamanNoch keine Bewertungen

- Batch CostingDokument9 SeitenBatch Costingstudyandstudymore18Noch keine Bewertungen

- Ch-3 Cost BehaviorDokument25 SeitenCh-3 Cost BehaviorNeelesh MishraNoch keine Bewertungen

- Order Costing Is Most Suitable For Products Which Are Unique and Customizable or According ToDokument1 SeiteOrder Costing Is Most Suitable For Products Which Are Unique and Customizable or According ToMark WatneyNoch keine Bewertungen

- Process Costing of Amul Ice CreamsDokument5 SeitenProcess Costing of Amul Ice CreamsSatwikNoch keine Bewertungen

- Issues and Decision Making in Management AccountingDokument9 SeitenIssues and Decision Making in Management AccountingWajeeh RehmanNoch keine Bewertungen

- Process Costing of Amul Ice CreamsDokument5 SeitenProcess Costing of Amul Ice CreamsamanNoch keine Bewertungen

- Costing FinalDokument4 SeitenCosting FinalEr Heena BhagiaNoch keine Bewertungen

- Welding Economics and Management WFC 212-1Dokument59 SeitenWelding Economics and Management WFC 212-1ibrahim mustaphaNoch keine Bewertungen

- Process CostingDokument11 SeitenProcess CostingsunilNoch keine Bewertungen

- Cost AccountingDokument44 SeitenCost Accountingknowledge informationNoch keine Bewertungen

- Utilisation of Product Costing Systems in The Manufacturing IndustryDokument15 SeitenUtilisation of Product Costing Systems in The Manufacturing Industryrina00Noch keine Bewertungen

- Process CostingDokument10 SeitenProcess Costingspark sparkNoch keine Bewertungen

- Job Order vs Process Costing: Understanding the Key DifferencesDokument3 SeitenJob Order vs Process Costing: Understanding the Key DifferencesUmair Siyab100% (1)

- Amol Cost AssignmentDokument39 SeitenAmol Cost AssignmentsamethNoch keine Bewertungen

- Reflection PaperDokument4 SeitenReflection PaperMau Dela CruzNoch keine Bewertungen

- Absorption CostingDokument6 SeitenAbsorption CostingHsin Wua ChiNoch keine Bewertungen

- Job Contract & Batch CostingDokument37 SeitenJob Contract & Batch CostingthilaganadarNoch keine Bewertungen

- Cost AccumulationDokument4 SeitenCost AccumulationAziz Bin AnwarNoch keine Bewertungen

- Amirullah NDokument5 SeitenAmirullah NTAPOSH MUNJALNoch keine Bewertungen

- Cost Accounting ConceptsDokument18 SeitenCost Accounting Concepts18arshiNoch keine Bewertungen

- Cost Accounting: Tracking Expenses for Management DecisionsDokument16 SeitenCost Accounting: Tracking Expenses for Management DecisionsKanchanaNoch keine Bewertungen

- What is a Costing System ExplainedDokument4 SeitenWhat is a Costing System ExplainedNeriza PonceNoch keine Bewertungen

- 79 52 ET V1 S1 - Unit - 6 PDFDokument19 Seiten79 52 ET V1 S1 - Unit - 6 PDFTanmay JagetiaNoch keine Bewertungen

- What Is Process CostingDokument12 SeitenWhat Is Process CostingPAUL TIMMYNoch keine Bewertungen

- Managerial Economics-Chapter 5-Essentials of Producion and Producion CostsDokument9 SeitenManagerial Economics-Chapter 5-Essentials of Producion and Producion CostsChristian AlcaparasNoch keine Bewertungen

- Process Costing SystemDokument15 SeitenProcess Costing SystemAmmad SheikhNoch keine Bewertungen

- MA AssignmentDokument11 SeitenMA AssignmentSathyendra Singh ChauhanNoch keine Bewertungen

- Cost Management: A Case for Business Process Re-engineeringVon EverandCost Management: A Case for Business Process Re-engineeringNoch keine Bewertungen

- 68 GaarDokument2 Seiten68 GaarmercatuzNoch keine Bewertungen

- 67.ifrs ConvergenceDokument2 Seiten67.ifrs ConvergencemercatuzNoch keine Bewertungen

- 7.stpi & SezDokument3 Seiten7.stpi & SezmercatuzNoch keine Bewertungen

- 64.role of Chartred Accountants in Financial InstitutionsDokument2 Seiten64.role of Chartred Accountants in Financial Institutionsmercatuz100% (1)

- Certificate of Deposit: Add-On CdsDokument4 SeitenCertificate of Deposit: Add-On CdsmercatuzNoch keine Bewertungen

- 63 KaizenDokument4 Seiten63 KaizenmercatuzNoch keine Bewertungen

- 9.corporate GovernanceDokument3 Seiten9.corporate GovernancemercatuzNoch keine Bewertungen

- 17.role of Tax ConsultantsDokument4 Seiten17.role of Tax Consultantsmercatuz100% (1)

- 33.tax Planning Under Indirect TaxationsDokument3 Seiten33.tax Planning Under Indirect TaxationsmercatuzNoch keine Bewertungen

- 8.global WarmingDokument3 Seiten8.global WarmingmercatuzNoch keine Bewertungen

- 65.role of A ConsultantDokument2 Seiten65.role of A ConsultantmercatuzNoch keine Bewertungen

- 66.six SigmaDokument3 Seiten66.six SigmamercatuzNoch keine Bewertungen

- 61.forensic AccountingDokument3 Seiten61.forensic Accountingmercatuz0% (1)

- 62.insider TradingDokument5 Seiten62.insider TradingmercatuzNoch keine Bewertungen

- System Audit: Foundations of Information System AuditingDokument4 SeitenSystem Audit: Foundations of Information System AuditingmercatuzNoch keine Bewertungen

- 6.standards On Quality ControlDokument2 Seiten6.standards On Quality ControlmercatuzNoch keine Bewertungen

- 57.pricing DecisionsDokument3 Seiten57.pricing DecisionsmercatuzNoch keine Bewertungen

- 60.central Excise Compliance CertificateDokument3 Seiten60.central Excise Compliance CertificatemercatuzNoch keine Bewertungen

- 56.IFRS Vs IASDokument3 Seiten56.IFRS Vs IASmercatuzNoch keine Bewertungen

- 55.profesional EthicsDokument5 Seiten55.profesional EthicsmercatuzNoch keine Bewertungen

- 51.limited Liability PartnershipDokument8 Seiten51.limited Liability PartnershipmercatuzNoch keine Bewertungen

- 54.banking Regulation ActDokument5 Seiten54.banking Regulation ActmercatuzNoch keine Bewertungen

- 5.money LaunderingDokument3 Seiten5.money LaunderingmercatuzNoch keine Bewertungen

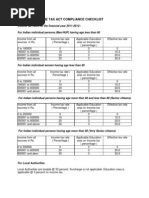

- 53.income Tax Compliance Check ListDokument5 Seiten53.income Tax Compliance Check ListmercatuzNoch keine Bewertungen

- 50.cost Control & Cost ReductionDokument6 Seiten50.cost Control & Cost ReductionmercatuzNoch keine Bewertungen

- 46.repo ArrangementsDokument5 Seiten46.repo ArrangementsmercatuzNoch keine Bewertungen

- 52.analysis For Decision MakingDokument4 Seiten52.analysis For Decision MakingmercatuzNoch keine Bewertungen

- 49.transfer PricingDokument4 Seiten49.transfer PricingmercatuzNoch keine Bewertungen

- Due Diligence Review: Purpose of Due-Diligence Review-The Purpose of Due Diligence Review Is To Assist TheDokument4 SeitenDue Diligence Review: Purpose of Due-Diligence Review-The Purpose of Due Diligence Review Is To Assist ThemercatuzNoch keine Bewertungen

- The Importance of Process CostingDokument3 SeitenThe Importance of Process CostingPraWin KharateNoch keine Bewertungen

- Process Costing: Learning ObjectivesDokument69 SeitenProcess Costing: Learning ObjectivesShaiful HussainNoch keine Bewertungen

- Process Costing TheoryDokument3 SeitenProcess Costing TheorycoolchethanNoch keine Bewertungen

- 06 Process CostingDokument16 Seiten06 Process CostingChristian Blanza LlevaNoch keine Bewertungen

- Job Costing Chapter 20 SummaryDokument43 SeitenJob Costing Chapter 20 SummaryJitender RawatNoch keine Bewertungen

- Process CostingDokument63 SeitenProcess CostingReiner NuludNoch keine Bewertungen

- Hansen AISE IM Ch06Dokument49 SeitenHansen AISE IM Ch06AimanNoch keine Bewertungen

- Cost Accounting ConceptsDokument18 SeitenCost Accounting Concepts18arshiNoch keine Bewertungen

- ACC102 Chapter4newDokument17 SeitenACC102 Chapter4newjohn_26_jjmNoch keine Bewertungen

- Project - Process Costing-Mcom - 1Dokument39 SeitenProject - Process Costing-Mcom - 1Asif ShaikhNoch keine Bewertungen

- Chapter 4 Accounting Flashcards - QuizletDokument11 SeitenChapter 4 Accounting Flashcards - QuizletEdi wow WowNoch keine Bewertungen

- Pre-Course PackageDokument238 SeitenPre-Course PackageJan GodlewskiNoch keine Bewertungen

- Process CostingDokument6 SeitenProcess CostingNibu Raj SNoch keine Bewertungen

- Notes On Process Costing System - PDF - ProtectedDokument14 SeitenNotes On Process Costing System - PDF - Protectedhildamezmur9Noch keine Bewertungen

- Chapter 20 Job Batch and Process CostingDokument24 SeitenChapter 20 Job Batch and Process CostingAmy Estes100% (4)

- Chapter 10 - AnswerDokument15 SeitenChapter 10 - AnswerAgentSkySkyNoch keine Bewertungen

- Process Costing WorksheetDokument21 SeitenProcess Costing WorksheetpchakkrapaniNoch keine Bewertungen

- Process Costing of Amul Ice CreamsDokument5 SeitenProcess Costing of Amul Ice CreamsSatwikNoch keine Bewertungen

- Systems Designs - Job and Process CostingDokument49 SeitenSystems Designs - Job and Process Costingjoe6hodagameNoch keine Bewertungen

- Handout 7 - Process CostingDokument32 SeitenHandout 7 - Process CostingDonovan Leong 도노반Noch keine Bewertungen

- Principles of Accounting Chapter 18Dokument36 SeitenPrinciples of Accounting Chapter 18myrentistoodamnhighNoch keine Bewertungen

- CH 03Dokument41 SeitenCH 03Nam NguyenNoch keine Bewertungen

- Chapter 4Dokument15 SeitenChapter 4TaylorCohenNoch keine Bewertungen

- Chap 011Dokument47 SeitenChap 011AakashSinghNoch keine Bewertungen

- Process Costing: Learning ObjectivesDokument15 SeitenProcess Costing: Learning ObjectivesjuangwapotalagaNoch keine Bewertungen

- Activity 2Dokument7 SeitenActivity 2Mae FerrerNoch keine Bewertungen