Beruflich Dokumente

Kultur Dokumente

Soluble Oil

Hochgeladen von

Carlos SalazarOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Soluble Oil

Hochgeladen von

Carlos SalazarCopyright:

Verfügbare Formate

Soluble Oil

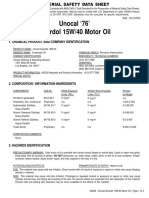

Material Safety Data Sheet

1. Product and Company Identification

Product Name: MSDS Number: Intended Use: Manufacturer/Supplier: Soluble Oil 778690 Metalworking Fluid ConocoPhillips Lubricants 600 N. Dairy Ashford, 2W900 Houston, Texas 77079-1175 Chemtrec: 800-424-9300 (24 Hours) U.S.: 800-822-6457 or International: +1-83-2486-3363 800-766-0050 Internet: http://w3.conocophillips.com/NetMSDS/

Emergency Health and Safety Number: Customer Service: Technical Information: MSDS Information:

2. Hazards Identification

Emergency Overview WARNING! Eye and Skin Irritant NFPA

Appearance: Dark amber Physical Form: Liquid Odor: Petroleum Potential Health Effects Eye: Eye irritant. Contact may cause stinging, watering, redness, and swelling. Skin: Mild to moderate skin irritant. Contact may cause redness, itching, a burning sensation, and skin damage. Prolonged or repeated contact may cause drying and cracking of the skin, dermatitis (inflammation), burns, and severe skin damage. No information available on skin absorption. Inhalation (Breathing): No information available on acute toxicity. Ingestion (Swallowing): Low to moderate degree of toxicity by ingestion. Signs and Symptoms: Effects of overexposure may include irritation of the digestive tract, nausea and diarrhea. Inhalation of oil mist or vapors at elevated temperatures may cause respiratory irritation. Inhalation of oil mist or vapors at elevated temperatures may cause respiratory irritation. Pre-Existing Medical Conditions: Conditions which may be aggravated by exposure include skin disorders and eye disorders. See Section 11 for additional Toxicity Information.

________________________________________________________________________________________________ 778690 - Soluble Oil Page 1/7 Date of Issue: Status: Final

778690 - Soluble Oil Page 2/7 Date of Issue: 12-Nov-2008 Status: Final ________________________________________________________________________________________________

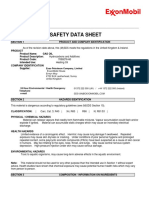

3. Composition / Information on Ingredients

Component Hydrotreated Distillate, Heavy Naphthenic ..C20-50 Hexylene Glycol Fatty Acids, Tall-Oil, Potassium Salts Sodium Petroleum Sulfonate Modified Polyethoxylated Alcohol CASRN 64742-52-5 107-41-5 61790-44-1 68608-26-4 Proprietary Concentration* 87-93 1-2 1-5 3-7 1-5

* All concentrations are percent by weight unless ingredient is a gas. Gas concentrations are in percent by volume.

4. First Aid Measures

Eye Contact: If irritation or redness develops from exposure, flush eyes with clean water. Remove contact lenses if present and easy to do. For direct contact, hold eyelids apart and flush the affected eye(s) with clean water for at least 15 minutes. If irritation persists, seek medical attention. Skin Contact: Remove contaminated shoes and clothing, and flush affected area(s) with large amounts of water. If skin surface is damaged, apply a clean dressing and seek medical attention. If skin surface is not damaged, cleanse affected area(s) thoroughly by washing with mild soap and water or a waterless hand cleaner. If irritation or redness develops, seek medical attention. Wash contaminated clothing before reuse. Inhalation (Breathing): If respiratory symptoms develop, move victim away from source of exposure and into fresh air in a position comfortable for breathing. If symptoms persist, seek medical attention. Ingestion (Swallowing): If swallowed, seek emergency medical attention. If victim is drowsy or unconscious and vomiting, place on the left side with the head down and do not give anything by mouth. If victim is conscious and alert and ingestion occurred within the last hour, vomiting should be induced for ingestions of large amounts (more than 5 ounces in an adult) preferably under direction from a physician or poison center. Do not leave victim unattended and observe closely for adequacy of breathing. Notes to Physician: Acute aspirations of large amounts of oil-laden material may produce a serious aspiration pneumonia. Patients who aspirate these oils should be followed for the development of long-term sequelae. Inhalation exposure to oil mists below current workplace exposure limits is unlikely to cause pulmonary abnormalities.

5. Fire-Fighting Measures

NFPA 704 Hazard Class Health: 1 Flammability: 1 Instability: 0 (0-Minimal, 1-Slight, 2-Moderate, 3-Serious, 4-Severe)

Unusual Fire & Explosion Hazards: This material may burn, but will not ignite readily. Vapors are heavier than air and can accumulate in low areas. If container is not properly cooled, it can rupture in the heat of a fire. Extinguishing Media: Dry chemical, carbon dioxide, foam, or water spray is recommended. Water or foam may cause frothing of materials heated above 212F. Carbon dioxide can displace oxygen. Use caution when applying carbon dioxide in confined spaces. Fire Fighting Instructions: For fires beyond the incipient stage, emergency responders in the immediate hazard area should wear protective clothing. When the potential chemical hazard is unknown, in enclosed or confined spaces, a self contained breathing apparatus should be worn. In addition, wear other appropriate protective equipment as conditions warrant (see Section 8). Isolate immediate hazard area and keep unauthorized personnel out. Stop spill/release if it can be done safely. Move undamaged containers from immediate hazard area if it can be done safely. Water spray may be useful in minimizing or dispersing vapors and to protect personnel. Cool equipment exposed to fire with water, if it can be done safely. Avoid spreading burning liquid with water used for cooling purposes. Hazardous Combustion Products: Combustion may yield smoke, carbon monoxide, and other products of incomplete combustion. Oxides of sulfur, nitrogen or phosphorus may also be formed. See Section 9 for Flammable Properties including Flash Point and Flammable (Explosive) Limits

778690 - Soluble Oil Page 3/7 Date of Issue: 12-Nov-2008 Status: Final ________________________________________________________________________________________________

6. Accidental Release Measures

Personal Precautions: This material may burn, but will not ignite readily. Keep all sources of ignition away from spill/release. The use of explosion-proof electrical equipment is recommended. Stay upwind and away from spill/release. Notify persons down wind of the spill/release, isolate immediate hazard area and keep unauthorized personnel out. Wear appropriate protective equipment, including respiratory protection, as conditions warrant (see Section 8). See Sections 2 and 7 for additional information on hazards and precautionary measures. Environmental Precautions: Stop spill/release if it can be done safely. Prevent spilled material from entering sewers, storm drains, other unauthorized drainage systems, and natural waterways. Use water sparingly to minimize environmental contamination and reduce disposal requirements. Spills into or upon navigable waters, the contiguous zone, or adjoining shorelines that cause a sheen or discoloration on the surface of the water, may require notification of the National Response Center (phone number 800-424-8802). Methods for Containment and Clean-Up: Notify relevant authorities in accordance with all applicable regulations. Immediate cleanup of any spill is recommended. Dike far ahead of spill for later recovery or disposal. Absorb spill with inert material such as sand or vermiculite, and place in suitable container for disposal.

7. Handling and Storage

Precautions for safe handling: Use good personal hygiene practices and wear appropriate personal protective equipment. Wear eye/face protection. Wear protective gloves. Wash thoroughly after handling. Do not enter confined spaces such as tanks or pits without following proper entry procedures such as ASTM D-4276 and 29CFR 1910.146. Do not wear contaminated clothing or shoes. "Empty" containers retain residue and may be dangerous. Do not pressurize, cut, weld, braze, solder, drill, grind, or expose such containers to heat, flame, sparks, or other sources of ignition. They may explode and cause injury or death. "Empty" drums should be completely drained, properly bunged, and promptly shipped to the supplier or a drum reconditioner. All containers should be disposed of in an environmentally safe manner and in accordance with governmental regulations. Before working on or in tanks which contain or have contained this material, refer to OSHA regulations, ANSI Z49.1, and other references pertaining to cleaning, repairing, welding, or other contemplated operations. Conditions for safe storage: Use and store this material in cool, dry, well-ventilated area away from heat and all sources of ignition. Store only in approved containers. Keep away from any incompatible material (see Section 10). Protect container(s) against physical damage. Keep container(s) tightly closed.

8. Exposure Controls / Personal Protection

Component Hydrotreated Distillate, Heavy Naphthenic ..C20-50 Hexylene Glycol Sodium Petroleum Sulfonate US-ACGIH TWA: 5mg/m3 STEL: 10 mg/m3 (as Oil Mist, if Generated) Ceiling: 25 ppm TWA: 5mg/m3 STEL: 10 mg/m3 (as Oil Mist, if Generated) OSHA TWA: 5 mg/m3 (as Oil Mist, if Generated) --TWA: 5 mg/m3 as Oil Mist, if Generated Other ---

-----

Note: State, local or other agencies or advisory groups may have established more stringent limits. Consult an industrial hygienist or similar professional, or your local agencies, for further information. Engineering controls: If current ventilation practices are not adequate to maintain airborne concentrations below the established exposure limits, additional engineering controls may be required. Eye/Face Protection: The use of eye protection (such as splash goggles) that meets or exceeds ANSI Z.87.1 is recommended when there is potential liquid contact to the eye. Depending on conditions of use, a face shield may be necessary. Skin/Hand Protection: The use of gloves impervious to the specific material handled is advised to prevent skin contact. Users should check with manufacturers to confirm the breakthrough performance of their products. Suggested protective materials: Nitrile

778690 - Soluble Oil Page 4/7 Date of Issue: 12-Nov-2008 Status: Final ________________________________________________________________________________________________ Respiratory Protection: Where there is potential for airborne exposure above the exposure limit a NIOSH certified air purifying respirator equipped with R or P95 filters may be used. A respiratory protection program that meets or is equivalent to OSHA 29 CFR 1910.134 and ANSI Z88.2 should be followed whenever workplace conditions warrant a respirator's use. Air purifying respirators provide limited protection and cannot be used in atmospheres that exceed the maximum use concentration (as directed by regulation or the manufacturer's instructions), in oxygen deficient (less than 19.5 percent oxygen) situations, or under conditions that are immediately dangerous to life and health (IDLH). Other Protective Equipment: Eye wash and quick-drench shower facilities should be available in the work area. Thoroughly clean shoes and wash contaminated clothing before reuse. Suggestions provided in this section for exposure control and specific types of protective equipment are based on readily available information. Users should consult with the specific manufacturer to confirm the performance of their protective equipment. Specific situations may require consultation with industrial hygiene, safety, or engineering professionals.

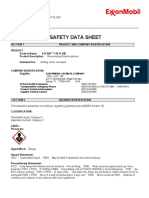

9. Physical and Chemical Properties

Note: Unless otherwise stated, values are determined at 20C (68F) and 760 mm Hg (1 atm). Data represent typical values and are not intended to be specifications. Appearance: Physical Form: Odor: Odor Threshold: pH: Vapor Pressure: Vapor Density (air=1): Boiling Point/Range: Melting/Freezing Point: Solubility in Water: Partition Coefficient (n-octanol/water) (Kow): Specific Gravity: Bulk Density: Viscosity: Percent Volatile: Evaporation Rate (nBuAc=1): Flash Point: Test Method: LEL (vol % in air): UEL (vol % in air): Autoignition Temperature: Dark amber Liquid Petroleum No data 8.8 - 9.6 at water:oil ratio 95:5 <1 mm Hg >1 No data No data Completely soluble after agitation No data 0.92 @ 60F (15.6C) 7.6 lbs/gal 6 cSt @ 100C; 29 cSt @ 40C Negligible No data 350F / 177C Cleveland Open Cup (COC), ASTM D92 No data No data No data

10. Stability and Reactivity

Stability: Stable under normal ambient and anticipated conditions of use. Conditions to Avoid: Avoid all possible sources of ignition. Extended exposure to high temperatures can cause decomposition. Materials to Avoid (Incompatible Materials): Avoid contact with strong oxidizing agents and strong acids. Avoid contact with strong oxidizing agents and strong reducing agents. Hazardous Decomposition Products: Not anticipated under normal conditions of use. Hazardous Polymerization: Not known to occur.

778690 - Soluble Oil Page 5/7 Date of Issue: 12-Nov-2008 Status: Final ________________________________________________________________________________________________

11. Toxicological Information

Chronic Data: A mortality study sponsored by General Motors and the United Auto Workers suggested a link between cutting oils or machining fluids and various forms of cancer (e.g., esophageal, laryngeal,and rectal) The study evaluated workplace exposures from 1940-1984. Since the composition of these materials has changed substantially since 1940, and because the most notable effects were seen among those with work histories dating back to that time, the relevance of these findings to present-day exposures is uncertain. Cutting oils or machining fluids have not been identified as carcinogens by NTP, IARC, or OSHA. Hydrotreated Distillate, Heavy Naphthenic ..C20-50 Carcinogenicity: The petroleum base oils contained in this product have been highly refined by a variety of processes including severe hydrocracking/hydroprocessing to reduce aromatics and improve performance characteristics. All of the oils meet the IP-346 criteria of less than 3 percent PAH's and are not considered carcinogens by NTP, IARC, or OSHA. Target Organs: Administration of certain mineral oils in the diet to Fischer 344 rats at 1500 mg/kg/day for 90 days resulted in the formation of microgranulomas in the liver. However, this response was not observed in studies conducted with other rat strains or dogs. Microgranulomas like those observed in the Fischer 344 rat studies have not been observed in humans. Hexylene Glycol Reproductive: Exposure to hexylene glycol during pregnancy has demonstrated limited evidence of developmental toxicity in laboratory animals. Increased skeletal variations were seen in oral studies, but only at doses that were toxic to the mother. No fetal toxicity was seen at doses that were not maternally toxic. Component Oral LD50 Dermal LD50 Inhalation LC50 Hydrotreated Distillate, Heavy >5 mg/kg (rat) >2 g/kg (rabbit) No data Naphthenic ..C20-50 Hexylene Glycol 3.7-4.79 g/kg (rat) >2 to 12.3 g/kg (rabbit) No data Sodium Petroleum Sulfonate No data No data No data

12. Ecological Information

Ecological Information: Not evaluated.

13. Disposal Considerations

The generator of a waste is always responsible for making proper hazardous waste determinations and needs to consider state and local requirements in addition to federal regulations. This material, if discarded as produced, would not be a federally regulated RCRA "listed" hazardous waste and is not believed to exhibit characteristics of hazardous waste. See Sections 7 and 8 for information on handling, storage and personal protection and Section 9 for physical/chemical properties. It is possible that the material as produced contains constituents which are not required to be listed in the MSDS but could affect the hazardous waste determination. Additionally, use which results in chemical or physical change of this material could subject it to regulation as a hazardous waste. This material under most intended uses would become "Used Oil" due to contamination by physical or chemical impurities. Whenever possible, Recycle Used Oil in accordance with applicable federal and state or local regulations. Container contents should be completely used and containers should be emptied prior to discard.

14. Transportation Information

U.S. Department of Transportation (DOT) Shipping Description: Not regulated Note: If shipped by land in a packaging having a capacity of 3,500 gallons or more, the provisions of 49 CFR, Part 130 apply. (Contains oil) International Maritime Dangerous Goods (IMDG) Shipping Description: Not regulated Note: U.S. DOT compliance requirements may apply. See 49 CFR 171.22, 23 & 25. International Civil Aviation Org. / International Air Transport Assoc. (ICAO/IATA) UN/ID #: Not regulated Note: U.S. DOT compliance requirements may apply. See 49 CFR 171.22, 23 & 24.

778690 - Soluble Oil Page 6/7 Date of Issue: 12-Nov-2008 Status: Final ________________________________________________________________________________________________

14. Transportation Information

LTD. QTY Packaging Instruction #: Max. Net Qty. Per Package: -----

Passenger Aircraft -----

Cargo Aircraft Only -----

15. Regulatory Information

CERCLA/SARA - Section 302 Extremely Hazardous Substances and TPQs (in pounds): This material does not contain any chemicals subject to the reporting requirements of SARA 302 and 40 CFR 372. CERCLA/SARA - Section 311/312 (Title III Hazard Categories) Yes Acute Health: No Chronic Health: No Fire Hazard: No Pressure Hazard: No Reactive Hazard: CERCLA/SARA - Section 313 and 40 CFR 372: This material does not contain any chemicals subject to the reporting requirements of SARA 313 and 40 CFR 372. EPA (CERCLA) Reportable Quantity (in pounds): This material does not contain any chemicals with CERCLA Reportable Quantities. California Proposition 65: This material does not contain any chemicals which are known to the State of California to cause cancer, birth defects or other reproductive harm at concentrations that trigger the warning requirements of California Proposition 65. Canadian Regulations: This product has been classified in accordance with the hazard criteria of the Controlled Products Regulations (CPR) and the MSDS contains all the information required by the Regulations. WHMIS Hazard Class D2B National Chemical Inventories: All components are either listed on the US TSCA Inventory, or are not regulated under TSCA. All components are either on the DSL, or are exempt from DSL listing requirements. U.S. Export Control Classification Number: EAR99

16. Other Information

Date of Issue: Status: Previous Issue Date: Revised Sections or Basis for Revision: MSDS Number: Guide to Abbreviations:

ACGIH = American Conference of Governmental Industrial Hygienists; CASRN = Chemical Abstracts Service Registry Number; CEILING = Ceiling Limit (15 minutes); CERCLA = The Comprehensive Environmental Response, Compensation, and Liability Act; EPA = Environmental Protection Agency; IARC = International Agency for Research on Cancer; LEL = Lower Explosive Limit; NE = Not Established; NFPA = National Fire Protection Association; NTP = National Toxicology Program; OSHA = Occupational Safety and Health Administration; PEL = Permissible Exposure Limit (OSHA); SARA = Superfund Amendments and Reauthorization Act; STEL = Short Term Exposure Limit (15 minutes); TLV = Threshold Limit Value (ACGIH); TWA = Time Weighted Average (8 hours); UEL = Upper Explosive Limit; WHMIS = Worker Hazardous Materials Information System (Canada)

12-Nov-2008 Final 20-Jun-2007 Regulatory information (Section 15) 778690

778690 - Soluble Oil Page 7/7 Date of Issue: 12-Nov-2008 Status: Final ________________________________________________________________________________________________ Disclaimer of Expressed and implied Warranties: The information presented in this Material Safety Data Sheet is based on data believed to be accurate as of the date this Material Safety Data Sheet was prepared. HOWEVER, NO WARRANTY OF MERCHANTABILITY, FITNESS FOR ANY PARTICULAR PURPOSE, OR ANY OTHER WARRANTY IS EXPRESSED OR IS TO BE IMPLIED REGARDING THE ACCURACY OR COMPLETENESS OF THE INFORMATION PROVIDED ABOVE, THE RESULTS TO BE OBTAINED FROM THE USE OF THIS INFORMATION OR THE PRODUCT, THE SAFETY OF THIS PRODUCT, OR THE HAZARDS RELATED TO ITS USE. No responsibility is assumed for any damage or injury resulting from abnormal use or from any failure to adhere to recommended practices. The information provided above, and the product, are furnished on the condition that the person receiving them shall make their own determination as to the suitability of the product for their particular purpose and on the condition that they assume the risk of their use. In addition, no authorization is given nor implied to practice any patented invention without a license.

Das könnte Ihnen auch gefallen

- Produced Water Treatment Field ManualVon EverandProduced Water Treatment Field ManualBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Chemicals Zetag MSDS LDP Zetag 7875 FS 40 - 0610Dokument7 SeitenChemicals Zetag MSDS LDP Zetag 7875 FS 40 - 0610PromagEnviro.comNoch keine Bewertungen

- Payslip 795119 CIN Sep 2019 PDFDokument1 SeitePayslip 795119 CIN Sep 2019 PDFRaju UllengalaNoch keine Bewertungen

- SWOT AnalysisDokument6 SeitenSWOT AnalysisAli Najaf NaqviNoch keine Bewertungen

- Addressing ExerciseDokument5 SeitenAddressing ExerciseKaranveer Singh GahuniaNoch keine Bewertungen

- Employment Application - PcaDokument6 SeitenEmployment Application - Pcaapi-292987619Noch keine Bewertungen

- Conoco Bentone Grease MSDSDokument6 SeitenConoco Bentone Grease MSDSJas SumNoch keine Bewertungen

- Msds HP 20w50Dokument7 SeitenMsds HP 20w50Anonymous PvHmtbNoch keine Bewertungen

- MSDS 15W40Dokument4 SeitenMSDS 15W40Sukhjeet SinghNoch keine Bewertungen

- Havoline Super 2T SDS 31899 21 Feb 2012Dokument7 SeitenHavoline Super 2T SDS 31899 21 Feb 2012Miguel TorresNoch keine Bewertungen

- Safety Data Sheet: Rando HDZ 68Dokument7 SeitenSafety Data Sheet: Rando HDZ 68Om Prakash RajNoch keine Bewertungen

- MSDS 15w-40Dokument7 SeitenMSDS 15w-40Farhat AzharNoch keine Bewertungen

- SDS - Used Lubricating Oil (New) 2019Dokument7 SeitenSDS - Used Lubricating Oil (New) 2019VivekNoch keine Bewertungen

- Fleetguard DCA-4 Liquid - CumminsDokument12 SeitenFleetguard DCA-4 Liquid - CumminsYasser JaviNoch keine Bewertungen

- Msds Chevron 15w40Dokument7 SeitenMsds Chevron 15w40Luis Sanchez LlicoNoch keine Bewertungen

- Capella WF 68Dokument9 SeitenCapella WF 68Edwin CalmaNoch keine Bewertungen

- Mercury 4t Oil MSDSDokument5 SeitenMercury 4t Oil MSDSCelesNoch keine Bewertungen

- Gas Oil MsdsDokument10 SeitenGas Oil MsdsWilson WanNoch keine Bewertungen

- MSDS - Shell Spirax - Gear OilDokument7 SeitenMSDS - Shell Spirax - Gear OilAnonymous LfeGI2hMNoch keine Bewertungen

- Ms Ds Detail PageDokument9 SeitenMs Ds Detail PageCarlos GuashcoNoch keine Bewertungen

- Material Safety Data Sheet: Section 1: Product IdentificationDokument7 SeitenMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1Noch keine Bewertungen

- Duron e 15w40 MsdsDokument7 SeitenDuron e 15w40 MsdsEnhtuwshin Barkhasbadi100% (1)

- Safety Data Sheet: Product Name: GAS OILDokument10 SeitenSafety Data Sheet: Product Name: GAS OILJustice MachiwanaNoch keine Bewertungen

- GSB 78 SDS 2022Dokument6 SeitenGSB 78 SDS 2022Jelian Grace Gonti�asNoch keine Bewertungen

- Safety Data Sheet: Chevron Open Gear GreaseDokument8 SeitenSafety Data Sheet: Chevron Open Gear GreaseWork ForceNoch keine Bewertungen

- Hydrocholoric AcidDokument4 SeitenHydrocholoric AcidchapulincoloradoNoch keine Bewertungen

- Safety Data Sheet: Chevron Ultra-Duty Grease EP NLGI 0, 1, 2Dokument8 SeitenSafety Data Sheet: Chevron Ultra-Duty Grease EP NLGI 0, 1, 2Sofels FemiNoch keine Bewertungen

- Safety Data Sheet: Section 1 - Product and Company IdentificationDokument10 SeitenSafety Data Sheet: Section 1 - Product and Company IdentificationAndhie OsloNoch keine Bewertungen

- SKF MSDS LGHP 2 PDFDokument5 SeitenSKF MSDS LGHP 2 PDFMunkhnasan MonaNoch keine Bewertungen

- Diesel Msds ReportDokument0 SeitenDiesel Msds ReportsahilchemNoch keine Bewertungen

- Tarospecial HT 70 PDFDokument7 SeitenTarospecial HT 70 PDFOm Prakash RajNoch keine Bewertungen

- Safety Data Sheet: Delo Gold Ultra SAE 15W-40Dokument6 SeitenSafety Data Sheet: Delo Gold Ultra SAE 15W-40Nasta Ina RobayasaNoch keine Bewertungen

- LEHDER Environmental Services LimitedDokument8 SeitenLEHDER Environmental Services LimitedAnonymous oQKQLFNoch keine Bewertungen

- Safety Data Sheet: Chevron Soluble Oil BDokument8 SeitenSafety Data Sheet: Chevron Soluble Oil BSofels FemiNoch keine Bewertungen

- Material Safety Data Sheet For Usa and Canada: Ecopower Motor OilDokument11 SeitenMaterial Safety Data Sheet For Usa and Canada: Ecopower Motor OilΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNoch keine Bewertungen

- MSDS HCLDokument6 SeitenMSDS HCLYuni Ayu LestariNoch keine Bewertungen

- Taro 20 Taro 30 DP 30Dokument6 SeitenTaro 20 Taro 30 DP 30Om Prakash RajNoch keine Bewertungen

- Material Safety Data Sheet: Product and Company Identification 1Dokument6 SeitenMaterial Safety Data Sheet: Product and Company Identification 1onejako12Noch keine Bewertungen

- Safety Data Sheet: Rando HDZ 46Dokument6 SeitenSafety Data Sheet: Rando HDZ 46Om Prakash RajNoch keine Bewertungen

- Msds VGODokument8 SeitenMsds VGOJaideepNoch keine Bewertungen

- Safety Data Sheet: Veritas 800 Marine 30Dokument7 SeitenSafety Data Sheet: Veritas 800 Marine 30Om Prakash RajNoch keine Bewertungen

- Capella wf32Dokument7 SeitenCapella wf32Om Prakash RajNoch keine Bewertungen

- Escaid 110 Exxon MobileDokument11 SeitenEscaid 110 Exxon MobilePatricio Santis CortésNoch keine Bewertungen

- Safety Data Sheet (SDS) : SHELL ALVANIA EP GREASE R000, R00, R0,1,2 Code:613131 Date:June 1, 2016 Page.1/5Dokument5 SeitenSafety Data Sheet (SDS) : SHELL ALVANIA EP GREASE R000, R00, R0,1,2 Code:613131 Date:June 1, 2016 Page.1/5Nam ĐặngNoch keine Bewertungen

- Aceite SKF LHMF 300Dokument5 SeitenAceite SKF LHMF 300DAvid Alvarez CastilloNoch keine Bewertungen

- Safety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Dokument5 SeitenSafety Data Sheet (SDS) : Nippon Grease Co., Ltd. E4377005 Date:June 1, 2016 Page.1/5Chanchai PrugpadeeNoch keine Bewertungen

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDokument4 SeitenSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthNoch keine Bewertungen

- Material Safety Data Sheet: Natural GasDokument5 SeitenMaterial Safety Data Sheet: Natural Gasprasad5034Noch keine Bewertungen

- Safety Data Sheet: Texclad 2Dokument7 SeitenSafety Data Sheet: Texclad 2Om Prakash RajNoch keine Bewertungen

- Alvania EP GreaseDokument5 SeitenAlvania EP Greasemingyu parkNoch keine Bewertungen

- Hypogear 80W-90 - BP Australia Pty LTDDokument5 SeitenHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilNoch keine Bewertungen

- Material Safety Data Sheet - Docx AlerrrrDokument11 SeitenMaterial Safety Data Sheet - Docx AlerrrrELHaj Zouaimia زوايمية العربيNoch keine Bewertungen

- Sulfuric Acid, 52 - 100 %: 1. Product IdentificationDokument4 SeitenSulfuric Acid, 52 - 100 %: 1. Product IdentificationchapulincoloradoNoch keine Bewertungen

- Section I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000Dokument2 SeitenSection I: Material Safety Data Sheet Date of Preparation: 02/11/11 6010000sebaversaNoch keine Bewertungen

- SDS - Durosan - English (Uk) - DubaiDokument5 SeitenSDS - Durosan - English (Uk) - DubaiBalasubramanian AnanthNoch keine Bewertungen

- MsdsbiodieselDokument10 SeitenMsdsbiodieselHafid AlwanNoch keine Bewertungen

- Chevron Lubricant SDSDokument9 SeitenChevron Lubricant SDSSofels FemiNoch keine Bewertungen

- Safety Data Sheet: Texclad 2Dokument7 SeitenSafety Data Sheet: Texclad 2KuhnNoch keine Bewertungen

- White OilDokument6 SeitenWhite OilAxel Mahya AvichenaNoch keine Bewertungen

- MSDS Type II Nytro 11 GBX US Transformer Oil 11-08-10Dokument5 SeitenMSDS Type II Nytro 11 GBX US Transformer Oil 11-08-10Yovany Padilla50% (2)

- Anabond 202 MSDSDokument4 SeitenAnabond 202 MSDSPoovannan Prakash0% (1)

- After a Disaster: Information to Help You and Your Family RecoverVon EverandAfter a Disaster: Information to Help You and Your Family RecoverNoch keine Bewertungen

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEVon EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENoch keine Bewertungen

- 3.sistema de Control SobrellenadoDokument11 Seiten3.sistema de Control SobrellenadoCarlos SalazarNoch keine Bewertungen

- Tks de IndiaDokument5 SeitenTks de IndiaCarlos SalazarNoch keine Bewertungen

- 3.sistema de Control SobrellenadoDokument11 Seiten3.sistema de Control SobrellenadoCarlos SalazarNoch keine Bewertungen

- Tks de IndiaDokument5 SeitenTks de IndiaCarlos SalazarNoch keine Bewertungen

- P16 1174Dokument11 SeitenP16 1174Carlos SalazarNoch keine Bewertungen

- Text Summary ALOHA® 5.4.7Dokument1 SeiteText Summary ALOHA® 5.4.7Carlos SalazarNoch keine Bewertungen

- HeavyDokument6 SeitenHeavyCarlos SalazarNoch keine Bewertungen

- Combustion: Journal of Applied MechanicsDokument1 SeiteCombustion: Journal of Applied MechanicsCarlos SalazarNoch keine Bewertungen

- 20064317365672487Dokument8 Seiten20064317365672487Carlos SalazarNoch keine Bewertungen

- Transportation of Heavy and Extra-Heavy Crude Oil by Pipeline. A Review (2011)Dokument9 SeitenTransportation of Heavy and Extra-Heavy Crude Oil by Pipeline. A Review (2011)Samuel CarballoNoch keine Bewertungen

- Transportation of Heavy and Extra-Heavy Crude Oil by Pipeline. A Review (2011)Dokument9 SeitenTransportation of Heavy and Extra-Heavy Crude Oil by Pipeline. A Review (2011)Samuel CarballoNoch keine Bewertungen

- Storage Tanks: Fixed or Semi-Fixed SystemsDokument9 SeitenStorage Tanks: Fixed or Semi-Fixed SystemsCarlos SalazarNoch keine Bewertungen

- Separation Technologies in Oil and Gas Production: Sebastian Osvaldo Zuniga BenavidesDokument40 SeitenSeparation Technologies in Oil and Gas Production: Sebastian Osvaldo Zuniga BenavidesCarlos SalazarNoch keine Bewertungen

- Integrantes:: Field Ooip Mmbbls Eur Wells MmblsDokument3 SeitenIntegrantes:: Field Ooip Mmbbls Eur Wells MmblsCarlos SalazarNoch keine Bewertungen

- Heat Exchanger AnalysisDokument12 SeitenHeat Exchanger AnalysisPatil Hemant100% (1)

- Hoja de ReporteDokument2 SeitenHoja de ReporteCarlos SalazarNoch keine Bewertungen

- Development of A QRA Method To Calculate The Risks Generated by Liquefied Natural Gas (LNG) Filling Stations For Road TrucksDokument16 SeitenDevelopment of A QRA Method To Calculate The Risks Generated by Liquefied Natural Gas (LNG) Filling Stations For Road TrucksCarlos SalazarNoch keine Bewertungen

- FBOP 20121027 1920 Force On A BaffleDokument1 SeiteFBOP 20121027 1920 Force On A BaffleCarlos SalazarNoch keine Bewertungen

- Pump Basics. A Guide To Installation and SelectionDokument18 SeitenPump Basics. A Guide To Installation and SelectionArsalan QadirNoch keine Bewertungen

- CompensationDokument4 SeitenCompensationNeha GuptaNoch keine Bewertungen

- Pearl Continental Hotel Non Monetary Rewards To EmployeesDokument3 SeitenPearl Continental Hotel Non Monetary Rewards To EmployeesAhmed Habib MalikNoch keine Bewertungen

- LM A1.1Dokument17 SeitenLM A1.1Dat HoangNoch keine Bewertungen

- Induction and Orientation: Group MembersDokument16 SeitenInduction and Orientation: Group MembersK SrivarunNoch keine Bewertungen

- Chapter Five-Macroeconomic PolicyDokument24 SeitenChapter Five-Macroeconomic Policynotes.mcpuNoch keine Bewertungen

- Position Description FormDokument4 SeitenPosition Description FormRandomized Minds82% (11)

- Project AppraisalDokument14 SeitenProject AppraisalVamshi Krishna Mallela50% (2)

- Case 1Dokument8 SeitenCase 1Pratibha SeshamNoch keine Bewertungen

- TWP 93272105 IffcoTokioDokument2 SeitenTWP 93272105 IffcoTokioSudeep Kumar67% (3)

- PHS3013 Human Resource Information SystemsDokument8 SeitenPHS3013 Human Resource Information Systems树荫世界Noch keine Bewertungen

- Hawthrone Experiments in BriefDokument3 SeitenHawthrone Experiments in BriefDivya PrakashNoch keine Bewertungen

- Nike SweatshopsDokument5 SeitenNike SweatshopsMichelle I. Smith0% (1)

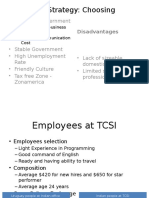

- Locational Strategy: Choosing Uruguay: - Access To GovernmentDokument3 SeitenLocational Strategy: Choosing Uruguay: - Access To GovernmentVasu GandhiNoch keine Bewertungen

- Project Management UK College AssignmentDokument21 SeitenProject Management UK College AssignmentAhnafTahmidNoch keine Bewertungen

- Group Dynamics and Work Teams 1.ppt 2018-19Dokument86 SeitenGroup Dynamics and Work Teams 1.ppt 2018-19Deeksha Singh100% (1)

- Operations Manager or Director of Operations or Warehouse ManageDokument3 SeitenOperations Manager or Director of Operations or Warehouse Manageapi-121367305Noch keine Bewertungen

- Reg Section 1.861-4Dokument13 SeitenReg Section 1.861-4EDC AdminNoch keine Bewertungen

- How To Write A CVDokument10 SeitenHow To Write A CVRainy DayNoch keine Bewertungen

- Factors Influencing Employee CommitmentDokument79 SeitenFactors Influencing Employee Commitmentkpdarshana100% (2)

- 2011 r083020t Toverengwa Chigweremba's Industrial Attachment ReportDokument93 Seiten2011 r083020t Toverengwa Chigweremba's Industrial Attachment ReportPaul Chibange69% (26)

- Maersk Vs RamosDokument3 SeitenMaersk Vs RamosSheryl Ogoc100% (1)

- Employee Expectations and Their Retention in The Hospitality Industry in BrasovDokument1 SeiteEmployee Expectations and Their Retention in The Hospitality Industry in BrasovAlex NicolaeNoch keine Bewertungen

- Revised Press Release - Mphasis Transfers Significant Portion of Its Domestic India Business To Hinduja Global Solutions (Company Update)Dokument1 SeiteRevised Press Release - Mphasis Transfers Significant Portion of Its Domestic India Business To Hinduja Global Solutions (Company Update)Shyam SunderNoch keine Bewertungen

- FlashcardsDokument5 SeitenFlashcardsNitin ParasNoch keine Bewertungen

- Employees' Provident Funds and Miscellaneous Provisions Act, 1952 (EPF&MP Act, 1952)Dokument17 SeitenEmployees' Provident Funds and Miscellaneous Provisions Act, 1952 (EPF&MP Act, 1952)bhargaviNoch keine Bewertungen

- The Key Challenges of Youth in EthiopiaDokument5 SeitenThe Key Challenges of Youth in EthiopiaPremier Publishers100% (2)