Beruflich Dokumente

Kultur Dokumente

Advantages TOFD - Phased Array

Hochgeladen von

MKAMRANBHATTIOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Advantages TOFD - Phased Array

Hochgeladen von

MKAMRANBHATTICopyright:

Verfügbare Formate

Advantages of TOFD & Phased Array

TOFD

Permanent data recording (life

Phased Array

Electronic scanning possible without moving probe forward and sideward Replaced multiple probes (only single probe use for various angle) electronic focusing allows the use of a single probe for working at different depths Comprehensive data collection with auditable, repeatable results. High-speed inspection using single-axis scans instead of conventional raster scan. Adaptable to complex configurations complex parts including thick components. Automated scanning processes ensure reliability and accuracy. Increased sensitivity to the detection of planar defects (as compared to radiography) Provides capability to size the depth (vertical component) of a defect. Better detection in austenitic materials and dissimilar metal (DM) welds Real-time data acquisition increases production times and reduces component downtime Does not require work stoppage as needed when performing radiography No hazards in signal transmission or instrument transportation as found with radiography. PA-AUT permits the use of Engineering Critical Assessment, which typically allows larger defects. Typical PAUT crews require fewer personnel than that of a radiography crew Reduced the cycle time between when a weld is complete and the disposition of the weld's acceptance PAUT technology is rapidly advancing every day, creating even more options for performance and accuracy.

Time) with B-scan type imaging (side view). Accurate sizing capability (height)-through-wall height most critical for fracture mechanics. Technique allows for rapid scanning.

2

Detection and sizing almost

orientation independent. TOFD has a potential throughwall dimension accuracy of 1 mm and monitoring capability of 0.3mm Setup virtually independent of weld configuration Wide coverage area No Area barrication requirement. Only Single side access required Can performed during service

Compliance with codes

ASME Boiler & Pressure Vessel Code, Section V, Article 4. ASME Boiler & Pressure Vessel Code, CASE 2235-9 ASME Code for Pressure Piping B31, Case 181.

Das könnte Ihnen auch gefallen

- Icp Fee Structure Initial Certification (Exam) API Member Non-MemberDokument1 SeiteIcp Fee Structure Initial Certification (Exam) API Member Non-MemberMKAMRANBHATTINoch keine Bewertungen

- API 936 General InformationDokument1 SeiteAPI 936 General InformationMKAMRANBHATTINoch keine Bewertungen

- Body of Knowledge For API 936 ExamDokument3 SeitenBody of Knowledge For API 936 ExamMKAMRANBHATTI67% (3)

- Scope of NDT in Aviation IndustryDokument3 SeitenScope of NDT in Aviation IndustryMKAMRANBHATTINoch keine Bewertungen

- ASME Sec IX - Questions For API ExamDokument21 SeitenASME Sec IX - Questions For API ExamMKAMRANBHATTI87% (31)

- Photo Detectors: Devices Used For The Detection of LightDokument12 SeitenPhoto Detectors: Devices Used For The Detection of LightMKAMRANBHATTINoch keine Bewertungen

- Acid Pickling of Steel PipesDokument134 SeitenAcid Pickling of Steel PipesMKAMRANBHATTINoch keine Bewertungen

- Reverse Engineering Project ReportDokument53 SeitenReverse Engineering Project ReportMKAMRANBHATTI100% (6)

- Shape Memory PolymersDokument24 SeitenShape Memory PolymersFarooq MuhammadNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Know The Escalation Matrix To ReportDokument1 SeiteKnow The Escalation Matrix To ReportHemal GandhiNoch keine Bewertungen

- Washing MachinesDokument6 SeitenWashing MachinesAnonymous wK36hLNoch keine Bewertungen

- KBC Nano in English PDFDokument57 SeitenKBC Nano in English PDFBHUKKAD BOX100% (1)

- PDF CatalogEngDokument24 SeitenPDF CatalogEngReal Gee MNoch keine Bewertungen

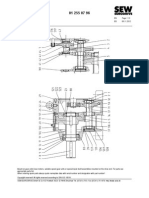

- Parts List 01 255 07 96: Helical Gear Unit R107Dokument3 SeitenParts List 01 255 07 96: Helical Gear Unit R107Parmasamy Subramani50% (2)

- Swifty Loudspeaker KitDokument5 SeitenSwifty Loudspeaker KitTNNoch keine Bewertungen

- Bangkok-Singapore CDM JournalDokument20 SeitenBangkok-Singapore CDM JournalvasidhartaNoch keine Bewertungen

- Atoll 3.3.2 Technical Reference Guide RadioDokument912 SeitenAtoll 3.3.2 Technical Reference Guide Radioratelekoms100% (4)

- VCEguide 300-360Dokument25 SeitenVCEguide 300-360olam batorNoch keine Bewertungen

- Lampiran BDokument3 SeitenLampiran BIqbhal WanaharaNoch keine Bewertungen

- CEN ISO TR 17844 (2004) (E) CodifiedDokument7 SeitenCEN ISO TR 17844 (2004) (E) CodifiedOerroc Oohay0% (1)

- 50 Practice Questions With Topics For IELTS Speaking Part 3Dokument5 Seiten50 Practice Questions With Topics For IELTS Speaking Part 3Adeel Raza SyedNoch keine Bewertungen

- Kota StationDokument5 SeitenKota StationshashankjeeNoch keine Bewertungen

- Walk inDokument1 SeiteWalk inCHATHURNoch keine Bewertungen

- Clearcase Branching and Labeling Best Practices For Parallel DevelopmentDokument50 SeitenClearcase Branching and Labeling Best Practices For Parallel DevelopmentakkachotuNoch keine Bewertungen

- Tds Cross 0325Dokument1 SeiteTds Cross 0325manox007Noch keine Bewertungen

- ILO - Working Conditions of Contract Workers in The Oil and Gas IndustriesDokument106 SeitenILO - Working Conditions of Contract Workers in The Oil and Gas IndustriesLuís Augusto Lopes100% (1)

- Colphenebswh 1816Dokument2 SeitenColphenebswh 1816vinoth kumar SanthanamNoch keine Bewertungen

- Bomba Submersa FE - Petro STPDokument6 SeitenBomba Submersa FE - Petro STProbsonlagambaNoch keine Bewertungen

- For Calibration List - OrginalDokument62 SeitenFor Calibration List - Orginaluttam khatriNoch keine Bewertungen

- Laboratorio de Microondas - Medicion en Lineas de TX Usando Lineas RanuradasDokument5 SeitenLaboratorio de Microondas - Medicion en Lineas de TX Usando Lineas RanuradasacajahuaringaNoch keine Bewertungen

- The GPSA 13th Edition Major ChangesDokument2 SeitenThe GPSA 13th Edition Major Changespatrickandreas77Noch keine Bewertungen

- Mca Voice Morphing ReportDokument4 SeitenMca Voice Morphing Reportmango sravanreddyNoch keine Bewertungen

- Loupe S Dental Brochure Sur 6351Dokument16 SeitenLoupe S Dental Brochure Sur 6351bernadinadwiNoch keine Bewertungen

- A30050-X6026-X-4-7618-rectifier GR60Dokument17 SeitenA30050-X6026-X-4-7618-rectifier GR60baothienbinhNoch keine Bewertungen

- Presentation 1Dokument12 SeitenPresentation 1Varun MaheshwariNoch keine Bewertungen

- Waterjet CutterDokument4 SeitenWaterjet CutterCarlos RamirezNoch keine Bewertungen

- FacebookDokument13 SeitenFacebookDivya SharmaNoch keine Bewertungen

- Experiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsDokument24 SeitenExperiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsVarun GargNoch keine Bewertungen