Beruflich Dokumente

Kultur Dokumente

ICLP 2006 Bridge-Corrected

Hochgeladen von

lau_hy2158Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ICLP 2006 Bridge-Corrected

Hochgeladen von

lau_hy2158Copyright:

Verfügbare Formate

1

Lightning protection of a cable-stayed bridge

A. Rousseau, SEFTIM1, L. Boutillon, VINCI Grands Projets2, A. Huynh, FREYSSINET3

Abstract-- On the 27th of January 2005 one of the longest stay cable bridges in the world has been struck by lightning leading to the failure of one stay cable. This event has been thoroughly studied in order first to explain the failure mechanism and then to find appropriate protection solutions. Many tests have been performed either on components or on the whole stay cable including metallurgical inspections, mechanical, high voltage and surge current tests. At the end of the investigation period the scenario of the failure has been established and enhancement of the existing lightning protection system has been defined and implemented.. Index Terms-- bridge, high voltage test, impulse current, lightning protection, stay cable, standards, tests.

I. INTRODUCTION On the 27 of January one of the longest stay cable bridges in the world has been impacted by a lightning strike which created a fire on one of the upper stay cables leading finally to the collapse of this stay cable. Stay cables are made of parallel monostrands consisting in hot dip galvanized prestressing strands, wax protected and coated by a high density polyethylene (HDPE) extruded layer, which are located inside a high density polyethylene duct. A witness has seen a horizontal strike around 10 oclock in the vicinity of the bridge. First structural consequence of the lightning strike has been recorded by the monitoring probes at 10:15. Stands failed under the conjugated effects of the heat and of the tension one after the other. At 11.22 the cable fell down on the deck. First measurement and calculation quickly shown that the bridge structure was not impacted and that the

th

bridge could be re-open to the traffic. Time necessary to remove the hanging stay cable and to make extended analysis lead to a full re-opening on the 1st of February. Fire location was near a metallic part named the cross tie provisional collar. Two of these collars are equally located on the top stay cables. They are provisional collars which had no use at this period but which could be used in future to upgrade the bridge dynamic behaviour .under wind effects. Normally such a structure like a stay cable is able to withstand by itself high lightning currents. As such it doesnt need any protection. Experience on a lot of bridges of the same type all over the world (more than 1 000 bridge.year) shows that lightning protection is not really needed. A few impacts may be found on the stay cable and and they never lead to failure of a monostrand. For this bridge the sole protection was made of equipotentiality along the deck and an ESE at the top of each pylon (there are 4 pylons) connected to 2 downconductors and to immersed earthing systems. ESE protection was clearly not able to protect the whole length of the 300 m long stay cables. Why, in that case, the lightning strike leaded to a failure of one complete stay cable when it has never been the case before for any other bridges of the same type in various areas in the world, even in more severe lightning area than Greece? II. INVESTIGATION TESTS To understand what was the failure mechanism and thus find appropriate solutions, following tests have been carried out : Mechanical tests on intact and damaged strands Metallurgical inspection of the damaged strands at the strike point Preliminary high voltage and lightning current tests on small scale stay cable samples High voltage lightning tests on a full scale stay cable sample High current lightning tests on a full scale stay cable sample

A. Rousseau SEFTIM 49 rue de la bienfaisance 94300 Vincennes France E-mail: alain.rousseau@seftim.fr

L. Boutillon VINCI Construction Grands Projets 5 cours Ferdinand de lesseps 92851 Rueil malmaison cedex France E-mail: lboutillon@vinciconstruction.com

A. Huynh FREYSSINET 1 bis rue du Petit Clamart 78140 Velizy France E-mail: ahuynh@freyssinet.com

A. Mechanical tests. Six samples taken from the damaged stay cable were sent to Freyssinet test centre in France. Tensile tests with stay cable jaws have been performed on all samples. Elongation at maximum load is greater than 2. Strands which have been exposed to the fire show a slight reduction in ductility and tensile resistance but remains within the tolerances of the specification. B. Metallurgical analysis. All samples found with lightning marks have been sent for expertise to a technical centre in France called CETIM (CEntre Technique des Industries Mcaniques). There were ten samples with one melting mark, and one with two marks. Three samples have been selected and submitted to a detailed inspection. All damages were visually similar. The purpose of the inspection is to quantify the metallurgical modifications induced by the lightning strike. We used the following methodology : Analysis of the morphology of the damages by means of a MEB microscope providing pictures and macrographies (see Fig. 1). Chemical composition analysis of the metal at the damage by means of a micro-spectrometer Metallurgical analysis of the damages by micrographies, in order to any identify microstructural alterations Micro-hardness tests of the steel wire trough the damage to detect micro-structural alterations

100 kV. Tests ware also performed at 100 kA 10/350 as per IEC 62305-1 and with a longer waveshape 50 kA 10/500. Only the longer waveshape tests on a sample combining strands and HPE duct have been able to generate few flames but no longer than 4 seconds before they self-extinguish. The flame clearly resulted from the combustion of the vaporized plastic produced by hot liquid metal which was sprayed on the outer plastic duct. These preliminary tests gave interesting ideas for future test program. D. High voltage lightning tests. High voltage tests have been performed on a 8 m top stay cable in order to determine the most probable attachment location as well as possible protection means. Tests have been performed on a standard stay, on a stay equipped with the provisional cross tie collar and with a stay fitted with a protective stretch wire. Tests have been performed at CEAT in France due to the high voltage and large dimensions required for these tests. CEAT is used to performed tests on aircrafts. The top electrode is a plate 10x5 m located above the tested samples. Competition tests have been performed in different configurations. When fitted with a stretch grounded wire located 20 cm above the stay cable the attachment point was the stretch wire but when there was no such stretch wire the preferred attachment point was the metallic collar even during tests where the neighbouring stay cable was replaced by a larger metal tube connected to earth. Other tests were performed to establish the sparkover voltage of the complete assembly. Test configuration limitation proved only that the sparkover voltage was greater than 600 kV and in fact calculation shown that it should be around 900 kV. E. High current lightning tests. As it was clear from preliminary tests that long duration current tests was the key parameter to reproduce the fire ignition, we decided to perform extended tests at DEHN laboratory in Germany due to their high capability of 700 C. Tests samples were 3 m long for most of the tests and when the mechanism was well know we used 1 m long, such samples being more practical. A copper fuse wire is used to initiate the arc.

Fig. 1. Detail of the porous area made of zinc located at the observed marks. Grey zone at the top is made of steel (no alteration).

Inspections and tests enabled to conclude that the direct damages induced by the lightning strike were limited to the zinc layer (melting) without affecting the steel of the wires. In complement, failure areas of the strands were inspected: no brittle failure, only a ductile morphology showing that the wires tensile strengths were exceeded. C. Preliminary lightning tests. Tests have been performed on reduced size samples at the ELEMKO lightning laboratory in Greece in order to try understanding the possible effects of lightning. High voltage tests have shown that the breakdown voltage of each of the strand being part of the stay cable was

Fig. 2. Fuse wire connected to one of the strand inside the duct

First tests have been performed with the copper wire directly in contact with the strands outside of the duct. After a few seconds the fire stops even for charges as big as 680 C !

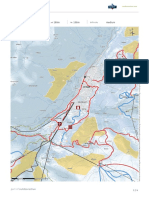

electrical charge transferred were such that a small fire was ignited at the edge of the hole in the HDPE duct. Despite the wind and the probable rain, the combustion did not stop. Once the fire of the duct was strong enough to burn by itself, the heat was transmitted to the steel strands. Consequently the lightning protection enhancement will focus on : Use fire retardant material in the vicinity of the collar to modify the local conditions and to prevent the fire from starting Reduce the number of potential flashes to the top stay cables by installing stretch wires above them. Try avoiding collars to be preferential impact points In addition, enhance lightning protection of the pylon to be compliant with new IEC 62305-3 standard. IV. LIGHTNING PROTECTION ENHANCEMENT The lightning capture area for the whole bridge has been determined in accordance with IEC 62305-2 and is equal to 2.1 km, see Figure 5. As this part of Greece as a keraunic level around 30, the expected number of lightning flashes is around 6,3 per year. The expected number of flashes to the stay cables has been estimated in the same way to be 4 per year. Surges counters installed on the down-conductor suggest that at least 21 lightning strikes hit the pylons from August 2004 to June 2005.

Fig. 3. Tests performed on the free length.

Then we performed tests on a complete assembly reproducing the top stay cable. Tests performed over the free length confirmed the expected high fire resistance. Even tests made of combination between high impulse current (up to 50 kA) as per IEC 62305-11 and long duration (up to 680 C) lead to stop of fire after 5 s. Tests in vicinity of the collar leaded to results similar to those obtained during the flame tests. It was needed to have both a 500 C current and a 10 mm diameter hole to generate a small fire which did not self-extinguish and that we had to stop manually.

Fig. 5. Calculated capture area.

Fig. 4. Tests performed near the collar.

III. POSSIBLE SCENARIO BASED

ON INVESTIGATION TESTS

The upper stay cable has been struck very likely by a lightning flash nearby its upper collar, on the upper side, which was an attracting point. The flash was powerful enough to punch the HDPE outer duct of the stay cable creating a hole larger than 10 mm in diameter. It has then impacted the strands in at least eleven locations, generating a superficial melting of the wires zinc layers. The conditions near the collar and the

This is 3 times bigger than what we could be expected from the keraunic data. New surge counters measuring current, charge and having time stamp will be fitted to better determine in future what is the exact number of lightning flashes to the pylons. Whatever is the real number of impact on this site, it was decided to enhance the lightning protection and especially to avoid too many flashes to strike the provisional cross tie collars. To achieve this it has been decided : To install stretch wires above the stay cables to intercept most of the lightning flashes To implement lightning protection complying in full with new standard 62305-3 (it was still a draft at this time) on pylons

Fig. 7. Stretch wire and stay cables

Fig. 6. Enhance pylon protection

A. Pylon protection enhancement As it was likely that corner and edge of the top part of the pylon be the preferential attachment point, a ring conductor with 4 rods at each corner have been installed. Two additional down-conductors have been also implemented to make a mesh as well as 3 more ring electrodes evenly spaced from top of the pylon to the bottom of the metallic stay cable anchorage box. Another ring conductor has been installed at sea level to share the current between 4 earthing systems. Equipotential bonding of pylon metallic part has also been provided (see Fig. 6). B. Stay cable protection Stainless steel high strength strands have been used to build a stretch wire above the top stay cables, connected to the pylon mast upper ring conductors. The stretch wire is running parallel to the upper stay cable and is connected at mid-span to a central piece which is attached by hangers to the deck The tension in the stretch wire is close to the tension in the stay cable strand so as to have similar deflections in order to ensure a minimum distance between stretch wires and stay cables. Safety distance has been calculated so that even in case of strong wind and lightning occurring at the same time the distance between the stretch wire and the upper stay cable always remain above the spark over voltage. At last redundancy ensures that no stretch wires can fall on the deck even in case of exceptional strike.

V. CONCLUSION Thorough study of the 27th of January 2005 event has been made over almost one year. Long experience of stay cable bridges over the world even in more severe areas than Greece demonstrates what we can naturally feel. Such a big mass of steel cannot be seriously impacted by a lightning strike. Normally no specific protection is provided on the stay cables and only pylons are protected. It appears that no lightning impulse current has been able in laboratory to generate a fire. Situation was surely more critical on the bridge as wind and rain were present. Only a quite large long duration current has been able to create such circumstances in laboratory and only in a very specific configuration. The study performed has been able to propose and validate a likely scenario. In spite of the extremely low probability of such an event it has been decided to enhance the existing bridge lightning protection, consisting in reducing the number of direct strikes on the stay cables by means of stretch wires and in preventing the fire to start by neutralizing the local conditions near the provisional cross tie collar. VI. REFERENCES IEC 62305-1, Protection against lightning part 1 general principles, January 2006.

Das könnte Ihnen auch gefallen

- Rundweg Zermatt: 6.5km 2:00h 198m 198m MediumDokument4 SeitenRundweg Zermatt: 6.5km 2:00h 198m 198m Mediumlau_hy2158Noch keine Bewertungen

- Glacier Region WalksDokument29 SeitenGlacier Region Walkslau_hy2158Noch keine Bewertungen

- General Specification: 2017 EDITION (Incorporating Corrigendum No. Gsee01-2017)Dokument419 SeitenGeneral Specification: 2017 EDITION (Incorporating Corrigendum No. Gsee01-2017)lau_hy2158Noch keine Bewertungen

- Guidance Notes For: The Safe Isolation of Electricity Source at WorkDokument16 SeitenGuidance Notes For: The Safe Isolation of Electricity Source at Worklau_hy2158Noch keine Bewertungen

- LE501 Service ManualDokument73 SeitenLE501 Service Manuallau_hy2158100% (1)

- ABB Ring Main Unit For The Secondary Distribution NetworkDokument80 SeitenABB Ring Main Unit For The Secondary Distribution NetworkVIJAY MOHAN DAVE67% (3)

- Abb Manual On MV Switch GearDokument60 SeitenAbb Manual On MV Switch GearUrooj RizviNoch keine Bewertungen

- 24 NewDevelopmentsinCableStayVibrationSuppressionDokument69 Seiten24 NewDevelopmentsinCableStayVibrationSuppressionlau_hy2158Noch keine Bewertungen

- AbbrDokument40 SeitenAbbrlau_hy2158Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Centrifugal Pumps: Turbo Machines Amit Pathania Roll No:09309 Mechanical EngineeringDokument4 SeitenCentrifugal Pumps: Turbo Machines Amit Pathania Roll No:09309 Mechanical EngineeringAmit PathaniaNoch keine Bewertungen

- Bosch KE-Jetronic System DescriptionDokument3 SeitenBosch KE-Jetronic System DescriptionJack Tang50% (2)

- Dissertation MA History PeterRyanDokument52 SeitenDissertation MA History PeterRyaneNoch keine Bewertungen

- Most Dangerous City - Mainstreet/Postmedia PollDokument35 SeitenMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartNoch keine Bewertungen

- En 1993 09Dokument160 SeitenEn 1993 09Vio ChiNoch keine Bewertungen

- Formulae HandbookDokument60 SeitenFormulae Handbookmgvpalma100% (1)

- Use The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficeDokument5 SeitenUse The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficedakingNoch keine Bewertungen

- Tecsun Pl310et PDFDokument30 SeitenTecsun Pl310et PDFAxel BodemannNoch keine Bewertungen

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDokument2 Seiten22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnNoch keine Bewertungen

- Hydrology Report at CH-9+491Dokument3 SeitenHydrology Report at CH-9+491juliyet strucNoch keine Bewertungen

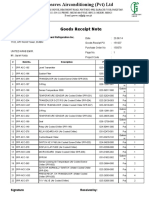

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDokument4 SeitenGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNoch keine Bewertungen

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersDokument8 SeitenDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloNoch keine Bewertungen

- CUIT 201 Assignment3 March2023Dokument2 SeitenCUIT 201 Assignment3 March2023crybert zinyamaNoch keine Bewertungen

- Norberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishDokument14 SeitenNorberto Elias: Graduation of Teach Portuguese Language With Ability in EnglishGildo Joaquim FranciscoNoch keine Bewertungen

- Ib Psychology - Perfect Saq Examination Answers PDFDokument2 SeitenIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- Aectp 300 3Dokument284 SeitenAectp 300 3AlexNoch keine Bewertungen

- Analysis Chart - Julie Taymor-ArticleDokument3 SeitenAnalysis Chart - Julie Taymor-ArticlePATRICIO PALENCIANoch keine Bewertungen

- Slide 7 PV NewDokument74 SeitenSlide 7 PV NewPriyanshu AgrawalNoch keine Bewertungen

- JCPS School Safety PlanDokument14 SeitenJCPS School Safety PlanDebbie HarbsmeierNoch keine Bewertungen

- IU IIDC Time Management and Organizational SkillsDokument40 SeitenIU IIDC Time Management and Organizational SkillsAsger HamzaNoch keine Bewertungen

- WT Capability Statement PE 2020Dokument1 SeiteWT Capability Statement PE 2020Muhannad SuliemanNoch keine Bewertungen

- How To Install 64 Bits IDES On 32 Bits OSDokument1 SeiteHow To Install 64 Bits IDES On 32 Bits OSMuhammad JaveedNoch keine Bewertungen

- Unit 3Dokument5 SeitenUnit 3Narasimman DonNoch keine Bewertungen

- Namagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishDokument10 SeitenNamagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishMonydit santinoNoch keine Bewertungen

- SDOF SystemsDokument87 SeitenSDOF SystemsAhmet TükenNoch keine Bewertungen

- Electro TechniquesDokument2 SeitenElectro TechniquesPinkk DaisyfieldNoch keine Bewertungen

- Angle ModulationDokument26 SeitenAngle ModulationAtish RanjanNoch keine Bewertungen

- Concept of Lokmitra Kendra in Himachal PradeshDokument2 SeitenConcept of Lokmitra Kendra in Himachal PradeshSureshSharmaNoch keine Bewertungen

- Make Yeast StarterDokument2 SeitenMake Yeast StarterAlexandraNoch keine Bewertungen

- CE-23113-SP-902-R01-00 Asset SpecificationDokument14 SeitenCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберNoch keine Bewertungen