Beruflich Dokumente

Kultur Dokumente

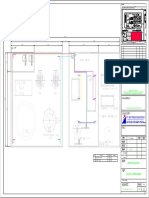

Drawings - Kappa 400kV Tubular Busbar Layout Signed

Hochgeladen von

nunoandreOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Drawings - Kappa 400kV Tubular Busbar Layout Signed

Hochgeladen von

nunoandreCopyright:

Verfügbare Formate

1

10

11

12

13

14

15

16

17

18

19

20

21

22

SCHEDULE OF TUBULAR BUSBAR CLAMPS

YA

A

20000 20000 20000 20000 20000 20000 20000 20000

MK

DESCRIPTION {250 TO {250 TUBE FULL IN-LINE

TYPE

QTY

A

TBFX-250/225/FS 57

1 EXPANSION CLAMP FIXED/SLIDER 225mm PCD DAMPING CONDUCTOR SCHEDULE {250 TO {250 TUBE SLIDING COUPLER SUPPORT 2 CLAMP FIXED/SLIDER 225mm PCD QUANTITY VIBRATION DAMPER /

2

DIAMETER GA

DIAMETER GB

DIAMETER GC

(SEE DETAIL "A")

FEEDER 4

TBSC-250/225 WT

42

FEEDER 3

FEEDER 2

FEEDER 1

SUPPORT

SUPPORT

SUPPORT

SUPPORT

SUPPORT

SUPPORT

SUPPORT

SUPPORT

SUPPORT

DESCRIPTION

P.I. &

P.I. &

P.I. &

P.I. &

P.I. &

P.I. &

P.I. &

P.I. &

P.I. &

CENTIPEDE (400mm)

3 2200m

CONDUCTOR FIXING END CAP {250 OD x {238 ID

TBEC/C-250

150

4

5500 5500

CORONA FREE END CAP

TBEC/CR-250

RED WHITE BLUE

16 16 16

B

48

C L

C L

C L

C L

C L

C L

C L

C L

C L

C L

C L

C L

C L

C L

C L

C L

5 C L BUSBAR 1 7 400kV

PLAIN END CAP {250 OD x {238 ID

TBEC/P-250

POST INSULATOR (10kN) C10 - 25mm/kV DAMPING CONDUCTOR COMPRESSION SLEEVE

99

B 8 (FERRULE) 50mm LONG 150

C

26500 37500

SCHEDULE OF {250 x 6WT BUSBAR TUBES

5500 5500

ITEM No C L CONNECTOR 1 1 400kV

LENGTH (mm)

QUANTITY

REMARKS

D

TO BE CUT INTO 6 x 300mm LENGTHS FOR 2000 1 USE AT BUSBAR ENDS, SEE DET B 2 20000 39 SEE NOTES 2 & 3

3

40000 29000

20250

18

SEE NOTES 2 & 4

23100

12

SEE NOTES 2 & 4

E

5 23350 7 SEE NOTES 2 & 4 (1 SPARE TUBE)

5500 5500

400kV C L CONNECTOR 2

NOTES: 1. ALL TUBES 250 DIA x 6 WT ALUMINIUM AS PER SPECIFICATIONS. 2. TUBE LENGTHS GIVEN ARE NOMINAL BEFORE TRIMMING TO FINAL MEASURED REQUIREMENTS AND THE ITEM NUMBERS CORRESPOND TO THOSE ITEMS OF TUBE LISTED IN SCHEDULES A, B & C OF SPECIFICATION FOR SUPPLY & INSTALLATION

32000

400kV YARD

OF TUBULAR Al CONDUCTORS. 3. TUBES TO BE TRIMMED TO ALLOW FOR A SYMMETRICAL GAP OF 100mm ON THE CLAMP TYPE: TBFX-250/225/FS. 4. TUBE ITEMS 3, 4 & 5 NEED NOT BE TRIMMED EXCEPT TO EQUALISE THE LENGTH PER SET OF 3

SOL

26500

5500 5500

X1

STATION SOL

400kV C L BUSBAR 2

5500

5. MAXIMUM ALLOWABLE FAULT LEVEL OF 50kA FOR CURRENT BUSBAR DESIGN

PLAN

H

YB

50 20250 250 ITEM 3 50 20000 ITEM 2 50 50 20000 ITEM 2 50 50 20000 ITEM 2 50 50 20000 ITEM 2 50 50 20000 ITEM 2 50 50 20000 ITEM 2

C L

2

BUSBAR C L

12540

CLAMP MK 50 ITEM 1

1 3 3

F

1 3

S

1 3 3

F

1 3

S

1 3 3

F

1 3

S

1 3 3

F

50

4

TBSC-200/225 (Mc WADE)

3

F S

3

F

3

F

4

S

BUSBAR C L

12540

ITEM 2 OR 4

300

J

5

TBEC/CR-200 (Mc WADE)

DETAIL C

DETAIL B

ELEVATION 400kV BUSBAR 1

(24) TBEC-C-200-188

FLAT END CAP

FLAT END CAP WITH CONDUCTOR FIXING CLAMP 23350 50 50 50 50

(23) TBEC/P-200-188

CORONA FREE END CAP

20250 250 250 ITEM 3

23100 ITEM 4 3100 250

20250 ITEM 3

23100 ITEM 4 3100

POST INSULATOR

3100

ITEM 5

TACKWELD IN THREE PLACES DETAIL "B" (N.T.S)

3

BUSBAR C L

12540

2 3

2 4

TBSC-200/225 (Mc WADE)

2 3

TBSC-200/225 (Mc WADE)

1 4 3

F

2 3

TBSC-200/225 (Mc WADE)

3 3 4

2 4

TBSC-200/225 (Mc WADE)

1 3

F

2 3

TBSC-200/225 (Mc WADE)

3 4

BUSBAR C L

12540

TBSC-200/225 (Mc WADE)

F/S

DETAIL C DIA. GA

DETAIL C DIA. GB CONN 1

DETAIL C DIA. GC CONN 1

DETAIL C

ELEVATION 400kV CONNECTORS 1

C L

CLAMP MK 2

CONN 1

L

CORONA FREE END CAP

250/3100 23350 3100 ITEM 5 250 3100 ITEM 4 ITEM 3 23100 50 50 20250 250 3100 ITEM 4 ITEM 3 23100 50 50 20250 250 4 ITEM 3, 4 OR 5

TBEC/CR-200 (Mc WADE)

(24) TBEC-C-200-188

3

BUSBAR C L

12540

2 3

2 4

TBSC-200/225 (Mc WADE)

3 4

2 3

TBSC-200/225 (Mc WADE)

1 3

F S

2 3

TBSC-200/225 (Mc WADE)

3 4 4

2 3

TBSC-200/225 (Mc WADE)

1 3

F S

2 3

TBSC-200/225 (Mc WADE)

BUSBAR C L

12540

TBSC-200/225 (Mc WADE)

3 POST INSULATOR

TBSC-200/225 (Mc WADE)

FLAT END CAP WITH CONDUCTOR FIXING CLAMP

DETAIL C DIA. GA CONN 2 50 20250 250 ITEM 3 50 20000 ITEM 2 50 50 20000 ITEM 2 50 50

DETAIL C DIA. GB CONN 2 50 20000 ITEM 2 50 20000 ITEM 2 50 50

DETAIL C DIA. GC CONN 2 50 20000 ITEM 2 50 20000 ITEM 2 50 50 20000 ITEM 2

DETAIL C

ELEVATION 400kV CONNECTORS 2

DETAIL "C" (N.T.S)

TACKWELD IN THREE PLACES

N

2

BUSBAR C L

12540

N

1 3

TBSC-200/225 (Mc WADE)

1 3

S

1 3 3

F

1 3

S

1 3 3

F

1 3

S

1 3 3

F

1 3

S

3

F

3

F S

3

F

3

F

3

F

4

S

BUSBAR C L

12540

ELEVATION 400kV BUSBAR 2

P

DETAIL C

TYPICAL DETAIL A

DETAIL B

2488 2487 2486

OPERATING DIAGRAM EARTHWIRE BAY SCHEDULES FENCE LAYOUT STEELWORK

KEYPLAN STATION ELECTRIC

L =

20000 TO 23300 (NOM)

2485 2484

Q

END CAP WITH CONDUCTOR FIXING CLAMP

3

(24) TBEC-C-200-188 = C17443

2/3 L DAMPING CONDUCTOR

2489

3

(24) TBEC-C-200-188 = C17443

COMPRESSION TUBE/FERRULE

END CAP WITH CONDUCTOR FIXING CLAMP

0

REV

FIRST ISSUE

REVISION DESCRIPTION

2482

BY

CHKD

AUTH

DATE

0.68/ REFERENCE DRAWINGS

APPROVED BY

ESKOM HOLDINGS LIMITED REG NO. 2002/015527/06

A.AMOD

TACKWELD IN THREE PLACES

400mm AL CONDUCTOR ({26,5 CENTIPEDE)

DETAIL "A" (N.T.S.)

TACKWELD IN THREE PLACES COMPRESSION TUBE/FERRULE

DATE:

28/07/2011

CHECKED BY

M.PEFFER

8

R

DATE: 28/07/2011

KAPPA

400kV YARD TUBULAR BUSBAR LAYOUT

c

SHEET NUMBER REVISION

DAMPING CONDUCTOR REQUIREMENT

DRAWN BY

N.HARILAL

DATE:

28/07/2011

SCALE 1:500

0.68/2490

21

0

22

0

SIZE GROOTTE

10

11

12

13

14

15

16

17

18

19

20

A0L

Das könnte Ihnen auch gefallen

- 1532 Base PlanDokument1 Seite1532 Base PlanAnonymous qEPNPwA0% (1)

- Structural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkDokument1 SeiteStructural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkOladunni AfolabiNoch keine Bewertungen

- DWG Cable Trench - 850x800Dokument1 SeiteDWG Cable Trench - 850x800Anshuman PandeyNoch keine Bewertungen

- Cable Tray Selection GuideDokument18 SeitenCable Tray Selection Guidestuart3962Noch keine Bewertungen

- Brochure High MastDokument72 SeitenBrochure High MastSenoPati KudusNoch keine Bewertungen

- Automatic Power Factor Controller Relay: Operating InstructionsDokument7 SeitenAutomatic Power Factor Controller Relay: Operating InstructionsKatty MenaNoch keine Bewertungen

- Transmission Towers BrochureDokument24 SeitenTransmission Towers BrochureGhhNoch keine Bewertungen

- Tower ParticularsDokument20 SeitenTower ParticularsStephen BridgesNoch keine Bewertungen

- Price List DT 10.09.20 PDFDokument48 SeitenPrice List DT 10.09.20 PDFIshan Goel100% (1)

- Approved+vendors +upto+01.07.2019Dokument36 SeitenApproved+vendors +upto+01.07.2019Kapil VatsNoch keine Bewertungen

- Guarantee Technical ParametersDokument3 SeitenGuarantee Technical ParametersDramebaaz SandeepNoch keine Bewertungen

- Minimum Electrical Clearance. Electrical Notes & ArticalsDokument8 SeitenMinimum Electrical Clearance. Electrical Notes & ArticalsJoenathan EbenezerNoch keine Bewertungen

- 1 General Electrical Layout DRG of KRCD SSP 21.7.2022Dokument1 Seite1 General Electrical Layout DRG of KRCD SSP 21.7.2022abdul rubNoch keine Bewertungen

- General notes and details for substation constructionDokument1 SeiteGeneral notes and details for substation constructionA.K.M Shafiq MondolNoch keine Bewertungen

- Highlighted Points For Is 1180 (Part 1) : 2014Dokument6 SeitenHighlighted Points For Is 1180 (Part 1) : 2014Awnish Kumar100% (1)

- PGCIL Make List For 420kV For Power Transformer AccessoriesDokument8 SeitenPGCIL Make List For 420kV For Power Transformer AccessoriesParths ShahNoch keine Bewertungen

- Updated Details of Transformers 02.05.18Dokument28 SeitenUpdated Details of Transformers 02.05.18Chief Engineer TransOMNoch keine Bewertungen

- Plan Sump and Pump HouseDokument1 SeitePlan Sump and Pump Housevenkatesh19701Noch keine Bewertungen

- TBG DBase LOT 2 (UKD)Dokument21 SeitenTBG DBase LOT 2 (UKD)Rizki AryaNoch keine Bewertungen

- Government of India Ministry of RailwaysDokument56 SeitenGovernment of India Ministry of RailwaysSalim KhanNoch keine Bewertungen

- Power Transmission Companies - IndiaDokument2 SeitenPower Transmission Companies - IndiaAkash TyagiNoch keine Bewertungen

- Energy Efficient MotorsDokument6 SeitenEnergy Efficient MotorsRoumya Darshan RayNoch keine Bewertungen

- LED Product Explorer 2018 highlights Crompton's commercial lighting solutionsDokument52 SeitenLED Product Explorer 2018 highlights Crompton's commercial lighting solutionswritetorahulsinha9028Noch keine Bewertungen

- Material Inspection SummaryDokument34 SeitenMaterial Inspection SummarySUDDHA CHAKRABARTYNoch keine Bewertungen

- Empanelment of Vendors For Major Electrical Items in DMRC PDFDokument17 SeitenEmpanelment of Vendors For Major Electrical Items in DMRC PDFSatish KumarNoch keine Bewertungen

- List of Standard (Electrical)Dokument5 SeitenList of Standard (Electrical)Gaurav KumarNoch keine Bewertungen

- cb12 07-15-05 V8Dokument1 Seitecb12 07-15-05 V8Katracho2Noch keine Bewertungen

- Hanwha 115kv Transmission Line Conceptual Design-Template No.1Dokument15 SeitenHanwha 115kv Transmission Line Conceptual Design-Template No.1JojolasNoch keine Bewertungen

- Final DG Set 1500KVA X 2 Set 24062022Dokument4 SeitenFinal DG Set 1500KVA X 2 Set 24062022vishu talapeNoch keine Bewertungen

- Prestressed Concrete Poles - State-of-the-Art PDFDokument52 SeitenPrestressed Concrete Poles - State-of-the-Art PDFEduardo QuintanaNoch keine Bewertungen

- Best Solar Mounting Structure ManufacturersDokument6 SeitenBest Solar Mounting Structure Manufacturerssolar mountNoch keine Bewertungen

- 1-Calculate Overhead Line Conductor Resistance Per Unitlength by ASTM StandardDokument9 Seiten1-Calculate Overhead Line Conductor Resistance Per Unitlength by ASTM StandardRatana Kem100% (1)

- GTP of Jointing KitsDokument2 SeitenGTP of Jointing KitsAshutosh Soral100% (1)

- Technical Specification: Odisha Power Transmission Corporation LimitedDokument55 SeitenTechnical Specification: Odisha Power Transmission Corporation LimitedPritam SinghNoch keine Bewertungen

- MSEDCL-Vender Approval PDFDokument11 SeitenMSEDCL-Vender Approval PDFKuldeep KumarNoch keine Bewertungen

- 33s Monopole StaadDokument10 Seiten33s Monopole StaadMd MohsinNoch keine Bewertungen

- 100 KVA Substation OfferDokument7 Seiten100 KVA Substation Offeraftiaee maNoch keine Bewertungen

- CIVIL Drawings: 220/66kV ITI S/s Drawings Required Very Urgent Submissi On Date Engg Remarks Action byDokument6 SeitenCIVIL Drawings: 220/66kV ITI S/s Drawings Required Very Urgent Submissi On Date Engg Remarks Action byUmamaheshwarrao VarmaNoch keine Bewertungen

- Amended Annexure - I: Ref:Mempl/Wo/Kptcl-Thabakadahonnalli/Benakatti/2021-22/071A Dated: 05.12.2021Dokument19 SeitenAmended Annexure - I: Ref:Mempl/Wo/Kptcl-Thabakadahonnalli/Benakatti/2021-22/071A Dated: 05.12.2021PRADEEP basannavarNoch keine Bewertungen

- Arvensis Profile-PDokument17 SeitenArvensis Profile-PSourav BhattacharyaNoch keine Bewertungen

- Circular MSC Implementation of Is 1180 in All Schemes04072016Dokument10 SeitenCircular MSC Implementation of Is 1180 in All Schemes04072016Anonymous MDkp0hnb3lNoch keine Bewertungen

- Compet DDokument63 SeitenCompet Dvasudeva yasasNoch keine Bewertungen

- PLTD Cpo 2X2,8Mw Belitung: Maintenance, Engineering & ContractorDokument6 SeitenPLTD Cpo 2X2,8Mw Belitung: Maintenance, Engineering & ContractoranoNoch keine Bewertungen

- Design Calculation of Oc+15 MTR TowerDokument14 SeitenDesign Calculation of Oc+15 MTR TowerGuru MishraNoch keine Bewertungen

- Is 802 1977 PDFDokument21 SeitenIs 802 1977 PDFBhavin Shah0% (1)

- BOQ Jabalpur - 6 LotDokument15 SeitenBOQ Jabalpur - 6 Lotvipinkr_2000Noch keine Bewertungen

- Naogaon 230/132 KV GIS SubstationDokument2 SeitenNaogaon 230/132 KV GIS SubstationWahid wrbelNoch keine Bewertungen

- Cable Gland & Cleat Selection ChartDokument1 SeiteCable Gland & Cleat Selection ChartMohamed AdelNoch keine Bewertungen

- Stelmec VCBDokument2 SeitenStelmec VCBnithinmundackal3623Noch keine Bewertungen

- Experience CertificateDokument1 SeiteExperience CertificatepalanipaaaaNoch keine Bewertungen

- OHM Energy BrochureDokument24 SeitenOHM Energy BrochureNatarajan Nathan100% (1)

- ABB Limited: LV Motors FRSM-57C Effective From 01.10.2012 Price ListDokument5 SeitenABB Limited: LV Motors FRSM-57C Effective From 01.10.2012 Price ListSudipto MajumderNoch keine Bewertungen

- D-4 Design of Module Mounting Structure & Civil Works: Technical SpecificationsDokument4 SeitenD-4 Design of Module Mounting Structure & Civil Works: Technical SpecificationsAshish VajirNoch keine Bewertungen

- XLPE Cables ABB Guide LineDokument28 SeitenXLPE Cables ABB Guide LineCarlos FernandezNoch keine Bewertungen

- HT Cable ScheduleDokument2 SeitenHT Cable ScheduletceterexNoch keine Bewertungen

- Recommended Vendor List - Electrical: Slno Product ManufacturerDokument2 SeitenRecommended Vendor List - Electrical: Slno Product ManufacturerAbdul Muqeem MohammedNoch keine Bewertungen

- Crest SLDDokument1 SeiteCrest SLDSECI 2020Noch keine Bewertungen

- 11kv 200a Ab Switch PDFDokument2 Seiten11kv 200a Ab Switch PDFhimanshuNoch keine Bewertungen

- E3 Catalog PDFDokument54 SeitenE3 Catalog PDFmjellis68Noch keine Bewertungen

- 33 KV Gis CBDokument12 Seiten33 KV Gis CBanurag_jay12464Noch keine Bewertungen

- Introduction To MOS TechnologiesDokument15 SeitenIntroduction To MOS TechnologieslokeshwarrvrjcNoch keine Bewertungen

- How electric motors workDokument25 SeitenHow electric motors workGular JabrayilovaNoch keine Bewertungen

- Low-Cost 270 MHZ Differential Receiver Amplifiers: S at G 1 S at G 10Dokument28 SeitenLow-Cost 270 MHZ Differential Receiver Amplifiers: S at G 1 S at G 10flo72afNoch keine Bewertungen

- Analysis of Via To Via Crosstalk For Single Ended Signals in The Time & Frequency Domains PDFDokument24 SeitenAnalysis of Via To Via Crosstalk For Single Ended Signals in The Time & Frequency Domains PDFAnh Viet NguyenNoch keine Bewertungen

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) CommunicationsDokument120 SeitenSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) CommunicationsKeilaeFrancisco ArceNoch keine Bewertungen

- Setup report for SolarEdge Venus-III power board assemblyDokument29 SeitenSetup report for SolarEdge Venus-III power board assemblyMiriam JonesNoch keine Bewertungen

- Mitsubishi Electrique SPLIT-TYPE AIR CONDITIONERS Servoce ManualDokument48 SeitenMitsubishi Electrique SPLIT-TYPE AIR CONDITIONERS Servoce ManualEtienne GuinardNoch keine Bewertungen

- SPC4 SP 410 Uls 20180810Dokument4 SeitenSPC4 SP 410 Uls 20180810A3K InversionesNoch keine Bewertungen

- A MPPT With Sliding Mode Control For PV System: AuthorDokument8 SeitenA MPPT With Sliding Mode Control For PV System: AuthorAkbar aliNoch keine Bewertungen

- GaN HEMTDokument19 SeitenGaN HEMTMegat Muhammad IkhsanNoch keine Bewertungen

- Rudder Angle Instruction ManualDokument37 SeitenRudder Angle Instruction ManualtosveNoch keine Bewertungen

- Protection Relay Tester: Model No. JBC-702Dokument3 SeitenProtection Relay Tester: Model No. JBC-702pemanr1914Noch keine Bewertungen

- ET Quiz3Dokument11 SeitenET Quiz3Pradeep Kumar BowmarajuNoch keine Bewertungen

- Design and Modeling of Photovoltaic Water Pumping System: Dr. C.K. Panigrahi, Pradosh Ranjan Parida, M. Das, J.PatiDokument4 SeitenDesign and Modeling of Photovoltaic Water Pumping System: Dr. C.K. Panigrahi, Pradosh Ranjan Parida, M. Das, J.PatiTarek BouallegNoch keine Bewertungen

- Electric Power Systems Course OverviewDokument25 SeitenElectric Power Systems Course OverviewRizkyHaryogiNoch keine Bewertungen

- A Simplified Forward and Backward Sweep ApproachDokument5 SeitenA Simplified Forward and Backward Sweep ApproachImranAhmadQuadriNoch keine Bewertungen

- IEC 62133 Battery Testing Top 9 FAQ's by Intertek PDFDokument2 SeitenIEC 62133 Battery Testing Top 9 FAQ's by Intertek PDFharishwarreddy100% (1)

- Electrical Engg QuesDokument1 SeiteElectrical Engg Quesjayj_5Noch keine Bewertungen

- Design High Gain DC-DC Boost Converter With Coupling Inductor and Simulation in PsimDokument8 SeitenDesign High Gain DC-DC Boost Converter With Coupling Inductor and Simulation in PsimInternational Journal of Research in Engineering and TechnologyNoch keine Bewertungen

- G7100-90000 CE System User Ebook PDFDokument286 SeitenG7100-90000 CE System User Ebook PDFjohn chinNoch keine Bewertungen

- Infraredthermography PDFDokument21 SeitenInfraredthermography PDFVitalyNoch keine Bewertungen

- F05 Fault On An Allen BradleyDokument12 SeitenF05 Fault On An Allen Bradleymextico06Noch keine Bewertungen

- UA6176 ManualDokument46 SeitenUA6176 ManualmpewebNoch keine Bewertungen

- WEG w22 Three Phase Motor Technical Nema Market 50029265 Brochure EnglishDokument44 SeitenWEG w22 Three Phase Motor Technical Nema Market 50029265 Brochure EnglishDerwaish JeeNoch keine Bewertungen

- Spice DemoDokument13 SeitenSpice DemoChiquita WhiteNoch keine Bewertungen

- MVSI Series Vibrating Motors GuideDokument5 SeitenMVSI Series Vibrating Motors Guidezvornik1Noch keine Bewertungen

- YDokument26 SeitenYAshutosh PatilNoch keine Bewertungen

- 663Dokument96 Seiten663ramesh epiliNoch keine Bewertungen

- Circuit breaker operating sequence and pre-insertion resistor (PIRDokument2 SeitenCircuit breaker operating sequence and pre-insertion resistor (PIRabhi_akNoch keine Bewertungen