Beruflich Dokumente

Kultur Dokumente

Mine and Reclamation

Hochgeladen von

Insun WijayaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mine and Reclamation

Hochgeladen von

Insun WijayaCopyright:

Verfügbare Formate

MINE RECLAMATION

http://www.mii.org/recl.html

MINE RECLAMATION

SURFACE MINING TECHNIQUE

Pictured is an Eastern Kentucky mountain top mining site. With the use of large equipment, this mining operation is removing the entire tops of the mountains, not just small strips around the edge. Although much greater surface disturbance occurs during the mining operation, all water runoff from the mine is directed into sedimentation that prevents off-site pollution. As the mining is completed at this operation, it is being reclaimed to farm land. This Wyoming coal mine is one of the largest producing coal mines in the United States. Because the coal seam is 80- to 100-feet thick, there is a very small area of disturbance compared to a large volume of coal extracted. This photo shows the coal seam being blasted to break it up for loading. Coal is transported by train to electric generating plants or sea ports for shipping to other parts of the world.

Mountain Top Mining

Coal Seam Blasting

MINE RECLAMATION

MINING AND RECLAMATION

Mining inevitably disturbs land. Modern mines reclaim the surface during and after mining is completed, returning the land to useful purposes. Following is information about a few of the many mined land reclamation success stories. Note the differences in the pictures between how the land looks during mining and how the reclaimed areas look after mining. The reclaimed mine lands are often more attractive to wildlife and human uses than before mining started.

During Mining

After Reclamation

MINE RECLAMATION

Reclamation and Farming

The precedent for successful farming on surfacemined land was well established long before Congress mandated reclamation. In Indiana, Illinois, Pennsylvania, and Ohio, several extensive spreads of grain, row crops, and livestock are operating on land that once was a home to draglines, the huge machines used to remove soil at surface coal mines. The success of these operations was the result of careful tilling, planting, fertilizing, and irrigating. The same practices apply to todays operations, coupled with the more specific requirements of the federal law. If farmland is to be mined, the coal company must prove that the productivity of the land will be restored.

Arch Mineral Corp.s 9,000-acre farm and agricultural lab at active mine site includes livestock.

MINE RECLAMATION

Reclamation and Farming

When prime farmland is mined, the law requires that all topsoil and the first layer of subsoil be replaced once mining is completed. When mining begins, the topsoil is removed with mechanical shovels and stockpiled for future use. Then the remaining overburden (the dirt and rock above the coal seam) is removed and stored in another place. Once the coal has been removed from its seam and hauled away, the intermediary layer of overburden is returned to the pit and is graded to approximate the lands pre-mining contour. The topsoil is replaced last, providing the growing medium for the vegetation that will then be planted. Because water is a major concern in areas to be reclaimed, applicants for mining permits must include detailed hydrological data collected over a one-year period showing that the quantity and quality of surface and subsurface waters will not be permanently affected in an adverse manner.

MINE RECLAMATION

Reclamation and Farming

Where coal is removed by underground rather than surface mining, the law contains strict provisions regarding subsidence (a lowering of the surface). In partial extraction mining, the law requires that coal pillars be left in place to support the surface. In full extraction mining, the operator is required to submit a detailed subsidence control plan. Farms on mined land have been shown to yield corn, wheat, rye, and other crops in amounts equal to or greater than neighboring non-mined farms.

Arch Mineral Corp. reclaimed land while mining continues just beyond the field.

Many reclaimed coal mine sites have been turned into successful agricultural areas.

MINE RECLAMATION

Coal Combustion Products

Coal Combustion Products (CCPs) are produced from the combustion of coal, the principal fuel source for todays electric energy needs. The four basic types of coal are anthracite, bituminous, subbituminous and lignite. Coal ash is produced in electric power plants by the burning of coal in steam boiler furnaces. The furnace is equipped for continuous combustion and the coal is injected into the furnace where combustion takes place. The coal ash, or non-combustible portion of the coal, is collected from the bottom of the boiler or exits the boiler in the flue gas stream to be captured using dust collection devices. These residue products include fly ash, bottom ash, boiler slag, and other clean-coal combustion materials.

Fly ash has a powdery appearance and fine texture. It feels very much like talcum powder

MINE RECLAMATION

Coal Combustion Products

Fly ash for use in portland cement concrete represents the largest usage for CCPs. One of the first large-volume use of CCPs was by the U.S. Army Corps of Engineers in construction of the Hungry Horse Dam near Glacier National Park in Montana in the late 1940s. The Federal Aviation Administration has created standards which provide for fly ash use in concrete for airport runways and related facilities. The addition of coal fly ash produces concrete with improved strength and durability. Other applications include road base, snow and ice control, structural fill, waste stabilization, blasting grit, filler in plastics, paints and metals, absorbing oil spills, roofing granules, wallboard manufacture, and material for plant growth media.

Fly ash concrete supported tower cranes on the grounds of the U.S. Capitol building during bicentennial renovations.

MINE RECLAMATION

Coal Combustion Products

Direct application of fly ash can aid in the successful establishment of vegetation as part of a reclamation program. Addition of fly ash to surface soils improves the physical characteristics of the soil, with the fine material creating a better graded soil texture. This change improves the water holding capacity of the soil and better supports vegetation. Fly ash also provides nutrients and neutralizes acidity. Fly ash typically is added at rates up to four hundred tons per acre to mine spoils as part of revegetation programs.

Fly ash concrete supported tower cranes on the grounds of the U.S. Capitol building during bicentennial renovations.

MINE RECLAMATION

Coal Mining Reclamation

Before a company can begin extracting coal, a multitude of government permits federal, state and local are required. The process of obtaining these permits is time-consuming and costly, requiring painstaking analyses of the mining site. Once all the necessary information is compiled a process that can take three years or longer the coal company files for a permit application. The law requires that a period of time then be allowed for public review and comment so that citizen concerns are adequately addressed. Additionally, a coal operator must post a performance bond sufficient to cover the cost of restoring the site to assure reclamation (ranging as high as $10,000 per acre). This must be done before a permit can be granted. The bond is not finally released until the final revegetation of the site has been determined to be successful this time period could be up to ten years following reclamation.

Hydroseeding is often used to help restore mined areas to their original or better condition

MINE RECLAMATION

Coal Combustion Products

Each day in locations across the country, companies which are working hard to mine the coal needed to power our homes and industries are applying an equally intense effort to restore the land they have disturbed. Reclaimed mine sites are returned to productive use in a variety of ways that will benefit generations to come.

Before

After

MINE RECLAMATION

Protecting the Wildlife

Maintaining wildlife is a special concern on land that is surface mined, and it has been demonstrated that mining and wildlife can be compatible. Mined areas can be reshaped in many ways to provide and enhance windbreaks, food, water, and suitable habitats for wildlife. In North Dakota, studies show that the population of song birds, game birds, mule deer, rabbits and foxes are higher than they were before the land was mined and subsequently reclaimed. Deer and antelope thrive alongside mine operations in Wyoming, and in response to encouragement by the State Game and Fish Department, a number of operators have begun to allow archery hunting in an effort to thin the herds. When large scale mining began in the area the Department was concerned about possible reductions in wildlife population, but the current realization is that the mines actually provide refuge environments in which overpopulation can become a problem.

MINE RECLAMATION

Dents Run Watershed

The Dents Run watershed is a 14.6-squaremile area located in the rolling hills which dot the heart of West Virginia coal country near Morgantown. Today, Dents Run and its tributaries show no sign of acid mine drainage that once gave the streams a reddish-orange cast. Nor is there any hint that the hills once bore the deep scars of surface mining.

Watershed before reclamation; heavily affected by acid mine drainage.

More than 400 acres of barren land have been reclaimed, leaving a rich green cover of vegetation and clear streams reflecting the beauty of the restored surroundings. Dents Runs comeback is the result of teamwork between Consolidation Coal Co. (Consol), the West Virginia Department of Natural Resources, and the Environmental Protection Agency.

Dramatic recovery due to a water treatment program instituted by Consol

MINE RECLAMATION

Dents Run Watershed

Consol initiated the restoration efforts, financed initial feasibility studies, and spent more than one million dollars to build new water treatment facilities so its active mining operations would not contribute to water pollution. The WV Department of Natural Resources launched an effort to end the drainage from 28 orphan surface mines and longabandoned coal mining refuse piles, and to transform the piles into grassy knolls, providing forage and cover for wildlife. Dents Run is a fine example of how private coal companies are working hand in hand with government agencies to correct past environmental failures, and to maintain a commitment to environmental quality for the future. To make sure pollution doesnt happen in the future, two strict federal laws, The Clean Water Act and the Surface Mining Control and Reclamation Act, require stringent water quality protection. Company hydrologists begin their studies in the pre-mining stage, when streams, rivers and aquifers in the mining area are sampled for quality and quantity. Their job continues in careful monitoring of the water throughout the entire mining cycle. As in the case of Dents Run, water quality control is a costly and time-consuming effort. It is also one that yields enormous benefits in preserving and restoring our precious waters.

MINE RECLAMATION

EROSION & SEDIMENT CONTROL

SETTLING POND Sediment carried by rainfall is one of the greatest potential environmental hazards of surface mining. Surface water flowing off disturbed areas of the mine must be routed through sediment ponds. The ponds are designed to slow the flow of water.

MINE RECLAMATION

EROSION & SEDIMENT CONTROL

RIPRAP One of the most commonly used erosion control practices found in mine reclamation, highway construction, and throughout the construction industry is rock riprap. Here at this Southern Indiana reclaimed mine site riprap is used in the emergency overflow of a permanent pond. If high rainfall occurs and more water flows into the pond than the drain can handle, the excess will flow safely over the riprap without causing erosion. This rock lining of the drainage channel slows the flowing water and prevents erosion of the soil under the rock.

MINE RECLAMATION

EROSION & SEDIMENT CONTROL

JUT MATTING At this North Dakota mine reclamation site, a natural drainage swale is lined with a jute mat to prevent erosion until the grass becomes established. This is an erosion control practice that has been used successfully for many years on farms all across the country and is now commonly used in mine reclamation.

This is a short-term erosion control practice that is a safeguard in areas prone to flash flooding or where it takes a long time to establish a dense grass cover. The matting is placed over the prepared seedbed and "stapled" to the ground to prevent it from washing down the slope. The mat holds the soil in place and provides cover for the new grass seedlings as they become established.

MINE RECLAMATION

EROSION & SEDIMENT CONTROL

CONCRETE DRAINAGE CHANNEL At this reclaimed abandoned mine project, water flows continuously down the channel to a stream at the bottom of the hill. Because the continuous flow of water and steep grade would damage a less resistant erosion control practice, a specialized mat was set in the graded channel and filled with concrete.

When the concrete dried it formed a permanent channel for the water to flow. Although more expensive than a grass or riprap water way, this practice provides long-term erosion control for the fast moving water that drains off this reclaimed land.

MINE RECLAMATION

EROSION & SEDIMENT CONTROL

ROCK-LINED DRAIN Large rock-lined drains have become one of the most commonly used methods of channeling water down steep hillsides at mine sites. Here on this Kentucky mine reclamation site, the operator has carefully set flat rock on the bottom and sides of the water channel. As one mine inspector said "if rock drains at all mines were constructed like these we would eliminate almost all chance of erosion occurring where collected water was drained from the reclamation site." This rock-lined drain carries water down the steep hill and into a pond at the bottom. Its wide (7- to 8foot) flat bottom can carry large flows of water and will continue to function many years after the reclamation bond has been released.

MINE RECLAMATION

EROSION & SEDIMENT CONTROL

EROSION CONTROL STRUCTURES To prevent soil erosion during periods of heavy rainfall and high stream flow, two concrete structures are constructed. The concrete structures allow rapidly flowing water to drop in elevation without causing erosion of the creek bed. At the bottom of the structure concrete blocks are constructed to slow the flow of water and dissipate the force of the water. These structures provide a permanent solution to erosion control of the stream bed and provide a stable hydrologic environment that will remain for many years.

MINE RECLAMATION

EROSION & SEDIMENT CONTROL

MINE SITE TODAY Today, after reclamation, the stream channel in this rural Texas landscape remains functional, aesthetically pleasing, and an important part of the natural environment. The successful mine reclamation has resulted in a productive environment that is difficult to distinguish from the surrounding unmined landscape.

MINE RECLAMATION

RECLAMATION SUCCESS

New Residential Areas Condominiums constructed on sand and overburden fill in a sand and gravel pit along the White River in Indiana

Apartments and condominiums constructed around a quarry in Ohio. The residential development preserved the character of the rock formations and also provided waterfront sites for home development

MINE RECLAMATION

RECLAMATION SUCCESS

Housing development built around a series of lakes created by a sand and gravel mining operation in Michigan. The mining company and developer worked together to landscape and provide special terrain features for the individual lots

The Mystic Bay condominium project in Indiana is built on a 60-acre sand and gravel site. The shoreline is shaped to provide access to the gravel pit lake

MINE RECLAMATION

RECLAMATION SUCCESS

The specially contoured and landscaped berm screens a sand and gravel mining area on the right from a residential area on the left. The mining operation is located 150 feet from the road

A "sunken" processing plant with earth berms screening the mining operation and effectively controlling noise levels

Das könnte Ihnen auch gefallen

- Surface Coal Mine ReclamationDokument17 SeitenSurface Coal Mine ReclamationNdlondong LegiNoch keine Bewertungen

- Rainwater Catchment Systems in Kenya and BotswanaDokument11 SeitenRainwater Catchment Systems in Kenya and BotswanaGreen Action Sustainable Technology GroupNoch keine Bewertungen

- Soil Conservation and WatershedDokument8 SeitenSoil Conservation and WatershedKeyaNoch keine Bewertungen

- Farming Action: Catchment Reaction: The Effect of Dryland Farming on the Natural EnvironmentVon EverandFarming Action: Catchment Reaction: The Effect of Dryland Farming on the Natural EnvironmentNoch keine Bewertungen

- EU Guidelines Green InfrastructureDokument4 SeitenEU Guidelines Green InfrastructureNeven TrencNoch keine Bewertungen

- Handbook of Catchment ManagementVon EverandHandbook of Catchment ManagementRobert C. FerrierNoch keine Bewertungen

- California San Francisco Low Impact Design Toolkit For StormwaterDokument52 SeitenCalifornia San Francisco Low Impact Design Toolkit For StormwaterFree Rain Garden ManualsNoch keine Bewertungen

- Portland Tree Canopy Monitoring 2020Dokument22 SeitenPortland Tree Canopy Monitoring 2020KGW News100% (1)

- Topic: Soil and Water Conservation Engg. & StructureDokument22 SeitenTopic: Soil and Water Conservation Engg. & StructureasdNoch keine Bewertungen

- Teknik Konservasi Tanah Di Pantai BerpasirDokument9 SeitenTeknik Konservasi Tanah Di Pantai BerpasirenikwahyuniatiNoch keine Bewertungen

- Miyawaki Method of AfforestationDokument2 SeitenMiyawaki Method of AfforestationDibyajyoti RabhaNoch keine Bewertungen

- Runoff FarmingDokument39 SeitenRunoff FarmingAziz Khan KakarNoch keine Bewertungen

- Singapore Botanic Gardens: A Legacy of GreeningDokument39 SeitenSingapore Botanic Gardens: A Legacy of GreeningAmarNoch keine Bewertungen

- Duisburg Nord 1presentationDokument27 SeitenDuisburg Nord 1presentationarya vsNoch keine Bewertungen

- Decision Making in Water Resources Policy and Management: An Australian PerspectiveVon EverandDecision Making in Water Resources Policy and Management: An Australian PerspectiveNoch keine Bewertungen

- Emily Manderson LowresDokument72 SeitenEmily Manderson LowresJaime GonzalezNoch keine Bewertungen

- Options For Ecosystem Based Adaptation in Coastal Environments Low-ResDokument110 SeitenOptions For Ecosystem Based Adaptation in Coastal Environments Low-ResAnjuli Elegado100% (1)

- Indonesian Peatland Map: Method, Certainty, and Uses: August 2014Dokument17 SeitenIndonesian Peatland Map: Method, Certainty, and Uses: August 2014Siska Novelia ZaiNoch keine Bewertungen

- Alaska Rain Gardens: A How-To Manual For Homeowners in The Municipality of AnchorageDokument32 SeitenAlaska Rain Gardens: A How-To Manual For Homeowners in The Municipality of AnchorageFree Rain Garden ManualsNoch keine Bewertungen

- Subsurface DamsDokument8 SeitenSubsurface DamssamoonibrahimNoch keine Bewertungen

- Urban Sustainability and River Restoration: Green and Blue InfrastructureVon EverandUrban Sustainability and River Restoration: Green and Blue InfrastructureNoch keine Bewertungen

- Summary National Policy Strategy For Infrastructure and Spatial PlanningDokument24 SeitenSummary National Policy Strategy For Infrastructure and Spatial Planningandre turnerNoch keine Bewertungen

- Grading Plan: Ruby Jirongo B02/31698/2014Dokument7 SeitenGrading Plan: Ruby Jirongo B02/31698/2014Proyek MotamassinNoch keine Bewertungen

- Ecosystems Services Case Studies ForesteDokument48 SeitenEcosystems Services Case Studies ForesteAnimalista IserniaNoch keine Bewertungen

- Intermittent Rivers and Ephemeral Streams: Ecology and ManagementVon EverandIntermittent Rivers and Ephemeral Streams: Ecology and ManagementThibault DatryNoch keine Bewertungen

- Proceedings of The 1st International Workshop, Jakarta 2009Dokument63 SeitenProceedings of The 1st International Workshop, Jakarta 2009ilham2keyNoch keine Bewertungen

- Satellite Town and Garden CitiesDokument31 SeitenSatellite Town and Garden Citiesjanhavi28100% (2)

- Wildlife and Wind Farms - Conflicts and Solutions: Onshore: Potential EffectsVon EverandWildlife and Wind Farms - Conflicts and Solutions: Onshore: Potential EffectsMartin PerrowNoch keine Bewertungen

- Wsud 090315185906 Phpapp02Dokument85 SeitenWsud 090315185906 Phpapp02Tri WahyuningsihNoch keine Bewertungen

- Geodiversity Valuing and Conserving Abiotic NatureDokument450 SeitenGeodiversity Valuing and Conserving Abiotic NatureIMVG DatabaseNoch keine Bewertungen

- Storm Water Harvesting GuidelineDokument16 SeitenStorm Water Harvesting GuidelineJulio CabezasNoch keine Bewertungen

- Sewerage in TokyoDokument62 SeitenSewerage in TokyoSyed Yasir AliNoch keine Bewertungen

- Indonesian Peatland Map: Method, Certainty, and Uses: August 2014Dokument17 SeitenIndonesian Peatland Map: Method, Certainty, and Uses: August 2014Ispo Sendika DisnuNoch keine Bewertungen

- A Study On Present Status of Betel Nut Growers of AssamDokument5 SeitenA Study On Present Status of Betel Nut Growers of AssamKeshav SinghNoch keine Bewertungen

- Delaware Highways Manual - Roadside Vegetation ManagementDokument157 SeitenDelaware Highways Manual - Roadside Vegetation ManagementDelaware Center for HorticultureNoch keine Bewertungen

- Landscape Ecology and Enivornment and EiaDokument26 SeitenLandscape Ecology and Enivornment and EiaparvathabaskarNoch keine Bewertungen

- Guide to Local Level Land Resource ManagementDokument10 SeitenGuide to Local Level Land Resource ManagementRajanRanjanNoch keine Bewertungen

- Peatland Mapping and Monitoring: Recommendations and Technical OverviewVon EverandPeatland Mapping and Monitoring: Recommendations and Technical OverviewNoch keine Bewertungen

- Landscape Design 2Dokument70 SeitenLandscape Design 2Heba Ezzat KamelNoch keine Bewertungen

- Cities and Climate Change PDFDokument328 SeitenCities and Climate Change PDFRabin JoshiNoch keine Bewertungen

- Using Green Roofs To Enhance Biodiversity in The City of Toronto (2010)Dokument47 SeitenUsing Green Roofs To Enhance Biodiversity in The City of Toronto (2010)T.O. Nature & DevelopmentNoch keine Bewertungen

- Practitioners GuideDokument96 SeitenPractitioners Guideapoorv0009Noch keine Bewertungen

- Design To Include Existing Site FeaturesDokument12 SeitenDesign To Include Existing Site FeaturesAShu Saini50% (2)

- Landscape ElementsDokument24 SeitenLandscape ElementsAnkita SharmaNoch keine Bewertungen

- Overview West SumbawaDokument70 SeitenOverview West SumbawaDita L SudarmawanNoch keine Bewertungen

- Deep Pipe IrrigationDokument8 SeitenDeep Pipe IrrigationXuxuxelNoch keine Bewertungen

- Copper Forum: Magazine For Copper in The Construction Industry - 24 /2008Dokument39 SeitenCopper Forum: Magazine For Copper in The Construction Industry - 24 /2008CopperConceptNoch keine Bewertungen

- Park LandscapeDokument27 SeitenPark Landscapebabah ashongNoch keine Bewertungen

- Urbanism Si Mobila UrbanaDokument148 SeitenUrbanism Si Mobila UrbanaLaura FinkelsteinNoch keine Bewertungen

- The Future of Soil Carbon: Its Conservation and FormationVon EverandThe Future of Soil Carbon: Its Conservation and FormationNoch keine Bewertungen

- Stormwater Campbelltowm CouncilDokument3 SeitenStormwater Campbelltowm CouncilRohan Dutt SharmaNoch keine Bewertungen

- GP 18 Watershed ManagementDokument21 SeitenGP 18 Watershed ManagementHabtamu YalewNoch keine Bewertungen

- 02 Ecological Concept in BriefDokument5 Seiten02 Ecological Concept in BriefdedhsaNoch keine Bewertungen

- Wetlands in IndiaDokument4 SeitenWetlands in IndiaPratheep KalamNoch keine Bewertungen

- Site AnalysisDokument2 SeitenSite AnalysisAmie FanNoch keine Bewertungen

- Crookes Valley Park - Masterplan-Ponderosa - Philadelphia GreenspaceDokument195 SeitenCrookes Valley Park - Masterplan-Ponderosa - Philadelphia Greenspace焚烛Noch keine Bewertungen

- Glacial LandformsDokument42 SeitenGlacial LandformsKingsuk BurmanNoch keine Bewertungen

- Gis in Raster Analyses PDFDokument16 SeitenGis in Raster Analyses PDFInsun WijayaNoch keine Bewertungen

- Aster Gdem Readme - Ev1.0Dokument6 SeitenAster Gdem Readme - Ev1.0Ivan MendezNoch keine Bewertungen

- ERMapper and ArcGISDokument2 SeitenERMapper and ArcGISSi Lumba BfNoch keine Bewertungen

- Development of Rock Engeeniering Hoeck PDFDokument17 SeitenDevelopment of Rock Engeeniering Hoeck PDFClau TorrejónNoch keine Bewertungen

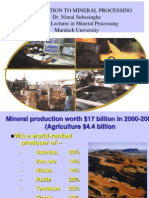

- Mineral Processing Nimal He 1Dokument38 SeitenMineral Processing Nimal He 1Insun WijayaNoch keine Bewertungen

- JIRA Essentials Third Edition - Sample ChapterDokument43 SeitenJIRA Essentials Third Edition - Sample ChapterPackt PublishingNoch keine Bewertungen

- XCC 638Dokument32 SeitenXCC 638Nico NicoNoch keine Bewertungen

- ServiceLink Release 4.94 Upgrade InstructionsDokument4 SeitenServiceLink Release 4.94 Upgrade InstructionsOsvaldo Mamani TiconaNoch keine Bewertungen

- Master The Five Remote Function CallDokument25 SeitenMaster The Five Remote Function Callntesla2009Noch keine Bewertungen

- Lumascape Lightings CatalogueDokument265 SeitenLumascape Lightings CatalogueajlounicNoch keine Bewertungen

- Neurodiagnostic TechnologyDokument3 SeitenNeurodiagnostic TechnologyJeyarajasekar TtrNoch keine Bewertungen

- List of Documents ISO 9001 ISO 14001 ISO 45001 Documentation Toolkit enDokument9 SeitenList of Documents ISO 9001 ISO 14001 ISO 45001 Documentation Toolkit enAquino Sianipar67% (3)

- Basic Principles of Counseling ProcessDokument2 SeitenBasic Principles of Counseling ProcessBhavna SinghalNoch keine Bewertungen

- CRANE RUNWAY BEAM DESIGN - ASD 9Dokument5 SeitenCRANE RUNWAY BEAM DESIGN - ASD 9MITHUN BDML100% (1)

- ACFM Inspection Procedure PDFDokument40 SeitenACFM Inspection Procedure PDFNam DoNoch keine Bewertungen

- State Bank of India - Recruitment of Probationary Officers PDFDokument2 SeitenState Bank of India - Recruitment of Probationary Officers PDFTapas Kumar NandiNoch keine Bewertungen

- Auto TurnDokument156 SeitenAuto TurnrrrraduNoch keine Bewertungen

- Lecture 6 Cairo UniversityDokument20 SeitenLecture 6 Cairo UniversityWRAINoch keine Bewertungen

- Recommended Battery Bank ConfigurationsDokument10 SeitenRecommended Battery Bank ConfigurationsUlisesGómezNoch keine Bewertungen

- User Manual SR 9797HDDokument47 SeitenUser Manual SR 9797HDnavamivbNoch keine Bewertungen

- Vibration PPV EstimationDokument8 SeitenVibration PPV EstimationJensen TanNoch keine Bewertungen

- Ekspanzioni VentilDokument6 SeitenEkspanzioni VentilNevena AksićNoch keine Bewertungen

- Ford Pinto Case Study HandoutDokument2 SeitenFord Pinto Case Study HandoutSteven Snitch TranNoch keine Bewertungen

- Thermodynamic properties of R740 (ammonia) in SI unitsDokument1 SeiteThermodynamic properties of R740 (ammonia) in SI unitsJose LuisNoch keine Bewertungen

- Bharat Institute of EngineeringDokument2 SeitenBharat Institute of EngineeringdasarioramaNoch keine Bewertungen

- SB07 Decorative Effects 04Dokument14 SeitenSB07 Decorative Effects 04Mohamed AliNoch keine Bewertungen

- Major ICT and manufacturing companies in EthiopiaDokument3 SeitenMajor ICT and manufacturing companies in EthiopiafiraolNoch keine Bewertungen

- CircuitsDokument26 SeitenCircuitsDarian ShiNoch keine Bewertungen

- 01 Rude DoctypeDokument215 Seiten01 Rude DoctypeChristal Rae Tac-anNoch keine Bewertungen

- 695 y and 695 D Series - Trap Primer Splitter - PrimeperfectDokument1 Seite695 y and 695 D Series - Trap Primer Splitter - PrimeperfectjituplanojrNoch keine Bewertungen

- Tiempos de entrega y actividades de aprendizajeDokument2 SeitenTiempos de entrega y actividades de aprendizajejuanNoch keine Bewertungen

- Application of PWM Speed ControlDokument7 SeitenApplication of PWM Speed ControlJMCproductsNoch keine Bewertungen

- Radiscreen-C Coarse Screen BR-ENDokument4 SeitenRadiscreen-C Coarse Screen BR-ENmriosqNoch keine Bewertungen

- Dyeing Process Guide: Types, Machines & OptimizationDokument3 SeitenDyeing Process Guide: Types, Machines & OptimizationVipin Singh KandholNoch keine Bewertungen

- Ubd WonderDokument13 SeitenUbd Wonderapi-422461005100% (1)