Beruflich Dokumente

Kultur Dokumente

STUDY OF MAGNETIC FIELD EFFECTS ON COPPER ELECTRODEPOSITION (Poster RSCE-SOMCHE 2008)

Hochgeladen von

SudibyoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

STUDY OF MAGNETIC FIELD EFFECTS ON COPPER ELECTRODEPOSITION (Poster RSCE-SOMCHE 2008)

Hochgeladen von

SudibyoCopyright:

Verfügbare Formate

STUDY OF MAGNETIC FIELD EFFECTS ON COPPER

ELECTRODEPOSITION

Sudibyo , M.B. How, N. I. Basir and N. Aziz*

School of Chemical Engineering,, Universiti Sains Malaysia

14300 Nibong Tebal, Seberang Perai Selatan, Pulau Pinang, Malaysia

*Corresponding author., Tel : +6(04)5996457 Fax : +6(04) 5941013 Email: chnaziz@eng.usm.my

Introduction

Electrodeposition is used to improve contact resistance, corrosion resistance, reflection properties of material and to impart friction properties.

Obtaining a uniform, dense and compact deposition is one of the major problem in electrodeposition.

One of methods available to overcome this problem is magnetoelectrodeposition (MED).

-MED application are : to synthesize metal alloy, thin film, multilayer, nanowires, multilayer nanowires, dot array and nanocontacts which are

the technology of the future to build the next generation of computing devices.

-The advantages of MED are : - Electrodeposits more uniform compact and denser

- Increase mass transport

- Increase Limiting Curret Density

Objectives of this research :

-To study the effect of magnetic strength, the voltage supplied and the alignment of the magnetic field towards growth fractal electrodeposits.

Experimental :

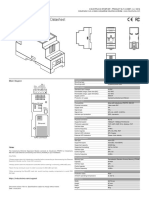

S ID E V IE W R O D E L E C T R O D E (C A T H O D E )

ELE C TR O LY TE

S ID E V IE W F IL T E R PA P E R

MULTIMETER RECTIFIER

S ID E V IE W EXTERNAL

S ID E V IE W M AGNET R IN G E L E C T R O D E (A N O D E )

B T O P V IE W C U S T O M IZ E D

B P E T R I D IS H

B

EXTERNAL EXTER NAL

A FLAT CIRCULAR CELL MAGNET

EXTERNAL M A G NET

E L E C T R O D E P O S IT IO N U N IT M AGNET

Figure 1: Schematic diagram for the MED (a) (b) (c)

system.

Figure 2 : Schematic diagram of the MED system with various degree of magnet Figure 3: Schematic diagram for

alignment : (a) magnet at 00, (b) magnet at 450 and (c) magnet at 900 (B is the direction the electrodeposition unit

of the magnet fluxSources of Magnetic Field : A Ferrite (18 gauss) and Neodymium

permanent magnets (31 gauss)

Result and Discussion

Effect of Magnetic Field Strength Effect of Electrical Potential

(a) (b) (c) (a) (b) (c)

Figure 4 : Copper electrodeposits (applied voltage 6 V, CuSO4 0.2 M, Figure 5 : Copper electrodeposits (neodium magnet, CuSO4 0.2 M, time duration 20

time duration 20 minutes) : (a) without magnet, ( b) in weak magnetic minutes): (a) applied voltage 4 V, (b) applied voltage 6 V, (c) applied voltage 8 V

field (ferrite magnet), (c) in strong magnetic field (neodium magnet)

Effect of Magnetic Field Placement

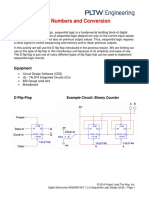

M as s de pos ite d vs . Voltage

0.05

Mass Deposited (gr)

0.04

(a)

(b) (c)

0.03

0.02

(e)

(d)

0.01

0

4 6 8

Figure 5 : Copper electrodeposits (applied voltage 6 V, time duration 20 minutes,

Voltage (V)

CuSO4 0.2 M, neodium magnet): the magnet placed (a) at 0o from vertical plane,

(b) at 45o from vertical plane, (c) at 90o from vertical plane, (d) at 135o from

vertical plane, (e) at 180o from vertical plane. Figure 6: Mass copper electrodeposits in variation an applied voltage

CONCLUSIONS

- Under the influence of magnetic field, the fractal electrodeposits are observed to be much denser and more compact due to the presence of

MHD effect.

- The MHD effect is actually generated by the magnetic force and as the magnetic field strength increases, the strength of the MHD effect

increases as well.

- Increasing applied voltage also lead the electrodeposits more denser and compact.

- The most compact and dense electrodeposits achieved when the magnet is placed at 0o from vertical plane as the magnetic force is parallel to

the cathode surface.

ACKNOWLEDGMENT

This work was supported by Ministry of Higher Education Malaysia

under FRGS grant No. 607113

Das könnte Ihnen auch gefallen

- Engineering Mechanics Dynamics 13th Edition Hibbeler Solutions Manual Full Chapter PDFDokument67 SeitenEngineering Mechanics Dynamics 13th Edition Hibbeler Solutions Manual Full Chapter PDFalmaydyd100% (14)

- 96.2 - 2021 07 29 - EBESProductionQualityManual (B, MIZ RAN, RJC RAM, CORE RAN)Dokument36 Seiten96.2 - 2021 07 29 - EBESProductionQualityManual (B, MIZ RAN, RJC RAM, CORE RAN)Tran The AnhNoch keine Bewertungen

- Residential Building Estimate Module PPT FinDokument257 SeitenResidential Building Estimate Module PPT FinNicole RodilNoch keine Bewertungen

- ESDA Technology Roadmap Final WebsiteDokument23 SeitenESDA Technology Roadmap Final WebsiteAlfredoNoch keine Bewertungen

- A Quantitative Feasibility On The Effectiveness of Eggshell As An Alternative Material To CementDokument8 SeitenA Quantitative Feasibility On The Effectiveness of Eggshell As An Alternative Material To Cementlexly cortezNoch keine Bewertungen

- TOPIC 9 ElectricalDokument13 SeitenTOPIC 9 ElectricalVLADIMIR VERA VELARDE100% (1)

- Industruino ETHERNET Specification May'2016 Rev1.0Dokument1 SeiteIndustruino ETHERNET Specification May'2016 Rev1.0Andres OrozcoNoch keine Bewertungen

- Course in Electrical Engineering Vol 1 DC Dawes 1937Dokument796 SeitenCourse in Electrical Engineering Vol 1 DC Dawes 1937ORTEGA , Christine MaeNoch keine Bewertungen

- Digital Booklet - Bottoms UpDokument9 SeitenDigital Booklet - Bottoms UpVadimNoch keine Bewertungen

- Works: The Science Engineer Ing & Technology MagazineDokument21 SeitenWorks: The Science Engineer Ing & Technology MagazineNETParkNetNoch keine Bewertungen

- Chapter 1 (Modified - 210309)Dokument47 SeitenChapter 1 (Modified - 210309)Santiago BritoNoch keine Bewertungen

- Tunç Durmuş Medeni̇ PDFDokument15 SeitenTunç Durmuş Medeni̇ PDFİskender GüneşNoch keine Bewertungen

- CV & Certificate PDFDokument11 SeitenCV & Certificate PDFArif FuadiantoNoch keine Bewertungen

- IndelecDokument6 SeitenIndelecvasilevigor100% (1)

- Papel de Buena Conducta INGLES RADAISYDokument1 SeitePapel de Buena Conducta INGLES RADAISYLOSCORRUPTOSHDNoch keine Bewertungen

- 113.1 - 22 07 19 - GlassReplacementPlan&Procedures (B, CORE NR, RJC R, SF RAN)Dokument15 Seiten113.1 - 22 07 19 - GlassReplacementPlan&Procedures (B, CORE NR, RJC R, SF RAN)Tran The AnhNoch keine Bewertungen

- Artificial Intelligence in Non-Destructive TestingDokument43 SeitenArtificial Intelligence in Non-Destructive TestingRafael QueirozNoch keine Bewertungen

- Lenze Servo DriverDokument186 SeitenLenze Servo DriverElyNoch keine Bewertungen

- Vol. 41, Issue 45 - November 5, 2010Dokument48 SeitenVol. 41, Issue 45 - November 5, 2010BladeNoch keine Bewertungen

- SF2 AbmDokument1 SeiteSF2 AbmKatherine Munez Rivero PadernalNoch keine Bewertungen

- Moto Z Play 2 (Houdini) - R2-D2-FinalDokument121 SeitenMoto Z Play 2 (Houdini) - R2-D2-Finalkarenchristinasantos87Noch keine Bewertungen

- High Current Interrupt TechniqueDokument6 SeitenHigh Current Interrupt TechniqueMohamed Abd El MohsenNoch keine Bewertungen

- Ilgc Midsem PresentationDokument17 SeitenIlgc Midsem Presentationyashvi.maheshwariNoch keine Bewertungen

- DO TH E NU M BE RS D UP ?: Oc K of in G, B Ut A Re RT Io NDokument76 SeitenDO TH E NU M BE RS D UP ?: Oc K of in G, B Ut A Re RT Io NShabin ShabiNoch keine Bewertungen

- Corporateprofile enDokument8 SeitenCorporateprofile ensheraz.vinceNoch keine Bewertungen

- Launchxl2 570lc43 Rm57l SchematicsDokument17 SeitenLaunchxl2 570lc43 Rm57l SchematicsMartin Valencia AlejoNoch keine Bewertungen

- Electronic Word ExerciseDokument1 SeiteElectronic Word ExerciseEuvan MatienzoNoch keine Bewertungen

- FA SH I ON PRO DUC TDE Sign: C Areer PO Ssibiliti ESDokument1 SeiteFA SH I ON PRO DUC TDE Sign: C Areer PO Ssibiliti ESRichard ScottNoch keine Bewertungen

- Toaz - Info Chapter 4 Transformers PRDokument37 SeitenToaz - Info Chapter 4 Transformers PRMostafa MongyNoch keine Bewertungen

- Wa0011Dokument4 SeitenWa0011mvsakthiNoch keine Bewertungen

- Catalogo Tom 2Dokument16 SeitenCatalogo Tom 2Luz Arce FarfanNoch keine Bewertungen

- The Folk Element in Hindu Culture PDFDokument341 SeitenThe Folk Element in Hindu Culture PDFBalakrishna GopinathNoch keine Bewertungen

- Tri Hadi Saput R O: Draf T Er Desi GN Ar Chi T Ect & MEPDokument1 SeiteTri Hadi Saput R O: Draf T Er Desi GN Ar Chi T Ect & MEPTri Hadi SaputroNoch keine Bewertungen

- Citizen Everlight - Optical SensorsDokument4 SeitenCitizen Everlight - Optical SensorsbaixadocNoch keine Bewertungen

- CER135 M1 - Fundamanetals - MicrosDokument18 SeitenCER135 M1 - Fundamanetals - MicrosDEANZEL CABATU-ANNoch keine Bewertungen

- Coursera Y84CLPVK7WXYDokument1 SeiteCoursera Y84CLPVK7WXYldelgado.dcNoch keine Bewertungen

- 13 April 2020 Session1 - Basic Principles of Remote Sensing - Dr. Manu Mehta PDFDokument40 Seiten13 April 2020 Session1 - Basic Principles of Remote Sensing - Dr. Manu Mehta PDFAnita Sofia KeyserNoch keine Bewertungen

- Electronic Paper PDFDokument6 SeitenElectronic Paper PDFDeepthi DeepuNoch keine Bewertungen

- COM UTE NET: InternetworkingDokument110 SeitenCOM UTE NET: InternetworkingAnugrah MNoch keine Bewertungen

- Geocentric Datum For Malaysia: Implementation and ImplicationsDokument15 SeitenGeocentric Datum For Malaysia: Implementation and Implicationsahmad bahiyuddin21Noch keine Bewertungen

- Intelligent and Green BuildingsDokument35 SeitenIntelligent and Green Buildingsmagda badrNoch keine Bewertungen

- Curri Cul Umvi Tae: Personali Nformati OnDokument2 SeitenCurri Cul Umvi Tae: Personali Nformati OnBilal MasoodNoch keine Bewertungen

- Beamex PGM Manual ESPDokument6 SeitenBeamex PGM Manual ESPbiotech666Noch keine Bewertungen

- MURI Progress Review:: Electromagnetic Simulation of Antennas and Arrays With Accurate Modeling of AntennaDokument51 SeitenMURI Progress Review:: Electromagnetic Simulation of Antennas and Arrays With Accurate Modeling of AntennaSalam FaithNoch keine Bewertungen

- I NT Er Netofthi NgsDokument90 SeitenI NT Er Netofthi NgsNavinNoch keine Bewertungen

- DTF and VSWR Sbtd012g, Bukit GombakDokument34 SeitenDTF and VSWR Sbtd012g, Bukit GombakArfan TulifNoch keine Bewertungen

- BarlowDokument1 SeiteBarlowsustainableunhNoch keine Bewertungen

- WP Contentuploads2018102017 DSE MATH EPM2 1 PDFDokument28 SeitenWP Contentuploads2018102017 DSE MATH EPM2 1 PDFRaymond KwokNoch keine Bewertungen

- NETWorks Autumn 2009Dokument40 SeitenNETWorks Autumn 2009NETParkNetNoch keine Bewertungen

- Isbn 9789526061122Dokument132 SeitenIsbn 9789526061122Roland RüttenNoch keine Bewertungen

- s20231278 Persatuan Kompang Warisan Pemuda Puteri Kampung BaruDokument1 Seites20231278 Persatuan Kompang Warisan Pemuda Puteri Kampung Baruiijakajak IjakNoch keine Bewertungen

- NPD Models Role of Information and Idea Generation For NPD: Session 2Dokument31 SeitenNPD Models Role of Information and Idea Generation For NPD: Session 2Hina SaadNoch keine Bewertungen

- EarthworksDokument26 SeitenEarthworksElvin G. TactacNoch keine Bewertungen

- Thontadharya CVDokument2 SeitenThontadharya CVgowreesh ysNoch keine Bewertungen

- Flecdic: (Eds DsffrdsDokument5 SeitenFlecdic: (Eds DsffrdsParshvi TyagiNoch keine Bewertungen

- Curri Culum Vi Tae: Engr .HamayunkhanDokument4 SeitenCurri Culum Vi Tae: Engr .HamayunkhanhamayunNoch keine Bewertungen

- Origami EarthDokument1 SeiteOrigami EarthFernando RomanNoch keine Bewertungen

- Applied Solid State Science: Advances in Materials and Device ResearchVon EverandApplied Solid State Science: Advances in Materials and Device ResearchRaymond WolfeNoch keine Bewertungen

- Sensory QuestionnaireDokument11 SeitenSensory QuestionnaireElisa DellaNoch keine Bewertungen

- Omreport TriageDokument4 SeitenOmreport TriagerejnanNoch keine Bewertungen

- Usage: Universal Programmable Poe Injector (P/N I0Atpi24)Dokument4 SeitenUsage: Universal Programmable Poe Injector (P/N I0Atpi24)jimpomaNoch keine Bewertungen

- Ece-V-Information Theory & Coding (10ec55) - AssignmentDokument10 SeitenEce-V-Information Theory & Coding (10ec55) - AssignmentLavanya Vaishnavi D.A.Noch keine Bewertungen

- Gatee Security Using Rasberry PiDokument5 SeitenGatee Security Using Rasberry PiIsaq ShikalgarNoch keine Bewertungen

- Tapered Slot Antenna DesignDokument10 SeitenTapered Slot Antenna DesignPavan NanduriNoch keine Bewertungen

- rr322404 Automotive Electrical and AutotronicsDokument4 Seitenrr322404 Automotive Electrical and AutotronicsSRINIVASA RAO GANTANoch keine Bewertungen

- LCD TV: Service ManualDokument44 SeitenLCD TV: Service ManualDaniel Norberto DemariaNoch keine Bewertungen

- EIE FormatDokument13 SeitenEIE Formatapi-19989949Noch keine Bewertungen

- Flashing LEDDokument5 SeitenFlashing LEDrashid sharifNoch keine Bewertungen

- 1.2.4.AK SequentialLogicDesign - Counters - DLBDokument7 Seiten1.2.4.AK SequentialLogicDesign - Counters - DLBSean MonahanNoch keine Bewertungen

- Effect of Temperature On ResistanceDokument3 SeitenEffect of Temperature On ResistanceKiran KarthikNoch keine Bewertungen

- Ecat 2013 FinalDokument7 SeitenEcat 2013 FinalAitazaz AhsanNoch keine Bewertungen

- OMM 0121 - D+GF 205+BMK 750 3000+G 19 0010+and+UP+Install Startup - 5 9 19Dokument122 SeitenOMM 0121 - D+GF 205+BMK 750 3000+G 19 0010+and+UP+Install Startup - 5 9 19benNoch keine Bewertungen

- KT-502H en Tcd210202ab 20211221 Manual WDokument3 SeitenKT-502H en Tcd210202ab 20211221 Manual WGopal HegdeNoch keine Bewertungen

- CS QuestionsDokument2 SeitenCS QuestionsKarthik MambersNoch keine Bewertungen

- RH5X Relative Humidity SensorDokument3 SeitenRH5X Relative Humidity SensorMelba EstrellaNoch keine Bewertungen

- Rio 2e Manual PDFDokument33 SeitenRio 2e Manual PDFBradley BergNoch keine Bewertungen

- AN/SSQ-62E DICASS Sonobuoy: Active DirectionalDokument2 SeitenAN/SSQ-62E DICASS Sonobuoy: Active DirectionalCarlos AraujoNoch keine Bewertungen

- Aks PHPDokument8 SeitenAks PHParyaNoch keine Bewertungen

- Lecture 6 Import Design and FloorplanDokument54 SeitenLecture 6 Import Design and FloorplanVamsi KrishnaNoch keine Bewertungen

- ElectroMagnetic Locator (Pipe Cable Locator)Dokument92 SeitenElectroMagnetic Locator (Pipe Cable Locator)Fred Strokes50% (2)

- ShimDLL - 2020 09 12 - 19 02 10 - 0718Dokument52 SeitenShimDLL - 2020 09 12 - 19 02 10 - 0718Анатолий РябоконьNoch keine Bewertungen

- Mosfet & Igbt: Ee3147 Power ElectronicsDokument16 SeitenMosfet & Igbt: Ee3147 Power ElectronicsHoàng TúNoch keine Bewertungen

- Ali Campbell Complete PA Spec 2011 V8Dokument7 SeitenAli Campbell Complete PA Spec 2011 V8Duke Smith-Holley0% (1)

- OSN 8800 6800 3800 V100 Routine Maintenance 06Dokument26 SeitenOSN 8800 6800 3800 V100 Routine Maintenance 06terenteNoch keine Bewertungen

- 14 Manuais PDFDokument78 Seiten14 Manuais PDFThales LiberatoNoch keine Bewertungen

- Dokumen - Tips Ready Admit Card Cooch Behar Without Admit Card Will Not Be Allowed For WrittenDokument410 SeitenDokumen - Tips Ready Admit Card Cooch Behar Without Admit Card Will Not Be Allowed For WrittenCavya DealsNoch keine Bewertungen

- Design Calculations of Lightning Protection Systems - Part ElevenDokument37 SeitenDesign Calculations of Lightning Protection Systems - Part ElevenHansika RajapakshaNoch keine Bewertungen

- INR-SI47-1283b-E - PG Interface CardDokument6 SeitenINR-SI47-1283b-E - PG Interface CardSaptyawan KasidjoNoch keine Bewertungen