Beruflich Dokumente

Kultur Dokumente

Forming

Hochgeladen von

patel ketanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Forming

Hochgeladen von

patel ketanCopyright:

Verfügbare Formate

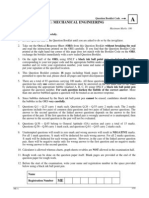

Forming Processes

Metal Forming/Press Operations

Forming processes are one of the most popular means of producing high volume products. Examples include appliance, aircraft, and automotive industries.

Major Reasons:

Production costs are low Well suited for high production applications Process capabilities Processes are built into tooling

GMP

Tools

One of the basic tools used in these processes is a punch & die.

A punch is the portion of the tool attached to the ram of the press and is inserted into the die. A die is usually the stationary portion of the tool attached to the press bed. It has a cavity to accept the punch.

GMP

Tools

Punch & die

GMP

Tools

A progressive die is a tool capable of performing several operations from raw material to final product. These dies can be made from catalog items and divided into removable sections.

GMP

Tools

Die alignment and clearance

Uniform clearance General rule - 5-7% material thickness

GMP

Tools

Punch & dies are capable of performing the following examples of cold working(CW) operations:

Blanking - cutting desired shape from strip, burrs left on strip Piercing - leaving desired shape on strip, burrs on scrap

GMP

Tools

Punch & die capabilities continued:

Forming & Bending Shearing Ironing Drawing

GMP

Process Capabilities

Blanking vs. Piercing

GMP

Tools

Forming & Bending

GMP

Tools

Shearing

GMP

Tools

Ironing

GMP

Process Capabilities

Drawing

GMP

Calculating Pressure for a Process (Tons)

General formula for a hole

Diameter of hole x Thickness of material x Ultimate Tensile Strength (UTS) = Pressure in Tons Guidelines

Mild Steel = 80 - 60,000 psi, Brass = 60,000 psi, Bronze = 40,000 psi, Copper = 30,000 psi Alum = 20,000 psi

Example

2 dia. hole in steel plate

2 x .250 x 80= 40 tons

GMP

Calculating Pressure for a Process (Tons)

General Formula - Profile

P= (L x 1/3) x material thickness x 60 (UTS) Example = Punch a 1x 2 rectangle in brass

P= (6 x 1/3) x .250 x 60 = 29.7 ~ 30 tons Machinerys Handbook 23rd Edition

GMP

Progressive Dies

GMP

Progressive Dies

GMP

Machine Tools- Presses

Classification

Manual

Foot operated

Light work -shearing

GMP

Machine Tools- Presses

Mechanical

Max pressure near bottom of stroke Faster motion Operations - cutting, shallow forming, drawing, and progressive die operations Limitation - length of stroke set by design of mechanism = less flexibility Capacities up to 6,000 tons

GMP

Machine Tools- Presses

Mechanical Press Drive Mechanisms

Crank = Simple design - used for piercing, blanking, and drawing operations Eccentric/Cam = Short ram stroke which provides a dwell a bottom of stroke Knuckle Fast action and high mechanical advantage Applications include coining and sizing Toggle = Drawing presses to move the blank holder Screw = Slow action

GMP

Machine Tools- Presses

Hydraulic

Motion as a result of piston motion = longer or variable stroke lengths can be programmed (within limitations of the piston). Steady pressure for operations such as deep drawing Single-slide Multiple-slide Capacities up to 50,000 tons

GMP

Machine Tools- Presses

Frame classification

Gap

Open arrangement of press frame Excellent clearance around dies Can handle long and wide parts

Arch

Lower portion of press near the bed is wide to accommodate large sheet material

GMP

Machine Tools- Presses

Frame classification continued:

Straight side

Strong frame designheavy loads are taken up in vertical direction of massive frame Less of a tendency for punch & die to misalign

Horn

Heavy shaft projecting from frame Used primarily for cylindrical work involving seaming, flanging, riveting, and embossing

GMP

Machine Tools- Presses

Frame classification continued:

Inclined

Vertical design can be tilted back to allow parts and scrap to slide out Used on parts involving bending, piercing, blanking, etc.

Turret Presses

Production of sheet metal parts having a variety of patterns, holes, cutouts, etc. in various sizes Current presses are CNC controlled and combined into machining centers, capable of laser, forming, and water-jet operations.

GMP

Machine Tools- Presses

Frame classification continued:

Four Slide

Complex forming of small to medium size parts Machine Basics 4-slides at 90 degrees controlled by cam to progressively move through a cycle to achieve a final part Can be tooled with punches, cut-off tools, lifting/shifting tools, and welding systems.

GMP

Machine Tools- Presses

Frame classification

GMP

Machine Tools- Presses

Accessories

GMP

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Handbook of Mechanical Engineering TermsDokument366 SeitenHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Hot Cold WorkingDokument40 SeitenHot Cold Workingpatel ketanNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Introduction To MetrologyDokument55 SeitenIntroduction To Metrologypatel ketan92% (36)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Heat Treatment Chapter 2Dokument24 SeitenHeat Treatment Chapter 2patel ketan100% (4)

- Jigs and FixturesDokument85 SeitenJigs and Fixturespatel ketan80% (15)

- CE ENG HL660,660L, HL665,665L AUG2018 Rev.0 WebDokument4 SeitenCE ENG HL660,660L, HL665,665L AUG2018 Rev.0 WebJohn LeonneNoch keine Bewertungen

- Mec281: Materials Science: Phase DiagramDokument74 SeitenMec281: Materials Science: Phase Diagrampatel ketan100% (1)

- Mechanical Objective by Upkar PublicationDokument108 SeitenMechanical Objective by Upkar Publicationpatel ketan100% (16)

- Gear IntroductionDokument17 SeitenGear Introductionpatel ketan100% (1)

- Lecture of CNC ProgramDokument29 SeitenLecture of CNC ProgramMargam Kiran KumarNoch keine Bewertungen

- Medical WaiverDokument1 SeiteMedical WaiverCheerBUNoch keine Bewertungen

- Linear MeasurementDokument144 SeitenLinear Measurementpatel ketan100% (2)

- OHS Policies and Guidelines (TESDA CSS NC2 COC1)Dokument1 SeiteOHS Policies and Guidelines (TESDA CSS NC2 COC1)Anonymous fvY2BzPQVx100% (2)

- EML3500 CH 4 SlidesDokument134 SeitenEML3500 CH 4 Slidespatel ketan100% (1)

- EML3500 CH 4 SlidesDokument134 SeitenEML3500 CH 4 Slidespatel ketan100% (1)

- Classic Text Messages Morning GreetingsDokument2 SeitenClassic Text Messages Morning GreetingsDhamukarthikeyanNoch keine Bewertungen

- Dye Penetrate TestDokument68 SeitenDye Penetrate Testpatel ketan92% (13)

- Cold FormingDokument25 SeitenCold Formingpatel ketan100% (3)

- Significant Ships 1993Dokument101 SeitenSignificant Ships 1993Joe TahirNoch keine Bewertungen

- DRILLING OPERATIONS GUIDEDokument18 SeitenDRILLING OPERATIONS GUIDEHeris SitompulNoch keine Bewertungen

- Shaping Grinding and Realated OperationsDokument26 SeitenShaping Grinding and Realated Operationspatel ketanNoch keine Bewertungen

- Slotting MachineDokument32 SeitenSlotting Machinepatel ketanNoch keine Bewertungen

- PPT of ShaperDokument59 SeitenPPT of Shaperpatel ketanNoch keine Bewertungen

- QpmeDokument16 SeitenQpmeSandeep PandeyNoch keine Bewertungen

- 6 Shearing StressesDokument26 Seiten6 Shearing Stressestigin100% (4)

- Fund Mech Eng SiemensDokument150 SeitenFund Mech Eng SiemensRafael Pacheco100% (2)

- BP-ConnectingRods 000Dokument114 SeitenBP-ConnectingRods 000patel ketanNoch keine Bewertungen

- Ed PresentationDokument302 SeitenEd Presentationpatel ketan100% (1)

- Level 2Dokument31 SeitenLevel 2patel ketanNoch keine Bewertungen

- Forgingforging ProcessDokument13 SeitenForgingforging Processpatel ketanNoch keine Bewertungen

- Gear Finishing MethodDokument9 SeitenGear Finishing Methodpatel ketan50% (2)

- GEARDokument13 SeitenGEARpatel ketan89% (9)

- Electrobeam MachiningDokument8 SeitenElectrobeam Machiningpatel ketan67% (3)

- CNCDokument23 SeitenCNCpatel ketanNoch keine Bewertungen

- Calibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Dokument16 SeitenCalibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Daniel Rolando Gutierrez FuentesNoch keine Bewertungen

- Module 4 NotesDokument20 SeitenModule 4 NotesvijaykumaryadavNoch keine Bewertungen

- 2010 Final Exam (Answers)Dokument10 Seiten2010 Final Exam (Answers)T FNoch keine Bewertungen

- ResearchDokument48 SeitenResearchCai De JesusNoch keine Bewertungen

- Willie Soon, Peter Frick, and Sallie BaliunasDokument4 SeitenWillie Soon, Peter Frick, and Sallie BaliunasMiguel CervantesNoch keine Bewertungen

- Hemera Creality CR10s Pro Upgrade Guide (Edition 1)Dokument24 SeitenHemera Creality CR10s Pro Upgrade Guide (Edition 1)gumushNoch keine Bewertungen

- Control Charts For Lognormal DataDokument7 SeitenControl Charts For Lognormal Dataanjo0225Noch keine Bewertungen

- Final AnswersDokument4 SeitenFinal AnswersAnshul SinghNoch keine Bewertungen

- Chowringhee - (Iisco House) Concept Encapsulation Session: The Oldest FIITJEE Centre in KolkataDokument12 SeitenChowringhee - (Iisco House) Concept Encapsulation Session: The Oldest FIITJEE Centre in KolkataHemendra PrasannaNoch keine Bewertungen

- Ethics PresentationDokument2 SeitenEthics PresentationAbhinavGuptaNoch keine Bewertungen

- The Monkey's PawThe Lady of The Barge and Others, Part 2. by Jacobs, W. W., 1863-1943Dokument20 SeitenThe Monkey's PawThe Lady of The Barge and Others, Part 2. by Jacobs, W. W., 1863-1943Gutenberg.orgNoch keine Bewertungen

- Disaster Readiness Exam SpecificationsDokument2 SeitenDisaster Readiness Exam SpecificationsRICHARD CORTEZNoch keine Bewertungen

- Advisory Note 11 ASFP Cell Beam RationaleDokument2 SeitenAdvisory Note 11 ASFP Cell Beam RationalePavaloaie Marian ConstantinNoch keine Bewertungen

- INCaDokument47 SeitenINCaMehdi SoltaniNoch keine Bewertungen

- The Ultimate Guide to Building an Engaged CommunityDokument24 SeitenThe Ultimate Guide to Building an Engaged CommunityCarla UttermanNoch keine Bewertungen

- 2d3d Opal Card Vending Machine ManualDokument40 Seiten2d3d Opal Card Vending Machine ManualbsimonopalNoch keine Bewertungen

- MY LIFE VISION, MISSION AND CORE VALUES BMEC 2W 2122Dokument4 SeitenMY LIFE VISION, MISSION AND CORE VALUES BMEC 2W 2122Nikolai Avery NorthNoch keine Bewertungen

- List of Syonoyms: Word Synonym SynonymDokument6 SeitenList of Syonoyms: Word Synonym SynonymPraveen KumarNoch keine Bewertungen

- Valve Type Trim Type CF XTDokument1 SeiteValve Type Trim Type CF XTAye KyweNoch keine Bewertungen

- Systems ClassDokument53 SeitenSystems ClassBhetariya PareshNoch keine Bewertungen

- Maintenance Manual - Booms: S Booms Z BoomsDokument185 SeitenMaintenance Manual - Booms: S Booms Z BoomsRafael Vieira De AssisNoch keine Bewertungen

- Cable Percussion Rig ChecksDokument2 SeitenCable Percussion Rig Checksargon39Noch keine Bewertungen

- UN 9252-06 Part 1-UD-AU-000-EB-00020 PDFDokument7 SeitenUN 9252-06 Part 1-UD-AU-000-EB-00020 PDFManjeet SainiNoch keine Bewertungen

- Children's Film in The Digital Age - Essays On Audience, Adaptation and Consumer Culture (PDFDrive)Dokument211 SeitenChildren's Film in The Digital Age - Essays On Audience, Adaptation and Consumer Culture (PDFDrive)Basia KowalskaNoch keine Bewertungen

- Department of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADDokument2 SeitenDepartment of Mechanical Engineering Polytechnic Sultan Haji Ahmad Shah Kuantan, Pahang DJJ 30122-CADAbdul MalikNoch keine Bewertungen