Beruflich Dokumente

Kultur Dokumente

STD Work Presentation (LQL)

Hochgeladen von

toyota952Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

STD Work Presentation (LQL)

Hochgeladen von

toyota952Copyright:

Verfügbare Formate

1

STANDARD WORK

2

TRAINING OBJECTIVES

Understand basics of Standard Work

Understand tools of Standard Work

Provide structured, consistent approach

to eliminate waste

Prepare for cell implementation, training

of associates & Value Stream Mapping

3

STANDARD WORK

Standard Work is a tool that defines

the interaction of a person and the

work area while performing work.

Standard Work details the motion of

the operator during the work process.

4

BASICS OF

STANDARD WORK

5

8 Types of Waste

Over Production

Waiting

Motion

Inventory

Transportation

Rework

Processing

Customers

Availability? Yield? Waiting?

Inventories? Re-work?

and people mis-utilization

6

3 DESIGN PRINCIPLES

Standard Work is a set of tools

to implement these principles.

1. TAKT - Rate of production required to

meet customer demand

2. FLOW - Smooth product flow with

minimum in-process inventory

Goal is 1 piece flow

Make flow visual

3. PULL - Produce what is needed, when it

is needed, in the amount it is needed

7

PULL

Suppliers

KCA

(Kit Consolidation Area)

1

2

3

PKA

(Part Kitting Area)

Suppliers

TEST

MODEL

B

MODEL

A

MODEL

A

TAKT TAKT

TAKT

FLOW

3 DESIGN PRINCIPLES

8

ELEMENTS OF WORK

Manual

^ Operator/mechanic hands-on activity

Automatic

^ Machine/equipment cycle

Walking

Delay

^ Holding or waiting to perform next

sequence

9

BENEFITS OF

STANDARD WORK

Documents the actual process

Targets areas above Takt Time

Tool for continuous improvement

Reduce inventory

Reduce lead time

Increase productivity

Standardize the work process

Increase capacity without increasing

resources

10

Takt Time

Work

Sequence

Standard

Work-In-Process

Components of

Standard Work

AFSxxxxx

Op10

Op20

Op30

11

TAKT TIME

Takt time is the time in which a unit

must be produced in order to match

the rate of customer demand.

Takt Time determines rate of production

Takt Time is subject to change every month

Total daily working time

Total daily customer demand

Takt Time =

11

12

AVAILABLE TIME EXAMPLE

Weekly 6S/TPM shutdown 120 24

Weekly QCPC meeting 60 12

Daily cleanup 75 15

Daily tool box meeting 25 5

Weekly

Time

Daily

Time

TOTAL 280 56 Min.

Available time for 2 crews = 2 x (480 - 56) = 848 min per day

13

TAKT TIME EXAMPLE

Average Daily Schedule = 100 units

# Working Minutes = 848

= 8.48 min/unit

Time available

Customer Demand

=

848 Min.

100 units

Takt Time =

Or

T/T = 8 minutes, 29 seconds

14

TAKT TIME, CYCLE TIME &

LEAD TIME

Takt Time = Rate of production to meet customer

demand

Cycle Time = Manual + walking + waiting time for

the operator to complete one cycle of work

sequence

Lead Time = Total time required for one unit to

complete entire process

= Total time for all operations + total

time in all inventories

15

WORK SEQUENCE

The order in which an operator performs manual operations

including walking and waiting.

Incoming

1

2

4

3

3

1

2

1

3

2

Operator A

Operator C

Operator B

Work sequence

1

2

3

4

5

6

7

8

9

10

Process Sequence

Outgoing

14

16

STANDARD WORK-IN-PROCESS

The minimum inventory required at each

workstation to support continuous flow and

meet customer demand (Takt).

Incoming

Outgoing

1

2

3

4

5

6

7

8

9

10

1 pc =

SWIP = 8

15

17

STANDARD WORK-IN-PROCESS

One-Piece Flow

Each work station or machine has

one piece (upstream and downstream

operations must be consideredcompare cycle times to Takt)

Minimum number of pieces

required for batch loads

(multiply by 2 to facilitate flow - see next page)

Auto time + unload/load time

Takt Time

Batch

Min. Batch Size =

18

BATCH OPERATIONS

Furnace

Auto Cycle = 480 Min.

(I ncludes load/unload)

T/T = 4 Min/pc

Auto time + load/unload time

Takt Time

480 Min.

4 Min/pc

(120 pieces)

Curtain

240 = Number of

SWIP for this furnace

Pull from this supply one

piece at a time for

return to one piece flow

Supply this side one

piece at a time

Batch Size =

= =

120 pcs

19

TOOLS OF STANDARD WORK

20

Standard

Work Tools

Time Observation

Chart

Standard

Work Sheet

Percent

Loading Chart

Standard Work Sheet

Scope of From Date prepared

Operations To or revised:

Quality Safety Standard Work- # of Pieces of Std. TAKT Cycle Operator

Check Precaution in-Process Work-in-Process Time Time Number

ELEMENT NO. ELEMENT TASK 1 2 3 4 5 TASK TIME NOTES ( M - W - A TIME)

USE BACK OF THIS PAGE

TO SKETCH WORKPLACE

P&W FORM 7837A REVISED 3/97

TIME OBSERVATION SHEET PAGE OF

PART NUMBER OPERATION NUMBER REV. LETTER SUM. LETTER

OPERATOR

PART NAME

DEPARTMENT NUMBER / NAME PREPARED BY

PCS / LOAD

OPERATION DESCRIPTION

DATE

BRASS TAG

MACHINE DESCRIPTION TIME

TOTAL

Process

Capacity Sheet

2

MACHINE CAPACITY BY PROCESS PAGE _____ OF ____

NEW / REVISED DATE

PART NUMBER DEPARTMENT NUMBER / NAME

PART NAME CURRENT DAILY OUTPUT AVAILABLE TIME MAXIMUM OUTPUT PER DAY

A B C D E F G H I J K

MACHINE PCS. / WALK MANUAL MANUAL AUTO TOTAL TIME/ PC TIMETO # PCS. TO TIME/ PC TOT / PC CALC. / REMARKS PROCESSCAPACITY

TASK # DESCRIPTION OF TASK NUMBER LOAD TIME INT EXT TIME (D + E) (F / A) CHANGE CHANGE (H / I ) (G+ J) (AVAI L. TI ME / K)

TOTAL NOTE: REVISE TIMES WHEN SIGNIFICANT IMPROVEMENTS ARE

INCORPORATED. DOCUMENT THE REASON IN THE

GRAND TOTAL "REMARKS" COLUMN.

Percent Load Chart

Operators

0

10

20

30

40

50

60

70

80

90

A B C D E

Operators

S

e

c

o

n

d

s

Walk

Manual External

Manual Internal

Walk

Manual External

Manual Internal

T/T

2 Shift

1 6

4

3

32

Operation

10

Operation

20

Operation

30

Operation

40

Auto

Manual

Walk

Wait

2 shift T/T = 37 sec

Time,

sec

50

38

38

30

STANDARD WORK COMBINATION SHEET (SWCS)

PART NUMBER OPERATION NUMBER REV. LETTER SUM. LETTER DATE TAKT TIME MANUAL

AUTOMATIC

WALK VVVVVVVVV

PART NAME DEPARTMENT NUMBER / NAME PREPARED BY WAIT

MAN.MACH.

STEP DESCRIPTION OF PCS / MAN

NO. TASK LOAD MACH MAN AUTO

TOTAL

TIME PER PIECE USE MINUTES PER PIECE FOR STANDARD WORK DATABASE

P&W F-7837 Revised 3/97

TASK TIME: 1 LINE = MINUTES SECONDS

WALK

Standard Work

Combination Sheet

5

Operations

Bar Chart

21

Old time observations

Guesstimates

Simulations

Time Observation

Establish Standard Work by observation

Multiple measures are recommended

2nd shortest observed time should be used

ELEMENT NO. ELEMENT TASK 1 2 3 4 5 TASK TIME NOTES ( M - W - A TIME)

USE BACK OF THIS PAGE

TO SKETCH WORKPLACE

P&W FORM 7837A REVISED 3/97

TIME OBSERVATION SHEET PAGE OF

PART NUMBER OPERATION NUMBER REV. LETTER SUM. LETTER

OPERATOR

PART NAME

DEPARTMENT NUMBER / NAME PREPARED BY

PCS / LOAD

OPERATION DESCRIPTION

DATE

BRASS TAG

MACHINE DESCRIPTION TIME

TOTAL

Std. Work begins with

time observation

22

E

L

E

M

E

N

T

N

O

.

E

L

E

M

E

N

T

T

A

S

K

1

2

3

4

5

T

A

S

K

T

I

M

E

N

O

T

E

S

(

M

-

W

-

A

T

I

M

E

)

U

S

E

B

A

C

K

O

F

T

H

I

S

P

A

G

E

T

O

S

K

E

T

C

H

W

O

R

K

P

L

A

C

E

P

&

W

F

O

R

M

7

8

3

7

A

R

E

V

I

S

E

D

3

/

9

7

T

I

M

E

O

B

S

E

R

V

A

T

I

O

N

S

H

E

E

T

P

A

G

E

O

F

P

A

R

T

N

U

M

B

E

R

O

P

E

R

A

T

I

O

N

N

U

M

B

E

R

R

E

V

.

L

E

T

T

E

R

S

U

M

.

L

E

T

T

E

R

O

P

E

R

A

T

O

R

P

A

R

T

N

A

M

E

D

E

P

A

R

T

M

E

N

T

N

U

M

B

E

R

/

N

A

M

E

P

R

E

P

A

R

E

D

B

Y

P

C

S

/

L

O

A

D

O

P

E

R

A

T

I

O

N

D

E

S

C

R

I

P

T

I

O

N

D

A

T

E

B

R

A

S

S

T

A

G

M

A

C

H

I

N

E

D

E

S

C

R

I

P

T

I

O

N

T

I

M

E

T

O

T

A

L

23

E L E M E N T

N O . E L E M E N T T A S K 1 2 3 4 5

T A S K T I M E

N O T E S ( M - W - A T I M E )

U S E B A C K O F T H I S P A G E

T O S K E T C H W O R K P L A C E

P & W F O R M 7 8 3 7 A R E V I S E D 3 / 9 7

T I M E O B S E R V A T I O N S H E E T P A G E O F

P A R T N U M B E R

O P E R A T I O N N U M B E R R E V . L E T T E R S U M . L E T T E R

O P E R A T O R

P A R T N A M E

D E P A R T M E N T N U M B E R / N A M E P R E P A R E D B Y

P C S / L O A D O P E R A T I O N D E S C R I P T I O N D A T E

B R A S S T A G M A C H I N E D E S C R I P T I O N T I M E

T O T A L

1. Fill in all

information

2. Observe operator

& record tasks

3. Record elapsed time

in upper square

-start at zero

4. Record task times

in lower square

5. Data accuracy increased through

multiple time observation

6. Use 2nd lowest

time for task

7. Record

Auto Times

Non repeatable Tasks

Observations

Opportunities for waste

reduction

8. Compute total times

0 0 0 0 0

24

2 Team Members per Observations:

1. Take 2 to 3 cycles to define the tasks. Make sure

you watch the same operator.

2. Once the tasks are well defined review with the

operator.

3. One person reads the watch the other observes

the tasks and calls out time when the task is

complete. Then he/she writes in the time on the

form

25

TIPS FOR TIME OBSERVATION

Fully understand and record work sequence

prior to timing

Keep watch running continuously

Stop the watch if operator work is

interrupted

Record time for tooling changes

Stop watch time observation is faster; video

is more accurate

Time observation should be conducted with

a proficient operator

26

Production Capacity

by Process

Part Process for

all parts in the cell

Operator time

(manual, walk, wait)

Machine time

*Automatic (untended)

*Tooling change & dressing cycles

Separates Manual

Work From

Automatic Work

1 2 3

6 5 4

27

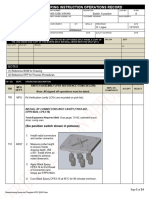

MACHINE CAPACITY BY PROCESS PAGE _____ OF ____

NEW / REVISED DATE

PART NUMBER DEPARTMENT NUMBER / NAME

PART NAME REQUIRED DAILY OUTPUT AVAILABLE TIME MAXIMUM OUTPUT PER DAY

A B C D E F G H I J K

MACHINE PCS. / WALK MANUAL MANUAL AUTO TOTAL TIME / PC TIME TO # PCS. TO TIME / PC TOT / PC CALC. / REMARKS PROCESS CAPACITY

TASK # DESCRIPTION OF TASK NUMBER LOAD TIME INT EXT TIME (D + E) (F / A) CHANGE CHANGE (H / I) (G + J) (AVAIL. TIME / K)

TOTAL NOTE: REVISE TIMES WHEN SIGNIFICANT IMPROVEMENTS ARE

INCORPORATED. DOCUMENT THE REASON IN THE

GRAND TOTAL "REMARKS" COLUMN.

28

MACHINE CAPACITY BY PROCESS PAGE _____ OF ____

NEW / REVISED DATE

PART NUMBER DEPARTMENT NUMBER / NAME

PART NAME REQUIRED DAILY OUTPUT AVAILABLE TIME MAXIMUM OUTPUT PER DAY

A B C D E F G H I J K

MACHINE PCS. / WALK MANUAL MANUAL AUTO TOTAL TIME / PC TIME TO # PCS. TO TIME / PC TOT / PC CALC. / REMARKS PROCESS CAPACITY

# Process Descritption NUMBER LOAD TIME INT EXT TIME (D + E) (F / A) CHANGE CHANGE (H / I) (G + J) (AVAIL. TIME / K)

TOTAL NOTE: REVISE TIMES WHEN SIGNIFICANT IMPROVEMENTS ARE

INCORPORATED. DOCUMENT THE REASON IN THE

GRAND TOTAL "REMARKS" COLUMN.

Record all information 1. Record all information

2. Record operations 3. Record operation times

Manual int = machine running

Manual ext = machine stopped

Auto time

4. Record tool changes

times

frequency

5. Compute

F - Total auto + ext. manual time

G - Total time per piece

J - Time per piece for tooling change

K - Total time per pc including tooling

tooling changes

6. Compute process capacity

Process capacity = Available

time per day / total time per pc

29

INTERNAL vs EXTERNAL

Manual Internal

Operator performs manual work

while machine is running.

Manual External

Operator performs manual work

while machine is stopped.

30

MACHINE CAPACITY BY PROCESS PAGE _____ OF ____

NEW / REVISED DATE 2/18/98

PART NUMBER DEPARTMENT NUMBER / NAME

PART NAME REQUIRED DAILY OUTPUT AVAILABLE TIME MAXIMUM OUTPUT PER DAY

840 Min.

A B C D E F G H I J K

MACHINE PCS. / WALK MANUAL MANUAL AUTO TOTAL TIME / PC TIME TO # PCS. TO TIME / PC TOT / PC CALC. / REMARKS PROCESS CAPACITY

TASK # DESCRIPTION OF TASK NUMBER LOAD TIME INT EXT TIME (D + E) (F / A) CHANGE CHANGE (H / I) (G + J) (AVAIL. TIME / K)

TOTAL NOTE: REVISE TIMES WHEN SIGNIFICANT IMPROVEMENTS ARE

INCORPORATED. DOCUMENT THE REASON IN THE

GRAND TOTAL "REMARKS" COLUMN.

770102 / 808302 / 808602

Blade

2643 Small Hollow - Front End

633pcs.

Brush

Mark

Chamfer

Vibratory Bowl

Polish

Wash

Plug Weld

QA Clear

1

2

3

4

5

6

7

8

1

1

1

1

1

1

40

20

2

3

2

0

1

0

0

26

30

18

0

0

0

0

0

8

6

8

56

13

46

74

13

66

19

17

0

27

0

0

90

74

25

25

56

40

46

74

103

74

25

25

56

40

46

74

103

60

30

360

180

0

30

180

10800

60

120

300

2000

0

300

300

6000

1

.25

1.2

.09

0

.1

.6

1.8

75

25.25

26.2

56.09

40

46.1

74.6

104.8

672

1996

1923

898

1260

1093

675

480

74 224 8

306

480pcs.

1

1

31

TIPS FOR CAPACITY SHEET

Do not include abnormal situations

- machine goes down

- set-up time (changeover) should not be included

Use caution in computing time per pc

- each task time needs to be reviewed prior to normalization

Enter process steps, not individual operator tasks

Available time is same as that used in Takt time calculation

32

Operations Bar

Chart

32

Operation

10

Operation

20

Operation

30

Operation

40

Auto

Manual

Walk

Wait

2 shift T/T = 37 sec

Time,

sec

50

38

38

30

Determine balance

between operations

32

Operation

10

Operation

20

Operation

30

Operation

40

Auto

Manual

Walk

Wait

2 shift T/T = 37 sec

Time,

sec

50

38

38

30

Assess each operation

vs Takt time

Identifies targets

for Kaizen

35

2 shift T/T

Operation

20

Time

Auto

Manual

Walk

Defines operator /

machine interaction

33

2 shift T/T

Operation

20

Put tasks in order

they are performed

Show each manual and auto task

Time

BAR CHART SHOWS

OPERATOR/MACHINE INTERACTION

Auto

Walk

Manual

34

Operation

10

Operation

20

Operation

30

Operation

40

Auto

Manual Internal

Walk

SAMPLE BAR CHART

2 shift T/T = 37 sec

Time,

sec

45

38

30

Manual External

17

15

13

14

3

13

11

13

11

27

25

5

12

35

Bar Chart

Operations

8

6

8

13

56

13

46

74

66

19

17

90

27

0

10

20

30

40

50

60

70

80

90

100

110

B

r

u

s

h

M

a

r

k

C

h

a

m

f

e

r

V

-

B

o

w

l

P

o

l

i

s

h

W

a

s

h

P

l

u

g

W

e

l

d

Q

A

C

l

e

a

r

Operations

S

e

c

o

n

d

s

Manual Internal

Automatic

Manual External

T/T

2 Shift

74

103

56

25

25

74

40

46

30

18

40 pcs

20 pcs

30

18

36

36

OPERATIONS BAR CHART TIPS

Terminology: BAR CHART, NOT % LOAD

Times should be same as on capacity sheet

Takt time must be in RED & mark # of shifts

Use color code as shown on sample

Put total time on top of bar

- show individual times inside of corresponding bar

Label operation by name not number

Work in seconds

Best practice: Show manual and auto in sequence

1st Bar Chart: Dont normalize times

2nd Bar Chart: Normalize for 1 pc flow

Indicate batch sizes on bar chart

37

Percent

Loading Chart

Identifies targets

for Kaizen

Compares cycle

time to Takt time

0

10

20

30

40

50

60

A B C D

Cycle Time

T/T

OPERATORS

T

I

M

E

Highlights bottlenecks

or available resources

1

Time n shift T/T

Operator

A

Operator

B

Operator

C

Operator

D

Operator

E

Manual

Walk

Wait

Determines balance &

distribution between operators

Load Chart

Date: Prepared By:

Title:

Takt Time:

Cycle Time:

Load Chart

Date: Prepared By:

Title:

Takt Time:

Cycle Time:

175 seconds

159 Seconds Sub Assembly Area 5, Widget 10005

2/14/02 Mr. Oliver Operator

25

50

75

100

125

150

175

200

225

Value Add

103 Sec.

NVA

56 Sec.

TT

Operator A

Load Chart

Date: Prepared By:

Title:

Takt Time:

Cycle Time:

175 seconds

159 Seconds Sub Assembly Area 5, Widget 10005

2/14/02 Mr. Oliver Operator

25

50

75

100

125

150

175

200

225

Value Add

103 Sec.

NVA

56 Sec.

TT

Value Add

110 Sec.

NVA

25 Sec.

Value Add

135 Sec.

NVA

75 Sec.

Operator A Operator B Operator C

Load Chart

Date: Prepared By:

Title:

Takt Time:

Cycle Time:

175 seconds

159 Seconds Sub Assembly Area 5, Widget 10005

2/14/02 Mr. Oliver Operator

25

50

75

100

125

150

175

200

225

.

.

TT

Station 1 Station 2(A) Station 3

.

.

Station 2(B) Station 4 Station 5

Load Chart

Date: Prepared By:

Title:

Takt Time:

Cycle Time:

175 seconds

159 Seconds Sub AssemblyArea 5, Widget 10005

2/14/02 Mr. Oliver Operator

25

50

75

100

125

150

175

200

225

.

.

TT

Station1 Station2(A) Station3

.

.

Station2(B) Station4 Station5

Load Chart Examples

43

SAMPLE OPERATOR PERCENT

LOAD CHART

Time

n shift T/T

Operator

A

Operator

B

Operator

C

Operator

D

Operator

E

Manual

Walk

Wait

# operators

per shift

Total CT

T/T

=

44

Percent Load Chart

Operators

34

26

56

46

74

2

2

36

13

3

13

0

10

20

30

40

50

60

70

80

90

A B C D E

Operators

S

e

c

o

n

d

s

Walk

Manual External

T/T

2 Shift

Manpower = Sum of Cycle Time = 306 = 4

Takt Time 79

46

74

70

41

75

45

OPERATOR PER CENT LOAD - TIPS

Takt time must be in red & # of shifts indicated

Use same color codes as bar chart

Put total time on top of bar & individual times inside

bar

Show manpower calculation

Kaizen improvements to balance CT to T/T

- Understand the existing operator balance

- 1st attack times that exceed T/T

- Reduce walking times & utilize waiting time

- Redistribute operator work to improve balance

T/T =

60

51

45

58

43

T/T =

60

60 60 60

12

A B C D A B C D

Kaizen

Eliminate with

Kaizen

46

JT9D INDUCTION EXAMPLE

0

10

20

30

40

T/T

Stations

T

I

M

E

Cycle Time

50

60

1) Transfer work from station

to station

2) Productivity Improvements

3) Add People

47

JT9D INDUCTION EXAMPLE

0

10

20

30

40

T/T

Stations

T

I

M

E

Cycle Time

50

60

48

STANDARD WORK

COMBINATION SHEET

Visually displays manual, walking,

and waiting time of mechanic

Captures the products cycle times;

assembly, disassembly, inspection,

balancing, etc.

Compares Cycle Time to Takt Time to

insure proper capacity - one per

mechanic

49

Standard Work

Combination sheet

Work sequence of the operator,

not the part process

Recognizes walking

time of operator

One per operator

Highlights idle time,

or potential shortfall

Machine cycle

time displayed

50

STANDARD WORK COMBINATION SHEET (SWCS)

PART NUMBER OPERATION NUMBER REV. LETTER SUM. LETTER DATE TAKT TIME MANUAL

AUTOMATIC

WALK VVVVVVVVV

PART NAME DEPARTMENT NUMBER / NAME PREPARED BY WAIT

STEP DESCRIPTION OF PCS / MAN -

NO. TASK LOAD MACH MAN AUTO

WALK

TOTAL

TIME PER PIECE

USE MINUTES PER PIECE FOR STANDARD WORK DATABASE

P&W F-7837 Revised 11/97

TASK TIME: 1 LINE = MINUTES SECONDS

WALK

CAP.

51

STANDARD WORK COMBINATION SHEET (SWCS)

PART NUMBER OPERATION NUMBER REV. LETTER SUM. LETTER DATE TAKT TIME MANUAL

AUTOMATIC

WALK VVVVVVVVV

PART NAME DEPARTMENT NUMBER / NAME PREPARED BY WAIT

STEP DESCRIPTION OF PCS / MAN -

NO. TASK LOAD MACH MAN AUTO

WALK

TOTAL

TIME PER PIECE

USE MINUTES PER PIECE FOR STANDARD WORK DATABASE

P&W F-7837 Revised 11/97

TASK TIME: 1 LINE = MINUTES SECONDS

WALK

1. Fill in information

For Std. Work

Measurement Only

2. Insert tasks from

time observation

3. Fill in time and

compute total time

4. Set scale based

on total time

5. Takt time is RED line

6. Graph according to legend

CAP.

52

STANDARD WORK COMBINATION SHEET (SWCS)

PART NUMBER OPERATION NUMBER REV. LETTER SUM. LETTER DATE OPERATOR MANUAL

AUTOMATIC

WALK VVVVVVVVV

PART NAME DEPARTMENT NUMBER / NAME PREPARED BY WAIT

STEP DESCRIPTION OF PCS / MAN -

NO. TASK LOAD MACH MAN AUTO

WALK

TOTAL

TIME PER PIECE

USE MINUTES PER PIECE FOR STANDARD WORK DATABASE

P&W F-7837 Revised 11/97

TASK TIME: 1 LINE = MINUTES SECONDS

WALK

2/18/98

79 Sec. A. Parker

2643 / Small Hollow F. End

770102

1

2

3

4

5

6

7

Load Part in Mask /Q.V.

Load / Unload Part

Gage

Q.V. / Go To Mark

Load / Unload Part

Input Variable

Use Camera

1

1

1

1

1

1

1

12

8

11

3

11

6

14

6

6

1

X

5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95

T/T

70

A

TAKT TIME

Q.V. / Put Down Part 8

1

5

2

3

19

5

< >

Blade

CAP.

53

STANDARD WORK COMBINATION

SHEET - TIPS

Takt time must be recorded in top section and line

drawn in RED

Walk is not a separate task

Human time (CT = Manual + Walk + Wait) must be

continuous

SWCS should be for operator

If auto time less than T/T graph auto time to T/T line &

wrap around

------------------ -------

SWCS can be multiple pages to show detailed operator

work sequence

Use broken scale for large imbalance of task times

Do not total the auto times

Line for CT of operator should be at approximately 45 deg

T/T

0

Manual Auto

54

Standard Work

Sheet

Quality

Checks

Safety

Precautions

Standard Work

in Process

Show Machine Layout,

People & Part Flow

1

2

3

4

5

6

55

Standard Work Sheet

Scope of From Date prepared

Operations To or revised:

Quality Safety Standard Work- # of Pieces of Std. TAKT Cycle Operator

Check Precaution in-Process Work-in-Process Time Time Number

56

Standard Work Sheet

Scope of From Date prepared

Operations To or revised:

Quality Safety Standard Work- # of Pieces of Std. TAKT Cycle Operator

Check Precaution in-Process Work-in-Process Time Time Number

1. Fill in process start & finish

2. Diagram layout for

work area/cell

3. Show operator work sequence

4. Show SWIP at each work

station & record total

5. Show where inspection occurs

6. Mark location for safety precaution

7. Insert T/T

8. Insert operator CT

9. Insert operator #

/ Total operators

57

Standard Work Sheet

Scope of From Date prepared

Operations To or revised:

Quality Safety Standard Work- # of Pieces of Std. TAKT Cycle Operator

Check Precaution in-Process Work-in-Process Time Time Number

QA

Clear

Plug

Weld

Wash Polish Deburr

Vibro

Bowl

Burn

Out

EDM Brush Chamfer

Incoming

Brush

QA Clear

79 Sec. 123

2/18/98

Mark

5 306

X 2

X

2

58

STANDARD WORK SHEET - TIPS

Work sequence must be numbered

Show return trip with dashed line (no value

added)

Indicates part leaving line

Heat Treat

Does not have to be to scale, but show

distances

Operator represented by

59

MANPOWER REQUIREMENTS

Manpower to work to maximum capacity

Total human work (cycle) time based on 1 pc

Total time per pc for slowest operation

Operators Needed

per shift

=

Barriers

Contractual obligations

Operator skills

Layout

Operator willingness

Manpower required to meet customer demand

Operators Needed

per shift

Takt Time

=

Total human work (cycle) time based on 1 pc

60

Time obs.

Process

Capacity

% Load

Std work sheet

SWCS

Operation

Bar Chart

Make

Improvements

IMPLEMENTATION OF STD WORK

61

SUMMARY

Basic principles of JIT manufacturing

Takt

Flow

Pull

Standard Work Components

Takt Time

Work Sequence

Standard Work-in-Process

Standard Work Tools

Time Observation Form

Capacity by Process

Bar Chart

Per Cent Loading

Standard Work Combination Sheet

Standard Work Sheet

62

ADDITIONAL TOOLS

63

P-Q Analysis BU 263 Cell#3

0

1250

2500

3750

5000

6250

7500

8750

10000

11250

12500

7

9

4

7

0

1

8

4

0

0

0

1

8

0

8

6

0

2

8

5

5

9

0

1

7

7

0

1

0

2

8

0

8

3

0

2

8

5

6

0

0

1

8

0

8

3

1

2

8

5

6

1

0

1

8

3

9

2

0

1

8

1

5

7

2

1

8

1

5

8

2

1

8

1

5

7

4

1

8

1

5

9

4

1

7

9

5

1

3

2

8

1

5

8

3

1

8

5

4

0

0

1

Q

u

a

n

i

t

y

0.00%

20.00%

40.00%

60.00%

80.00%

100.00%

120.00%

T

o

t

a

l

%

64

PROCESS MATRIX

Part #

Machine

Part

Type

Process

794701

840001

808602

856001

770102

BT 500526

Brush Mark Chamfer

Burn

Out

Vibra

Bowl

Polish Wash

Plug

Weld

Blade

Blade

Blade

Blade

Blade

2 3 4 5 6 7 8

1

1

2 3 4

1 2

3 4

5

1

1

2

2

3

3

4

4 5

BT 007936 BT 237909 BT 505300 BT 421789 BT 511893 BT 356432 BT 111233

** All numbers used are for illustration purposes only.

65

Part Number______________

Process at a Glance

Process

Sketch

Work

Methods

Measuring

Gages

Jig or

Fixture

Cutting

Tools

Machine

T

i

m

e

Manual

Machine

Setup

Takt Time______________

Comments:

66

Spaghetti Chart

Measures the travel distance of the products and the travel

distance of the operator in order to highlight unnecessary

travel waste.

PW4000 2nd STAGE HPT VANE

PROCESS CENTERS FLOW

7,992 FT

8 WEEK LEADTIME

BEFORE

NORTH HAVEN FACILITY - 1st Floor

1,117 FT

3 WEEK LEADTIME

AFTER

67

N2-FCU Assy / I2-Line (before)

A1 A2 A3 A4 A5 A6

A7

A8

A9

A12 A10 A11 A15 A14 A13

B3

B2

B1

C1

D1 D2

WIP

INSPECTION R/M

P.P BANDING M/C

CREW SIZE = 21

STANDARD WORK SUMMARY(C1)

68

69

70

71

72

* Collect Current Demand Data by Model

- Determine Available Time to Produce Demand

4 Establish TAKT Time

^ Collect Current Work Content Times

= Complete Standard Work Combination Sheet and Create Load Chart

= Eliminate Waste by Separating Value-added and Non-value-added Activities

Redistribute Work Content to Meet TAKT Time and Create New Load Chart

Establish Standard Work-in-process

Verify New Work Content Times and Redistribute Again as Necessary

O Establish Method Sheets for Each Operation to Document Standard Method

Steps to Implement Standard Work

73

74

75

N-2 FCU Assy / I 2 - Line (after)

A1

A2 A3

A4

A5 A6

A7

A8

A9 A12

A10 A11

A15 A14 A13

B3

B2

B1

D1

C1

WIP

INSPECTION R/M

P.P BANDING M/C

CREW SIZE = 11

STANDARD WORK SUMMARY(C2)

Das könnte Ihnen auch gefallen

- GM AbbreviationDokument410 SeitenGM Abbreviationnguyenbmtsv87% (15)

- Lead Time in Garment IndustyDokument13 SeitenLead Time in Garment IndustyPraveen Kumar IpsNoch keine Bewertungen

- Sales Order ProcessDokument42 SeitenSales Order Processjorge_r_souza100% (3)

- Work Measurement Time Study Worksheet (Continuous Method)Dokument1 SeiteWork Measurement Time Study Worksheet (Continuous Method)Hum92reNoch keine Bewertungen

- SQ Mark & 100ppm ChecklistDokument14 SeitenSQ Mark & 100ppm Checklistkarpags100% (2)

- Logistics Process DesignDokument53 SeitenLogistics Process DesignbasmaNoch keine Bewertungen

- Capacity Verification Run at Rate IpaDokument4 SeitenCapacity Verification Run at Rate IpaIram ChaviraNoch keine Bewertungen

- Aluminum Vs Steel in Passenger CarsDokument14 SeitenAluminum Vs Steel in Passenger Carstoyota952Noch keine Bewertungen

- Aluminum Vs Steel in Passenger CarsDokument14 SeitenAluminum Vs Steel in Passenger Carstoyota952Noch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Work Measurement Time Study WorksheetDokument1 SeiteWork Measurement Time Study WorksheetErdal TokatNoch keine Bewertungen

- Geometric Dimension and Tolerancing For Body in White Sheet MetalDokument115 SeitenGeometric Dimension and Tolerancing For Body in White Sheet Metaltoyota952100% (1)

- PDF Operators, With Code Specific For Level 3Dokument21 SeitenPDF Operators, With Code Specific For Level 3toyota952Noch keine Bewertungen

- Uptime 8 - Total Productive MaintenanceDokument38 SeitenUptime 8 - Total Productive Maintenancetoyota952Noch keine Bewertungen

- II. Capacity Planning: I. Key InformationDokument7 SeitenII. Capacity Planning: I. Key Informationqzm74lNoch keine Bewertungen

- Automotive Industry Cluster TPM Training Material Kobetsu Kaizen Step 0 - 1Dokument42 SeitenAutomotive Industry Cluster TPM Training Material Kobetsu Kaizen Step 0 - 1raghavendrarh6464Noch keine Bewertungen

- MagnoliaDokument21 SeitenMagnoliaJaevin Uy Baquiran75% (4)

- Car Parts BasicsDokument24 SeitenCar Parts Basicstoyota952Noch keine Bewertungen

- SOP Material ManagementDokument7 SeitenSOP Material Managementwasee99Noch keine Bewertungen

- Line Balancing PresentationDokument39 SeitenLine Balancing Presentationelmaakoul oussama67% (3)

- Thermal Power Plant: Pre-Operational ActivitiesVon EverandThermal Power Plant: Pre-Operational ActivitiesBewertung: 4 von 5 Sternen4/5 (4)

- Chapter 2 Problem Solving ToolsDokument67 SeitenChapter 2 Problem Solving ToolsDebrina PuspitariniNoch keine Bewertungen

- 5031-ASCP Training Manual v1.2Dokument87 Seiten5031-ASCP Training Manual v1.2Ranvijay KumarNoch keine Bewertungen

- Batches and MultithreadingDokument7 SeitenBatches and MultithreadingPriyanka RautNoch keine Bewertungen

- Kaizen FormsDokument14 SeitenKaizen FormsGubaziNoch keine Bewertungen

- GEOMETDokument4 SeitenGEOMETtoyota952Noch keine Bewertungen

- Assembly Line BalancingDokument17 SeitenAssembly Line BalancingHarshad_S50% (2)

- Run at Rate AuditDokument12 SeitenRun at Rate AuditPurushothama Nanje GowdaNoch keine Bewertungen

- Work Measurement Time Study Worksheet (Continuous Method) : Adobe Professional 7.0Dokument1 SeiteWork Measurement Time Study Worksheet (Continuous Method) : Adobe Professional 7.0Rohit AbhishekNoch keine Bewertungen

- Capacity VerificationDokument5 SeitenCapacity VerificationHarsha MP100% (2)

- A Practical Guide to Maintenance EngineeringVon EverandA Practical Guide to Maintenance EngineeringBewertung: 4 von 5 Sternen4/5 (6)

- SCM NotesDokument166 SeitenSCM Notesnandini_mba4870100% (1)

- 2a Piping Estimate & Summary ExampleDokument15 Seiten2a Piping Estimate & Summary ExampleRaymond MetselaarNoch keine Bewertungen

- Reduction of 7 WasteDokument20 SeitenReduction of 7 WasteMititelu Liviu100% (1)

- Standardized Work and Problem SolvingDokument34 SeitenStandardized Work and Problem Solvingjayeshjpillai100% (3)

- Lean Production: Week 4: StandardizationDokument34 SeitenLean Production: Week 4: StandardizationQuynh Chau TranNoch keine Bewertungen

- Slam TestDokument17 SeitenSlam Testtoyota952Noch keine Bewertungen

- Standarized Work PresentationDokument55 SeitenStandarized Work PresentationaenymaNoch keine Bewertungen

- Hemming ProcessDokument4 SeitenHemming Processtoyota952Noch keine Bewertungen

- Computer Aided Production ManagementDokument35 SeitenComputer Aided Production ManagementSameer AmjadNoch keine Bewertungen

- Lean Project ManagementDokument15 SeitenLean Project Managementaugusto5615Noch keine Bewertungen

- Research Project Report On Supply Chain ManagmentDokument111 SeitenResearch Project Report On Supply Chain ManagmentSakshi VermaNoch keine Bewertungen

- Executive Shirt Company - Group 6Dokument8 SeitenExecutive Shirt Company - Group 6Puneet Agarwal100% (1)

- Comparative Study of Supply Chain Management Offast Fashion Giants Zara HM 2Dokument12 SeitenComparative Study of Supply Chain Management Offast Fashion Giants Zara HM 2International Journal of Innovative Science and Research Technology100% (3)

- Takt Time: A Guide to the Very Basic Lean CalculationVon EverandTakt Time: A Guide to the Very Basic Lean CalculationBewertung: 5 von 5 Sternen5/5 (2)

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsVon EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Takt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsVon EverandTakt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsBewertung: 5 von 5 Sternen5/5 (1)

- Line Balance 059Dokument39 SeitenLine Balance 059smitaNoch keine Bewertungen

- Standard Work Combination Sheet: Part Number: Part Name: Operationtime (Inseconds)Dokument8 SeitenStandard Work Combination Sheet: Part Number: Part Name: Operationtime (Inseconds)Bhupinder Singh MakanNoch keine Bewertungen

- RPW Method Nov 2021Dokument24 SeitenRPW Method Nov 2021Ayesha RachhNoch keine Bewertungen

- FHcom Kaizen FormsDokument14 SeitenFHcom Kaizen FormsUrsula JohnsonNoch keine Bewertungen

- Thread Job Order Form For WorkshopDokument2 SeitenThread Job Order Form For WorkshopsourabhNoch keine Bewertungen

- Line Balance 059Dokument39 SeitenLine Balance 059Sonam SinghNoch keine Bewertungen

- Process AnalysisDokument32 SeitenProcess Analysisur23095Noch keine Bewertungen

- Basic Kaizen ToolsDokument14 SeitenBasic Kaizen ToolsDaffa HanifNoch keine Bewertungen

- Form Penilaian Praktek Periodic Service PC 200-8M0: No Langkah Kerja Nilai Keterangan 0 1 2 3Dokument2 SeitenForm Penilaian Praktek Periodic Service PC 200-8M0: No Langkah Kerja Nilai Keterangan 0 1 2 3Adi PriyantoNoch keine Bewertungen

- Emad 21522379 Type A KWH PDFDokument8 SeitenEmad 21522379 Type A KWH PDFEMAD ABDULRAHMAN ABDULLAH HASAN MASHRAH -Noch keine Bewertungen

- L2 Machinist Tech Unit 005 Handfitting Centering Tool Job Pack 2 2021 VersionDokument11 SeitenL2 Machinist Tech Unit 005 Handfitting Centering Tool Job Pack 2 2021 VersionMark LovettNoch keine Bewertungen

- L2 Machinist Tech Unit 005 Handfitting Centering Tool Job Pack 1 2021 VersionDokument12 SeitenL2 Machinist Tech Unit 005 Handfitting Centering Tool Job Pack 1 2021 VersionMark LovettNoch keine Bewertungen

- Industrial Engineering Laboratory ManualDokument27 SeitenIndustrial Engineering Laboratory ManualsatishNoch keine Bewertungen

- TELabDokument121 SeitenTELabSrinu ReddyNoch keine Bewertungen

- PPC Unit - 4Dokument29 SeitenPPC Unit - 4TEJAANAND PEGUDANoch keine Bewertungen

- Plant Layout and Workstation DesignDokument13 SeitenPlant Layout and Workstation DesignVishal ChoudharyNoch keine Bewertungen

- Ijeit1412201203 45 PDFDokument4 SeitenIjeit1412201203 45 PDFSathish SigamaniNoch keine Bewertungen

- Chapter ThreeDokument8 SeitenChapter ThreeEndashaw YohannesNoch keine Bewertungen

- Chapter 5 - Scheduling ManagementDokument70 SeitenChapter 5 - Scheduling Managementhani adliNoch keine Bewertungen

- Mts Charts Complete OriginalDokument12 SeitenMts Charts Complete OriginalFerlyn Joy Elomina GonzalesNoch keine Bewertungen

- Lakshmi Precision Screws Ltd. Plant-Ii Rohtak: Control PlanDokument6 SeitenLakshmi Precision Screws Ltd. Plant-Ii Rohtak: Control PlanArvinda KumarNoch keine Bewertungen

- Charts Used in Method StudyDokument13 SeitenCharts Used in Method StudyAnonymous 3rajW3TK9Noch keine Bewertungen

- WSAD Course SummaryDokument16 SeitenWSAD Course SummaryAbdulwahab AlmaimaniNoch keine Bewertungen

- Short Keys and Formulas of ExcelDokument40 SeitenShort Keys and Formulas of ExcelSattar CANoch keine Bewertungen

- Line BalancingDokument5 SeitenLine Balancingsaravananpg8697Noch keine Bewertungen

- KPPF Reliability Data Collection Sheet April 2013Dokument34 SeitenKPPF Reliability Data Collection Sheet April 2013Hervé EKOMINoch keine Bewertungen

- Assembly Line BalancingDokument17 SeitenAssembly Line BalancingHarshad_SNoch keine Bewertungen

- Vis 11Dokument6 SeitenVis 11mg_catanaNoch keine Bewertungen

- EKUPROYTRDokument8 SeitenEKUPROYTRNaila HasanNoch keine Bewertungen

- Lean Manufacturing: Supplier Stage 1 Stage 2 SupplierDokument15 SeitenLean Manufacturing: Supplier Stage 1 Stage 2 SupplierAnkit GuptaNoch keine Bewertungen

- 2 Herkansing PM 18 Mei 2016 Met Uitwerking Aangepast Voor CanvasDokument8 Seiten2 Herkansing PM 18 Mei 2016 Met Uitwerking Aangepast Voor CanvasKarim SalehNoch keine Bewertungen

- Mi565 5208 3 RohsDokument14 SeitenMi565 5208 3 RohsTomás Daniel Cueto GuzmánNoch keine Bewertungen

- Layover Insp SCHD Issue 01 Rev 01 (Leap)Dokument17 SeitenLayover Insp SCHD Issue 01 Rev 01 (Leap)Gurunath PhadkeNoch keine Bewertungen

- Guidelines For OperationsDokument5 SeitenGuidelines For OperationsYassine LachhabNoch keine Bewertungen

- OM - Case - Analysis - Donner Company Case ReportDokument8 SeitenOM - Case - Analysis - Donner Company Case Reportpusparghya pakrasiNoch keine Bewertungen

- SIMPTWW PSV C12aDokument4 SeitenSIMPTWW PSV C12aVijay RajaindranNoch keine Bewertungen

- Indian Timber Manual PDFDokument84 SeitenIndian Timber Manual PDFtoyota952100% (1)

- Cost and Breakeven AnalysisDokument42 SeitenCost and Breakeven Analysistoyota952Noch keine Bewertungen

- Indian Timber ManualDokument84 SeitenIndian Timber Manualtoyota952Noch keine Bewertungen

- Henrob Self Piercing RivetsDokument20 SeitenHenrob Self Piercing Rivetstoyota952Noch keine Bewertungen

- Spot WeldingDokument8 SeitenSpot Weldingtoyota952Noch keine Bewertungen

- STD Work Presentation (LQL)Dokument75 SeitenSTD Work Presentation (LQL)toyota952Noch keine Bewertungen

- Continuous Improvement For Libraries: Session NineDokument58 SeitenContinuous Improvement For Libraries: Session Ninetoyota952Noch keine Bewertungen

- Welcome: Training Programme On Statistical Process ControlDokument36 SeitenWelcome: Training Programme On Statistical Process Controltoyota952Noch keine Bewertungen

- SPC Study Activity No. 1.3.11Dokument1 SeiteSPC Study Activity No. 1.3.11toyota952Noch keine Bewertungen

- Manufacturing Systems - Lesson 2Dokument27 SeitenManufacturing Systems - Lesson 2Atanu MandalNoch keine Bewertungen

- Donderwinkel MA BMSDokument87 SeitenDonderwinkel MA BMSSivakumar LakshminarayananNoch keine Bewertungen

- Mol 5Dokument42 SeitenMol 5pardianaivanNoch keine Bewertungen

- Re-Engineering Global Supply ChainsDokument22 SeitenRe-Engineering Global Supply ChainsVioleta SalampasiNoch keine Bewertungen

- Supply Chain MeasuresDokument9 SeitenSupply Chain MeasuresMANOHAR SIVVALA 20111632Noch keine Bewertungen

- Takt Time Cycle Time ThrougputDokument9 SeitenTakt Time Cycle Time ThrougputjiteshthakkarNoch keine Bewertungen

- Module 3 Unit 19Dokument75 SeitenModule 3 Unit 19raden gurnandaNoch keine Bewertungen

- Availability Check (ATP) and Transfer of Requirement (TOR) - ERP Operations - SCN WikiDokument3 SeitenAvailability Check (ATP) and Transfer of Requirement (TOR) - ERP Operations - SCN WikiNikhil RaviNoch keine Bewertungen

- Schlage Price Book 2012Dokument394 SeitenSchlage Price Book 2012Security Lock DistributorsNoch keine Bewertungen

- InventorymanualDokument133 SeitenInventorymanualArti MongaNoch keine Bewertungen

- VCPProfile PTFDokument27 SeitenVCPProfile PTFGops989Noch keine Bewertungen

- SC Performance and Achieving Strategic Fit 2Dokument63 SeitenSC Performance and Achieving Strategic Fit 2Srinivasan MastiNoch keine Bewertungen

- Time Fence ControlDokument3 SeitenTime Fence ControlnsabnisNoch keine Bewertungen

- Material ManagementDokument9 SeitenMaterial ManagementDeepakNoch keine Bewertungen

- Availability Date Can Be Calculated in Two WaysDokument1 SeiteAvailability Date Can Be Calculated in Two WaysSandeep KumarNoch keine Bewertungen

- Gaither Capitulo 14Dokument48 SeitenGaither Capitulo 14leandrop7Noch keine Bewertungen

- Plant Maximum Capacity (Tons) Cost Per Ton: Case 1Dokument4 SeitenPlant Maximum Capacity (Tons) Cost Per Ton: Case 1HEM BANSALNoch keine Bewertungen