Beruflich Dokumente

Kultur Dokumente

Atex Standards For Explosion Prevention

Hochgeladen von

bappabatliboiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Atex Standards For Explosion Prevention

Hochgeladen von

bappabatliboiCopyright:

Verfügbare Formate

EXPLOSION PROTECTION IN DEDUSTING PLANTS

BETH Filtration GmbH 2008 . Seite 2

BETHPULS Bag Filter prototype explosions pressure test

Explosion pressure shock resistant design in combination with explosion pressure venting

BETH Filtration GmbH 2008 . Seite 3

BETHPULS Bag Filter prototype explosions pressure test

Explosion pressure shock resistant design in combination with explosion pressure venting Photo page 2

Place of testing: Bergbau Versuchsstrecke / Dortmund Derne Kind of dust Dust explosion class Vessel volume Vent area Reduced explosion pressure Number of tests Max. explosion overpressure : Lignite ( 500 g / m3 ) : St 1 : 22 m3 : 2 m2 : 1.18 bar ( 0.18 bar overpressure ) : 36 : 0.44 bar

BETH Filtration GmbH 2008 . Seite 4

Explosion Protection in Dedusting Plants

Dedusting plants are in operation for the

collection and separation of dust. Consideration different kind of dust in dedusting plants concerning the applications and industrys For example: Wood, wood products Food, grain, cereal Coal, coal products Secondary fuel Plastic, rubber Chemical products, Metal etc.

BETH Filtration GmbH 2008 . Seite 5

Explosion Protection in Dedusting Plants

Vattenfall Europe Mining AG dedusting of the actual largest lignite mill of world

Source of dust Type of dust Capacity of the mill Bulk density dust Dust capacity Raw gas volume Operating temperature Dew point Raw gas dust content Operating pressure

: Vertical roller mil : Lignite : 88 t/h : 0.35 0.5 t/m3 : max. 293.3 m3/h : max. 150,000 Am3/h : 55 80C (short peaks 100C) : 30.9C : max. 587 g/m3 : - 45 mbar (rawgas inlet filter)

BETH Filtration GmbH 2008 . Seite 6

Explosion Protection in Dedusting Plants

Vattenfall Europe Mining AG dedusting of the actual largest lignite mill of world BETHPULS Bag Filter 6.90x10.7.20 (double line)

BETH Filtration GmbH 2008 . Seite 7

Explosion Protection in Dedusting Plants

Vattenfall Europe Mining AG dedusting of the actual largest lignite mill of world BETHPULS Bag Filter 6.90x10.7.20 (double line)

Filter type : BETHPULS 6.90x10.7.20 Operation method : On-line Number of filter bags : 900 Dimensions filter bags : 160 x 5,200 mm Filter cloth : PEAC 600 Si Filtering surface area : 2,400 m2 Air to cloth ratio : max. 1.044 m3/m2 x min Admissible operating pressure: - 140 mbar Main dimensions filter : 7.28 m x 10.2 m x 12.4 m

BETH Filtration GmbH 2008 . Seite 8

Explosion Protection in Dedusting Plants

Vattenfall Europe Mining AG dedusting of the actual largest lignite mill of world BETHPULS Bag Filter 6.90x10.7.20 (double line) Dust characteristics Kind of dust Dust explosion class KSt- value Explosion overpressure pmax Lignite St 1 150 bar x m x s-1 9.0 bar

Protective measures

Prevention of effective ignition sources Explosion pressure shock resistant Explosion venting Venting device Number / size Disengagement

up to1.4 bar according VDI 3673 BETH Explosion doors 16 / 0.53m2per each Diverter/rotary valves

BETH Filtration GmbH 2008 . Seite 9

Explosion Protection in Dedusting Plants

Defination of dust according VDI 3677 part 1 = Particle < 500 m This definition of dust are also valid in the explosion protection VDI 2263 Dust Fires and Dust Explosions Hazards Assessment Protective Measures Exception: Flock = Short staples which are generated by cutting endless fibers, grinding etc. Length: 0,5 2,5 mm Weight:0,5 bis 22 dtex = gram / 10 km fiber lenght Source: BMFT Band 64 Humanisierung des Arbeitslebens

BETH Filtration GmbH 2008 . Seite 10

Explosion Protection in Dedusting Plants

For the Recognition of Hazards according DIN EN 1127-1 Explosive atmospheres Explosion prevention and protection Part 1: Basic concepts and methodology German version EN 1127-1 : 1997 in dedusting plants and the required Analysis of Hazards is it very important to know Safety Characteristics of Dust ( Burning and Explosion Behaviour )

BETH Filtration GmbH 2008 . Seite 11

Explosion Protection in Dedusting Plants

Burning and Explosion Characteristics of Dust according BIA report 12/97 and / or BIA data bank GESTIS-STAUB-EX or tests according VDI 2263 Part 1 Test Methods for die Determination of the Safety Characteristic of Dust through authorize test / proof institute

BETH Filtration GmbH 2008 . Seite 12

Explosion Protection in Dedusting Plants

A dust explosion is possible when the hazard triangle is closed

Ignition source

Oxygen

Explosive dust Dust content in air higher the explosive limits ( lower dust concentration ) Oxygen concentration in the dust/air mixture higher limiting concentration Effective ignition source

BETH Filtration GmbH 2008 . Seite 13

Explosion Protection in Dedusting Plants

Safety Characteristics of Dust and the Explosion Hazards

are content of the

Explosion Protection Document according article 8 Directive 1999/92/EG ( ATEX 137 ) Responsible for the safety Consideration Example : Operating management of the plant : National law : Germany Betriebssicherheitsverordnung BetrSichV 6 BGR 104 ( alt ZH 1 / 10 ) Explosionsschutz-Regeln Regeln fr das Vermeiden der Gefahren durch explosionsfhige Atmosphre mit Beispielsammlung E 6

BETH Filtration GmbH 2008 . Seite 14

Explosion Protection in Dedusting Plants

Possible parts of a dedusting plant can be

Inertial separators Filtering separators Electrostatic precipitators Wet separator

if required in combination including

VDI 3676 VDI 3677 VDI 3678 VDI 3679

Ducts with all parts Fans, silencer Discharge devices ( rotary valves etc. ) Screw conveyors Silos etc All parts of the dedusting must be consider for the recognition of Explosion Hazards

BETH Filtration GmbH 2008 . Seite 15

Explosion Protection in Dedusting Plants

Consideration and assessment of the different separator types

Example:

Filtering separators acc. VDI 3677 Part 1 Bag filters, Envelope filters ( pocket ), Cartridge filters, Candle filters, Laef filters

Arrangement filter elements: Operation:

Vertical or horizontal Suction or pressure Regeneration divices

BETH Filtration GmbH 2008 . Seite 16

Explosion Protection in Dedusting Plants

Typical examples of dedusting plants 1.) Bag filter for mill dedusting

Rawgas Cleangas

: Ducts, cyclone, bag filter, screw conveyor, rotary valves : Bag filter, ducts, fan, silencer, stack

BETH Filtration GmbH 2008 . Seite 17

Explosion Protection in Dedusting Plants

Typical examples of dedusting plants 1.) Object dedusting combination cylone bag filter

Rawgas Cleangas

: Ducts, cyclone, bag filter, rotary valves : Bag filter, ducts, fan, silencer, stack

BETH Filtration GmbH 2008 . Seite 18

Explosion Protection in Dedusting Plants

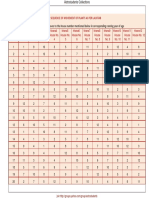

All parts of the dedusting plant must be consider and a assessment in zones is required: 0, 1 and 2 for gas 20, 21 and 22 for dust

Consideration of the location and installation of the dedusting plant. A influence of zones through apparatus etc. they are no part of the dedusting plant, but they are installed in the near of the dedusting plant, is possible and to consider by the selection and installation of the required protective measures.

Analysis of Hazards Explosion Protection Document Plant operating management supplier of the plant

BETH Filtration GmbH 2008 . Seite 19

Explosion Protection in Dedusting Plants

Protective Measures

Possibilities of Explosion Protection Measures:

Preventive and through Design Measures Preventive:

Prevention of Explosible Dust/Air Mixtures

Prevention of Dust Explosions through Inerting Prevention of Effective Ignition Sources

BETH Filtration GmbH 2008 . Seite 20

Explosion Protection in Dedusting Plants

Protective Measures Design Measures:

Explosion pressure resistant design for the max. explosion pressure Explosion pressure resistant design in combination with explosion venting (pressure relief) Explosion pressure resistant design in combination with explosion suppression Explosion Disengagement, Explosion Interruption

Explosion resistant:

Pressure resistant Pressure shock resistant = Safety factor 1.5 = Safety factor 1.0

BETH Filtration GmbH 2008 . Seite 21

Explosion Protection in Dedusting Plants

BETHPULS Bag Filter prototype explosions pressure test

Clean gas housing Venting openings for rupture disks or Explosion doors

Raw gas housing

Hopper

Screw conveyor

Stage of erection

BETH Filtration GmbH 2008 . Seite 22

Explosion Protection in Dedusting Plants

BETHPULS Bag Filter prototype explosions pressure test

Flames pressure

Hazards during the venting process in surrounding areas outside p red 0.53 bar g p red 0.64 bar g

BETH Filtration GmbH 2008 . Seite 23

Explosion Protection in Dedusting Plants

BETHPULS Bag Filter prototype explosions pressure test

Raw gas housing: Side panels End panels Hopper: End panels Side panels

Note: The result of incorrect sizing and design in particular concerning pressure shock resistance, flame tightness, calculation of venting area, venting devices (explosion doors, rupture disks), venting efficiency, explosion values of dust etc is the same

Result of exceeding the existing explosion pressure shock resistance damaged filter housing by p red 0.75 bar g

BETH Filtration GmbH 2008 . Seite 24

Explosion Protection in Dedusting Plants

EC suitability test of BETH explosion door according directive 94/9/EC (ATEX 95)

Beginning of the venting process

End of the venting explosion door closed

During venting process explosion door open pressure und flame propagation outside

BETH Filtration GmbH 2008 . Seite 25

Explosion Protection in Dedusting Plants

Certificate EC suitability test BETH explosion door according directive 94/9/EC

BETH Filtration GmbH 2008 . Seite 26

Explosion Protection in Dedusting Plants

Required QS certificates to supply EC suitability tested BETH explosion door acc 94/9/EC

BETH Filtration GmbH 2008 . Seite 27

Explosion Protection in Dedusting Plants

Scheme of execution examples of explosion protected filters proofed by notified body

BETH Filtration GmbH 2008 . Seite 28

Explosion Protection in Dedusting Plants

BETH diverter based of the VDI report 701 (real execution) test of disengagement by a notified body

Test field stage of erection

BETH Filtration GmbH 2008 . Seite 29

Explosion Protection in Dedusting Plants

BETH diverter based of the VDI report 701 (real execution) test of disengagement by a notified body

Cover fixed in the cage

Pressure and flame

Diverter DN 1000 Disengagement process during the test

Ductwork DN 1000

BETH Filtration GmbH 2008 . Seite 30

Explosion Protection in Dedusting Plants

Possible Design Measures by Example Plant Item 1.) 1.) Object dedusting combination cylone bag filter

Protective Measure Item 3 Vessel: Explosion pressure restistant design in combination with explosion venting (pressure relief) or explosion suppression. Explosion pressure resistant design for the maximum explosion pressure

BETH Filtration GmbH 2008 . Seite 31

Explosion Protection in Dedusting Plants

Example BETHPULS Bag Filter for Dedusting secondary fuel bunker

Diverter for explosion disengagement in the raw gas ductwork

Clean gas channel and duct

Vent duct behind the explosion flaps

BETHPULS Bag Filter Explosion pressure shock resistant 1.4 bar with explosion venting Fan

BETH Filtration GmbH 2008 . Seite 32

Explosion Protection in Dedusting Plants

Example BETHPULS Bag Filter for Dedusting secondary fuel bunker Dust characteristics Kind of dust Dust explosion class KSt- value Explosion overpressure pmax Protective measures Prevention of effective ignition sources Explosion pressure shock resistant Explosion venting Venting device Disengagement Wood etc. St 1 200 bar x m x s-1 10 bar

up to1.4 bar according VDI 3673 BETH Explosion flaps BETH diverter/rotary valve

BETH Filtration GmbH 2008 . Seite 33

Explosion Protection in Dedusting Plants

Example BETHPULS Bag Filter for Dedusting plant for aluminium powder

Duct cyclone to bag filter

Clean gas duct

Raw gas duct Bag filter

Cyclone outlet Cyclone inlet

Cyclone

Cylindrical BETPULS bag filter in combination with cyclone

BETH Filtration GmbH 2008 . Seite 34

Explosion Protection in Dedusting Plants

Example BETHPULS Bag Filter for Dedusting plant for aluminium powder Dust characteristics Kind of dust Dust explosion class KSt- value Explosion overpressure pmax Lower explosible limit Protective measures Prevention of effective ignition sources Explosion pressure shock resistant up to11.0 bar Disengagement raw gas side Rapid action valve clean gas side Rapid protection valve Overspraypowder St 2 259 bar x m x s-1 9.9 bar 60 g/m3

BETH Filtration GmbH 2008 . Seite 35

Explosion Protection in Dedusting Plants

Example BETHPULS Bag Filter for Dedusting a fuel-mixture preparation Clean gas duct Water-spray system Explosion flaps Bag filter Diverter with raw gas duct Maintenance platforms

Bag filter

Fan, silencer, and stack

BETHPULS Single-line bag filter protected by preventive and design measures

BETH Filtration GmbH 2008 . Seite 36

Explosion Protection in Dedusting Plants

Example BETHPULS Bag Filter for Dedusting a fuel-mixture preparation Dust characteristics Kind of dust Dust explosion class KSt- value Explosion overpressure pmax Protective measures Secondary fuel (house waste, wood) St 1 77 bar x m x s-1 7.0 bar

Prevention of effective ignition sources Explosion pressure shock resistant Explosion venting Venting device Disengagement

up to1.4 bar according VDI 3673 BETH Explosion flaps BETH diverter/rotary valve

BETH Filtration GmbH 2008 . Seite 37

Explosion Protection in Dedusting Plants

Conclusion Correct operation according the range of use The operation of explosion protected dedusting plants is only permissible with material and safety characteristics according the documentation of the plant ( operating instructions, data sheet etc. ) Analysis of Hazards Explosion Protection Document

Maintenance acc. the service manual of the supplier Observance of the maintenance cylce time acc. service manual

By no consideration is the dedusting plant in operation not safe Dust explosion and the damaging of the plant is possible. Danger for employees with all consequences for health and life

BETH Filtration GmbH 2008 . Seite 38

Explosion Protection in Dedusting Plants

Example of damaged bag filter through a dust explosion of lignite

Reason: Operating mistake, no maintenance acc. instructions Material change ( dust with higher safety characteristics )

BETH Filtration GmbH 2008 . Seite 39

Explosion Protection in Dedusting Plants

Example of damaged bag filter through a dust explosion of lignite

Reason: Operating mistake, no maintenance acc. instructions Material change ( dust with higher safety characteristics )

BETH Filtration GmbH 2008 . Seite 40

THANKS FOR YOUR ATTENTION

Peter Stender Senior Engineer BETHFiltration GmbH

BETH Filtration GmbH Borsigstrae 8 23560 Lbeck DEUTSCHLAND Fon +49 451 5307-500 Fax +49 7151 5307-600 info@beth-filter.de www.beth-filter.de

BETH Filtration (Schweiz) AG Balz-Zimmermannstrae 7 CH-8302 Kloten SCHWEIZ Fon +41 438133-380 Fax +41 438133-382 info@beth-filter.ch www.beth-filter.ch

WEIS ENVIRONMENTAL LLC Niederlassung USA 4445 Malone Road P.O. Box 181070 Memphis, TN 38118 USA Fon +1 901 531 6081 Fax +1 901 531 6085 info@weis-environmental.com www.weis-environmental.com

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Air Forces 2016Dokument12 SeitenAir Forces 2016bappabatliboi100% (6)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Chapter 2 Axial and Torsional ElementsDokument57 SeitenChapter 2 Axial and Torsional ElementsAhmad FaidhiNoch keine Bewertungen

- DLP - CO#1-for PandemicDokument4 SeitenDLP - CO#1-for PandemicEvelyn CanoneraNoch keine Bewertungen

- Audio File SizeDokument2 SeitenAudio File SizebappabatliboiNoch keine Bewertungen

- MIUI 6 ManualDokument53 SeitenMIUI 6 ManualbappabatliboiNoch keine Bewertungen

- Biomass Cofiring - New Challenges For ESPDokument6 SeitenBiomass Cofiring - New Challenges For ESPbappabatliboiNoch keine Bewertungen

- Paper 3A1 PDFDokument13 SeitenPaper 3A1 PDFavmurugan87Noch keine Bewertungen

- Tips To Improve PC Performance in Windows 10 - Windows HelpDokument19 SeitenTips To Improve PC Performance in Windows 10 - Windows HelpbappabatliboiNoch keine Bewertungen

- Farthest Galaxy Known in The Universe SpottwsDokument2 SeitenFarthest Galaxy Known in The Universe SpottwsbappabatliboiNoch keine Bewertungen

- AOSmith Hse Ses - LeafletDokument2 SeitenAOSmith Hse Ses - LeafletbappabatliboiNoch keine Bewertungen

- Gas Cleaning Efficiency Requirements For Different PollutantsDokument5 SeitenGas Cleaning Efficiency Requirements For Different PollutantsbappabatliboiNoch keine Bewertungen

- Pickup Velocity For Pneumatic ConveyingDokument2 SeitenPickup Velocity For Pneumatic ConveyingbappabatliboiNoch keine Bewertungen

- Book 1Dokument4 SeitenBook 1bappabatliboiNoch keine Bewertungen

- CRC Press Math CatalogueDokument116 SeitenCRC Press Math CataloguebappabatliboiNoch keine Bewertungen

- Samsung Universal Print Driver 2 - User's GuideDokument15 SeitenSamsung Universal Print Driver 2 - User's GuidebappabatliboiNoch keine Bewertungen

- DSD Database - Sheet1Dokument2 SeitenDSD Database - Sheet1bappabatliboiNoch keine Bewertungen

- 1962 10468053Dokument5 Seiten1962 10468053bappabatliboiNoch keine Bewertungen

- Super Audio CD Player With Usb-Dac: WWW - Marantz.EuDokument2 SeitenSuper Audio CD Player With Usb-Dac: WWW - Marantz.EubappabatliboiNoch keine Bewertungen

- Toshiba DVD RecorderDokument2 SeitenToshiba DVD RecorderbappabatliboiNoch keine Bewertungen

- Marantz Whitepaper PC-Audio NA-11S1Dokument13 SeitenMarantz Whitepaper PC-Audio NA-11S1bappabatliboiNoch keine Bewertungen

- DSD Database - Sheet1Dokument2 SeitenDSD Database - Sheet1bappabatliboiNoch keine Bewertungen

- Ipad User GuideDokument135 SeitenIpad User Guidehdave32Noch keine Bewertungen

- 1962 10468053Dokument5 Seiten1962 10468053bappabatliboiNoch keine Bewertungen

- Installation WinESP DemoDokument4 SeitenInstallation WinESP DemobappabatliboiNoch keine Bewertungen

- Irdac Manual Sh255 e F D N Es R 2Dokument12 SeitenIrdac Manual Sh255 e F D N Es R 2bappabatliboiNoch keine Bewertungen

- Abhishek Steel Industries LTD.: Ganga Steel Re-RollingDokument14 SeitenAbhishek Steel Industries LTD.: Ganga Steel Re-RollingbappabatliboiNoch keine Bewertungen

- State Bank of Ndia: Aper TokeDokument1 SeiteState Bank of Ndia: Aper TokebappabatliboiNoch keine Bewertungen

- Belkin Surge ProtectorDokument2 SeitenBelkin Surge ProtectorbappabatliboiNoch keine Bewertungen

- Easeus Partition Master User GuideDokument33 SeitenEaseus Partition Master User Guideamineki7639Noch keine Bewertungen

- Operation & Maintenance Instructions For Electrostatic PrecipitatorDokument3 SeitenOperation & Maintenance Instructions For Electrostatic PrecipitatorbappabatliboiNoch keine Bewertungen

- Scan - V. CardDokument1 SeiteScan - V. CardbappabatliboiNoch keine Bewertungen

- Sta404 07Dokument71 SeitenSta404 07Ibnu Iyar0% (1)

- All Papers of Thermodyanmics and Heat TransferDokument19 SeitenAll Papers of Thermodyanmics and Heat TransfervismayluhadiyaNoch keine Bewertungen

- Chapter 07Dokument16 SeitenChapter 07Elmarie RecorbaNoch keine Bewertungen

- 2021 Bookmatter BasicSciencesOfNuclearMedicineDokument12 Seiten2021 Bookmatter BasicSciencesOfNuclearMedicineBeatriz MartinhoNoch keine Bewertungen

- S010T1Dokument1 SeiteS010T1DUCNoch keine Bewertungen

- 05-11 Trainer Interview QuestionsDokument8 Seiten05-11 Trainer Interview QuestionsqulaityNoch keine Bewertungen

- Quemador BrahmaDokument4 SeitenQuemador BrahmaClaudio VerdeNoch keine Bewertungen

- Gilbert Cell Design PDFDokument22 SeitenGilbert Cell Design PDFvysNoch keine Bewertungen

- Sample File: The Ultimate Adventurers Guide IDokument6 SeitenSample File: The Ultimate Adventurers Guide IDingusbubmisNoch keine Bewertungen

- Introduction To The Iceberg ModelDokument5 SeitenIntroduction To The Iceberg ModelAbhay Tiwari100% (1)

- ECON 401/601, Microeconomic Theory 3/micro 1: Jean Guillaume Forand Fall 2019, WaterlooDokument3 SeitenECON 401/601, Microeconomic Theory 3/micro 1: Jean Guillaume Forand Fall 2019, WaterlooTarun SharmaNoch keine Bewertungen

- A Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Dokument292 SeitenA Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Jonathan MannNoch keine Bewertungen

- Slipform Construction TechniqueDokument6 SeitenSlipform Construction TechniqueDivyansh NandwaniNoch keine Bewertungen

- RHB Islamic Bank BerhadDokument2 SeitenRHB Islamic Bank BerhadVape Hut KlangNoch keine Bewertungen

- Aquinas Five Ways To Prove That God Exists - The ArgumentsDokument2 SeitenAquinas Five Ways To Prove That God Exists - The ArgumentsAbhinav AnandNoch keine Bewertungen

- BS 07533-3-1997Dokument21 SeitenBS 07533-3-1997Ali RayyaNoch keine Bewertungen

- 1974 - Roncaglia - The Reduction of Complex LabourDokument12 Seiten1974 - Roncaglia - The Reduction of Complex LabourRichardNoch keine Bewertungen

- Catálogo StaubliDokument8 SeitenCatálogo StaubliJackson BravosNoch keine Bewertungen

- Lalkitab Varshphal Chart PDFDokument6 SeitenLalkitab Varshphal Chart PDFcalvinklein_22ukNoch keine Bewertungen

- Question BankDokument3 SeitenQuestion BankHimanshu SharmaNoch keine Bewertungen

- Research Paper On N Queen ProblemDokument7 SeitenResearch Paper On N Queen Problemxvrdskrif100% (1)

- FmatterDokument12 SeitenFmatterNabilAlshawish0% (2)

- 2SA1016Dokument4 Seiten2SA1016catalina maryNoch keine Bewertungen

- Barack ObamaDokument3 SeitenBarack ObamaVijay KumarNoch keine Bewertungen

- Dady - Piernas LargasDokument12 SeitenDady - Piernas LargasSarha NietoNoch keine Bewertungen

- Yumemiru Danshi Wa Genjitsushugisha Volume 2Dokument213 SeitenYumemiru Danshi Wa Genjitsushugisha Volume 2carldamb138Noch keine Bewertungen

- Jarir IT Flyer Qatar1Dokument4 SeitenJarir IT Flyer Qatar1sebincherianNoch keine Bewertungen

- Electromechani Cal System: Chapter 2: Motor Control ComponentsDokument35 SeitenElectromechani Cal System: Chapter 2: Motor Control ComponentsReynalene PanaliganNoch keine Bewertungen