Beruflich Dokumente

Kultur Dokumente

Thermal Stress

Hochgeladen von

gaspardo123Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thermal Stress

Hochgeladen von

gaspardo123Copyright:

Verfügbare Formate

Mechanics of Deformable Bodies

COURSE CONTENT IN

BRIEF

6. Simple stresses and strains

7. Statically indeterminate problems and thermal stresses

8. Stresses on inclined planes

9. Stresses due to fluid pressure in thin cylinders

The subject strength of materials deals with the relations

between externally applied loads and their internal effects on

bodies. The bodies are no longer assumed to be rigid and the

deformations, however small, are of major interest

Alternatively the subject may be called the mechanics of solids.

The subject, strength of materials or mechanics of materials

involves analytical methods for determining the strength ,

stiffness (deformation characteristics), and stability of various

load carrying members.

6. Simple stresses and strains

GENERAL CONCEPTS

STRESS

No engineering material is perfectly rigid and hence,

when a material is subjected to external load, it

undergoes deformation.

While undergoing deformation, the particles of the

material offer a resisting force (internal force). When

this resisting force equals applied load the equilibrium

condition exists and hence the deformation stops.

These internal forces maintain the externally applied

forces in equilibrium.

Stress = internal resisting force / resisting cross sectional

area

The internal force resisting the deformation per unit area is

called as stress or intensity of stress.

STRESS

A

R

=

gigapascal, 1GPa = 110

9

N/m

2

= 110

3

MPa

= 110

3

N/mm

2

SI unit for stress

N/m

2

also designated as a pascal (Pa)

Pa = N/m

2

kilopascal, 1kPa = 1000 N/m

2

megapascal, 1 MPa = 110

6

N/m

2

= 110

6

N/(10

6

mm

2

) = 1N/mm

2

1 MPa = 1 N/mm

2

STRESS

AXIAL LOADING NORMAL STRESS

Consider a uniform bar of cross

sectional area A, subjected to a

tensile force P.

Consider a section AB normal to

the direction of force P

Let R is the total resisting force

acting on the cross section AB.

Then for equilibrium condition,

R = P

Then from the definition of stress,

normal stress = = R/A = P/A

P

P

P

R

B

A

R

P

STRESS

= Normal Stress

Symbol:

Direct or Normal

Stress:

AXIAL LOADING NORMAL STRESS

Intensity of resisting force perpendicular to or normal

to the section is called the normal stress.

Normal stress may be tensile or compressive

Tensile stress: stresses that cause pulling on the surface of

the section, (particles of the materials tend to pull apart

causing extension in the direction of force)

Compressive stress: stresses that cause pushing on the

surface of the section, (particles of the materials tend to push

together causing shortening in the direction of force)

STRESS

The resultant of the internal forces for

an axially loaded member is normal

to a section cut perpendicular to the

member axis.

A

P

A

F

ave

A

=

A

A

=

A

o o

0

lim

The force intensity on that section is

defined as the normal stress.

STRESS

Illustrative Problems

A composite bar consists of an aluminum section

rigidly fastened between a bronze section and a steel

section as shown in figure. Axial loads are applied at

the positions indicated. Determine the stress in each

section.

Bronze

A= 120 mm

2

4kN

Steel

A= 160 mm

2

Aluminum

A= 180 mm

2

7kN

2kN

13kN

300mm

500mm

400mm

Q 6.1

To calculate the stresses, first determine the forces in

each section.

For equilibrium condition algebraic sum of forces on

LHS of the section must be equal to that of RHS

4kN

7kN

2kN

13kN

To find the Force in bronze section,

consider a section bb

1

as shown in the figure

Bronze

b

b

1

Bronze

4kN

7kN

2kN

13kN

13kN

2kN

7kN

Bronze

4kN

4kN

Force acting on Bronze section is 4kN, tensile

Stress in Bronze

section =

Force in Bronze section

Resisting cross sectional area of the Bronze section

=

2

2 2

/ 33 . 33

120

1000 4

120

4

mm N

mm

N

mm

kN

=

= = 33.33MPa

(Tensile stress)

(= )

b

1

b

4kN

7kN

2kN

13kN

2kN

7kN

Aluminum

9kN

Force in Aluminum section

Force acting on Aluminum section is 9kN,

(Compressive)

4kN

13kN

Aluminum

(= )

4kN

7kN

2kN

13kN

7kN

steel

7kN

Force in steel section

Force acting on Steel section is 7kN, ( Compressive)

4kN

2kN

13kN

steel

Stress in Steel section =

Force in Steel section

Resisting cross sectional area of the Steel section

=

2

2 2

/ 75 . 43

160

1000 7

160

7

mm N

mm

N

mm

kN

=

= = 43.75MPa

Stress in Aluminum

section =

Force in Al section

Resisting cross sectional area of the Al section

=

2

2 2

/ 50

180

1000 9

180

9

mm N

mm

N

mm

kN

=

= = 50MPa

(Compressive stress)

Compressive stress

STRAIN

STRAIN :

when a load acts on the material it will undergo

deformation. Strain is a measure of deformation produced by

the application of external forces.

If a bar is subjected to a direct load, and hence a stress, the

bar will changes in length. If the bar has an original length L

and change in length by an amount L, the linear strain

produced is defined as,

L

L o

c =

Original length

Change in length

=

Strain is a dimensionless quantity.

Linear strain,

Linear Strain

strain normal

stress

= =

= =

L

A

P

o

c

o

L

A

P

A

P

o

c

o

=

= =

2

2

L L

A

P

o o

c

o

= =

=

2

2

STRESS-STRAIN DIAGRAM

In order to compare the strength of various materials it is

necessary to carry out some standard form of test to establish

their relative properties.

One such test is the standard tensile test in which a circular

bar of uniform cross section is subjected to a gradually

increasing tensile load until failure occurs.

Measurement of change in length over a selected gauge

length of the bar are recorded throughout the loading

operation by means of extensometers.

A graph of load verses extension or stress against strain is

drawn as shown in figure.

STRESS-STRAIN DIAGRAM

Typical tensile test curve for mild steel

Proportionality limit

STRESS-STRAIN DIAGRAM

Typical tensile test curve for mild steel showing upper yield point

and lower yield point and also the elastic range and plastic range

Limit of Proportionality :

From the origin O to a point called proportionality limit the

stress strain diagram is a straight line. That is stress is

proportional to strain. Hence proportional limit is the maximum

stress up to which the stress strain relationship is a straight

line and material behaves elastically.

From this we deduce the well known relation, first postulated

by Robert Hooke, that stress is proportional to strain.

Beyond this point, the stress is no longer proportional to strain

A

P

P

P

= o

Load at proportionality limit

Original cross sectional area

=

Stress-strain Diagram

Elastic limit:

It is the stress beyond which the material will not return to its

original shape when unloaded but will retain a permanent

deformation called permanent set. For most practical purposes

it can often be assumed that points corresponding proportional

limit and elastic limit coincide.

Beyond the elastic limit plastic deformation occurs and strains

are not totally recoverable. There will be thus some permanent

deformation when load is removed.

A

P

E

E

= o

Load at proportional limit

Original cross sectional area

=

Stress-strain Diagram

Yield point:

It is the point at which there is an appreciable elongation or

yielding of the material without any corresponding increase of

load.

A

P

Y

Y

= o

Load at yield point

Original cross sectional area

=

Stress-strain Diagram

Ultimate strength:

It is the stress corresponding to

maximum load recorded during

the test. It is stress corresponding

to maximum ordinate in the

stress-strain graph.

A

P

U

U

= o

Maximum load taken by the material

Original cross sectional area

=

Rupture strength (Nominal Breaking stress):

It is the stress at failure.

For most ductile material including structural steel breaking

stress is somewhat lower than ultimate strength because the

rupture strength is computed by dividing the rupture load

(Breaking load) by the original cross sectional area.

A

P

B

B

= o

load at breaking (failure)

Original cross sectional area

=

True breaking stress =

load at breaking (failure)

Actual cross sectional

area

Stress-strain Diagram

The capacity of a material to allow these large plastic

deformations is a measure of ductility of the material

After yield point the graph becomes much more shallow and

covers a much greater portion of the strain axis than the

elastic range.

Ductile Materials:

The capacity of a material to allow large extension i.e. the

ability to be drawn out plastically is termed as its ductility.

Material with high ductility are termed ductile material.

Example: Low carbon steel, mild steel, gold, silver, aluminum

Stress-strain Diagram

Stress-strain Diagram

Percentage elongation

A measure of ductility is obtained by measurements of the

percentage elongation or percentage reduction in area,

defined as,

increase in gauge length (up to fracture)

original gauge length

100

Percentage reduction in

area original area

100

=

=

Reduction in cross sectional area

of necked portion (at fracture)

Cup and cone fracture for a Ductile

Material

Stress-strain Diagram

Brittle Materials :

A brittle material is one which exhibits relatively small

extensions before fracture so that plastic region of the tensile

test graph is much reduced.

Example: steel with higher carbon content, cast iron,

concrete, brick

Stress-strain diagram for a typical brittle material

HOOKES LAW

Hookes Law

For all practical purposes, up to certain limit the relationship

between normal stress and linear strain may be said to be

linear for all materials

Thomas Young introduced a constant of proportionality that

came to be known as Youngs modulus.

stress () strain ()

stress ()

strain ()

=

constant

stress ()

strain ()

=

E

Modulus of Elasticity

Youngs Modulus

=

or

HOOKES LAW

Youngs Modulus is defined as the ratio of normal stress to

linear strain within the proportionality limit.

From the experiments, it is known that strain is always a very

small quantity, hence E must be large.

For Mild steel, E = 200GPa = 210

5

MPa = 210

5

N/mm

2

stress ()

strain ()

= E

=

L A

PL

L

L

A

P

o

o

=

The value of the Youngs modulus is a definite property of a

material

Deformations Under Axial Loading

AE

P

E

E = = =

o

c c o

From Hookes Law:

From the definition of strain:

L

o

c =

Equating and solving for the

deformation,

AE

PL

= o

With variations in loading, cross-

section or material properties,

=

i i i

i i

E A

L P

o

A specimen of steel 20mm diameter with a gauge length of

200mm was tested to failure. It undergoes an extension of

0.20mm under a load of 60kN. Load at elastic limit is

120kN. The maximum load is 180kN. The breaking load is

160kN. Total extension is 50mm and the diameter at

fracture is 16mm. Find:

a) Stress at elastic limit

b) Youngs modulus

c) % elongation

d) % reduction in area

e) Ultimate strength

f) Nominal breaking stress

g) True breaking stress

Q.6.2

Solution:

a) Stress at elastic limit,

E

=

Load at elastic limit

Original c/s area

MPa

mm

N

mm

kN

A

P

E

97 . 381 97 . 381

16 . 314

120

2

2

= = = =

b) Youngs Modulus,

GPa

MPa

mm

N

mm

mm

mm

kN

L

L

A

P

E

98 . 190

190980

190980

10 1

98 . 190

200

20 . 0

16 . 314

60

2

3

2

=

=

=

= = = =

o

c

o

(consider a load which is within the elastic

limit)

c) % elongation,

% elongation =

Final length at fracture original length

Original length

% 25 100

200

50

= =

d) % reduction in area =

% 36 100

16 . 314

4

16

16 . 314

2

=

=

t

Original c/s area -Final c/s area at fracture

Original c/s area

e) Ultimate strength,

Ultimate strength =

Maximum load

Original c/s area

) (

/ 96 . 572

16 . 314

180

2

2

MPa

mm N

mm

kN

= =

f) Nominal breaking

Strength =

MPa

kN

29 . 509

16 . 314

160

= =

Breaking load

Original c/s area

g) True breaking

Strength =

MPa

mm

kN

38 . 795

06 . 201

160

2

= =

Breaking load

c/s area at fracture

A composite bar consists of an aluminum section rigidly

fastened between a bronze section and a steel section as

shown in figure. Axial loads are applied at the positions

indicated. Determine the change in each section and the

change in total length. Given

E

br

= 100GPa, E

al

= 70GPa, E

st

= 200GPa

Bronze

A= 120 mm

2

4kN

Steel

A= 160 mm

2

Aluminum

A= 180 mm

2

7kN

2kN

13kN

300mm

500mm

400mm

Q.6.3

From the Example 1, we know that,

P

br

= +4kN (Tension)

P

al

= -9kN (Compression)

P

st

= -7kN (Compression)

stress ()

strain ()

=

E

=

L A

PL

o

=

AE

PL

L = o Change in length =

Change in length of

bronze =

) / ( 10 100 120

300 4000

2 3 2

mm N mm

mm N

L

br

= o

= 0.1mm

Deformation due to

compressive force is

shortening in length, and is

considered as -ve

= + +

st al br

L L L o o o

Change in total

length =

Change in length of

steel section =

) / ( 10 200 160

500 7000

2 3 2

mm N mm

mm N

L

st

= o

= -0.109mm

Change in length of

aluminum section =

) / ( 10 70 180

400 9000

2 3 2

mm N mm

mm N

L

al

= o

= -0.286mm

+0.1 0.286 - 0.109

= -0.295mm

An aluminum rod is fastened to a steel rod as

shown. Axial loads are applied at the positions

shown. The area of cross section of aluminum and

steel rods are 600mm

2

and 300mm

2

respectively.

Find maximum value of P that will satisfy the

following conditions.

a)

st

140 MPa

b)

al

80 MPa

c)Total elongation 1mm,

2P

Steel

Aluminum

2P

4P

2.8m

0.8m

Q.6.4

Take E

al

= 70GPa,

E

st

= 200GPa

To find P, based on the condition,

st

140 MPa

Stress in steel must be less than or equal to 140MPa.

Hence,

st

=

= 140MPa

st

st

A

P

=

2P

Steel

Aluminum

2P

4P

4P

2P

2P

2P

2P

2

/ 140

2

mm N

A

P

st

= =

kN N

A

P

st

21 21000

2

140

= =

=

Tensile

To find P, based on the condition,

al

80 MPa

Stress in aluminum must be less than or equal to

80MPa.

Hence,

al

=

= 80MPa

al

al

A

P

=

2P

Steel

Aluminum

2P

4P

4P

2P

2P

2P

2P

2

/ 80

2

mm N

A

P

al

= =

kN N

A

P

al

24 24000

2

80

= =

=

Compressive

To find P, based on the condition, total elongation 1mm

Total elongation = elongation in aluminum + elongation in

steel.

st al

AE

PL

AE

PL

|

.

|

\

|

+

|

.

|

\

|

=

|

|

.

|

\

|

+

+

|

|

.

|

\

|

=

st st

st

al al

al

E A

PL

E A

PL 2 2

|

.

|

\

|

+

+

|

.

|

\

|

=

3 3

10 200 300

2800 2

10 70 600

800 2 P P

1mm

1mm

1mm

P = 18.1kN

Ans: P = 18.1kN (minimum of the three values)

Q.6.5

Derive an expression for the total extension of the tapered bar

of circular cross section shown in the figure, when subjected to

an axial tensile load , W

W

W

A

B

L

Diameter

d

1

Diameter

d

2

Consider an element of length, x at a distance x from A

B

W W

A

x

d

1

d

2

d

x

Diameter at x,

( )

x

L

d d

d

+ =

1 2

1

c/s area at x,

( )

2

1

2

1

4

4

kx d

d

+ = =

t

t

x k d + =

1

Change in length over a

length dx is

( )

|

|

|

|

.

|

\

|

+

=

|

.

|

\

|

=

E kx d

Wdx

AE

PL

dx

2

1

4

t

Change in length over a

length L is

( )

}

|

|

|

|

.

|

\

|

+

=

L

E kx d

Wdx

0

2

1

4

t

Consider an element of length, x at a distance x from A

Put d

1

+kx = t,

Then k dx = dt

Change in length over a

length L is

( )

}

|

|

|

|

.

|

\

|

+

=

L

E kx d

Wdx

0

2

1

4

t

( )

}

|

|

|

|

.

|

\

|

=

L

E t

k

dt

W

0

2

4

t

L

L

L

kx d Ek

W

t Ek

W t

Ek

W

0

1 0

0

1 2

) (

1 4 1 4

1

4

(

=

(

=

(

=

+

t t t

E

d d

WL

d Ed

WL

= =

4

4

2 1

2 1

t

t

Q.6.6

A two meter long steel bar is having uniform diameter of 40mm

for a length of 1m, in the next 0.5m its diameter gradually

reduces to 20mm and for remaining 0.5m length diameter

remains 20mm uniform as shown in the figure. If a load of

150kN is applied at the ends, find the stresses in each section

of the bar and total extension of the bar. Take E = 200GPa.

500mm

= 40mm

= 20mm

150kN

150kN

500mm

1000mm

500mm

= 40mm

= 20mm

150kN

150kN

500mm

1000mm

If we take a section any where along the length of the bar, it is

subjected to a load of 150kN.

2

1

3

MPa

kN

MPa

kN

MPa

kN

d

kN

MPa

kN

46 . 477

4

20

150

46 . 477

4

20

150

37 . 119

4

40

150

4

150

37 . 119

4

40

150

2

3

2

min. 2,

2

. max , 2

2

2

2

1

= =

= =

= = =

= =

t

o

t

o

t

o

t

o

t

o

500mm

= 40mm

= 20mm

150kN

150kN

500mm

1000mm

If we take a section any where along the length of the bar, it is

subjected to a load of 150kN.

2

1

3

( )

( )

mm

E

kN

l

mm

E

kN

d Ed

PL

l

mm

E

kN

l

194 . 1

4

20

500 150

597 . 0

20 40

500 150 4 4

597 . 0

4

40

1000 150

2

3

2 1

2

2

1

=

=

=

= =

=

=

t

o

t t

o

t

o

mm l 388 . 2 total, = o

Q.6.7

Derive an expression for the total extension of the tapered bar

AB of rectangular cross section and uniform thickness, as

shown in the figure, when subjected to an axial tensile load ,W.

W

W

A

B

L

d

1

d

2

b

b

W W

A

B

x

d

1

d

2

b

b

dx

Consider an element of length, x at a distance x from A

depth at x,

( )

x

L

d d

d

+ =

1 2

1

c/s area at x,

( )b kx d + =

1

x k d + =

1

Change in length over a

length dx is

( )

|

|

.

|

\

|

+

=

|

.

|

\

|

=

E b kx d

Wdx

AE

PL

dx 1

Change in length over a

length L is

( )

} |

|

.

|

\

|

+

=

L

E b kx d

Wdx

0

1

( )

1 2

log log d d

k E b

P

e e

=

( )

( )

1 2

1 2

log log

302 . 2

d d

d d E b

L P

=

Q.6.8

Derive an expression for the total extension produced by self

weight of a uniform bar, when the bar is suspended vertically.

L

Diameter

d

P

1

x

P

1

= weight of the bar below

the section,

= volume specific weight

= ( d

2

/4) x

= A x

Diameter

d

dx dx

element

Extension of

the element

due to weight

of the bar

below that,

AE

dx x A

AE

dx P

AE

PL

dx

) (

1

= =

(

=

The above expression

can also be written as

Hence the total extension

entire bar

E

L

E

x

AE

dx x A

L

L

2 2

) (

2

0

2

0

=

(

=

=

}

AE

PL

AE

L AL

A

A

E

L

=

= =

2

1

2

) (

2

2

Where, P = (AL)

= total weight of the bar

SHEAR STRESS

Consider a block or portion of a material shown in Fig.(a)

subjected to a set of equal and opposite forces P. then there is a

tendency for one layer of the material to slide over another to

produce the form failure as shown in Fig.(b)

P

The resisting force developed by any plane ( or section) of the

block will be parallel to the surface as shown in Fig.(c).

P

Fig. a Fig. b Fig. c

P

P

R

R

The resisting forces acting parallel to the surface per unit area is

called as shear stress.

Shear stress ()

=

Shear resistance

Area resisting shear

If block ABCD subjected to shearing stress as shown in

Fig.(d), then it undergoes deformation. The shape will not

remain rectangular, it changes into the form shown in Fig.(e),

as AB

'

C'D.

B

Fig. d

Shear strain

A

P

=

This shear stress will always be tangential to the area on which

it acts

D

C

A

B'

D

C'

A

B

C

Fig. e

The angle of deformation is measured in radians and hence

is non-dimensional.

D

B' C'

A

Fig. e

B

C

| | ~ =

'

= tan strain shear

AB

B B

|

The angle of deformation is then termed as shear strain

|

Shear strain is defined as

the change in angle

between two line element

which are originally right

angles to one another.

SHEAR MODULUS

For materials within the proportionality limit the shear strain is

proportional to the shear stress. Hence the ratio of shear stress

to shear strain is a constant within the proportionality limit.

For Mild steel, G= 80GPa = 80,000MPa = 80,000N/mm

2

Shear stress ()

Shear strain ()

= constant

=

The value of the modulus of rigidity is a definite property

of a material

G

Shear Modulus

or

Modulus of Rigidity

=

example: Shearing Stress

Forces P and P are applied

transversely to the member AB.

A

P

=

ave

t

The corresponding average shear stress is,

The resultant of the internal shear

force distribution is defined as the

shear of the section and is equal to

the load P.

Corresponding internal forces act in

the plane of section C and are

called shearing forces.

The shear stress distribution cannot be

assumed to be uniform.

State of simple shear

Force on the face AB = P = AB t

Consider an element ABCD in a strained material

subjected to shear stress, as shown in the figure

Where, t is the thickness of the

element.

A

B

C D

Force on the face DC is also equal to

P

P

State of simple shear

The element is subjected

to a clockwise moment

Now consider the equilibrium of the element.

(i.e., Fx = 0, Fy = 0, M = 0.)

P AD = ( AB t) AD

P

A

B

C D

But, as the element is actually in equilibrium, there must be

another pair of forces say P' acting on faces AD and BC,

such that they produce a anticlockwise moment equal to ( P

AD )

For the force diagram shown,

Fx = 0, & Fy = 0,

But M = 0

force

State of simple shear

Equn.(1) can be written as

If

1

is the intensity of the shear

stress on the faces AD and BC,

then P ' can be written as,

P '

= '

AD t

P ' AB = P AD

= ( AB t) AD ----- (1)

P

P

A B

C D

P '

P '

( ' AD t ) AB = ( AB t) AD ----- (1)

' =

A B

C D

'

'

State of simple shear

Thus in a strained material a shear stress is always

accompanied by a balancing shear of same intensity at

right angles to itself. This balancing shear is called

complementary shear.

The shear and the

complementary shear together

constitute a state of simple

shear

A

B

C D

'=

'=

Direct stress due to pure shear

Consider a square element of side a subjected to shear

stress as shown in the Fig.(a). Let the thickness of the

square be unity.

Fig.(b) shows the deformed shape of the element. The length of

diagonal DB increases, indicating that it is subjected to tensile

stress. Similarly the length of diagonal AC decreases indicating

that compressive stress.

a

A

B

C D

a

A

B

C D

a

a

Fig.(a).

Fig.(b).

Direct stress due to pure shear

Now consider the section, ADC of the element, Fig.(c).

Resolving the forces in

n

direction, i.e., in the X-direction

shown

a

Fig.(c).

a

a

A

C D

( )a 2

For equilibrium

A

n

C D

a

X

( ) ( )

t o

t o

=

=

=

n

n

a a

Fx

45 cos 2 1 2

0

Direct stress due to pure shear

Therefore the intensity of normal tensile stress

developed on plane BD is numerically equal to the

intensity of shear stress.

Similarly it can be proved that the intensity of compressive

stress developed on plane AC is numerically equal to the

intensity of shear stress.

Poissons Ratio:

Consider the rectangular bar shown in Fig.(a) subjected to a

tensile load. Under the action of this load the bar will increase

in length by an amount L giving a longitudinal strain in the

bar of

POISSONS RATIO

l

l

l

o

c =

Fig.(a)

The associated lateral strains will be equal and are of

opposite sense to the longitudinal strain.

POISSONS RATIO

The bar will also exhibit, reduction in dimension laterally, i.e.

its breadth and depth will both reduce. These change in

lateral dimension is measured as strains in the lateral

direction as given below.

d

d

b

b

lat

o o

c = =

Provided the load on the material is retained within the elastic

range the ratio of the lateral and longitudinal strains will

always be constant. This ratio is termed Poissons ratio ()

POISSONS RATIO

Lateral strain

Longitudinal strain

=

l

l

d

d

o

o

) (

=

l

l

b

b

o

o

) (

OR

Poissons Ratio =

For most engineering metals the value of lies between 0.25 and

0.33

In general

z

y

x

P

P

Poissons

Ratio

Lateral strain

Strain in the direction of

load applied

=

x

x

y

y

l

l

l

l

o

o

=

OR

x

x

z

z

l

l

l

l

o

o

=

L

x

L

y

L

z

Poissons Ratio =

In general

Strain in X-direction =

x

z

y

x

P

x

P

x

L

x

L

y

L

z

x

x

l

l o

=

Strain in Y-direction =

y

Strain in Z-direction =

z

x

x

y

y

l

l

l

l

o

o

= =

x

x

z

z

l

l

l

l o

o

= =

Load applied in Y-direction

Poissons

Ratio

Lateral strain

Strain in the direction of

load applied

=

y

y

x

x

l

l

l

l

o

o

=

OR

y

y

z

z

l

l

l

l

o

o

=

z

y

x

P

y

L

x

L

y

L

z

P

y

Strain in X-direction =

x

y

y

x

x

l

l

l

l

o

o

= =

Load applied in Z-direction

Poissons

Ratio

Lateral strain

Strain in the direction of

load applied

=

z

z

x

x

l

l

l

l

o

o

=

OR

z

z

y

y

l

l

l

l

o

o

=

y

z

x

P

z

L

x

L

y

L

z

P

z

Strain in X-direction =

x

z

z

x

x

l

l

l

l o

o

= =

Load applied in X & Y direction

Strain in X-direction =

x

z

y

x

P

x

P

x

L

x

L

y

L

z

P

y

P

y

Strain in Y-direction =

y

E E

x

y

o

o

=

Strain in Z-direction =

z

E E

x

y

o

o

=

E E

y

x

o

o

=

General

case:

Strain in X-direction =

x

Strain in Y-direction =

y

Strain in Z-direction =

z

z

y

x

P

x P

x

P

y

P

y

P

z

P

z

E E E

z

y

x

x

o

o

c =

E E E

z x

y

y

o

o

c =

E E E

x

y

z

z

o

o

c =

y

Bulk Modulus

Bulk Modulus

A body subjected to three mutually perpendicular equal direct

stresses undergoes volumetric change without distortion of

shape.

If V is the original volume and dV is the change in volume,

then dV/V is called volumetric strain.

Bulk modulus, K

A body subjected to three mutually perpendicular equal direct

stresses then the ratio of stress to volumetric strain is called

Bulk Modulus.

|

.

|

\

|

=

V

dV

o

Relationship between volumetric strain and linear strain

Relative to the unstressed state, the change

in volume per unit volume is

( )( )( ) | | | |

e unit volum per in volume change

1 1 1 1 1 1

1

=

+ + =

+ + + = + + + =

z y x

z y x z y x

dV

c c c

c c c c c c

Consider a cube of side 1unit, subjected to

three mutually perpendicular direct

stresses as shown in the figure.

Relationship between volumetric strain and linear strain

|

|

.

|

\

|

=

E E E

z

y

x

o

o

|

|

.

|

\

|

+

E E E

z x

y

o

o

|

|

.

|

\

|

+

E E E

x

y

z

o

o

z y x

V

dV

c c c + + =

Volumetric strain

( )

z y x

E

o o o

+ +

=

2 1

For element subjected to uniform hydrostatic pressure,

( )

( )

2 - 1 3K E

or

modulus bulk

2 1 3

=

=

=

E

K

o o o o = = =

z y x

( )

( ) 3

2 1

2 1

o

o o o

E V

dV

E V

dV

z y x

=

+ +

=

|

.

|

\

|

=

V

dV

K

o

Relationship between youngs modulus of elasticity (E)

and modulus of rigidity (G) :-

A

D

B

a

a

45

A

1

B

1

Consider a square element ABCD of side a subjected to pure shear

. DA'B'C is the deformed shape due to shear . Drop a perpendicular

AH to diagonal A'C.

Strain in the diagonal AC = /E (- /E) [

n

= ]

= /E [ 1 + ] -----------(1)

Strain along the diagonal AC=(A'CAC)/AC=(A'CCH)/AC=A'H/AC

C

H

In le AA'H

Cos 45 = A'H/AA'

A'H= AA' 1/2

AC = 2 AD ( AC = AD

2

+AD

2

)

Strain along the diagonal AC = AA'/ (2 2 AD)=/2 ----(2)

Modulus of rigidity = G = /

= /G

Substituting in (2)

Strain along the diagonal AC = /2G -----------(3)

Equating (1) & (3)

/2G = /E[1+]

E=2G(1+ )

Substituting in (1)

E = 2G[ 1+(3K 2G)/ (2G+6K)]

E = 18GK/( 2G+6K)

E = 9GK/(G+3K)

Relationship between E, G, and K:-

We have

E = 2G( 1+ ) -----------(1)

E = 3K( 1-2) -----------(2)

Equating (1) & (2)

2G( 1+ ) =3K( 1- 2)

2G + 2G=3K- 6K

= (3K- 2G) /(2G +6K)

(1) A bar of certain material 50 mm square is subjected to an axial

pull of 150KN. The extension over a length of 100mm is 0.05mm

and decrease in each side is 0.0065mm. Calculate (i) E (ii) (iii) G

(iv) K

Solution:

(i) E = Stress/ Strain = (P/A)/ (dL/L) = (15010

3

100)/(50 50 0.05)

E = 1.2 x 10

5

N/mm

2

(ii) = Lateral strain/ Longitudinal strain = (0.0065/50)/(0.05/100) = 0.26

(iii) E = 2G(1+ )

G= E/(2 (1+ )) = (1.2 10

5

)/ (2 (1+ 0.26)) = 0.47 10

5

N/mm

2

(iv) E = 3K(1-2)

K= E/(1-2) = (1.2 10

5

)/ (3 (1- 2 0.26)) = 8.3 10

4

N/mm

2

(2) A tension test is subjected on a mild steel tube of external

diameter 18mm and internal diameter 12mm acted upon by

an axial load of 2KN produces an extension of 3.36 x 10

-

3

mm on a length of 50mm and a lateral contraction of 3.62

x 10

-4

mm of outer diameter. Determine E, ,G and K.

(i) E = Stress/Strain = (2 10

3

50)/ (/4(18

2

12

2

) 3.36 10

-3

)

= 2.11 10

5

N/mm

2

ii) =lateral strain/longitudinal strain = [(3.62 10

-4

)/18]/[(3.36 10

-3

)/50]

= 0.3

iii) E = 2G (1 + )

G = E / 2(1+ ) = (2.11 10

5

)/(2 1.3) = 81.15 10

3

N/mm

2

iv) E = 3K(1 -2 )

K = E/ [3(1-2 )] = (2.1110

5

)/{3[1-(2 0.3)]} = 175.42 10

3

N/mm

2

Working stress: It is obvious that one cannot take risk of

loading a member to its ultimate strength, in practice. The

maximum stress to which the material of a member is

subjected to in practice is called working stress.

This value should be well within the elastic limit in elastic

design method.

Factor of safety: Because of uncertainty of loading

conditions, design procedure, production methods, etc.,

designers generally introduce a factor of safety into their

design, defined as follows

Factor of safety =

Allowable working

stress

Maximum stress

Allowable working

stress

Yield stress (or proof stress)

or

Homogeneous: A material which has a uniform structure

throughout without any flaws or discontinuities.

Malleability: A property closely related to ductility, which

defines a materials ability to be hammered out in to thin

sheets

Isotropic: If a material exhibits uniform properties throughout

in all directions ,it is said to be isotropic.

Anisotropic: If a material does not exhibit uniform properties

throughout in all directions ,it is said to be anisotropic or

nonisotropic.

Q.6.9

A metallic bar 250mm100mm50mm is loaded as shown in

the figure. Find the change in each dimension and total

volume. Take E = 200GPa, Poisson's ratio, = 0.25

250

400kN

50

100

2000kN

4000kN

4000kN

400kN

2000kN

Stresses in different

directions

100

250

400kN

50

2000kN

4000kN

100

250

50

MPa

mm

N

x

80

50 100

1000 400

2

=

= o

MPa

mm

N

y

160

100 250

1000 4000

2

=

= o

MPa

mm

N

z

160

50 250

1000 2000

2

=

= o

Stresses in different direction

MPa 80

MPa 160

MPa 160

E E E

z

y

x

x

o

o

c =

4

10 4

160 160 80

=

+

+

=

E E E

x

c

mm l

l

l

l

x

x

x

x

1 . 0

10 4

250

4

=

= =

o

o o

E E E

z x

y

y

o

o

c =

( )

3

10 1 . 1

160 80 160

=

+

=

E E E

y

c

( )

mm l

l

l

l

y

y

y

y

005 . 0

10 1 . 1

50

3

=

= =

o

o o

MPa 80

MPa 160

MPa 160

( )

mm l

l

l

l

z

z

z

z

09 . 0

10 9

250

4

+ =

+ = =

o

o o

E E E

x

y

z

z

o

o

c =

( )

4

10 9

80 160 160

+ =

+

+

=

E E E

z

c

MPa 80

MPa 160

MPa 160

( )

( ) ( )

3

4 4

4 4

250

50 100 250 10 2 10 2

10 2 10 9 11 4

mm dV

V dV

V

dV

+ =

= =

= + =

z y x

V

dV

c c c + + =

To find change in volume

( )

( )

( )

4

10 2 80

E

2 - 1

160 160 80

2 1

2 1

= =

+ +

=

+ +

o o o

E V

dV

E V

dV

z y x

Alternatively,

MPa 80

MPa 160

MPa 160

Q.6.10

A metallic bar 250mm100mm50mm is loaded as shown in

the Fig. shown below. Find the change in value that should

be made in 4000kN load, in order that there should be no

change in the volume of the bar. Take E = 200GPa, Poisson's

ratio, = 0.25

250

400kN

50

100

2000kN

4000kN

We know that

( )

z y x

E V

dV

o o o

u

+ +

=

2 1

In order that change in volume to be

zero

( )

( ) 0

2 1

0

= + +

+ +

=

z y x

z y x

E

o o o

o o o

u

( )

kN P

P

MPa

y

y

y

y

6000

100 250

240

240

0 160 80

=

=

=

= + + +

o

o

MPa 80

MPa 160

MPa 160

The change in value should be an

addition of 2000kN compressive force

in Y-direction

Exercise Problems

Q1. An aluminum tube is rigidly fastened between a brass

rod and steel rod. Axial loads are applied as indicated in the

figure. Determine the stresses in each material and total

deformation. Take E

a

=70GPa, E

b

=100GPa, E

s

=200GPa

500mm 700mm 600mm

steel

aluminum

brass

20kN 15kN 15kN 10kN

A

b

=700mm

2

A

a

=1000mm

2

A

s

=800mm

2

Ans:

b

=28.57MPa,

a

=5MPa,

s

=12.5MPa, l = - 0.142mm

Q2. A 2.4m long steel bar has uniform diameter of 40mm for

a length of 1.2m and in the next 0.6m of its length its

diameter gradually reduces to D mm and for remaining

0.6m of its length diameter remains the same as shown in

the figure. When a load of 200kN is applied to this bar

extension observed is equal to 2.59mm. Determine the

diameter D of the bar. Take E =200GPa

= 40mm

= D mm

200kN

200kN

500mm 500mm 1000mm

Q3. The diameter of a specimen is found to reduce by

0.004mm when it is subjected to a tensile force of 19kN.

The initial diameter of the specimen was 20mm. Taking

modulus of rigidity as 40GPa determine the value of E and

Ans: E=110GPa, =0.36

Q4. A circular bar of brass is to be loaded by a shear load of

30kN. Determine the necessary diameter of the bars (a) in

single shear (b) in double shear, if the shear stress in

material must not exceed 50MPa.

Ans: 27.6, 19.5mm

Q5. Determine the largest weight W that can be supported

by the two wires shown. Stresses in wires AB and AC are

not to exceed 100MPa and 150MPa respectively. The cross

sectional areas of the two wires are 400mm

2

for AB and

200mm

2

for AC.

Ans: 33.4kN

W

A

C

B

30

0

45

0

Q6. A homogeneous rigid bar of weight 1500N carries a

2000N load as shown. The bar is supported by a pin at B

and a 10mm diameter cable CD. Determine the stress in

the cable

Ans: 87.53MPa

3m

A

C

B

2000 N

3m

D

Q7. A stepped bar with three different cross-sectional

areas, is fixed at one end and loaded as shown in the

figure. Determine the stress and deformation in each

portions. Also find the net change in the length of the

bar. Take E = 200GPa

250mm 270mm 320mm

300mm

2

450mm

2

250mm

2

10kN

40kN

20kN

Ans: -33.33, -120, 22.2MPa, -0.042, -0.192, 0.03mm, -0.204mm

Q8. The coupling shown in figure is constructed from steel of

rectangular cross-section and is designed to transmit a

tensile force of 50kN. If the bolt is of 15mm diameter

calculate:

a) The shear stress in the bolt;

b) The direct stress in the plate;

c) The direct stress in the forked end of the coupling.

Ans: a)141.5MPa, b)166.7MPa, c)83.3MPa

Q9. The maximum safe compressive stress in a hardened

steel punch is limited to 1000MPa, and the punch is used to

pierce circular holes in mild steel plate 20mm thick. If the

ultimate shearing stress is 312.5MPa, calculate the

smallest diameter of hole that can be pierced.

Ans: 25mm

Q10. A rectangular bar of 250mm long is 75mm wide and

25mm thick. It is loaded with an axial tensile load of 200kN,

together with a normal compressive force of 2000kN on

face 75mm250mm and a tensile force 400kN on face

25mm250mm. Calculate the change in length, breadth,

thickness and volume. Take E = 200GPa & =0.3

Ans: 0.15,0.024,0.0197mm, 60mm

3

Q11. A piece of 180mm long by 30mm square is in

compression under a load of 90kN as shown in the figure. If

the modulus of elasticity of the material is 120GPa and

Poissons ratio is 0.25, find the change in the length if all

lateral strain is prevented by the application of uniform

lateral external pressure of suitable intensity.

180

90kN

30

30

Ans: 0.125mm

Q12. Define the terms: stress, strain, elastic limit,

proportionality limit, yield stress, ultimate stress, proof

stress, true stress, factor of safety, Youngs modulus,

modulus of rigidity, bulk modulus, Poisson's ratio,

Q13. Draw a typical stress-strain diagram for mild steel rod

under tension and mark the salient points.

Q14 Diameter of a bar of length L varies from D

1

at one end

to D

2

at the other end. Find the extension of the bar under

the axial load P

Q15. Derive the relationship between Youngs modulus and

modulus of rigidity.

Q17 A flat plate of thickness t tapers uniformly from a width

b

1

at one end to b

2

at the other end, in a length of L units.

Determine the extension of the plate due to a pull P.

Q18 Find the extension of a conical rod due to its own weight

when suspended vertically with its base at the top.

Q19. Prove that a material subjected to pure shear in two

perpendicular planes has a diagonal tension and

compression of same magnitude at 45

o

to the planes of

shear.

Q16 Derive the relationship between Youngs modulus and

Bulk modulus.

Q20. For a given material E=1.110

5

N/mm

2

&

G=0.4310

5

N/mm

2

.Find bulk modulus & lateral

contraction of round bar of 40mm diameter & 2.5m

length when stretched by 2.5mm. ANS:

K=83.33Gpa, Lateral contraction=0.011mm

Q21. The modulus of rigidity of a material is 0.810

5

N/mm

2

,

when 6mm6mm bar of this material subjected to an axial

pull of 3600N.It was found that the lateral dimension of the

bar is changed to 5.9991mm5.9991mm. Find & E.

ANS: =0.31, E= 210Gpa.

Das könnte Ihnen auch gefallen

- Thermal StressDokument104 SeitenThermal Stressmanishtopsecrets100% (1)

- Therefore, the principal stresses are:σ1 = 110 MPa (maximum principal stress)σ2 = 0 MPa (minimum principal stress)The principal planes make an angle of θp1 = -23.7° and θp2 = 66.3° from the x-axisDokument55 SeitenTherefore, the principal stresses are:σ1 = 110 MPa (maximum principal stress)σ2 = 0 MPa (minimum principal stress)The principal planes make an angle of θp1 = -23.7° and θp2 = 66.3° from the x-axisAfif Azhar100% (1)

- Failure Static LoadingDokument183 SeitenFailure Static LoadingoperationmanagerNoch keine Bewertungen

- Strength of Materials 2 Mark QuestionsDokument42 SeitenStrength of Materials 2 Mark Questionssiraj100% (5)

- Shaft DesignDokument73 SeitenShaft Designmeenakumari05Noch keine Bewertungen

- Simple Stresses and Strains PDFDokument104 SeitenSimple Stresses and Strains PDFyaminiNoch keine Bewertungen

- Failure Theories Von MisesDokument12 SeitenFailure Theories Von Misesrezajun2820Noch keine Bewertungen

- Strength of Materials (HE 306)Dokument463 SeitenStrength of Materials (HE 306)Anu ParameswaranNoch keine Bewertungen

- CIVL 222 AXIAL MEMBERSDokument27 SeitenCIVL 222 AXIAL MEMBERSskhan247100% (1)

- ME 202 Advanced Mechanics of SolidsDokument3 SeitenME 202 Advanced Mechanics of SolidsMohammed Asif NNoch keine Bewertungen

- Chapter 4 - Axial LoadingDokument50 SeitenChapter 4 - Axial LoadingAbdullrahman Ahmed100% (1)

- ME 6306 Strength of Materials Course OverviewDokument8 SeitenME 6306 Strength of Materials Course OverviewGokulraju Rangasamy100% (2)

- Tension Compression and ShearDokument27 SeitenTension Compression and ShearRizal Muhammad FaradayNoch keine Bewertungen

- Transient Response Analysis - Time-Dependent Loads & Structural Responses in 40 CharactersDokument2 SeitenTransient Response Analysis - Time-Dependent Loads & Structural Responses in 40 Charactersserleb44Noch keine Bewertungen

- Mirzaei FractureMechanicsLecture PDFDokument61 SeitenMirzaei FractureMechanicsLecture PDFkoohestani_afshinNoch keine Bewertungen

- Fatigue Failure: Causes, Examples and Testing MethodsDokument12 SeitenFatigue Failure: Causes, Examples and Testing MethodsUok RitchieNoch keine Bewertungen

- Dynamics of MachineryDokument92 SeitenDynamics of Machinerygkgj100% (1)

- Von MisesDokument8 SeitenVon MisesAlex OliveiraNoch keine Bewertungen

- FALLSEM2020-21 MEE3001 TH VL2020210101665 Reference Material I 31-Aug-2020 Module 4 Design of Riveted Joint 8 PDFDokument53 SeitenFALLSEM2020-21 MEE3001 TH VL2020210101665 Reference Material I 31-Aug-2020 Module 4 Design of Riveted Joint 8 PDFAK PRODUCTIONSNoch keine Bewertungen

- Stress Analysis and Design FundamentalsDokument62 SeitenStress Analysis and Design Fundamentalsmuhammad hamzaNoch keine Bewertungen

- Fatigue BasicsDokument30 SeitenFatigue BasicsABY.SAAJEDI879Noch keine Bewertungen

- Compressible Flow ReviewDokument8 SeitenCompressible Flow Reviewthehighlife1080Noch keine Bewertungen

- Stress Analysis of Thin Walled Pressure Vessel by Ibrahim Et. Al.Dokument10 SeitenStress Analysis of Thin Walled Pressure Vessel by Ibrahim Et. Al.Ivan Ernest TomagosNoch keine Bewertungen

- Mechanics of MaterialsDokument18 SeitenMechanics of MaterialsSaad FaheemNoch keine Bewertungen

- 09 Stresses and Deformations Arising From Torsional LoadingDokument31 Seiten09 Stresses and Deformations Arising From Torsional LoadingMich AngelesNoch keine Bewertungen

- Torsional Vibrations and Torsion ModulusDokument5 SeitenTorsional Vibrations and Torsion ModulusJose Galvan100% (1)

- Mechanical Behavior of Materials - Lecture Slides - Chapter 9Dokument73 SeitenMechanical Behavior of Materials - Lecture Slides - Chapter 9Jun-Dong LeeNoch keine Bewertungen

- Strength of Materials For Technicians Chapter6Dokument110 SeitenStrength of Materials For Technicians Chapter6MR150Noch keine Bewertungen

- 9 Beam Deflection-Mechanics of MaterialsDokument34 Seiten9 Beam Deflection-Mechanics of MaterialsNhân Trần100% (1)

- Entropy Notes PDFDokument69 SeitenEntropy Notes PDFAsza ShahizaNoch keine Bewertungen

- Thin-Walled Pressure Vessel TheoryDokument3 SeitenThin-Walled Pressure Vessel TheoryTerminatorX75Noch keine Bewertungen

- Sources and remedies for high-frequency piping vibrationDokument24 SeitenSources and remedies for high-frequency piping vibrationSmith780512Noch keine Bewertungen

- Review of Tilting Pad Lubrication TheoryDokument24 SeitenReview of Tilting Pad Lubrication Theoryhimadri.banerji60Noch keine Bewertungen

- Material SelectionDokument19 SeitenMaterial Selectionmohamed abd eldayemNoch keine Bewertungen

- Lecture 8 & 9 - TorsionDokument12 SeitenLecture 8 & 9 - TorsionHowell TungolNoch keine Bewertungen

- Chapter 5: Application of Dimensional Analysis On TurbomachinesDokument32 SeitenChapter 5: Application of Dimensional Analysis On TurbomachinesTonye AYAFA100% (1)

- Mechanic of MaterialsDokument32 SeitenMechanic of MaterialsHussain RizviNoch keine Bewertungen

- Webinar OptiSLang4 Ansys WBDokument39 SeitenWebinar OptiSLang4 Ansys WBkiran_wakchaureNoch keine Bewertungen

- 04a Torsion of ThinWalled StructuresDokument35 Seiten04a Torsion of ThinWalled StructuresYan NingNoch keine Bewertungen

- Turbines, pumps and compressors explainedDokument5 SeitenTurbines, pumps and compressors explainedJuan HeroNoch keine Bewertungen

- Heat Transfer SummaryDokument16 SeitenHeat Transfer SummaryNuzhat SafdarNoch keine Bewertungen

- Pipe Fea Using AnsysDokument14 SeitenPipe Fea Using AnsysTONNoch keine Bewertungen

- Chap 06 - Stresses in Beams (Advanced Topics)Dokument48 SeitenChap 06 - Stresses in Beams (Advanced Topics)Muhammad Fahim100% (1)

- TorsionDokument51 SeitenTorsionsolaNoch keine Bewertungen

- Assignment 2Dokument2 SeitenAssignment 2just0% (2)

- Mechanics of Solids IntroductionDokument51 SeitenMechanics of Solids IntroductionSatish DhanyamrajuNoch keine Bewertungen

- BFC20903 - Ch5 (Transverse Shear)Dokument27 SeitenBFC20903 - Ch5 (Transverse Shear)azrinaishakNoch keine Bewertungen

- Dynamic Force AnalysisDokument42 SeitenDynamic Force Analysisdhruv001Noch keine Bewertungen

- Fluid MechDokument205 SeitenFluid MechMahesh Ramteke100% (1)

- TE 1 Notes PDFDokument196 SeitenTE 1 Notes PDFfatigue puttaNoch keine Bewertungen

- Pressure Vessel Cylinder Thermal StressDokument9 SeitenPressure Vessel Cylinder Thermal Stresstabloid07Noch keine Bewertungen

- MECHANICS OF DEFORMABLE BODIESDokument106 SeitenMECHANICS OF DEFORMABLE BODIESVinayak PrabhuNoch keine Bewertungen

- Strength of Materials 1Dokument73 SeitenStrength of Materials 1Altamash KhanNoch keine Bewertungen

- Chapter 1 - Stress and StrainDokument72 SeitenChapter 1 - Stress and StrainNazhan HaziqNoch keine Bewertungen

- Stress and StrainDokument60 SeitenStress and StrainMuhammad Shafie100% (1)

- Stress and Strain RenewDokument65 SeitenStress and Strain Renewshafarizy100% (1)

- Chapter 1 - Stress and StrainDokument77 SeitenChapter 1 - Stress and StrainIman Fitri IsmailNoch keine Bewertungen

- Chapter 1 - STRESS AND STRAIN PDFDokument34 SeitenChapter 1 - STRESS AND STRAIN PDFnurul eryn100% (1)

- Mechanical Properties IntroductionDokument29 SeitenMechanical Properties IntroductionHiwot DemisseNoch keine Bewertungen

- Applying Shielded Metal Arc Welding TechniquesDokument134 SeitenApplying Shielded Metal Arc Welding Techniquesgaspardo123Noch keine Bewertungen

- Applying SMAW TechniquesDokument134 SeitenApplying SMAW Techniquesgaspardo123Noch keine Bewertungen

- Applying SMAW TechniquesDokument134 SeitenApplying SMAW Techniquesgaspardo123Noch keine Bewertungen

- Type of Metals2Dokument17 SeitenType of Metals2gaspardo123Noch keine Bewertungen

- Testing Versus InspectionDokument40 SeitenTesting Versus Inspectiongaspardo123Noch keine Bewertungen

- Shielded Metal Arc Welding FundamentalsDokument134 SeitenShielded Metal Arc Welding Fundamentalsgaspardo123Noch keine Bewertungen

- Type of Metals3Dokument17 SeitenType of Metals3gaspardo123Noch keine Bewertungen

- Type of Metals2Dokument17 SeitenType of Metals2gaspardo123Noch keine Bewertungen

- Type of Metals3Dokument17 SeitenType of Metals3gaspardo123Noch keine Bewertungen

- Type of Metals3Dokument17 SeitenType of Metals3gaspardo123Noch keine Bewertungen

- Testing and InspectionDokument40 SeitenTesting and Inspectiongaspardo123Noch keine Bewertungen

- Type of Metals3Dokument17 SeitenType of Metals3gaspardo123Noch keine Bewertungen

- Tennessee-Tombigbee Waterway: U.S. Army Corps of Engineers Mobile DistrictDokument29 SeitenTennessee-Tombigbee Waterway: U.S. Army Corps of Engineers Mobile Districtgaspardo123Noch keine Bewertungen

- Test vs. inspection Part 1: Introduction to testing and inspection processesDokument40 SeitenTest vs. inspection Part 1: Introduction to testing and inspection processesgaspardo123Noch keine Bewertungen

- Test Versus Inspection: Tor StålhaneDokument40 SeitenTest Versus Inspection: Tor Stålhanegaspardo123Noch keine Bewertungen

- Introduction To WeldingDokument192 SeitenIntroduction To WeldingMirtunjay Kumar88% (8)

- Test Vs InspectionDokument40 SeitenTest Vs Inspectiongaspardo123Noch keine Bewertungen

- Testing of Preplaced ConcreteDokument27 SeitenTesting of Preplaced Concretegaspardo123Noch keine Bewertungen

- Hydro Test PreparationDokument22 SeitenHydro Test Preparationgaspardo123Noch keine Bewertungen

- Tennessee-Tombigbee Waterway: U.S. Army Corps of Engineers Mobile DistrictDokument29 SeitenTennessee-Tombigbee Waterway: U.S. Army Corps of Engineers Mobile Districtgaspardo123Noch keine Bewertungen

- Legg Test State OverviewDokument37 SeitenLegg Test State Overviewgaspardo123Noch keine Bewertungen

- Testing of Preplaced ConcreteDokument27 SeitenTesting of Preplaced Concretegaspardo123Noch keine Bewertungen

- Hydro Test PreparationDokument22 SeitenHydro Test Preparationgaspardo123Noch keine Bewertungen

- Stainless SteelDokument34 SeitenStainless SteelMohammed HilalNoch keine Bewertungen

- Spirituality of Louise de MarillacDokument19 SeitenSpirituality of Louise de Marillacgaspardo123Noch keine Bewertungen

- Electroslag WeldingDokument9 SeitenElectroslag WeldingGopal Jetani100% (1)

- Understanding Creep and Fatigue Deformation in MaterialsDokument20 SeitenUnderstanding Creep and Fatigue Deformation in Materialsgaspardo123Noch keine Bewertungen

- 10 - Reinforced Concrete DesignDokument26 Seiten10 - Reinforced Concrete DesignEssuconNoch keine Bewertungen

- Design Guide For US WeldingDokument6 SeitenDesign Guide For US Weldinggaspardo123Noch keine Bewertungen

- Unit-II EME AerospaceDokument51 SeitenUnit-II EME AerospacePranil Vijay SawalakheNoch keine Bewertungen

- CENG 6302 Chapter 7 Overview of Rigid Pavement DesignDokument22 SeitenCENG 6302 Chapter 7 Overview of Rigid Pavement DesignThe HackerNoch keine Bewertungen

- Cold-Formed (CF) Structures Erocode 9 - Part 1.4Dokument97 SeitenCold-Formed (CF) Structures Erocode 9 - Part 1.4mingNoch keine Bewertungen

- Activity 2 3 2 Tensile Testing With The SsaDokument9 SeitenActivity 2 3 2 Tensile Testing With The Ssaapi-280054778Noch keine Bewertungen

- Inelastic Buckling of Beams PDFDokument18 SeitenInelastic Buckling of Beams PDFlyeshiunNoch keine Bewertungen

- Solutions of Problem Set 5Dokument15 SeitenSolutions of Problem Set 5yasin yttNoch keine Bewertungen

- Behaviour of Continuous Pipeline Subject To Transverse PGD: Xuejie Liu S and Michael J. O'RourketDokument15 SeitenBehaviour of Continuous Pipeline Subject To Transverse PGD: Xuejie Liu S and Michael J. O'RourketMarcelo Andrés Rojas GonzálezNoch keine Bewertungen

- ASTM D695-02aDokument7 SeitenASTM D695-02agabrieldsaNoch keine Bewertungen

- Modeling and Manual Design Comparision of Streeses in Castellated Beam Using AnsysDokument5 SeitenModeling and Manual Design Comparision of Streeses in Castellated Beam Using AnsysAdnan NajemNoch keine Bewertungen

- Design Philosophy of Concrete Linings For Tunnels in Soft SoilsDokument249 SeitenDesign Philosophy of Concrete Linings For Tunnels in Soft SoilsJinChongNoch keine Bewertungen

- 3-D Numerical Model For Wave-Seabed Interactions Around Mono-Pile (2015)Dokument54 Seiten3-D Numerical Model For Wave-Seabed Interactions Around Mono-Pile (2015)RIOS TSENGNoch keine Bewertungen

- Reading 1Dokument20 SeitenReading 1Hwee Peng YeoNoch keine Bewertungen

- LS-DYNA Introductory Course April07Dokument171 SeitenLS-DYNA Introductory Course April07unmeshNoch keine Bewertungen

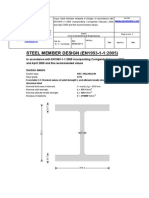

- Sachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Dokument6 SeitenSachpazis Steel Member Analysis & Design (EN1993-1!1!2005)Costas SachpazisNoch keine Bewertungen

- Crack Preparation and Capping for Concrete InjectionDokument59 SeitenCrack Preparation and Capping for Concrete Injectiongonzalez_m_aNoch keine Bewertungen

- Elasticity and Young's Modulus QuestionsDokument10 SeitenElasticity and Young's Modulus QuestionssmeenaNoch keine Bewertungen

- Mat LibDokument578 SeitenMat LibBoonme ChinnaboonNoch keine Bewertungen

- AS LAB Man IDokument84 SeitenAS LAB Man IVadivel AeroNoch keine Bewertungen

- Module 2Dokument12 SeitenModule 2Azeezan AlessaNoch keine Bewertungen

- Theory of Plates and Shells FundamentalsDokument213 SeitenTheory of Plates and Shells Fundamentalsआकाश संगीता प्रकाश पवार100% (2)

- Crystal Structures MSMDokument21 SeitenCrystal Structures MSMskchavanNoch keine Bewertungen

- One Word SubstitutionDokument5 SeitenOne Word SubstitutionKingashiqhussainPanhwerNoch keine Bewertungen

- Effect of fiber orientation on composite material propertiesDokument19 SeitenEffect of fiber orientation on composite material propertiesHitesh RanaNoch keine Bewertungen

- Nonlinear Analysis of Structures Cable - Truss: June 2015Dokument11 SeitenNonlinear Analysis of Structures Cable - Truss: June 2015Cesar ZamudioNoch keine Bewertungen

- Elastic Architecture: A B C D E F GDokument0 SeitenElastic Architecture: A B C D E F GNandhitha RajarathnamNoch keine Bewertungen

- 7 Design of Deep Flexural MemberDokument56 Seiten7 Design of Deep Flexural MemberfiorebloemNoch keine Bewertungen

- Objectives and Methods of Analysis and DesignDokument965 SeitenObjectives and Methods of Analysis and DesignRenad Elrashid100% (5)

- AEAS 205 Lecture 2 - Axial LoadingDokument73 SeitenAEAS 205 Lecture 2 - Axial LoadingSamiha Maysoon NooriaNoch keine Bewertungen

- Quiz 1Dokument3 SeitenQuiz 1Greg LoncaricNoch keine Bewertungen

- Beams On Elastic Foundation: The Simplified Continuum ApproachDokument9 SeitenBeams On Elastic Foundation: The Simplified Continuum ApproachFábio SouzaNoch keine Bewertungen