Beruflich Dokumente

Kultur Dokumente

GasSorption Intro

Hochgeladen von

geneticdiseaseOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GasSorption Intro

Hochgeladen von

geneticdiseaseCopyright:

Verfügbare Formate

Introduction to Gas Sorption

Introduction to Gas Sorption

2000 Quantachrome Corporation

PHYSISORPTION

Introduction

The Mechanisms of Adsorption

Interpretation of the Multi-point BET Plot

The Single-Point Method

Pore Size Measurement

Micropore Estimation

Introduction

Adsorption of a gas allows the probing of a solid

surface hence the determination of its area.

This includes surface irregularities and pore interiors.

To some extent, adsorption will always occur on

a solid surface exposed to a gas or vapor

The amount adsorbed is a function of

temperature,

gas pressure

interaction potential between gas and solid.

Introduction (continued)

Mathematical expression of gas adsorption will be

introduced.

Subsequent surface area calculation detailed.

Experimental conditions and theoretical considerations for

real-life applications.

Adsorption Process

Adsorbent

Adsorbate Adsorptive

Langmuir behavior

At equilibrium, the rate of arrival of adsorptive and the

rate of evaporation of adsorbate are equal, i.e.

Adsorption = Desorption

Confining adsorption to a monolayer,

the Langmuir equation can be written

KP

KP

V

V

m

+

=

1

Langmuir Equation

V

P

KV V

P

m

+ =

1

Or linearized as:

where V is the volume of gas adsorbed at

pressure P, Vm is the monolayer capacity and K

is a constant for any given gas-solid pair.

BET Equation

Extending the mechanism to multiple layers,

Brunauer, Emmett and Teller derived the little-

more complicated expression

( )( ) ) P P ( C P P ) P P (

) P P ( C

V

V

o o o

o

m

+

=

1 1

Which, when linearized gives...

BET Equation

the familiar form

|

|

.

|

\

|

+ =

0 0

1 1

1 /

1

P

P

C V

C

C V P P V

m m

where Po is the saturated vapor pressure of the gas over the

solid, P/Po is the relative pressure and C is the so-called BET

C-constant which is related to the net heat of adsorption.

Langmuir vs. BET

Langmuir vs. BET

Principles of BET Surface Area

Measurement and Calculation

Determine the monolayer capacity Vm from which the

surface area of the solid can be computed.

Adsorbate most commonly used is nitrogen...

Readily available in high purity

Appropriate coolant, liquid nitrogen, also plentiful.

Gas-solid interaction relatively strong.

Widely accepted cross sectional area.

Measurement

Obtain at least three data points in the relative pressure range

0.025 to 0.30

Plot 1/[V

STP

(Po/P)-1] versus P/Po. It should yield a straight

line if the BET model holds true.

On all surfaces the BET model fails to accurately predict the

multilayer adsorption behavior above P/Po = 0.5 (the onset of

capillary condensation which fills pores with liquid adsorbate)

Calculation

Fit best straight line through BET data set using

least squares regression to find:

C V

C

s slope

m

1

=

C V

i

m

1

= intercept

Calculation (continued)

i s

V

m

+

=

1

v

m av m

t

M

A L V

S =

Solving for V

m

Total surface area, S

t

, is calculated thus

L

AV

= 6.023 x 10

23

A

m

= 0.162 nm

2

M

v

= 22 414 mL nm

2

to m

2

, x 10

18

Interpretation of the Multi-point BET Plot

Never use data points too low in relative pressure.

Never use points too high in relative pressure.

Non-linear BET Behavior

Interpretation of the Multi-point BET Plot

Never use data points too low in relative pressure.

Never use points too high in relative pressure.

Discard those points at low relative pressure which represent

under-equilibrated data...

Under-equilibrated Data

B

Under-equilibrated Data

C

Interpretation of the Multi-point BET Plot

Never use data points too low in relative pressure.

Never use points too high in relative pressure.

Discard those points at low relative pressure which represent

under-equilibrated data.

Never use less than three, preferably five, data points in the

final calculation.

Always use equally, or near equally, spaced data points

whenever possible.

Confirm known or suspected sample characteristics with the

behavior of the BET plot at higher relative pressures.

The Single-point Method

By reducing the experimental requirement to

only one datum point, the single-point method

offers the advantage of simplicity and speed,

often with little loss in accuracy.

0

1 P P V V

m

=

i.e. V

m

= 1/slope

Multi-point/single point/corrected

single point comparison

Sample

No.

Multipoint

BET

(m2/g)

Uncorrected

Single-point

(m2/g)

Uncorrected

Difference

(%)

Corrected

Single-

point

(m

2

/g)

Corrected

Difference

(%)

1 4.923 4.241 -13.9 4.948 +0.51

2 4.286 3.664 -14.5 4.275 -0.26

3 8.056 6.867 -14.8 8.011 -0.56

4 5.957 5.194 -12.8 6.060 +1.73

Pharm. Processing 9-10 (Jan. 1993)

Multi-point/single point/corrected

single point comparison

Sample

No.

Multipoint

BET

(m2/g)

Uncorrected

Single-point

(m2/g)

Uncorrected

Difference

(%)

Corrected

Single-

point

(m

2

/g)

Corrected

Difference

(%)

1 4.923 4.241 -13.9 4.948 +0.51

2 4.286 3.664 -14.5 4.275 -0.26

3 8.056 6.867 -14.8 8.011 -0.56

4 5.957 5.194 -12.8 6.060 +1.73

Corrected by multiplier C/C-2

The Single-point Method

A relative pressure of 0.3 gives good general agreement with

the multi-point method.

A simple first-order empirical correction can be made for the

so-called single point error at P/P0 = 0.3 by multiplying the

single point BET value by C/C-2.

Variation in Single-point BET Surface Area

as a Function of Chosen Relative Pressure

Surface Area Test Methods

ASTM: Carbon C819

Carbon black D3037, D4820

Aluminum oxide C1069

Silica D1993

Ceramics C1251

Catalysts D4780, D4567, D4365, D3663

Pharmaceutical Industry: <846>

Inconvenient Single-point BET Behavior

In certain cases, the single -point value never goes

through a maximum, but continues to increase with

increasing relative pressure.

If there is truly no linear region, then the BET

equation is invalid for that particular sample.

Isotherms of such samples appear to have some

type III character at very low pressure, indicative of

very weak adsorption yet demonstrate enhanced

adsorption within the normal BET range.

Enhanced Adsorption

Can be attributed to cooperative adsorption process.

Described for slit-shaped pores of critical dimensions.

Water on carbon (hydrophobic surface) is a typical example.

Types of Isotherms

S. Lowell & J. E. Shields, Powder Surface Area and Porosity, 3rd Ed.

Chapman & Hall, NY, NY 1991

Types of Hysteresis

Cylindrical Slit

Tapered/wedge

Tapered/wedge Bottle-neck

Mesopore (Greek meso = middle): 2nm - 50 nm diameter

Macropore (Greek macro = large): >50 nm diameter

Pore Size Distribution

Hysteresis is indicative of the presence of mesopores

and the pore size distribution can be calculated from

the sorption isotherm.

Whilst it is possible to do so from the adsorption

branch, it is more normal to do so from the desorption

branch...

Micropore (Greek micro = small): 0 nm - 2 nm diameter

Pore Size Distribution

AG

ads

= RT(lnP

ads

- lnP

0

)

AG

des

= RT(lnP

des

- lnP

0

)

AG

des

< AG

ads

Adsorption / Desorption

Adsorption =

multilayer formation

Desorption =

meniscus development

Kelvin* Equation

u

cos

rRT

V 2

P

P

ln

0

) P / P log(

.

) A ( r

k

0

15 4

* Lord Kelvin a.k.a. W.T. Thomson

Pore Size

t r r

k p

r

p

= actual radius of the pore

r

k

= Kelvin radius of the pore

t = thickness of the adsorbed film

Statistical Thickness, t

Halsey equation

Generalized Halsey

deBoer equation

Carbon Black STSA

BJH Method

(Barrett-Joyner-Halenda)

Kelvin

2

pore

2

Kelvin pore

r

r

V V

t

t

=

t r r

Kelvin pore

Estimation of Micropores...

the t-plot method

This method uses a mathematical representation of multi-

layer adsorption. The thickness, t, of an adsorbate layer

increases with increasing pressure. The t-curve so

produced is very similar in appearance to a type II

isotherm. For every value of P/Po, the volume adsorbed

is plotted against the corresponding value of t.

If the model describes the experimental data a straight line

is produced on the t-plot...

t-plot Method

(mesoporous only)

1 2 3 4 5 6 7

t ()

Slope = V/t = A

t-plot Method

(in the presence of micropores)

1 2 3 4 5 6 7

t ()

Intercept = micropore volume

t-plot Method

showing a knee

1 2 3 4 5 6 7

t ()

X

X

X

X

X

X

X

C

A

B

A

C

B

Slope A - slope B = area contribution by micropores size C

Micropore (MP) Plot

t (A

)

Gas volume

is converted

to liquid

volume

Differences in tangents yields

pore area distribution assuming

cylindrical geometry

Estimation of Micropores

Dubinin-Radushkevich (DR) Theory

(

(

|

.

|

\

|

|

|

.

|

\

|

=

P

P

log

T

B exp W W

0

2

2

0

|

W = volume of the liquid adsorbate

W

0

= total volume of the micropores

B = adsorbent constant

| = adsorbate constant

A linear relationship should be found between log(W) and log

2

(Po/P)...

Log

2

(Po/P)

L

o

g

(

W

)

Extrapolation

yields Wo

Estimation of Micropores

Dubinin-Radushkevich (DR) Plot

0

Autosorb-1

Automatic operation

Easy-to-clean cold trap

60 hour dewar for

unattended operation

Two outgassing

stations

Windows analysis

and reporting

software

Chemisorption option

NOVA

Vacuum or flow

degassing

Heating Mantles

Status and data

display

Analysis selection

key pad

Degas temperature

controls

RS232 port

3.5 disk drive

Calibration

1 or 2 samples

Automatic dewar

elevator

Ports for printer and

alphanumeric

keyboard

Monosorb

Direct surface

area display

Calibration

loop(standard)

Adjustable

outgassing

temperature

Rapid table-top analyzer

Hi/Lo range

switching

Automatic

sample warming

Automatic dewar

elevator

Autosorb-6

Six analysis ports for

high throughput needs

Automatic operation

60 hour dewars for

unattended operation

Windows analysis and

reporting software

Autosorb Degasser

Six independent

preparation

stations

For more information

CORPORATE HEADQUARTERS

Quantachrome Corporation

1900 Corporate Drive

Boynton Beach, FL 33426 U.S.A.

Phone: (561) 731-4999

Fax: (561) 732-9888

E-mail: qc.sales@quantachrome.com

EUROPE

Quantachrome Limited

European Technical Center

Pale Lane Farm, Pale Lane

Hartley Wintney, Hook RG27 8BA, UK

Phone: 01252 819719

Fax: 01252 819901

Quantachrome GmbH

Rudolf-Diesel Str. 12

85235 Odelzhausen, Germany

Phone: 08 134/93240

Fax: 08 134/932425

www.quantachrome.com

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Ruling PlanetsDokument2 SeitenRuling PlanetsshivaprasadamNoch keine Bewertungen

- Wear On HOT RoLLING Mill RollsDokument15 SeitenWear On HOT RoLLING Mill RollssourajpatelNoch keine Bewertungen

- Maxwell-Boltzmann DistributionDokument8 SeitenMaxwell-Boltzmann DistributionlamyantingNoch keine Bewertungen

- Buffer SelectionDokument3 SeitenBuffer SelectionSandeep KumarNoch keine Bewertungen

- Machining PDFDokument5 SeitenMachining PDFlambrosNoch keine Bewertungen

- Evaluation of LS-DYNA Concrete Material Model 159Dokument209 SeitenEvaluation of LS-DYNA Concrete Material Model 159SudathipTangwongchaiNoch keine Bewertungen

- Pendulum Lab 1Dokument3 SeitenPendulum Lab 1Ashley AllenNoch keine Bewertungen

- Psslope ManualDokument47 SeitenPsslope ManualMed El Hadi AbidiNoch keine Bewertungen

- G. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFDokument2 SeitenG. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFinitbashNoch keine Bewertungen

- Equilibrium of Rigid BodiesDokument18 SeitenEquilibrium of Rigid BodiesjahirNoch keine Bewertungen

- Double Cone Synchronizer For Vehicle TransmissionDokument17 SeitenDouble Cone Synchronizer For Vehicle TransmissionMujammil Choudhari50% (2)

- DEFUZZDokument43 SeitenDEFUZZsunilkumareceNoch keine Bewertungen

- An Introduction To Numerical Methods For The Solutions of Partial Differential EquationsDokument12 SeitenAn Introduction To Numerical Methods For The Solutions of Partial Differential EquationseiroNoch keine Bewertungen

- TSL250R, TSL251R, TSL252R: Light-to-Voltage Optical SensorsDokument21 SeitenTSL250R, TSL251R, TSL252R: Light-to-Voltage Optical Sensorsthevincenzo@gmail.comNoch keine Bewertungen

- Chemical Reaction and Diffusion in A Spherical Onon-Isothermal Catalyst PelletDokument6 SeitenChemical Reaction and Diffusion in A Spherical Onon-Isothermal Catalyst PelletMaximiliano Valenzuela LamNoch keine Bewertungen

- Cable Element Analysis TechniquesDokument16 SeitenCable Element Analysis TechniquesPankaj_Taneja_9684Noch keine Bewertungen

- The Zeeman EffectDokument11 SeitenThe Zeeman EffectAlex TarrNoch keine Bewertungen

- 16 TewariDokument22 Seiten16 TewariNebojsa BascarevicNoch keine Bewertungen

- ENGINEERING GRAPHICS (ENGINEERING DRAWING) by P.H.JainDokument8 SeitenENGINEERING GRAPHICS (ENGINEERING DRAWING) by P.H.JainProf. P. H. Jain78% (9)

- Noritake Value ShadeDokument4 SeitenNoritake Value ShadeRobinson Vasquez Chavez100% (1)

- 1.10.0-.Calculo de Muros de Contencion PDFDokument304 Seiten1.10.0-.Calculo de Muros de Contencion PDFJose Antonio Paredes VeraNoch keine Bewertungen

- VicoDokument17 SeitenVicojustmenobleskNoch keine Bewertungen

- Tesis MIT Slurry TransportDokument81 SeitenTesis MIT Slurry TransportCarlos Esaú López GómezNoch keine Bewertungen

- Chapter 2 - CablesDokument6 SeitenChapter 2 - CablesFifie HoyehNoch keine Bewertungen

- How Is Electrical Energy MeasuredDokument4 SeitenHow Is Electrical Energy MeasuredSonya ReddyNoch keine Bewertungen

- Lab Report 1Dokument26 SeitenLab Report 1ParvinNoch keine Bewertungen

- Kinematic Analysis of SlopesDokument30 SeitenKinematic Analysis of SlopeslinawebNoch keine Bewertungen

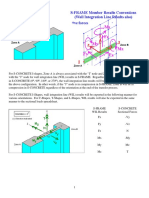

- Wall Integration Conventions S-CONCRETE R11 S-FRAMEDokument3 SeitenWall Integration Conventions S-CONCRETE R11 S-FRAMESyed RaziuddinNoch keine Bewertungen

- Quiz 6 EnergyDokument2 SeitenQuiz 6 Energyeloizamay100% (1)

- Estimating The Size of Onion Epidermal Cells From Diffraction PatternsDokument5 SeitenEstimating The Size of Onion Epidermal Cells From Diffraction PatternsAlexis Nathán RuedaNoch keine Bewertungen