Beruflich Dokumente

Kultur Dokumente

Unit 4

Hochgeladen von

amsk24_24Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Unit 4

Hochgeladen von

amsk24_24Copyright:

Verfügbare Formate

Unit 4 -Gas And Diesel Power Plants

Gas turbine types Open and closed cycle gas turbine Advantage and disadvantages Diesel engine power plant Component and layout Diesel engine power plant Components

Gas turbine power plant

A Gas Turbine consists of three main segments

Compressor Combustor Turbine.

Principle Of Operation

Ambient air is compressed to 11-30 bar pressure and as a consequence its temperature rises. Most of this warm air is used in the combustor to burn the fuel (natural gas or a liquid e.g. oil etc.). The resulting hot gas expands through the turbine, doing work, and exits at nearly atmospheric pressure but a temperature of up to 500-640 C.

Principle Of Operation

Work extracted during the expansion is used to turn the turbine which drives the generator that produces electricity.

The hot exit gas from the turbine still has significant amounts of energy which is used to raise steam to drive a steam-turbine and another generator. This combination of gas and steam cycle gives rise to the term combined cycle gas turbine (CCGT) plant

Open cycle-gas turbine

combined cycle gas turbine

Advantages Of Gas Turbine Plants

They are more compact, since fuel is burnt directly in the small combustion Chamber in the gas turbine rather than in a bulky boiler Gas Turbine has no condenser They can be started and take more load quickly (i.e.30 seconds to 30 min) They are simpler in design and easy to maintain They consume less metal and other materials for the same capacity They cost less Unlike steam turbines , they require very less water for cooling Gas Turbine is more suitable for power generation, where water scarcity exists or the water is more precious

Disadvantages Of Gas Turbine Plants

They have a lower specific power

They have lower efficiency at the modern state of progress They have a shorter service life They are more sensitive to fuel quality

Diesel Engine Power Plant

A Diesel power station(also known as Stand-by power station) uses a diesel engine as prime mover for the generation of electrical energy.

This power sattion is generally compact and thus can be located where it is actually required. This kind of power station can be used to produce limited amounts of electrical energy. In most countries these power stations are used as emergency supply stations

Operation

The diesel burns inside the engine and the combustion process causes rotational mechanical energy that turns the engine shaft and drives the alternator. The alternator inturn, converts mechanical energy into electrical energy.

This type of electricity generating power station will probably be used a long time into the future, due to a need for reliable stand-by electrical source for emergency situations.

Essential components of diesel power plant

Diesel engine Air intake system Exhaust system Fuel supply system Engine starting system Lubricating system Engine cooling system Governing system

Advantages

Higher thermal efficiency than thermal plant Wide range of fuels can be used Easy fuel handling Simple layout, easy to install Quick to respond to load variations Initial investment is less than other plants

Disadvantages

Diesel cost is high Does not work satisfactorily under continuous overload conditions Noise pollution Maintenance cost is high Capacity limited to 50 MW Life less than steam power plant

Das könnte Ihnen auch gefallen

- Gas Turbine Power Plant BasicsDokument21 SeitenGas Turbine Power Plant BasicsDurai Raj100% (1)

- Rover V8 Fuel Injection SystemsDokument16 SeitenRover V8 Fuel Injection SystemsClint Cooper100% (1)

- EE-415 Gas Turbine Power GenerationDokument31 SeitenEE-415 Gas Turbine Power GenerationMuhammad Farooq MalikNoch keine Bewertungen

- Comparison of Diesel and Petrol EnginesVon EverandComparison of Diesel and Petrol EnginesBewertung: 2.5 von 5 Sternen2.5/5 (3)

- Diesel Power Plantfinal PDFDokument26 SeitenDiesel Power Plantfinal PDFVedant NoNoch keine Bewertungen

- Diesel & GasDokument17 SeitenDiesel & GasJerry Andrews100% (1)

- Gas Engines, Combined Cycles and TrigenerationDokument9 SeitenGas Engines, Combined Cycles and Trigenerationsimon107Noch keine Bewertungen

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsVon EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsNoch keine Bewertungen

- Power Electronics For Renewable Energy Systems PDFDokument160 SeitenPower Electronics For Renewable Energy Systems PDFSUSHITANoch keine Bewertungen

- Working Principle Gas Turbine and Combined Cycles, Auxiliary SystemsDokument27 SeitenWorking Principle Gas Turbine and Combined Cycles, Auxiliary SystemsRey Danielle Navea100% (2)

- F0358 CMM 010Dokument164 SeitenF0358 CMM 010MJI EUWNoch keine Bewertungen

- Gas Turbine Power Plant BasicsDokument62 SeitenGas Turbine Power Plant Basicschegg study100% (2)

- Form I Integrated Science End of Year ExamDokument10 SeitenForm I Integrated Science End of Year ExamMiss Rambaran100% (2)

- CCIOM, Diagnostic Trouble CodesDokument6 SeitenCCIOM, Diagnostic Trouble CodesHari Hara Suthan80% (5)

- Power Plant Engineering Unit:Iv Gas Turbine PlantDokument30 SeitenPower Plant Engineering Unit:Iv Gas Turbine PlantshivaNoch keine Bewertungen

- Unit 2 Engineering Alloys (Ferrous and Non-Ferrous) : StructureDokument63 SeitenUnit 2 Engineering Alloys (Ferrous and Non-Ferrous) : StructureKelvin TyhNoch keine Bewertungen

- CFD (AE2402) Question BankDokument6 SeitenCFD (AE2402) Question Bankaeroacademic50% (2)

- TurbineDokument9 SeitenTurbineKabir Bashir ShariffNoch keine Bewertungen

- Astm G154Dokument11 SeitenAstm G154jesoneliteNoch keine Bewertungen

- Gas Turbine Power PlantDokument42 SeitenGas Turbine Power PlantMuralikrishnan GM100% (3)

- Cogeneration CycleDokument30 SeitenCogeneration Cyclekaladher5311937Noch keine Bewertungen

- Gas Turbine Power PlantsDokument8 SeitenGas Turbine Power Plantssakibsultan_308Noch keine Bewertungen

- Combined Cycle Power PlantDokument29 SeitenCombined Cycle Power Plantrajib0403050cuetNoch keine Bewertungen

- The Breaker Failure Protection BFP Schemes in UtilitiesDokument9 SeitenThe Breaker Failure Protection BFP Schemes in UtilitiesTrigras Bangun PerkasaNoch keine Bewertungen

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesVon EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNoch keine Bewertungen

- Gas Turbine Power Station: American International University-Bangladesh (AIUB)Dokument35 SeitenGas Turbine Power Station: American International University-Bangladesh (AIUB)Ahasan Ulla100% (2)

- Gas Turbines Applications ReportDokument9 SeitenGas Turbines Applications ReportKareem Ibrahim Mohamed NasrNoch keine Bewertungen

- Combined Gas and Steam Power PlantDokument8 SeitenCombined Gas and Steam Power Planttushar1128100% (1)

- Introduction To Gas Turbines: Aero Derivative AndDokument52 SeitenIntroduction To Gas Turbines: Aero Derivative And121710801027 HARI KRISHNAN SURESHNoch keine Bewertungen

- DSM Carbon Footprint StudyDokument12 SeitenDSM Carbon Footprint StudyAbdul Rahman100% (1)

- Steam Power PlantDokument9 SeitenSteam Power PlantAnne Gabrielle DavidNoch keine Bewertungen

- Induatrial Training at Pragati Ippgcl and PPCLDokument25 SeitenInduatrial Training at Pragati Ippgcl and PPCLshubham Shakya100% (1)

- Lecture 17Dokument27 SeitenLecture 17Saleem KhanNoch keine Bewertungen

- Introduction: Diesel Power Station: OperationDokument35 SeitenIntroduction: Diesel Power Station: OperationRomy Solino FongsiNoch keine Bewertungen

- Diesel EngineDokument15 SeitenDiesel EnginePankaj TripathiNoch keine Bewertungen

- Chapter 3Dokument29 SeitenChapter 3Hasif EnazNoch keine Bewertungen

- Natural Gas EquipmentDokument26 SeitenNatural Gas Equipmenthanisshi100% (1)

- AEMSDokument28 SeitenAEMSGARVIT SRIVASTAVANoch keine Bewertungen

- Gas Power Plant PDFDokument12 SeitenGas Power Plant PDFPraveenAnchupogu100% (1)

- Pasgt Act 3Dokument7 SeitenPasgt Act 3Ramil SalundagaNoch keine Bewertungen

- Gas Turbine Power Plant Working PrincipleDokument3 SeitenGas Turbine Power Plant Working PrincipleAraiza FloresNoch keine Bewertungen

- DIESEL POWER PLANT COMPONENTSDokument26 SeitenDIESEL POWER PLANT COMPONENTSMark LimboyNoch keine Bewertungen

- Lec-9 - MCE 4805 - Diesel Power PlantDokument44 SeitenLec-9 - MCE 4805 - Diesel Power PlantWinden CaveNoch keine Bewertungen

- Co-Generation SystemDokument5 SeitenCo-Generation SystemPavan AherNoch keine Bewertungen

- New Microsoft Word DocumentDokument7 SeitenNew Microsoft Word DocumentAnil KandakatlaNoch keine Bewertungen

- Topic: - Power Cogeneration Plant: Term Paper OF Project ManagementDokument13 SeitenTopic: - Power Cogeneration Plant: Term Paper OF Project ManagementankuaaaNoch keine Bewertungen

- Research For ReportingDokument4 SeitenResearch For ReportingAnonymous cMvETWUNoch keine Bewertungen

- Delacruz, Constantino, Hapita - GAS TURBINE POWER PLANTDokument11 SeitenDelacruz, Constantino, Hapita - GAS TURBINE POWER PLANTCliff Joen CarurucanNoch keine Bewertungen

- DGsetDokument14 SeitenDGsetAntony HegdeNoch keine Bewertungen

- Power Plant Engineering BasicsDokument21 SeitenPower Plant Engineering BasicsSiman NapstervkkNoch keine Bewertungen

- Gas Turbine Characteristics and OperationDokument41 SeitenGas Turbine Characteristics and OperationMohamed ElgendyNoch keine Bewertungen

- How Gas Turbine Power Plants WorkDokument6 SeitenHow Gas Turbine Power Plants WorkokemmaNoch keine Bewertungen

- DG Set System: Syllabus Diesel Generating System: Factors Affecting Selection, Energy Performance Assessment ofDokument14 SeitenDG Set System: Syllabus Diesel Generating System: Factors Affecting Selection, Energy Performance Assessment ofJitendra PatilNoch keine Bewertungen

- Gas TurbineDokument6 SeitenGas Turbineusama shehrozNoch keine Bewertungen

- Diesel Engine PPDokument52 SeitenDiesel Engine PPSushanthNoch keine Bewertungen

- 3 CH 9Dokument16 Seiten3 CH 9Pradeep Srivastava SrivastavaNoch keine Bewertungen

- Stirling Engine Term Project ReportDokument18 SeitenStirling Engine Term Project ReportAnis Badshah75% (4)

- Gas Turbines - Hassan ElBanhawiDokument3 SeitenGas Turbines - Hassan ElBanhawijesus_manrique2753Noch keine Bewertungen

- Unit-3: Diesel Power Plant LayoutDokument12 SeitenUnit-3: Diesel Power Plant LayoutPavankumar PavankumarpvNoch keine Bewertungen

- B 2.1 Introduction of Steam TurbineDokument22 SeitenB 2.1 Introduction of Steam TurbineSuren Thar100% (1)

- A Gas Turbine UnitDokument9 SeitenA Gas Turbine UnitTITU NATHNoch keine Bewertungen

- Unit-Iii PpeDokument17 SeitenUnit-Iii PpeRAJASEKHAR KNoch keine Bewertungen

- ME 2403 Power PlantDokument11 SeitenME 2403 Power Plantamsk24_24Noch keine Bewertungen

- KeyDokument1 SeiteKeyamsk24_24Noch keine Bewertungen

- University College of Engineering ThirukkuvalaiDokument7 SeitenUniversity College of Engineering Thirukkuvalaiamsk24_24Noch keine Bewertungen

- Unit-I Power PlantsDokument22 SeitenUnit-I Power Plantsamsk24_24Noch keine Bewertungen

- Impact FactorDokument338 SeitenImpact FactorsptbalaNoch keine Bewertungen

- BRM QPDokument3 SeitenBRM QPamsk24_24Noch keine Bewertungen

- Nuclear Engg Question BankDokument15 SeitenNuclear Engg Question Bankamsk24_24Noch keine Bewertungen

- Ppce Essay & Two MarksDokument29 SeitenPpce Essay & Two Marksamsk24_24Noch keine Bewertungen

- Nuclear Engg Question BankDokument15 SeitenNuclear Engg Question Bankamsk24_24Noch keine Bewertungen

- Mel341 2hDokument41 SeitenMel341 2hamsk24_24100% (1)

- Contents:: Rocket PropulsionDokument29 SeitenContents:: Rocket Propulsionamsk24_24Noch keine Bewertungen

- Impact FactorDokument338 SeitenImpact FactorsptbalaNoch keine Bewertungen

- Industrial Safety at RWE Power AG: Reducing Accidents Through Technical and Organizational MeasuresDokument18 SeitenIndustrial Safety at RWE Power AG: Reducing Accidents Through Technical and Organizational MeasuresCheu Hann Jong100% (1)

- LaptopDokument22 SeitenLaptopamsk24_24Noch keine Bewertungen

- Fluid Mechanics NotesDokument0 SeitenFluid Mechanics Notesamsk24_24Noch keine Bewertungen

- Anna University Anna University Anna University: Chennai-25 Chennai-25 Chennai-25Dokument1 SeiteAnna University Anna University Anna University: Chennai-25 Chennai-25 Chennai-25Rama ShivanNoch keine Bewertungen

- HDFC ApplicationDokument6 SeitenHDFC Applicationamsk24_24Noch keine Bewertungen

- Strength of MaterialsDokument21 SeitenStrength of MaterialsrssdpmNoch keine Bewertungen

- LGDokument1 SeiteLGamsk24_24Noch keine Bewertungen

- EE2252 Unit 1Dokument25 SeitenEE2252 Unit 1amsk24_24Noch keine Bewertungen

- Bhel Paper On 7TH AugustDokument15 SeitenBhel Paper On 7TH Augustamsk24_24Noch keine Bewertungen

- Bereavement Is InestimableDokument1 SeiteBereavement Is Inestimableamsk24_24Noch keine Bewertungen

- WT1 Production Planning and ControlDokument1 SeiteWT1 Production Planning and Controlamsk24_24Noch keine Bewertungen

- LicenseDokument6 SeitenLicensemerrysun22Noch keine Bewertungen

- CIVIL AND MECHANICAL ENGINEERING QUESTION BANKDokument11 SeitenCIVIL AND MECHANICAL ENGINEERING QUESTION BANKamsk24_24Noch keine Bewertungen

- Me2151 Engineering MechanicsDokument1 SeiteMe2151 Engineering Mechanicsamsk24_24Noch keine Bewertungen

- F1 04Dokument15 SeitenF1 04amsk24_24Noch keine Bewertungen

- Pump Inlet Piping DesignDokument2 SeitenPump Inlet Piping DesignWayaya WaziwupyaNoch keine Bewertungen

- Hypercell 1994 Engl by Hans HassDokument126 SeitenHypercell 1994 Engl by Hans HassClaimDestinyNoch keine Bewertungen

- Calibrar Slide Valve y Slid Stop en Compresor NH3Dokument4 SeitenCalibrar Slide Valve y Slid Stop en Compresor NH3Hector0412Noch keine Bewertungen

- Pharmaceutical Refrigerators with Built-In FreezerDokument2 SeitenPharmaceutical Refrigerators with Built-In FreezerEslam HassanNoch keine Bewertungen

- Engineering Physics - G. AruldhasDokument100 SeitenEngineering Physics - G. AruldhasJaya sankarNoch keine Bewertungen

- Marine Propulsion Engines GuideDokument20 SeitenMarine Propulsion Engines GuideyoungfpNoch keine Bewertungen

- Timing Chain InstallationDokument5 SeitenTiming Chain InstallationToriTo LevyNoch keine Bewertungen

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDokument5 SeitenTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNoch keine Bewertungen

- Biofuel For Sri LankaDokument0 SeitenBiofuel For Sri LankaJaanu SanthiranNoch keine Bewertungen

- 66 KV Design Parameters in GujaratDokument1 Seite66 KV Design Parameters in GujaratAkhilesh SolankiNoch keine Bewertungen

- IV Report 1-1Dokument11 SeitenIV Report 1-1sree lekshmiNoch keine Bewertungen

- Came 1998Dokument18 SeitenCame 1998pradeepsmart1988100% (1)

- Huawei PI OverviewDokument15 SeitenHuawei PI OverviewHdz EdilNoch keine Bewertungen

- DC DC Design GuideDokument23 SeitenDC DC Design Guidehammouche_soufianeNoch keine Bewertungen

- Klauke - Different Crimping MethodsDokument4 SeitenKlauke - Different Crimping MethodsBiplab PaulNoch keine Bewertungen

- 400TheoryTest AcrobatDokument4 Seiten400TheoryTest AcrobatRiahi RezegNoch keine Bewertungen

- Power and Wiring Cables GuideDokument82 SeitenPower and Wiring Cables GuideZzzdddNoch keine Bewertungen

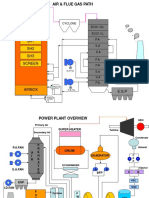

- Air & Flue Gas Path CFBCDokument2 SeitenAir & Flue Gas Path CFBCJAY PARIKHNoch keine Bewertungen

- Ega125 gr05 Emsc SG 0001 20200925Dokument238 SeitenEga125 gr05 Emsc SG 0001 20200925api-292325707Noch keine Bewertungen

- Water Wash Procedure For EconomizerDokument3 SeitenWater Wash Procedure For EconomizerRajendra100% (1)

- HuwaSan BrochureDokument8 SeitenHuwaSan BrochureWilly CalmaNoch keine Bewertungen

- Rod BaffelsDokument2 SeitenRod BaffelsVenkatesh SivarchanaNoch keine Bewertungen