Beruflich Dokumente

Kultur Dokumente

CFP

Hochgeladen von

sumit_b123Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CFP

Hochgeladen von

sumit_b123Copyright:

Verfügbare Formate

Priming of a centrifugal pump

Priming is the process of filling the suction

pipe, casing of the pump and the delivery

pipe upto the delivery valve with the liquid

to be pumped.

If priming is not done the pump cannot

deliver the liquid due to the fact that the

head generated by the

Impeller will be interms of meters of air

which will be very small (therefore specific

weight of air is very much smaller than that

of water).

Priming of a centrifugal pump can be done

by any one of the following methods.

i) Priming with suction/vacuum pump.

ii) Priming with a jet pump.

iii)Priming with separator.

iv)Automatic or self priming.

Heads on a centrifugal pump

Suction head (h

s

) it is the vertical distance

between the liquid level

in the sump and the centre line of the pump.

It is expressed as meters.

Delivery head (h

d

) It is the vertical distance

between the centre line of the pump and the

liquid level in the overhead tank or the supply

point. It is expressed in meters.

Static head (H

s

) It is the vertical difference

between the liquid levels

In the overhead tank and the sump, when the

pump is not working. It is expressed as

meters.Therefore H

S

=(h

s

+h

d

)

Friction head (h

f

) It is the sump of the head

loss due to the friction in the suction and

delivery pipes. The friction loss in both the

pipes is calculated using the Darcys

equation. H

f

=(fLV

2

/2gD).

Total head (H). It is the sum of the static head H

s

,

friction head (h

f

) and the velocity head in the

delivery pipe (Va

2

/2g). Where, V

d

=velocity in the

delivery pipe.

Manometric head(H

m

)It is the total head

developed by the pump. This head is slightly less

than the head generated by the impeller due to

some losses in the pump

) 1 (

2

2

|

|

.

|

\

|

+ + + =

g

Vd

h h h H

f d s m

Working of a centrifugal pump:

A centrifugal pump works on the principal

that when a certain mass of fluid is rotated

by an external source, it is thrown away

from the central axis of rotation and a

centrifugal head is impressed which enables

it to rise to a higher level.

Working operation of a centrifugal pump is

explained in the following steps.

1)Close the delivery valve and prime the pump.

2)Start the motor connected to the pump shaft,

this causes an increase in the impeller

pressure.

3)Open the delivery valve gradually, so that the

liquid starts flowing into the deliver pipe.

4) A partial vacuum is created at the eye of the

centrifugal action, the liquid rushed from the

sump to the pump due to pressure difference

at the two ends fo the suction pipe.

5) As the impeller continues to run, move &

more liquid is made available to the pump at

its eye. Therefore impeller increases the

energy of the liquid and delivers it to the

reservoir.

6) While stopping the pump, the delivery valve

should be closed first, otherwise there may be

back flow from the reservoir.

It may be noted that a uniform velocity of flow is

maintained in the delivery pipe. This is due to the

special design of the casing. As the flow proceeds

from the tongue of the casing to the delivery pipe,

the area of the casing increases. There is a

corresponding change in the quantity of the liquid

from the impeller. Thus a uniform flow occurs in

the delivery pipe.

Operation difficulties in centrifugal pumps

a) Pump fails to pump the fluid.

Cause Remedial Measures

1) Improper priming due

to leakage of foot valve

or incomplete filling.

Repair or replace the

foot valve, prime

completely.

2) Head more than

design head

Reduce the head or

change the pump

3) Clogging of impeller,

suction pipe or strainer

Clean the suspected

part

4) Suction lift may be

excessive

Reduce the height of

pump above the sump

5) Speed more than

design speed

Connect another prime

mover of higher speed

6) Direction of rotation of

impeller is wrong

Change the direction.

B) Pump does not give the

required capacity

a) Leakage of air through

the suction pipe or

through the gland

packing

Stop the leakage

b) Damage to some parts

of the pump by wear &

tear

Replace the damaged

parts

c) Clogging of impeller

passages

Clean the impeller

C) Pump has poor efficiency

a) Higher than design

speed

Reduce the speed

b) Low head & higher

discharge

Reduce the

discharge

c) Impeller touching, the

casing or improper

alignment of shaft

Carryout the

necessary repair.

D) Pump stops working

a) Air entry into suction

pipe

Stop the pump, plug

the leakage, reprime

and start

b) Suction lift is high Reduce the suction

lift.

Efficiencies of centrifugal pump

Manometric efficiency (): it is the ratio

of the manometric head to the head

actually generated by the impeller

)

`

=

)

`

=

2 2 2

u Vw

gHm

u2/g Vw

Hm

n mano

Mechanical efficiency(

mech

):

It is the ratio of the impeller power to the

power of the motor or the prime mover.

)

`

=

power motor

power impeller

mech n

Overall efficiency(

o

): It is the ratio of the

work done by the pump in lifting water

against gravity and friction in the pipes to the

energy supplied by the motor.

)

`

=

motor or mover prime the of power

friction gravity against done work

no

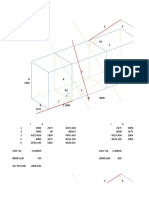

Velocity triangles of centrifugal pump:

Fig shows the inlet and outlet velocity

triangles for a centrifugal pump. It may be

noted that the inlet velocity triangle is

radial (i.e velocity of whirl at the inlet

0 V

w

=

Velocity Triangles of a Centrifugal Pump

Figure shows the inlet and outlet velocity

triangles for a centrifugal pump.It may be noted

that the inlet velocity triangle is radial,(velocity of

whirl is zero at inlet or vw1=0

Depending on the geometry of the blade at outlet

it can be:

Forward:if the blade angle<90

0

,Radial if =90

0

,

c) Backward if

0

90 > |

Work done by the impeller of a centrifugal

pump:

Figure shows the velocity triangles at the

inlet and outlet tips of a vane fixed to the

impeller.

Let N=speed of the impeller in RPM

D= Diameter of the impeller at inlet

1

D=Diameter of the impeller at outlet

U= Tangential velocity of the impeller at inlet

U= tangential velocity of the impeller at

outlet

V=absolute velocity of the liquid at inlet

v= absolute velocity of the liquid at outlet.

2

2

2

1

1

N/60 D

1

N/60 D

2

are the velocities of flow at

inlet and outlet.

2 1

Vf & Vf

2 1

Vr & Vr

Relative velocities at inlet and outlet

whirl velocity at outlet

angle made by with respect to

the motion of the vane

blade angle at inlet

2

Vw

o

1

V

u

= blade angle at outlet

For a series of curved vanes the force

exerted can be determined using the

impulse momentum equation

Work=force x distance.

similarly the work done/sec/unit weight

of the liquid striking the vane

|

) u Vw u (Vw

g

1

1 1 2 2

But for a centrifugal pump

Work done/sec/unit weight

And the work done/sec

Where Q=volume of liquid flowing per

second = Area x velocity of flow

) 5 ( =

2 2 2

Vf B D Q

0 V

1

=

g

u Vw

2 2

) 4 (

2 2

u Vw

g

Q

In eq (5), is the width of the

impeller at the outlet.

2

B

60

N D

u

2

2

=

Rim diameter

Design factors of centrifugal pumps:

a)Rim diameter

Rim velocity or impeller velocity

2

D

2gHm K

u

=

Hm 2gKu

N

60

D

2

=

Hm K

N

85

u

Where N= speed in RPM Hm=

manometric head, m

ratio speed 2gHm / U K

2 u

= =

Value of varies from 0.95 to

1.8 depending on the specific

speed.

b) Pipeline diameter:

u

K

The diameter of section and delivery pipes

are designed to give velocities not

exceeding 1.5 to 3 m/s on section and

delivery sides.

c) Discharge (Q): the discharge or capacity

of a centrifugal pump is given by

Where k =factor which accounts the

reduction in flow area due to

2 2 2

Vf B D K Q =

To thickness of impeller vanes,

D

2

=Rim diameter,B

2

=Rim width,

V

f2

=Constant velocity of flow through the

impeller. Generally k=1 is considered.

1. A centrifugal pump running at 800 Rpm is

working against a total head of 20.2 m. the

external diameter of the impeller is 480mm

and outlet width 60mm. If the valve angle at

outlet is 40 and manometric efficiency is 70%

determine

a)Flow velocity at outlet

b)Absolute velocity of water leaving

The vane.

c) Angle made by the absolute velocity at

outlet with the direction of motion at outlet.

d) Rate of flow through the pump.

Soln: velocity of vane at outlet

60

2

2

N D

u

t

=

2 2

u Vw

gHm

n efficiency manometric

mano

=

s m Vw / 08 . 14

2

=

From the outlet velocity triangle

2 2

2

tan

Vw u

Vf

= |

s m

x x

/ 1 . 20

60

800 48 . 0

= =

t

1 . 20

2 . 20 81 . 9

70 . 0

2

x Vw

x

=

s m x Vf / 05 . 5 ) 08 . 14 1 . 20 ( 40 tan

0

2

= =

s m Vw Vf V / 96 . 14 08 . 14 05 . 5

2 2 2

2

2

2 2

= + = + =

Angle made by the absolute velocity at outlet

with the direction of motion is given by

3586 . 0

08 . 14

05 . 5

tan

2

2

= = =

Vw

Vf

|

Absolute velocity of water leaving the valve

is given by

0

7 . 19 = |

2. A centrifugal pump impeller having

external and internal diameter 480mm

and 240mm respectively is running at 100

Rpm. The rate of flow through the pump is

0.0576 m3/s and velocity of flow

05 . 5 06 . 0 48 . 0

2 2 2

x x x Vf B D Q t t = =

s m / 3 457 . 0 =

Rate of flow through the pump

Is constant and equal to 2.4m/s. the diameter

of the section and delivery pipes are 180mm

and 120mm respectively and section and

delivery heads are 6.2m(abs) and 30.2m(abs)

of water respectively. If the power required to

drive the pump is 23.3KW and the outlet vane

angle is 45 determine. a) inlet vane angle

b) Overall efficiency c) manometric

efficiency of the pump

Soln: tangential velocity or impeller

velocity at inlet

s m

x x N D

u / 56 . 12

60

1000 24 . 0

60

1

1

= = =

t t

From the inlet velocity triangle

191 . 0

56 . 12

41 . 2

tan

1

1

= = =

u

Vf

|

) ( 8 . 10

0

angle vave inlet = u

3 . 23

05 . 0 81 . 9

0

xHm x

P

rQHm

n = =

Overall efficiency

) 1 ( 02387 . 0

0

Hm n =

)

`

|

|

.

|

\

|

+ +

|

|

.

|

\

|

+ + =

g

V

r

p

Z

g

V

r

p

Z Hm but

2 2

2

1 1

1

2

2 2

2

s m

x

x

d

Q

V V where

d

d

/ 01 . 5

12 . 0

0567 . 0 4 4

2 2

2

= = = =

t t

2 1

Z Z let =

s m

x

x

d

Q

V V where

s

s

/ 23 . 2

18 . 0

0567 . 0 4 4

2 2

2

= = = =

t t

i.e pump inlet and outlet are

at same level.

) ( 2 . 6

1

abs m h

r

p

s

= =

) ( 2 . 30

2

abs m h

r

p

d

= =

m

x x

Hm 03 . 25

81 . 9 2

23 . 2

2 . 6

81 . 9 2

01 . 5

2 . 30

2

2

=

|

|

.

|

\

|

+

|

|

.

|

\

|

+ =

overall efficiency of pump

=0.02387x25.03=0.597=59.7%

Velocity of the impeller at outlet

s m

x x N D

u / 13 . 25

60

1000 48 . 0

60

2

2

= = =

t t

From the outlet velocity triangle

0

n

2 2

2

tan

Vw u

Vf

= |

Manometric efficiency

% 43 43 . 0

13 . 25 73 . 22

03 . 25 81 . 9

2 2

= = = =

x

x

u Vw

gHm

n

mano

2

0

13 . 25

4 . 2

45 tan

Vw

=

s m Vw / 73 . 22

2

=

3.It is required to deliver 0.048m3/s of water

to a height of 24m through a 150mm

diameter and 120m long pipe by a

centrifugal pump. If the overall

Efficiency of the pump is 75% and co

efficient of friction f=0.01 for the pipe

line. Find the power required to drive

the pump.

Soln: velocity of water pipe

2

4

d

Q

V V V

d s

t

= = =

s m

x

x

/ 7 . 2

15 . 0

048 . 0 4

2

= =

t

Head loss due to friction

m

x x

x x x

0 . 3

15 . 0 81 . 9

048 . 0 120 01 . 0 8

5 2

2

=

|

|

.

|

\

|

=

t

5 2

2

8

D g

flQ

hf hf

d s

t

= +

Manometric head is given by

( ) ( )

g

Vd

hf hf h h H

d s d s m

2

2

+ + + + =

m

x

37 . 27

81 . 9 2

7 . 2

3 24

2

= + + =

P

rQHm

n =

0

P

x x 37 . 27 048 . 0 81 . 9

75 . 0 =

KW P 2 . 17 =

Overall efficiency

4. The impeller of a centrifugal pump is of

300mm diameter and 50mm width at the

periphery and has blades whose tip angle

incline backwards 60 from the radius. The

pump deliveries 17m3/min of water and

the impeller rotates at 1000

Rpm. Assuming that the pump is design to

admit radically. calculate

a)Speed and direction of water as it leaves

the impeller

b)Torque exerted by the impeller on water

c)Shaft power required

d)Lift of the pump. Take mechanical

=95% and hydraulic efficiency=75%

Soln: tangential velocity of the impeller at

the outlet

s m

x x N D

u / 71 . 15

60

1000 3 . 0

60

2

2

= = =

t t

2 2 2

Vf B D Q t =

From continuity equation

s m

x x

Vf / 6

05 . 0 3 . 0

2833 . 0

2

= =

t

s m

Vf

u Vw / 24 . 12

60 tan

6

71 . 15

tan

0

2

2 2

=

|

.

|

\

|

=

|

|

.

|

\

|

=

|

From the outlet velocity triangle

2 2

2

tan

Vw u

Vf

= |

Absolute velocity of water at the outlet tip of

the impeller

2 2 2

2

2

2 2

24 . 12 6 + = + = Vw Vf V

) ( / 63 . 13

2

magnitude s m V =

0 1

2

2

1

5 . 26

24 . 12

6

tan tan =

|

.

|

\

|

=

|

|

.

|

\

|

=

Vw

Vf

|

Torque exerted by the impeller on water

)

2

3 . 0

24 . 12 (

81 . 9

2833 . 0 81 . 9

) (

2 2

x x

x

R Vw

g

rQ

T = =

m KN 52 . 0 =

Shaft power (P) impeller or rotor power

KW

x x NT

45 . 54

60

52 . 0 1000 2

60

2

= =

t t

power shaft

power impeller

n

mech

=

But, mechanical efficiency

P

e i

45 . 54

95 . 0 . = KW P 31 . 57 =

Lift of the pump

Impeller power=r(Q+q)H

Where r=sp wt of water=9.81 KN/m3

H =ideal head=(theoretical head-hyd losses)

Q=leakage of water m3/s

Neglecting leakages q we have

i

i

1

54.45=9.81x0.2833xH

Or, H =19.59m

We know hydraulic efficiency

i

i

head ideal

lift or head Actual

n

h

=

) (

i h

H head xideal n hft Actual =

water of m x 71 . 13 59 . 19 70 . 0 =

5. The following data relate to a centrifugal

pump. Diameter of the impeller at inlet & outlet

=180mm and 360mm respectively. width of

impeller at inlet and outlet=144mm & 72mm

respectively. rate of flow through the

pump=17.28lps. Speed of the impeller = 1500

Rpm. Vave angle at outlet=45 water enters the

impeller radially at inlet neglecting losses

Through the impeller. Find the pressure

rise in the impeller.

Soln: velocity of flow at inlet

0144 . 0 18 . 0

01728 . 0

1 1

1

x x B D

Q

Vf

t t

= =

Velocity of flow at outlet

s m

x x B D

Q

Vf / 12 . 2

0072 . 0 36 . 0

01728 . 0

2 2

2

= = =

t t

Tangential velocity of impeller at outlet

s m

x x N D

u / 27 . 28

60

1500 36 . 0

60

2

2

= = =

t t

Pressure rise in the impeller is given by the

equation

{ } |

2 2

2

2

2

2

1

cos

2

1

ec Vf u Vf

g

+ =

{ }

0 2 2 2 2

45 cos 12 . 2 27 . 28 12 . 2

81 . 9 2

1

ec x

x

+ =

0

1 . 68 48 . 2 tan = = u u or

0

95 . 111 =

The vane angle with the direction of

motion=(180-68.1)

7. The impeller of a centrifugal pump runs

at 90 Rpm and has vaves inclined at 120 to

the direction of motion at exit. If the

manometric head is 20m and manometric

efficiency is 75%

a)Diameter of the impeller at exit. B) Vane

angles at inlet. Take the velocity of flow

as 2.5m/s, throughout and the diameter

of the impeller at exit as twice that at inlet.

Soln: From the definition of manometric

efficiency

2 2

/ u Vw gHm

mano

= q

) ( 6 . 261

75 . 0

20 81 . 9

2 2

i

x

u Vw = =

From the outlet velocity triangle

44 . 1

60 tan

5 . 2

60 tan

) (

0 0

2

2 2

= = =

Vf

Vw u

) 44 . 1 (

2 2

= u Vw

Substituting the value

2

Vw

s m u u / 9 . 16 6 . 261 ) 44 . 1 (

2 2

= =

60

2

2

N D

u but

t

=

s m

x

x

D / 59 . 3

90

9 . 16 60

2

= =

t

further

s m

u

u / 45 . 8

2

9 . 16

2

2

1

= = =

From the inlet velocity triangle

2959 . 0

45 . 8

5 . 2

tan

1

1

= = =

u

Vf

u

) ( 48 . 16

0

Angle Vane Inlet = u

8. A centrifugal pump delivers 250lps against

a head of 20m. When the impeller rotates at

1500rpm. If the mano metric efficiency is

75% and the loss of head in the pump is

0.033V

2

2

, where V

2

is the absolute velocity at

exit.

a)The diameter of the impeller

b)The blade angle at exit

Take the width of the impeller at

exit as 0.4D where D is the

diameter of the impeller

Soln: D

xDx N D

u 5 . 78

60

1500

60

2

2

= = =

t t

2

1

199 . 0

4 . 0

25 . 0

D D xDx DB

Q

Vf = = =

t t

From the definition of

manometric efficiency

2 2

u Vw

gHm

n

mano

=

But, manometric

head=(workdone the impeller

losses in the pump)

20 7 . 26 033 . 0

2

2

= V

s m V / 25 . 14

2

=

7 . 26

75 . 0

20

2 2

= = =

mano

n

Hm

g

u Vw

From eq (i) and (ii)

From the outlet velocity triangle

D

Vw or

D x Vw 34 . 3

7 . 26

81 . 9

5 . 78

2

2

= =

2

1

2

2

2

2

V Vw Vf = +

2

2 2

2

2 . 14

34 . 3 199 . 0

=

|

.

|

\

|

+

|

.

|

\

|

D D

Solving by trial and error

D=0.242 m

s m x D u / 19 242 . 0 5 . 78 5 . 78

2

= = =

s m

D

Vf / 4 . 3

242 . 0

199 . 0 199 . 0

2 2

2

= = =

654 . 0

8 . 13 19

4 . 3

tan

2 2

2

=

|

.

|

\

|

=

Vw u

Vf

|

s m

D

Vw / 8 . 13

242 . 0

34 . 3 34 . 3

2

= = =

) ( 2 . 33

0

angle vane outlet = |

9. A centrifugal pump lifts water against a static

head of 40m. The section and delivery pipes are

each 15cm in diameter. The head loss in the

section and delivery pipes are respectively

2.20m and 7.5m. The impeller is 40cm in

diameter and 2.5cm wide at the month. It

revolves at 1200Rpm and the vane angle at exit

is 30. if the manometric efficiency is 80%.

Calculate the discharge.

Q xV x

s

=

2

15 . 0

4

t

=velocity in the sectionpipe

s

V

) ( 6 . 56 i Q V

s

=

Q Vf B D =

2 2 2

) (t

Q Vf x x =

2

) 025 . 0 4 . 0 (t

) ( 8 . 31

2

ii Q Vf =

From eq (a) and (b)

) ( 56 . 0

2

iii V Vf

s

=

Soln:

s m

x x N D

u now / 1 . 25

60

1200 4 . 0

60

2

2

= = =

t t

g

Vs

hf hf h h H

d s d s m

2

) (

2

+ + + + =

g

Vs

H

m

2

5 . 7 2 . 2 40

2

+ + + =

) (

2

7 . 49

2

iv

g

Vs

H

m

+ =

2 2

u Vw

gHm

n

mano

=

( )

)

`

+ = 1 . 25 30 cot 56 . 0 1 . 25 /

2

7 . 49 81 . 9 8 . 0

0

2

x x V

g

Vs

x

s

0 33 39

2

= +

s s

V V

) sec ( / 83 . 0 pipe tion the in velocity s m V

s

=

) arg ( / 3 0147 . 0

6 . 56

83 . 0

& e Disch s m Q = =

10. A centrifugal pump has a total lift of 15m and is

placed 2m above the water level in the sump. The

velocity of water in the delivery pipe is 2m/s.

If the radial velocity of flow through the wheel is

3m/s and tangent to the vane at exit makes an

angle of 60 find (a) the velocity of water at exit

(b) the guide vane angle the pressure at the

impeller exit. Neglect friction and other losses.

Soln: total head

m

g

Vd

20 . 15

62 . 19

2

15

2

15

2 2

=

|

|

.

|

\

|

+ = + =

From the outlet velocity triangle

0

2

2 2

60 tan

Vf

u Vw =

) 73 . 1 (

3

3

2 2

= = u u

Hm

g

u Vw

now =

2 2

,

2 . 15

81 . 9

) 73 . 1 (

.

2 2

=

u u

e i

s m u / 12 . 13

2

=

s m Vw / 39 . 11 ) 73 . 1 12 . 13 (

2

= =

78 . 11 3 39 . 11

2 2 2

2

2

2 2

= + = + = Vf Vw V

263 . 0

39 . 11

3

tan

2

2

= = =

Vw

Vf

|

0

75 . 14 = |

(guide vane angle at exit)

Applying bernoullis equation to points on the

sump water surface and impeller exit, taking

datum at the sump level.

Hm

g

V

r

p

+ + = + + 0 0 2

2

2

2 2

|

|

.

|

\

|

=

62 . 19

78 . 11

2 2 . 15

2

2

r

p

=6.13m of water (gauge)

11. The axis of a centrifugal pump is 2.5m

above the water level in the sump and the

static lift from the pump centre is 35m. The

friction losses in the section and delivery

Pipes are of 15cm diameter. The impeller is

30cm diameter and 2cm wide at outlet and its

speed is 1800 Rpm. The blade angle at exit is 30.

calculate the shaft power to be supplied and the

discharge delivered. Take n mano=75% and n

o=70%. If the guages are connected to the

section and delivery sides of the pump

determine the pressure indicated by these

guages.

Soln:

s m

x x N D

u / 3 . 28

60

1800 3 . 0

60

2

2

= = =

t t

) 732 . 1 3 . 28 ( ) 30 cot (

2

0

2 2 2

Vf Vf u Vw = =

Q

x x

Q

Vf 53

02 . 0 3 . 0

2

=

|

.

|

\

|

=

t

( ) ) 92 3 . 28 ( 53 732 . 1 3 . 28

2

Q Q x Vw = =

g

Vd

H

m

2

8 1 35 5 . 2

2

+ + + + =

|

.

|

\

|

+ =

2

2

15 . 0

4

62 . 19

1

5 . 46

x

Q

t

2

163 5 . 46 Q H

m

+ =

)

`

= +

81 . 9

3 . 28 ) 92 3 . 28 ( 75 . 0

163 5 . 46

2

x Q x

Q

)

2

5 . 46 (

2

g

Vd

+ =

g

u Vw

x n H

mano m

2 2

=

0

n

rQHm

power shaft =

KW 12 . 48

70 . 0

) 0725 . 0 163 5 . 46 ( 0725 . 0 81 . 9

2

x x x +

Solving the quadratic equation

Q=0.0725 m3/s

s s

hf

g

Vs

h

r

Ps

also =

2

,

2

{ } m x 36 . 4 1 0725 . 0 163 5 . 2

2

= + +

) ( / 77 . 42

2

vaccum m KN =

) (

1

rHm P P

s

+ =

2

1

/ 8 . 421 m KN P =

Pressure at the exit is given by

| | 81 . 9 ) 0725 . 0 163 5 . 46 ( 77 . 42

2

x x + + =

12. A centrifugal pump is required

to handle a sherry consisting of

sand and water (s=1.08). If the

Quantity of slurry to be pumped is 250lps against

a head of 15m. Find the power required by the

pump, taking its overall efficiency as 70%. Find

also the pressure developed by the pump.

Soln: power required

0

n

rQH

=

KW

x x x

76 . 56

70 . 0

15 25 . 0 ) 81 . 9 08 . 1 (

= =

Pressure developed

rH=9.81x1.08x15

2

/ 159 m KN or Kpa =

13. Design centrifugal pump impeller for the

following conditions, speed=800Rpm, head

=8m hydraulic efficiency =88%, overall

efficiency=80% shaft input =20KW, peripheral

coefficient=1.15 ratio of inlet to outlet

diameter=0.6, ratio

Of width to diameter at outlet=0.15, flow area

blocked by vanes=6%, find to be pumped is

gasoline of specific gravity=0.80.

Soln:

s m x x gHm K u

u

/ 4 . 14 8 62 . 19 15 . 1 2

2

= = =

s m x u u / 64 . 8 4 . 14 6 . 0 6 . 0

2 1

= = =

m

x

x

N

u

D diameter outer 344 . 0

800

4 . 14 60 60

2

2

= = =

t t

=34.4cm

Inlet or eye diameter

cm D

x D D

6 . 20

4 . 34 6 . 0 6 . 0

1

1 1

=

= =

cm x D B 16 . 5 4 . 34 15 . 0 15 . 0

2 2

= = =

0

n

rQHm

s m Q

xQx x

/ 3 255 . 0

8 . 0

8 8 . 0 81 . 9

20

=

=

s m

x x x B D K

Q

Vf Vf

/ 86 . 4

0516 . 0 344 . 0 94 . 0

255 . 0

2 2

2 1

=

)

`

= = =

t t

Shaft power

s m

x

x

u n

gHm

Vw

h

/ 19 . 6

4 . 14 88 . 0

8 81 . 9

2

2

= = =

0 1

1

1

1

4 . 29

64 . 8

86 . 4

tan tan =

|

.

|

\

|

=

|

|

.

|

\

|

=

u

Vf

u

From the inlet velocity triangle

From the outlet velocity triangle

|

.

|

\

|

=

|

|

.

|

\

|

=

19 . 6 4 . 14

86 . 4

tan tan

1

2 2

2

1

Vw u

Vf

u

0

6 . 30 = u

14. Determine the manometric and overall

efficiencies of a centrifugal pump from the

following data. Head =22m

discharge=160lps liquid pumped=brine of

specific gravity=1.18 speed=1200 Rpm

diameter=30cm, width=5cm shaft

power=55KW, vane angle at outlet =35

s m

x x B D

Q

Vf / 4 . 3

05 . 0 3 . 0

16 . 0

2 2

2

= = =

t t

From the outlet velocity triangle

s m

Vf

u Vw / 14 )

35 tan

4 . 3

85 . 18 ( )

tan

(

0

2

2 2

= = =

u

% 8 . 81 818 . 0

85 . 18 14

22 81 . 9

2 2

= = = =

x

x

u Vw

gHm

n

mano

power shaft

rQHm

n efficiency overall =

0

s m

x x N D

u / 85 . 18

60

1200 3 . 0

60

2

2

= = =

t t

Soln:

% 1 . 74 741 . 0

55

22 16 . 0 81 . 9 18 . 1

= =

)

`

=

x x x

Minimum speed for starting a centrifugal

pump.

When a centrifugal pump is started ,

Will start delivering liquid only if the pressure rise

in the impeller is more than or equal to the

manometric head (H mano). In other words, there

will be no flow of liquid until the speed of the

pump is such that the required centrifugal head

caused by the centrifugal force or rotating water

when the impeller is rotating, but there is no flow

i.e flow will commence only if

m

H

g

u u

>

2

2

1

2

2

For minimum starting speed, we

must have

m

H

g

u u

>

2

2

1

2

2

We know

2 2

u Vw

gHm

n

mano

=

g

n u Vw

H or

mano

m

2 2

=

) 3 (

60

,

60

2

2

1

1

N D

u

N D

u

t t

= =

Substituting eqn (2) & (3) in eq (1)

Dividing both the sides by

And simplifying

g

N

60

t

60 60 60 2

1

2 2

2

1

2

2

N D

x

g

Vw

x n

N D N D

g

mano

t t t

=

|

.

|

\

|

|

.

|

\

|

( )

2 2

2

1

2

2

120

D xVw n D D

N

mano

=

t

Problems

1. The impeller of a centrifugal pump is 1.0m

in diameter and 0.1m wide. It delivers 2m3/s

of water through a height of 45m while

running at 600 Rpm. If the blades are curved

|

|

.

|

\

|

= =

) (

120

2

1

2

2

2 2

min

D D

xD xVw n

N N

mano

t

outlet at flow of velocity Vf =

2

Backward and the outlet angle is 30 calculate

the manometric efficiency and the power

required to run the pump. Estimate the

minimum speed to start the pump if the

impeller diameter at inlet is 0.6m

Soln: from continuity equation

2 2 2

Vf B D Q t =

s m

x x N D

u / 85 . 18

60

600 6 . 0

60

1

1

= = =

t t

s m

x x

/ 37 . 6

1 . 0 1

2

= =

t

s m

x x N D

u / 42 . 31

60

600 1

60

2

2

= = =

t t

From the outlet velocity triangle

2 2

2

tan

Vw u

Vf

= |

2 2

u Vw

gHm

n

mano

=

s m orVw

Vw

/ 38 . 20

42 . 31

37 . 6

30 tan

2

2

0

=

=

Manometric efficiency

689 . 0

42 . 31 38 . 20

45 81 . 9

= =

x

x

Power given to the liquid

rQHm=9.81x2x45=882.9KW

)

`

=

) (

120

2

1

2

2

2 2

min

D D

n D Vw

N

mano

t

Minimum starting speed

2. The diameters of the impeller of a

centrifugal pump at inlet and outlet

are 40cm and 80cm respectively.

Determine the minimum starting

Rpm RPm

x x x

840 838

) 6 . 0 1 (

689 . 0 1 38 . 20 120

2 2

~ =

=

t

Speed if it works against a head of

25m.

Soln: for minimum starting speed

Hm

g

u u

>

2

2

1

2

2

Hm

N D N D

g

e i >

)

`

2

2 2

1

2

2

2 2

2

2

60 60 2

1

.

t t

{ } 25 4 . 0 8 . 0

60 81 . 9 2

1

2 2

2

2 2

=

xN

x

x

t

Solving for N, N=610.5Rpm (Min starting speed)

Multistage centrifugal pumps

When a centrifugal pump consist of two or more

impellers the pump is know as a multistage

centrifugal pump.

The important functions of a multistage

centrifugal pump are;

(i)To produce high head (pumps in

series)

(ii)To deliver or discharge large

quantities of a liquid (pumps in

parallel)

Pumps in parallel: it is an

arrangement made by mounting a

number of impellers on the shaft of

a motor as shown. Such an

Arrangement is useful when the liquid has to

be pumped to large heights keeping the

discharge constant. If, Hm is the head

developed by one impeller n= number of

impellers. Then, nxHm= total head developed

by the pump Q=discharge through the pump.

Pumps in parallel: it is an arrangement made

by connecting

A number of pumps in parallel as shown. Such an

arrangement is useful when a large quantity of

liquid is to be pumped to a particular height.

If Q=discharge from one pump

N=identical number pumps.

Then, nxQ= total discharge delivered by the

pump

Hm is the head developed by the pump.

Problems:

1. A three stage centrifugal pump has an

impeller of 40cm diameter and 2.5cm

thickness at outlet. The vanes are curved

back at the outlet at 30 and reduce the

circumfarential area by 15% the

manometric efficiency is 85%

And overall efficiency is 75% determine the

head generated by the pump when running

at 1200 Rpm and discharging 0.06m 3/s.

find the power required to drive the pump.

Soln: from the continuity equation

K= total percentage area available

2 2 2

Vf B D K Q t =

For flow=(1-0.15)=0.85

2

025 . 0 4 . 0 85 . 0 06 . 0 xVf x x xt =

s m Vf / 25 . 2

2

=

s m

x x N D

u / 13 . 25

60

1200 4 . 0

60

2

2

= = =

t t

From outlet velocity triangle

2 2

2

tan

Vw u

Vf

= |

s m Vw / 23 . 21

30 tan

25 . 2

13 . 25

0

2

=

)

`

=

Manometric efficiency

2 2

u Vw

gHm

n

mano

=

m

x x

H or

m

23 . 46

81 . 9

85 . 0 13 . 25 23 . 21

= =

Total head developed by the pump

H=3Hm=3x46.23=138.7m

Output of the pump

P=rQh=9.81x0.06x138.7=81.64KW

Power required to drive the pump

KW

n

P

85 . 108

75 . 0

64 . 81

0

= =

2. Find the number of impellers and

the diameter of each impeller

required for a multistage centrifugal

pump to lift 80lps of water against a

total head of 225m. Assume

speed=1500Rpm, approximate

specific speed=600 peripheral

Coefficient=0.96 and overall

efficiency=80% what is the shaft

input required

Soln: specific speed

4

3

m

s

H

Q N

N =

) ( 63

600

80 1500

3

4

stage per head m

x

H

m

=

)

`

=

4 57 . 3

63

225

or stages of number = =

Diameter of each impeller

m u

H K

N

85

=

m x x 432 . 0 63 96 . 0

1500

85

= =

KW

x x

n

rQHm

input shaft 7 . 220

8 . 0

225 08 . 0 81 . 9

0

= =

Specific speed (Ns)

The specific speed of a centrifugal

pump is defined as the speed of a

geometrically similar pump which

Would deliver unit quantity (1m 3/s)

against a unit head (1m). It is

denoted by Ns.

Specific speed is a characterstic of

pumps which can be used as a

basis for comparing the

performance of different pumps.

Expression for specific speed(Ns)

From continuity equation

Q=Area x velocity of flow

f

DBxV t =

) 1 ( . DBVf Q e i o

Where, D & B are diameter and

width of pump impeller.

) (

2

ii Vf D Q

D B but

o

o

Tangential velocity u is given by

) (

60

iii DN u or

DN

u o

t

=

Hm Vf or gHm K V also

f

o 2 =

Comparing eq (iii) and (iv)

) (vi

N

Hm

D Hm DN or o o

Substituting the value of D from eq

(vi) in eq (ii)

) (v H Vf u

m

o o

Hm x

N

Hm

Q

2

)

`

o

2

2

3

.

N

Hm

Q e i o

In order to eliminate the value of K

substitute Q=1m 3/s, H=1m and

N=Ns in eq(vii)

) (

1

1

2

2

2

3

viii N K or

N

Kx

s

s

= =

) (

2

2

3

vii

N

Hm

K Q or =

Substituting in eq(vii)

) (

4

3

2

3

2

ix

Hm

Q N

N or

N

Hm

N Q

s s

|

|

|

.

|

\

|

= =

2

s

N K =

The range of specific speeds Ns

for different types of pumps are:

Radial flow = 10 to 30

(slow speed)

Radial flow = 30 to 50

(Medium speed)

Radial flow = 50 to 80

(high speed)

Mixed flow = 80 to 160

(screw type)

Propeller type = 160 to 500

(or axial flow)

Problems:

1. Calculate the specific speed of a

centrifugal pump running at 1000

Rpm. The diameter of the impeller

is 30 cm and its width 6cm. The

pump delivers 120lps with a

manometric efficiency of 85%. The

effective outlet blade angle is 30.

neglect the thickness of blades.

Soln:

s m

x x N D

u / 7 . 15

60

1000 3 . 0

60

2

2

= = =

t t

s m

x x flow of area

Q

Vf / 12 . 2

06 . 0 3 . 0

12 . 0

1

= = =

t

From the outlet velocity triangle

s m

Vf

u Vw / 03 . 12

30 tan

12 . 2

7 . 15

tan

0

2

2 2

=

)

`

=

)

`

=

|

From the definition of manometric

efficiency

85 . 0

7 . 15 03 . 12

81 . 9

2 2

= = =

x

xHm

u Vw

gHm

n

mano

s m Hm / 36 . 16 =

Specific speed

6 . 42

) 36 . 16 (

12 . 0 1000

4

3

4

3

=

= =

x

Hm

Q N

N

s

Performance of centrifugal pumps:

Generally a centrifugal pump is

Worked under its maximum

efficiency conditions, however when

the pump is run at conditions other

than this it performs differently. In

order to predict the behaviour of the

pump under varying conditions of

speed, discharge and head, full

scale tests are usually performed.

The results of these tests are

plotted in the form of characteristic

curves. These curves are very

useful for predicting the

performance of pumps under

different conditions of speed,

discharge and head.

Following four types of

characteristic curves are usually

prepared for a centrifugal pump.

a.Main characteristic.

b.Operating characteristics

c.Constant efficiency or Muschel

characteristic.

d.Constant head an constant

discharge curves.

a. Main Characteristic: the pump

is operated a particular constant

speed, discharge is varied by

adjusting the delivery valve.

Manometric head H

m

and the

shaft power P are measured for

each discharge. The overall

efficiency is then calculated. The

curves are plotted between H

m

&

Q, P & Q, & Q.

0

q

0

q

A set of similar curves are plotted by

running the pump at different

speeds. They will be as shown.

b. Operating characteristic: The

curves are obtained by running the

pump at the design speed, which is

also the driving speed of the motor.

The design discharge and head are

obtained from the corresponding

Curves, where the efficiency is

maximum as shown.

c. Constant efficiency curves:

The constant efficiency curves are

obtained from the main

characteristic curves. The line of

maximum efficiency is obtained by

joining the points of the maximum

curvature of the constant efficiency

lines. These curves are useful in

Determining the range of operation

of a pump.

d. Constant head and constant

discharge curves: If the pump has

a variable speed, the plots between

Q and N and that between H

m

and

N may be obtained by varying the

speed. In the first case H

m

is kept

constant & in the second Q is kept

contant.

Model testing of centrifugal

pumps: Models of centrifugal

pumps are usually tested to predict

the performance of prototypes. The

discharge (Q) delivered by a

centrifugal pump depends upon the

Manometric head (H

m

), impeller dia

(D), power (P), speed (N), viscosity

( ), density (P) and acceleration

due to gravity (g).

i.e

By dimensions analysis, it can be

shown that

Hence, for completely dynamic

similarly to exist between the pump

model and its prototype, assuming

that g,P & are the same in the

model & the proto type.

{ } g p N P D H Q

m

, , , , , , | =

)

`

=

(

P N D

P

eND D N

hH

ND

Q

m

3 5 2 2 2 3

, ,

|

m

D N

Hm

D N

H

ND

Q

ND

Q

m

m P

(

=

(

=

(

=

(

2 2 2 2 3 3

;

m

N D

P

N D

P

ND ND

P m P

(

=

(

=

(

=

(

3 5 3 5 3 2

;

1 1

As long as the flow in th emodel is

turbulent can be

ignored (i.e equality of Reynolds

number).

(

=

(

2 2

1 1

ND ND

P

Moreover, the specific speed of the

model should be equal to that of the

prototype. i.e.

m

m

P

m

H

Q N

H

Q N

(

(

=

(

(

4

3 3

4

Problems:1) A half scale model of a

centrifugal pump runs at 7000Rpm

and has an impeller of 15cm,

diameter. If it delivers 0.04 cumes of

water under a head of 40m.

Calculate the speed and the head of

the prototype assuming the same

efficiency, what is the specific speed

of the pump if the discharge in the

prototype is 0.08m

3

/sec

Soln:

3 3

m m

P

P

P

D N

Q

D N

Q

=

3

|

|

.

|

\

|

=

P

m

m

P

m

P

D

D

x

Q

Q

N

N

Rpm x X N or

P

1750

2

1

04 . 0

08 . 0

7000

3

=

|

.

|

\

|

=

Also

( )

2 2 2 2

m m

m

m

P P

m

D N

H

D N

H

=

( ) ( )

m

m

m

P

m

P

P

m

H x

D

D

x

N

N

H

2

2

2

2

=

( ) ( ) m x x 10 40 2

1750

7000

2

2

=

|

.

|

\

|

=

( )

88

10

08 . 0 1750

4

3

4

3

= = =

X

H

Q N

N Speed Specific

m

S

2. Two geometrically similar pumps

are running at the same speed of

1000Rpm. One pump has an impeller

diameter of 300mm and lifts water at

the rate of 0.02m

3

/s against a head

of 15m. Determine the head and

impeller diameter of the other pump

to deliver half the discharge.

Solution:

2

4

3

4

3

(

(

=

(

(

m m

H

Q N

H

Q N

( ) ( )

2

4

3

4

3

01 . 0 1000

15

02 . 0 1000

. .

m

H

x x

e i =

( ) m H

m

45 . 9

2

=

2 1

(

(

=

(

(

DN

H

DN

H

m m

1000

45 . 9

1000 3 . 0

15

. .

2

x D

x

e i =

mm M D 238 238 . 0

2

= =

3. 3m

3

/s of water is lifted to a height

of 30m with an efficiency of 75% by a

single stage centrifugal pump. The

impeller diameter is 300mm and it is

rotating at 2000Rpm. Find the

number of stages and diameter of

each impeller of a similar multi stage

pump of lift 5m

3

/s to a height of 200m

when rotating at 1500Rpm.

Das könnte Ihnen auch gefallen

- Piping Interview QuestionsDokument6 SeitenPiping Interview Questionssumit_b123Noch keine Bewertungen

- Bolt Length Calculation: IS 6392-Table 11Dokument3 SeitenBolt Length Calculation: IS 6392-Table 11sumit_b123Noch keine Bewertungen

- Piping Interview QuestionsDokument6 SeitenPiping Interview Questionssumit_b123Noch keine Bewertungen

- Critical Seed of ShaftDokument5 SeitenCritical Seed of Shaftsumit_b123Noch keine Bewertungen

- Piping Interview QuestionsDokument6 SeitenPiping Interview Questionssumit_b123Noch keine Bewertungen

- Piping Interview QuestionsDokument6 SeitenPiping Interview Questionssumit_b123Noch keine Bewertungen

- Appendix-7 (To para 13.17 of Instructions To The Tenderer)Dokument1 SeiteAppendix-7 (To para 13.17 of Instructions To The Tenderer)sumit_b123Noch keine Bewertungen

- Bolt LengthDokument2 SeitenBolt Lengthsumit_b123Noch keine Bewertungen

- STRL PlatformDokument1 SeiteSTRL Platformsumit_b123Noch keine Bewertungen

- 3d Bend CalculationDokument4 Seiten3d Bend Calculationsumit_b123Noch keine Bewertungen

- Schematic: Plate - RectangularDokument7 SeitenSchematic: Plate - Rectangularsumit_b123Noch keine Bewertungen

- G M I P F: Alvanized Alleable RON IPE IttingsDokument1 SeiteG M I P F: Alvanized Alleable RON IPE Ittingsreach_arindomNoch keine Bewertungen

- Preliminary PageDokument6 SeitenPreliminary Pagesumit_b123Noch keine Bewertungen

- Spare 3Dokument202 SeitenSpare 3sumit_b123Noch keine Bewertungen

- Basic Calculations Piping System Design PDFDokument14 SeitenBasic Calculations Piping System Design PDFjeff_shawNoch keine Bewertungen

- 333Dokument1 Seite333sumit_b123Noch keine Bewertungen

- Computer ErrorDokument1 SeiteComputer Errorsumit_b123Noch keine Bewertungen

- Coke Oven By-Product PlantDokument9 SeitenCoke Oven By-Product PlantYudy TriyogaNoch keine Bewertungen

- ASTM A 403/A 403M - 96: Dimensions and TolerancesDokument4 SeitenASTM A 403/A 403M - 96: Dimensions and Tolerancessumit_b123Noch keine Bewertungen

- GDFHDokument202 SeitenGDFHsumit_b123Noch keine Bewertungen

- Spare 2Dokument202 SeitenSpare 2sumit_b123Noch keine Bewertungen

- Ip PDFDokument1 SeiteIp PDFecruz_yhwhNoch keine Bewertungen

- G M I P F: Alvanized Alleable RON IPE IttingsDokument1 SeiteG M I P F: Alvanized Alleable RON IPE Ittingsreach_arindomNoch keine Bewertungen

- Ip PDFDokument1 SeiteIp PDFecruz_yhwhNoch keine Bewertungen

- LarheDokument202 SeitenLarhesumit_b123Noch keine Bewertungen

- LarheDokument202 SeitenLarhesumit_b123Noch keine Bewertungen

- Mobile Codes One Sheeter UpdatedDokument2 SeitenMobile Codes One Sheeter Updatedsumit_b123Noch keine Bewertungen

- Branch ConnectionsDokument40 SeitenBranch ConnectionsJensNoch keine Bewertungen

- RegenDokument202 SeitenRegensumit_b123Noch keine Bewertungen

- PurgeDokument202 SeitenPurgesumit_b123Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)