Beruflich Dokumente

Kultur Dokumente

FUNDAMETALS GDT

Hochgeladen von

GanesanGovindarjOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

FUNDAMETALS GDT

Hochgeladen von

GanesanGovindarjCopyright:

Verfügbare Formate

Geometric Dimensioning and Tolerancing

Fundamentals

GD & T Fundamentals

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

OBJECTIVES

Fundamental drawing rules Units of measurement(DIMESIONING) Method of Tolerancing Units of angle measurement Need of gd&t on cad database model

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

certain values of tolerances, there is generally no gain in economy by increasing them further. These tolerances are not exceeded in normal workshop practice without particular effort.This is the normal (customary) workshop accuracy.

Rs

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

Each dimension shall have a tolerance except those dimensions specifically identified as reference, maximum, minimum, or stock. Each feature shall be fully dimensioned and tolerance so that there is a complete description of the characteristics of each part. Use only the dimensions that are necessary for a full definition of the part. Reference dimensions should be kept to a minimum.

Each dimension shall be selected and arranged to satisfy the function and mating relationship of the part and shall not be subject to more than one interpretation.

The drawing should define the part without specifying a particular method of manufacturing.

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

A basic 90 angle applies where centerlines of features in a pattern or surfaces shown at right angles on a drawing are located or defined by basic dimensions and angles are not specified. Unless otherwise specified, all dimensions are to be measured at 68F (20C). Measurements made at other temperatures may be adjusted mathematically. All dimensions apply in the free-state condition except for nonrigid parts. Unless otherwise specified, all geometric tolerances apply for the full depth, full length, and full width of the feature. Dimensions and tolerances apply only at the drawing level where they are specified. For example, a dimension specified for a particular feature on a detailed drawing is not required for that feature on an assembly drawing.

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

Units of Measurements:(DIMENSIONING)

1.Metric system 2.Inch system

Some industries using dual system

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

Dimensioning method

When specifying millimeter dimensions on drawings as described above A zero is placed before the decimal point for values less than one millimeter. Zeros are not added to the right of the decimal point when dimensions are a whole number plus some decimal fraction of a millimeter. (This practice differs when tolerances are written bilaterally or as limits. See Specifying Tolerances below.) Neither a decimal point nor a zero is shown where the dimension is a whole number.

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

Dimensioning method

When specifying decimal inch dimensions: A zero is never placed before the decimal point for values less than one inch. Some designers routinely place zeros before the decimal point for values less than one inch. This practice is incorrect and confusing for the reader. A dimension is specified with the same number of decimal places as its tolerance even if zeros need to be added to the right of the decimal point.

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

Method of Tolerancing:

1.Limit Tolerancing 2.Plus and minus Tolerancing

8/18/2013

Intellectual Design & Engineering

Geometric Dimensioning and Tolerancing

Fundamentals

When a unilateral tolerance is specified and either the plus or the minus limit is zero, a single zero is shown and no plus or minus sign is used. Where bilateral tolerancing is specified, both tolerance values have the same number of decimal places. Zeros are added when necessary. Where limit dimensioning and tolerancing is used, both values have the same number of decimal places even if zeros need to be added after the decimal point.

8/18/2013

Intellectual Design & Engineering

10

Geometric Dimensioning and Tolerancing

Fundamentals

When a unilateral tolerance is specified and either the plus or the minus limit is zero, its zero value will have the same number of decimal places as the other limit and the appropriate plus or minus sign. Where bilateral tolerancing is specified, both the dimension and tolerance values have the same number of decimal places. Zeros are added when necessary. Where limit dimensioning and tolerancing is used, both values have the same number of decimal places even if zeros need to be added after the decimal place.

8/18/2013

Intellectual Design & Engineering

11

Geometric Dimensioning and Tolerancing

Fundamentals

Basic Dimensions with GD & T

8/18/2013

Intellectual Design & Engineering

12

Geometric Dimensioning and Tolerancing

Fundamentals

Angular dimension are specified

1.Degree and decimal parts 2.degrees( )minutes()and second()

8/18/2013

Intellectual Design & Engineering

13

Geometric Dimensioning and Tolerancing

Fundamentals

Dimensioning and Tolerancing for CAD/CAM Database Models

Many designers feel that solid model drawings produced with CAD/CAM programs do not need to be dimensioned or toleranced.

The method of producing a design and transmitting that information to the manufacturing equipment is not the major cause of irregularity in parts. Although these systems may eliminate some human error, the major cause of part variation occurs as a result of a variety of other sources, such as

8/18/2013

Intellectual Design & Engineering

14

Geometric Dimensioning and Tolerancing

Fundamentals

Manufacturing influences

Material rigidity of the work piece (shape); material; stress in the material. precision of the machine tool, bearing play; static and dynamic rigidity of the machine tool; thermal properties of the machine tool; maintenance; environment (e.g. vibrations). tool; chuck, fixing, clamping method; processing data (e.g. cutting speed, thickness of cut, cutting pressure,cooling). uncorrected systematic measuring deviations; random measuring deviations. education, skillness, precision of re-chucking; environment.

Intellectual Design & Engineering 15

Machine (tool)

Method

Measuring Manufacturer

8/18/2013

Das könnte Ihnen auch gefallen

- PROCESS-sand CastingDokument1 SeitePROCESS-sand CastingGanesanGovindarjNoch keine Bewertungen

- Basic Pro Test1Dokument2 SeitenBasic Pro Test1GanesanGovindarjNoch keine Bewertungen

- Basic Questions - EngineeringDokument18 SeitenBasic Questions - EngineeringGanesanGovindarjNoch keine Bewertungen

- Sakthi Designs ElanceDokument18 SeitenSakthi Designs ElanceGanesanGovindarjNoch keine Bewertungen

- Intellectual Design and EngineeringDokument5 SeitenIntellectual Design and EngineeringGanesanGovindarjNoch keine Bewertungen

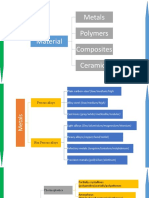

- Metals Polymers Composites CeramicsDokument23 SeitenMetals Polymers Composites CeramicsGanesanGovindarjNoch keine Bewertungen

- Pro/ENGINEER Questions-IIIDokument1 SeitePro/ENGINEER Questions-IIIGanesanGovindarjNoch keine Bewertungen

- Cold Rolled Full Annealed SheetsDokument1 SeiteCold Rolled Full Annealed SheetsGanesanGovindarjNoch keine Bewertungen

- Gaganesan CVDokument3 SeitenGaganesan CVGanesanGovindarjNoch keine Bewertungen

- Machinability The Relative Ease of Machining That Is Related To The Hardness of The Material To Be CutDokument1 SeiteMachinability The Relative Ease of Machining That Is Related To The Hardness of The Material To Be Cutgaganesan1972Noch keine Bewertungen

- IDE Firm Work FlowDokument1 SeiteIDE Firm Work FlowGanesanGovindarjNoch keine Bewertungen

- Backup of Intellectual - cdr1Dokument2 SeitenBackup of Intellectual - cdr1GanesanGovindarjNoch keine Bewertungen

- GopiDokument2 SeitenGopiGanesanGovindarjNoch keine Bewertungen

- Machinability The Relative Ease of Machining That Is Related To The Hardness of The Material To Be CutDokument1 SeiteMachinability The Relative Ease of Machining That Is Related To The Hardness of The Material To Be Cutgaganesan1972Noch keine Bewertungen

- SolidWorks Course MaterialDokument3 SeitenSolidWorks Course MaterialGanesanGovindarjNoch keine Bewertungen

- Mig WeldingDokument1 SeiteMig Weldinggaganesan1972Noch keine Bewertungen

- Injection MoldingDokument2 SeitenInjection MoldingGanesanGovindarjNoch keine Bewertungen

- Grinding OperationDokument1 SeiteGrinding Operationgaganesan1972Noch keine Bewertungen

- MMC GDTDokument34 SeitenMMC GDTGanesanGovindarjNoch keine Bewertungen

- Intellectualde Industry 2003Dokument20 SeitenIntellectualde Industry 2003GanesanGovindarjNoch keine Bewertungen

- Advanced WeldingDokument10 SeitenAdvanced WeldingGanesanGovindarjNoch keine Bewertungen

- Pro - E Course MaterialDokument4 SeitenPro - E Course MaterialGanesanGovindarjNoch keine Bewertungen

- Composite Tolerance GDTDokument67 SeitenComposite Tolerance GDTGanesanGovindarjNoch keine Bewertungen

- Unigraphics Course MaterialDokument5 SeitenUnigraphics Course MaterialGanesanGovindarjNoch keine Bewertungen

- Engineering Drawing & CAD Standards Mechanical Design/CAD Program C. Bales, M. VlamakisDokument24 SeitenEngineering Drawing & CAD Standards Mechanical Design/CAD Program C. Bales, M. VlamakisRajasekaran VtNoch keine Bewertungen

- Sakthi Design ProfileDokument12 SeitenSakthi Design ProfileGanesanGovindarjNoch keine Bewertungen

- Form Tolerance GDTDokument26 SeitenForm Tolerance GDTGanesanGovindarjNoch keine Bewertungen

- Orientation Tolerance GDTDokument30 SeitenOrientation Tolerance GDTGanesanGovindarjNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Meyer and Zack KM CycleDokument16 SeitenMeyer and Zack KM Cyclemohdasriomar84Noch keine Bewertungen

- HearstDokument16 SeitenHearstapi-602711853Noch keine Bewertungen

- GRADE 1 MUSIC Week 1 Learning PacketsDokument16 SeitenGRADE 1 MUSIC Week 1 Learning PacketsQuennie Rose EderNoch keine Bewertungen

- Glossario - GETTY - IngDokument24 SeitenGlossario - GETTY - IngFabio ZarattiniNoch keine Bewertungen

- Teacher Resource Disc: Betty Schrampfer Azar Stacy A. HagenDokument10 SeitenTeacher Resource Disc: Betty Schrampfer Azar Stacy A. HagenRaveli pieceNoch keine Bewertungen

- Esp-2000 BSDokument6 SeitenEsp-2000 BSByron LopezNoch keine Bewertungen

- English Literature Coursework Aqa GcseDokument6 SeitenEnglish Literature Coursework Aqa Gcsef5d17e05100% (2)

- Strategi Meningkatkan Kapasitas Penangkar Benih Padi Sawah (Oriza Sativa L) Dengan Optimalisasi Peran Kelompok TaniDokument24 SeitenStrategi Meningkatkan Kapasitas Penangkar Benih Padi Sawah (Oriza Sativa L) Dengan Optimalisasi Peran Kelompok TaniHilmyTafantoNoch keine Bewertungen

- Eat Something DifferentDokument3 SeitenEat Something Differentsrajendr200100% (1)

- Araldite 2020 + XW 396 - XW 397Dokument6 SeitenAraldite 2020 + XW 396 - XW 397Paul Dan OctavianNoch keine Bewertungen

- Industrial Training ReportDokument19 SeitenIndustrial Training ReportKapil Prajapati33% (3)

- Kharrat Et Al., 2007 (Energy - Fuels)Dokument4 SeitenKharrat Et Al., 2007 (Energy - Fuels)Leticia SakaiNoch keine Bewertungen

- New Python Basics AssignmentDokument5 SeitenNew Python Basics AssignmentRAHUL SONI0% (1)

- User Manual - Wellwash ACDokument99 SeitenUser Manual - Wellwash ACAlexandrNoch keine Bewertungen

- MSC 200Dokument18 SeitenMSC 200Amit KumarNoch keine Bewertungen

- Ansi Numerical CodeDokument6 SeitenAnsi Numerical Codekachra13Noch keine Bewertungen

- Role of ACT, S & WHO Guidlines For The Treatment of MalariaDokument34 SeitenRole of ACT, S & WHO Guidlines For The Treatment of MalariasalmanNoch keine Bewertungen

- Electrical System in AENDokument21 SeitenElectrical System in AENNilesh PatilNoch keine Bewertungen

- Karamadi - A Waning Practice of Shore Seine Operation Along Kerala, SouthwestDokument6 SeitenKaramadi - A Waning Practice of Shore Seine Operation Along Kerala, SouthwestQ8123Noch keine Bewertungen

- PTEG Spoken OfficialSampleTest L5 17mar11Dokument8 SeitenPTEG Spoken OfficialSampleTest L5 17mar11Katia LeliakhNoch keine Bewertungen

- Syllabus Math 305Dokument4 SeitenSyllabus Math 305Nataly SusanaNoch keine Bewertungen

- Generalised Ultimate Loads For Pile GroupsDokument22 SeitenGeneralised Ultimate Loads For Pile GroupsValerioNoch keine Bewertungen

- Personal ComputerDokument3 SeitenPersonal ComputerDan Mark IsidroNoch keine Bewertungen

- Unknown 31Dokument40 SeitenUnknown 31Tina TinaNoch keine Bewertungen

- Sip TrunkDokument288 SeitenSip TrunkSayaOtanashiNoch keine Bewertungen

- MY-SDK-10000-EE-005 - Method Statement For Concrete Pole Installation - GVB Rev1Dokument7 SeitenMY-SDK-10000-EE-005 - Method Statement For Concrete Pole Installation - GVB Rev1Seeths NairNoch keine Bewertungen

- Article On Role of Cyberspace in Geopolitics-PegasusDokument5 SeitenArticle On Role of Cyberspace in Geopolitics-PegasusIJRASETPublicationsNoch keine Bewertungen

- Vedic Town Planning ConceptsDokument17 SeitenVedic Town Planning ConceptsyaminiNoch keine Bewertungen

- Statistics 2Dokument121 SeitenStatistics 2Ravi KNoch keine Bewertungen

- Green Team Work PlanDokument2 SeitenGreen Team Work PlanScott FranzNoch keine Bewertungen