Beruflich Dokumente

Kultur Dokumente

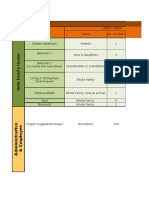

Anexa 3

Hochgeladen von

corneliamarcelaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Anexa 3

Hochgeladen von

corneliamarcelaCopyright:

Verfügbare Formate

Shaping a Simple Intarsia Rose

Is the the best way ?

No, it is the way we do it.. That does not make it the best for you. Try several until you find what you are comfortable with.

We start by gluing the pattern to the board, we use rubber cement

We choose the grain and color selection to cut

The piece we are working with is then cut out of the pattern

The saw we use is the DeWalt with a 20 throat

After the piece is cut, the pattern is peeled off

The uncut part of the pattern is peeled and used on the next piece

The pattern is then transferred to the next piece of the project

Each piece is added to the project as cut

Cutting continues

Cutting continues

Project completely cut out

The glue residue is removed from the cut pieces

Project with the glue removed

Leaves are marked to lower them

The leaves are cut or sanded to achieve the desired thickness

Leaf thickness has been reduced to add depth to the project

First flower petal is being shaped by sloping from outside edge

This shaping adds depth to the flower.

Second Petal is shaped, again sloping from outside edge

The third piece is rounded to give outside curve .

This piece is rounded from the Left and only slightly on the right

Notice the third piece appears to tuck under the piece to its right

The fourth piece is marked so it will stay above the third piece

This piece cups outward on the bottom and inward on the top

The outward curved bottom forms the base of the rose

The inside curve on the top of the piece forms the back petal

The fifth petal is shaped again from the outside to the inside

Remember this petal is reversed from the first petal

The sixth petal forms the back of the rose center

It is again formed from the outside sloping to the inside

The seventh petal is formed the same way

The eighth petal follows suit

The ninth piece if formed the same way, but because of size

A dremmel tool is used to form the slope

Ninth petal in place

The center of the rose is rounded over to fit the petals around it

The bottom petal is marked to fit against the previous pieces

It is then shaped to slope outwards from the center

It shapes with a short round over on the bottom side to show a fall

A flap sander is used for final sanding and to soften edges

Each piece is finish sanded

Special care is used to soften the edges

The flap sander works well to follow the contour of the petals

The finish sanding on the flower is completed

A light pencil mark is made as a guide for wood burning the veins

The veins are wood burned to give more movement to the leaf

The rose is ready to glue

The outline of the project is marked on the backing board

It is then cut out

On the roses, we do not edge glue, we glue only the backing

A coat of glue shown on the backing

The flower is placed onto the backing

Care is taken to make sure each piece is down firm on the backing

After the glue is dry, the backing is trimmed and beveled

We use Bartley Gel Varnish to finish our products

We find the paper rags are best for us they are cheap and lint free

We apply the varnish with a brush starting on the edge

The varnish is worked down into the rose to get complete coverage

We then wipe the gel off of the surface

Low air pressure melts the varnish that collects in cracks

The rose is complete

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Resit GrabDokument3 SeitenResit Grabhedzri50% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- (Chops From Hell) Francesco Fareri - Arpeggios PDFDokument47 Seiten(Chops From Hell) Francesco Fareri - Arpeggios PDFFernando Leme100% (6)

- E Indios de Bisayas (1668) by Francisco AlcinaDokument1 SeiteE Indios de Bisayas (1668) by Francisco AlcinaMary Ann Antenor100% (1)

- GR-DVL145: Digital Video CameraDokument64 SeitenGR-DVL145: Digital Video CameracorneliamarcelaNoch keine Bewertungen

- Strategii Si Politici Manageriale ANUL I, 2012-2013 Evaluarea Studenţilor Din Anul I La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RausDokument3 SeitenStrategii Si Politici Manageriale ANUL I, 2012-2013 Evaluarea Studenţilor Din Anul I La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RauscorneliamarcelaNoch keine Bewertungen

- Tgmures Medicina PDFDokument15 SeitenTgmures Medicina PDFcorneliamarcelaNoch keine Bewertungen

- MKCADokument3 SeitenMKCAcorneliamarcelaNoch keine Bewertungen

- MK1Dokument3 SeitenMK1corneliamarcelaNoch keine Bewertungen

- Mold - Bursier Mold - BursierDokument3 SeitenMold - Bursier Mold - Bursiercorneliamarcela100% (1)

- MG1Dokument3 SeitenMG1corneliamarcelaNoch keine Bewertungen

- Contabilitate Si Audit ANUL I, 2012-2013 Evaluarea Studenţilor Din Anul I La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RausDokument3 SeitenContabilitate Si Audit ANUL I, 2012-2013 Evaluarea Studenţilor Din Anul I La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din Rauscorneliamarcela0% (1)

- ECTS1Dokument3 SeitenECTS1corneliamarcelaNoch keine Bewertungen

- Ects Zi ANUL II 2012-2013 Evaluarea Studenţilor Din Anul Ii La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RausDokument3 SeitenEcts Zi ANUL II 2012-2013 Evaluarea Studenţilor Din Anul Ii La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RauscorneliamarcelaNoch keine Bewertungen

- Economie Agroalimentară Zi ANUL II 2012-2013 Evaluarea Studenţilor Din Anul Ii La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RausDokument3 SeitenEconomie Agroalimentară Zi ANUL II 2012-2013 Evaluarea Studenţilor Din Anul Ii La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RauscorneliamarcelaNoch keine Bewertungen

- CIG1Dokument3 SeitenCIG1corneliamarcelaNoch keine Bewertungen

- AI1Dokument2 SeitenAI1corneliamarcelaNoch keine Bewertungen

- Administrarea Afacerilor Internationale ANUL I, 2012-2013 Evaluarea Studenţilor Din Anul I La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RausDokument2 SeitenAdministrarea Afacerilor Internationale ANUL I, 2012-2013 Evaluarea Studenţilor Din Anul I La Sfârşitul Anului Universitar 2012-2013 Conform Legii Nr.224/2005 Şi Art.45 Din RauscorneliamarcelaNoch keine Bewertungen

- Firme 30Dokument14 SeitenFirme 30corneliamarcelaNoch keine Bewertungen

- B03 04 2010 Novac PDFDokument4 SeitenB03 04 2010 Novac PDFDejan MilenkovicNoch keine Bewertungen

- 020 - Autobiographical Power Point RubricDokument2 Seiten020 - Autobiographical Power Point RubricNarciso AgudaNoch keine Bewertungen

- Space Programming: Area/Space User'S Area Users No. of UsersDokument6 SeitenSpace Programming: Area/Space User'S Area Users No. of UsersMary Rose CabidesNoch keine Bewertungen

- Jan MielDokument6 SeitenJan MielBenjamin KonjicijaNoch keine Bewertungen

- Sienna Mynx-Black Butterfly - SexChecksFinalDokument9 SeitenSienna Mynx-Black Butterfly - SexChecksFinalLaura Rosales100% (2)

- Basic Belifs of Islam by Sayyed Qasim Mujtaba Moosavi KamoonpuriDokument166 SeitenBasic Belifs of Islam by Sayyed Qasim Mujtaba Moosavi Kamoonpurisarvarhasan100% (2)

- Fenestration Calculation GuidelineDokument26 SeitenFenestration Calculation GuidelineMichelle HoughNoch keine Bewertungen

- Dying Light Patch 1 4 nosTEAMDying Light Patch 1 4 nosTEAM PDFDokument4 SeitenDying Light Patch 1 4 nosTEAMDying Light Patch 1 4 nosTEAM PDFLeonNoch keine Bewertungen

- Orca Share Media1584246573322Dokument60 SeitenOrca Share Media1584246573322Jazzie SorianoNoch keine Bewertungen

- Irmis Popoff Gurdjieff PDFDokument195 SeitenIrmis Popoff Gurdjieff PDFdarkdoudouNoch keine Bewertungen

- TEKNION Expansion Cityline Brochure - Bluespace InteriorsDokument15 SeitenTEKNION Expansion Cityline Brochure - Bluespace Interiorsdavid wolfNoch keine Bewertungen

- VBC 800pi DsDokument2 SeitenVBC 800pi Dskunene07Noch keine Bewertungen

- Life Will ChangeDokument4 SeitenLife Will ChangeHachiman HikigayaNoch keine Bewertungen

- Oxford Present Perfect - Simple, Continuous, Passive - Making The Right NoisesDokument2 SeitenOxford Present Perfect - Simple, Continuous, Passive - Making The Right NoisesLucas ArtolaNoch keine Bewertungen

- Ten Songs For Another World by The World of SkinDokument11 SeitenTen Songs For Another World by The World of SkintoypomNoch keine Bewertungen

- TleDokument15 SeitenTleChristine Joy Dela CruzNoch keine Bewertungen

- Google Chrome: Melissa Brisbin Cherry Hill Public Library (856) 903-1243Dokument65 SeitenGoogle Chrome: Melissa Brisbin Cherry Hill Public Library (856) 903-1243Mihai SpineiNoch keine Bewertungen

- Filipino Building BeliefsDokument4 SeitenFilipino Building BeliefsShi YuNoch keine Bewertungen

- PSV 1Dokument104 SeitenPSV 1Bakau Cb0% (1)

- G. B. Shaw's War Antipathy in Arms and The Man and Major BarbaraDokument7 SeitenG. B. Shaw's War Antipathy in Arms and The Man and Major BarbaraIJELS Research JournalNoch keine Bewertungen

- Right Hand ManDokument2 SeitenRight Hand ManbluesnapplerocksNoch keine Bewertungen

- AustraliaDokument37 SeitenAustraliaQueenee VidadNoch keine Bewertungen

- Nakshatra Purva Phalguni 310510Dokument7 SeitenNakshatra Purva Phalguni 310510Anthony Writer100% (6)

- Golden Dawn - The Invoking Pentagram Ritual of AirDokument2 SeitenGolden Dawn - The Invoking Pentagram Ritual of AirFranco LazzaroniNoch keine Bewertungen

- Rent Payment Schedule - FDokument3 SeitenRent Payment Schedule - FTom CatNoch keine Bewertungen

- Innocence and Experience (Reading Execise 1)Dokument3 SeitenInnocence and Experience (Reading Execise 1)Izan SallehNoch keine Bewertungen

- Olidworks: S Edrawings ProfessionalDokument2 SeitenOlidworks: S Edrawings Professionalkambera2100% (1)