Beruflich Dokumente

Kultur Dokumente

Cranes

Hochgeladen von

Safetyboss100%(12)100% fanden dieses Dokument nützlich (12 Abstimmungen)

3K Ansichten38 SeitenCrane is used to lift & shift heavy materials.

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCrane is used to lift & shift heavy materials.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

100%(12)100% fanden dieses Dokument nützlich (12 Abstimmungen)

3K Ansichten38 SeitenCranes

Hochgeladen von

SafetybossCrane is used to lift & shift heavy materials.

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 38

Cranes

OSHAX.org - The Unofficial Guide To the OSHA 1

Major Causes of Crane

Accidents

○ Contact with power lines

○ Overturns

○ Falls

○ Mechanical failures

OSHAX.org - The Unofficial Guide To the OSHA 2

How Do Accidents Occur?

○Instability – unsecured load, load capacity

exceeded, or ground not level or too soft

○Lack of communication - the point of

operation is a distance from the crane

operator or not in full view of the operator

○Lack of training

○Inadequate maintenance or inspection

OSHAX.org - The Unofficial Guide To the OSHA 3

Who is at Risk

Operators

Persons at

Crane Site

OSHAX.org - The Unofficial Guide To the OSHA 4

Definitions

Crane – Consists of a rotating structure for lifting

and lowering horizontally on rubber tires or crawler

treads

Hoist - Used to lift and lower load.

Boom – An inclined spar, strut, or other long

member supporting the hoisting tackle

Boom stops – A device used to limit the angle of

the boom at its highest position

Brake – To slow or stop motion by friction or power

Block – Sheaves or grooved pulleys in a frame

with hook, eye and strap

Jib – Extension attached to the boom point to

provide added boom length for lifting specified

loads.

OSHAX.org - The Unofficial Guide To the OSHA 5

Crane Parts

OSHAX.org - The Unofficial Guide To the OSHA 6

Types of Cranes

Mobile

Hydraulic

Overhead

Gantry

Tower

OSHAX.org - The Unofficial Guide To the OSHA 7

Crane Hazards

Improper load rating • Working too close to

Excessive speeds power lines

No hand signals • Improper exhaust

Inadequate system

inspection and • Shattered windows

maintenance • No steps/guardrails

Unguarded parts walkways

Unguarded swing • No boom angle

radius indicator

• Not using outriggers

OSHAX.org - The Unofficial Guide To the OSHA 8

Planning Before Start-Up

Level the crane and ensure support surface is firm and able to

support the load

Contact power line owners and determine precautions. Know

the location and voltage of overhead power lines.

Know the basic crane capacities, limitations, and job site

restrictions, such as the location of power lines, unstable soil, or

high winds.

Make other personnel aware of hoisting activities.

Barricade areas within swing radius.

Ensure proper maintenance and inspections.

Determine safe areas to store materials and place machinery.

OSHAX.org - The Unofficial Guide To the OSHA 9

Competent Person

The competent person must

inspect all machinery and

equipment prior to each

use, and during use, to

make sure it is in safe

operating condition.

If it needs fixing, take it out

of service and don’t use it Broken

until it is fixed

Track

OSHAX.org - The Unofficial Guide To the OSHA 10

Load Capacity - Speed - Warnings

Make sure the crane

operator can see the:

Rated Load

Capacities

Operating Speeds

Special Hazard

Warning or Instruction

Load Rating Chart

OSHAX.org - The Unofficial Guide To the OSHA 11

Know the Weight of the Load

Refer to shipping ticket or other

documentation

Ensure lift calculations are correct

Ensure load is within load chart rating for

boom length and load radius of crane

Crane is rated by the maximum weight it will

lift at a minimum radius and minimum boom

length – the further from its centerpoint, the

less it will lift

OSHAX.org - The Unofficial Guide To the OSHA 12

Load Limiting Factors

Not level

Wind

Side loads

On its wheels

Lifting over the side

Use of extensions, jibs and other attachments

Limits of wire rope, slings and lifting devices

OSHAX.org - The Unofficial Guide To the OSHA 13

Mobile Cranes –

Lifting Principles

Center of Gravity

Leverage

Stability

Structural Integrity

OSHAX.org - The Unofficial Guide To the OSHA 14

Load Example –

30 ton crane

Will lift 60,000 pounds at 10 feet from the

center pin of the crane

Based on level surface, no wind, and

outriggers fully extended

At 25 feet from the center pin with an 80 foot

boom, the capacity is only 14,950 pounds

At 74 feet from the center pin, the capacity is

only 4,800 pounds

OSHAX.org - The Unofficial Guide To the OSHA 15

Improper Load

Improper loads or speeds can result

in the tipping of the crane

OSHAX.org - The Unofficial Guide To the OSHA 16

Improper Load

OSHAX.org - The Unofficial Guide To the OSHA 17

Improper Load

OSHAX.org - The Unofficial Guide To the OSHA 18

Power Lines

Stay clear

from power

lines at least

10 feet

OSHAX.org - The Unofficial Guide To the OSHA 19

Hand Signals

An illustration of

the signals must

be posted at the

job site

OSHAX.org - The Unofficial Guide To the OSHA 20

Guard Moving Parts

Unguarded

Chain Drive

Guard moving parts such as gears or belts

OSHAX.org - The Unofficial Guide To the OSHA 21

Swing Radius

Stay out of the swing radius of the crane –

Make sure there are barrier guards showing swing radius

OSHAX.org - The Unofficial Guide To the OSHA 22

Operator Visibility

Broken Window

Make sure broken windows or other obstructions

do not prevent the operator from seeing

OSHAX.org - The Unofficial Guide To the OSHA 23

Ladders

Ladder

Use ladders to get to the upper portion of the cab

OSHAX.org - The Unofficial Guide To the OSHA 24

Guardrails

Runways and steps need to have guardrails,

handholds and slip resistant surfaces

OSHAX.org - The Unofficial Guide To the OSHA 25

Suspended Loads

Don’t stand under suspended loads

OSHAX.org - The Unofficial Guide To the OSHA 26

Boom Angle Indicator

A boom angle indicator must be on the crane

OSHAX.org - The Unofficial Guide To the OSHA 27

Supporting Surface

Cranes must be on a firm supporting

surface and level within 1 percent

OSHAX.org - The Unofficial Guide To the OSHA 28

Sheaves

The grooves must be smooth and free from surface

defects which could cause rope damage

OSHAX.org - The Unofficial Guide To the OSHA 29

Rigging Equipment Slings

Types of slings include alloy steel chain, wire rope,

metal mesh, natural or synthetic fiber rope, and

synthetic web.

Chain Wire rope Metal mesh Synthetic

OSHAX.org - The Unofficial Guide To the OSHA 30

Annual Inspections

Inspection of the

hoisting machinery

must be made by a

competent person

The employer must

maintain a record of

these inspections Crane wasn’t inspected

and tipped over

OSHAX.org - The Unofficial Guide To the OSHA 31

What to Inspect

Correct air pressure and no leaks

Tires properly inflated

Clearance for tail swing

Wire rope wear

Physical damage to crane

Loose or missing hardware, nuts, or bolts

Fluid leaks

OSHAX.org - The Unofficial Guide To the OSHA 32

Remove From Service

Immediately remove damaged or

defective slings from service

OSHAX.org - The Unofficial Guide To the OSHA 33

Damaged wire rope

Crushed Rope

Broken Strands

Damaged wire rope must be taken out of service

OSHAX.org - The Unofficial Guide To the OSHA 34

Worn Part

OSHAX.org - The Unofficial Guide To the OSHA 35

Tire Inspections

Conduct

regular

inspections

of tires for

excessive

wear or

damage

OSHAX.org - The Unofficial Guide To the OSHA 36

Training

Operators:

must qualify on specific crane type

Must include on-the-job training

Supervisor / competent person

OSHAX.org - The Unofficial Guide To the OSHA 37

Summary

• An unstable load, lack of communication, lack of

training, and inadequate maintenance or inspection are

major contributors to crane accidents.

• Operators or others working in the area can be

victims to “struck by" and "caught in" injuries.

• Contact with power lines causes many accidents.

• A competent person must inspect a crane regularly

to insure it is in proper order.

• Planning and training reduces accidents.

OSHAX.org - The Unofficial Guide To the OSHA 38

Das könnte Ihnen auch gefallen

- The Vertical Transportation HandbookVon EverandThe Vertical Transportation HandbookGeorge R. StrakoschNoch keine Bewertungen

- CranesDokument80 SeitenCranesjoenediath9345Noch keine Bewertungen

- Crane Safety: 38 Hazards and ProtectionsDokument38 SeitenCrane Safety: 38 Hazards and ProtectionsunbridledsuccessNoch keine Bewertungen

- Offshore Crane Safety TrainingDokument29 SeitenOffshore Crane Safety TrainingBergensur100% (3)

- Bull Rigging Techniques ExplainedDokument51 SeitenBull Rigging Techniques ExplainedRezende JulioNoch keine Bewertungen

- LiftingDokument52 SeitenLiftingRenish Regi100% (1)

- Liftex Catalog 2016Dokument60 SeitenLiftex Catalog 2016Alberth Mauricio Casteblanco GomezNoch keine Bewertungen

- Crosby Rigging EquipmentDokument20 SeitenCrosby Rigging EquipmentJason MillerNoch keine Bewertungen

- RiggingDokument159 SeitenRiggingBeste Ardıç ArslanNoch keine Bewertungen

- Cranes Rigging Your Organization Iti - Com r031512Dokument33 SeitenCranes Rigging Your Organization Iti - Com r031512Mohsin Majeed0% (1)

- Rigging and Slinging TechniquesDokument15 SeitenRigging and Slinging TechniquesShiraz Najat100% (1)

- (Rigging) Certex PDFDokument376 Seiten(Rigging) Certex PDFMo'tasem SerdanehNoch keine Bewertungen

- Crane Safety ManualDokument28 SeitenCrane Safety Manualpuneet71% (7)

- Rigging GuideDokument4 SeitenRigging Guidemanufighter100% (3)

- Rigging - Sling HitchesDokument54 SeitenRigging - Sling HitchesIng. Alejandro Valencia HerreraNoch keine Bewertungen

- DOE-STD 1090-99 Hosting & RiggingDokument403 SeitenDOE-STD 1090-99 Hosting & RiggingalphadingNoch keine Bewertungen

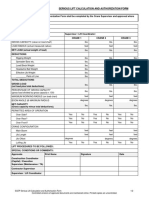

- Serious Lift Calculation and Authorization FormDokument2 SeitenSerious Lift Calculation and Authorization FormAbdulKather100% (1)

- Crane Safety Standards, Regulations and CertificationsDokument22 SeitenCrane Safety Standards, Regulations and CertificationsSai Shankar LakshminarayananNoch keine Bewertungen

- Slinging, Rigging & Manual Handling: Prepared By: Masood-Ur-RehmanDokument72 SeitenSlinging, Rigging & Manual Handling: Prepared By: Masood-Ur-RehmanAitazaz Ahsan100% (2)

- Ruud Optimal SecuringDokument28 SeitenRuud Optimal SecuringStian Eikanger SkålevikNoch keine Bewertungen

- CMCO Training BrochureDokument16 SeitenCMCO Training BrochuresugiyantoNoch keine Bewertungen

- Sling Rigger TrainingDokument12 SeitenSling Rigger Trainingegy pureNoch keine Bewertungen

- Wire Rope Sling Handbook - WireRopeSlingGuide1-09cDokument28 SeitenWire Rope Sling Handbook - WireRopeSlingGuide1-09cRoberto Alleyne100% (2)

- Lifting MethodsDokument10 SeitenLifting Methodsselva1965Noch keine Bewertungen

- New Crane Safety LawsDokument31 SeitenNew Crane Safety LawsFabian LandauNoch keine Bewertungen

- Rigger Training: Slings SafetyDokument340 SeitenRigger Training: Slings SafetySHIJAD SRAJU100% (1)

- Instructions For The Safe Use Of: Wire Rope SlingsDokument2 SeitenInstructions For The Safe Use Of: Wire Rope SlingsStuartWilliamGlennieNoch keine Bewertungen

- Crane Safety - IS StandardsDokument22 SeitenCrane Safety - IS StandardsgvramanaNoch keine Bewertungen

- Cranes & Lifting Appliances: Guidance On TheDokument41 SeitenCranes & Lifting Appliances: Guidance On Thethongchai_007Noch keine Bewertungen

- Lifting Plan OverviewDokument10 SeitenLifting Plan Overviewrery1985100% (2)

- Crane Training Handbook With GPR 8719.1B UpdateDokument558 SeitenCrane Training Handbook With GPR 8719.1B Updatemhd abdou100% (3)

- Overhead Crane SafetyDokument23 SeitenOverhead Crane SafetyBv Rao50% (2)

- Tips Critical Crane LiftDokument5 SeitenTips Critical Crane LiftSteve John PolandNoch keine Bewertungen

- Tower Crane InspectionDokument111 SeitenTower Crane InspectionMulatua Sirait80% (5)

- Safe Rigging PracticesDokument86 SeitenSafe Rigging Practicesmagantiramudu94% (31)

- Slinger Signaller Study GuideDokument40 SeitenSlinger Signaller Study GuidePrimelift Safety Resources Limited100% (1)

- HaGun Rigging Study and Lifting StudyDokument110 SeitenHaGun Rigging Study and Lifting StudyGunawan HaGun100% (9)

- Safe lifting rigging practicesDokument46 SeitenSafe lifting rigging practicesErik100% (1)

- Load Chart Crane LiftingDokument25 SeitenLoad Chart Crane LiftingLauren'sclub EnglishBimbel Sd-sma100% (1)

- 25 Specialized Rigging: Four-Leg GantriesDokument32 Seiten25 Specialized Rigging: Four-Leg GantriesVinicius Monteiro AmaralNoch keine Bewertungen

- Basic Rigging Work BookDokument45 SeitenBasic Rigging Work BookJohn Henry Sinurat100% (1)

- Lifting Plan For Presentation in BahasaDokument1 SeiteLifting Plan For Presentation in BahasaRizky Bimanda SaktiNoch keine Bewertungen

- NTC Load Restraint Guide 2018Dokument288 SeitenNTC Load Restraint Guide 2018Garry100% (1)

- Emergency Response & Rescue Planning: by Mr. G. S. Saini Director, National Civil Defence CollegeDokument90 SeitenEmergency Response & Rescue Planning: by Mr. G. S. Saini Director, National Civil Defence CollegeTomNoch keine Bewertungen

- Training Rigging EngineersDokument25 SeitenTraining Rigging Engineersa_roghib100% (3)

- Alloy Steel Chain SlingsDokument3 SeitenAlloy Steel Chain Slingsmoha19841100% (1)

- Instructions For Safe Use ShacklesDokument2 SeitenInstructions For Safe Use ShacklesNickNoch keine Bewertungen

- Rigging PracticesDokument58 SeitenRigging Practicesravi00098Noch keine Bewertungen

- Lift Planning Doug Swenson 10.10.2019Dokument138 SeitenLift Planning Doug Swenson 10.10.2019Alex Sandro Borges PereiraNoch keine Bewertungen

- Round SlingsDokument9 SeitenRound Slingswalkerproductions20009116100% (1)

- The Pro Rigger - Rigging WorkshopDokument19 SeitenThe Pro Rigger - Rigging WorkshopyogihardNoch keine Bewertungen

- Rigging Safety Essentials (OSHA 1926.251Dokument67 SeitenRigging Safety Essentials (OSHA 1926.251John Vem Bansag100% (1)

- Guide To Mobile CranesDokument7 SeitenGuide To Mobile CranesvigneshNoch keine Bewertungen

- Welcome To The Lecture On: Safe Material Lifting/HandlingDokument43 SeitenWelcome To The Lecture On: Safe Material Lifting/HandlingAli ImamNoch keine Bewertungen

- الأوناش عربيDokument38 Seitenالأوناش عربيYasser Mahmoud100% (1)

- Training Session: Mobile Crane Operator Safety TrainingDokument42 SeitenTraining Session: Mobile Crane Operator Safety TrainingAyaz GhouriNoch keine Bewertungen

- Crane Safety During Edc VCM Errction by Ank 1221024516777948 8Dokument39 SeitenCrane Safety During Edc VCM Errction by Ank 1221024516777948 8sujiyakhanNoch keine Bewertungen

- CranesDokument39 SeitenCranesMajji SatishNoch keine Bewertungen

- 1 Crane SafetyDokument44 Seiten1 Crane SafetyraezenbukalNoch keine Bewertungen

- 2COSH Crane SafetyDokument59 Seiten2COSH Crane SafetyEunice GayetaNoch keine Bewertungen

- Safety QuoteDokument1 SeiteSafety QuoteSafetybossNoch keine Bewertungen

- The Adyar Cancer InstituteDokument3 SeitenThe Adyar Cancer InstituteSafetybossNoch keine Bewertungen

- Team WorkDokument1 SeiteTeam WorkSafetybossNoch keine Bewertungen

- Think SafetyDokument1 SeiteThink SafetySafetybossNoch keine Bewertungen

- SAAD Certificate of Non ObjectionDokument1 SeiteSAAD Certificate of Non ObjectionSafetybossNoch keine Bewertungen

- NSC Safety NewsDokument3 SeitenNSC Safety NewsSafetybossNoch keine Bewertungen

- Visas in The UAEDokument2 SeitenVisas in The UAESafetybossNoch keine Bewertungen

- National Policy on Workplace Safety, Health and EnvironmentDokument11 SeitenNational Policy on Workplace Safety, Health and EnvironmentnarayanaraoNoch keine Bewertungen

- Fastest in The WorldDokument3 SeitenFastest in The WorldSafetybossNoch keine Bewertungen

- Recruitment Agencies in United Arab EmiratesDokument8 SeitenRecruitment Agencies in United Arab EmiratesSafetyboss100% (1)

- Mumbai International Airport Safety PolicyDokument1 SeiteMumbai International Airport Safety PolicySafetybossNoch keine Bewertungen

- National Relief FundDokument10 SeitenNational Relief FundSafetybossNoch keine Bewertungen

- The Doctor CheDokument1 SeiteThe Doctor CheSafetybossNoch keine Bewertungen

- Alcohol in Dubai and The UAEDokument6 SeitenAlcohol in Dubai and The UAESafetybossNoch keine Bewertungen

- Names of Indian SpicesDokument8 SeitenNames of Indian SpicesSafetybossNoch keine Bewertungen

- Sciatica Self Care BookletDokument49 SeitenSciatica Self Care BookletSafetyboss100% (3)

- All About OSHADokument32 SeitenAll About OSHASafetybossNoch keine Bewertungen

- F A Q On Industrial SafetyDokument10 SeitenF A Q On Industrial SafetySafetybossNoch keine Bewertungen

- Constitution of India-Complete Full TextDokument471 SeitenConstitution of India-Complete Full TextDaras Bir Singh67% (6)

- Labour Law in IndiaDokument11 SeitenLabour Law in IndiaSafetyboss100% (1)

- Safety Appreciation Certificate Emirates TowersDokument1 SeiteSafety Appreciation Certificate Emirates TowersSafetybossNoch keine Bewertungen

- Factories Act Safety OfficerDokument4 SeitenFactories Act Safety OfficerSafetyboss100% (8)

- UniversityDokument7 SeitenUniversitySafetybossNoch keine Bewertungen

- To Love Your Job But Don't Love Your Company Because You May Not Know When Your Company Stops Loving YouDokument20 SeitenTo Love Your Job But Don't Love Your Company Because You May Not Know When Your Company Stops Loving YouMahesh ReddyNoch keine Bewertungen

- Central Labour ActsDokument2 SeitenCentral Labour ActsSafetybossNoch keine Bewertungen

- UniversityDokument7 SeitenUniversitySafetybossNoch keine Bewertungen

- MahabharataDokument20 SeitenMahabharataKetan Bhatt100% (3)

- Guidelines For Food SafetyDokument6 SeitenGuidelines For Food SafetySafetybossNoch keine Bewertungen

- Human Rights UAEDokument18 SeitenHuman Rights UAESafetyboss100% (2)

- Revision of Bs 8002, 8004, AND 8081Dokument34 SeitenRevision of Bs 8002, 8004, AND 8081Rupesh Kaushik100% (1)

- Stationary Concrete Pumps en G 16345-0 PDFDokument20 SeitenStationary Concrete Pumps en G 16345-0 PDFLUIS ISAAC LEON PARONoch keine Bewertungen

- Ornl 2465Dokument101 SeitenOrnl 2465jesusNoch keine Bewertungen

- HalideDokument195 SeitenHalidejadecolourNoch keine Bewertungen

- 9853 1239 01 - COP 54 Service Poster - LOWDokument1 Seite9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasNoch keine Bewertungen

- PHP AngularJS CRUD with Search and PaginationDokument18 SeitenPHP AngularJS CRUD with Search and PaginationZaiful BahriNoch keine Bewertungen

- Ps 1 SolDokument3 SeitenPs 1 SolPang XsNoch keine Bewertungen

- Manual Service Aoc - E943fwskDokument51 SeitenManual Service Aoc - E943fwskEduardo BentoNoch keine Bewertungen

- Developing Recycled PET Fiber for Concrete ReinforcementDokument8 SeitenDeveloping Recycled PET Fiber for Concrete ReinforcementJunaid Ahmad100% (1)

- Instructions pour pied SeniorDokument52 SeitenInstructions pour pied SeniorPriyanka PatilNoch keine Bewertungen

- Supercharging: Superchargers & TurbochargersDokument11 SeitenSupercharging: Superchargers & TurbochargersAkhil Here100% (1)

- J 1 B 1211 CCDDokument3 SeitenJ 1 B 1211 CCDRegion 51Noch keine Bewertungen

- Manual Servicio SubaruDokument5.963 SeitenManual Servicio SubaruCristian Mauricio Alarcon RojasNoch keine Bewertungen

- Thu Thiem Tunnel Construction - Sequence - Immersed - Tunnel PDFDokument36 SeitenThu Thiem Tunnel Construction - Sequence - Immersed - Tunnel PDFThông PhanNoch keine Bewertungen

- PML Rev-I Preferred Manufacturer List for PT Pertamina EPDokument12 SeitenPML Rev-I Preferred Manufacturer List for PT Pertamina EPAndreas Schlager100% (1)

- Wire Rope Maintenance enDokument12 SeitenWire Rope Maintenance ensriabolfazlNoch keine Bewertungen

- QUS 303 CONSTRUCTION ECONOMICSDokument21 SeitenQUS 303 CONSTRUCTION ECONOMICSjudexnams1on1Noch keine Bewertungen

- 1986 Lobel RobinsonDokument18 Seiten1986 Lobel RobinsonNathallia SalvadorNoch keine Bewertungen

- SDCK CD Ies 01 (Rev B)Dokument125 SeitenSDCK CD Ies 01 (Rev B)Narada HerathNoch keine Bewertungen

- 01 4G64S4M & 4G69S4N Engine-2Dokument38 Seiten01 4G64S4M & 4G69S4N Engine-2vitor santosNoch keine Bewertungen

- Hit-Re 500 With Hit-V Has RodsDokument3 SeitenHit-Re 500 With Hit-V Has RodsMKNoch keine Bewertungen

- WATCHDokument9 SeitenWATCHGANTORONoch keine Bewertungen

- Conventional and Non-Conventional Energy Resources of India: Present and FutureDokument8 SeitenConventional and Non-Conventional Energy Resources of India: Present and FutureAnkit SharmaNoch keine Bewertungen

- LUCY SwitchgearDokument8 SeitenLUCY SwitchgearHillary McgowanNoch keine Bewertungen

- Michelson Interferometer Na Lamp-1Dokument11 SeitenMichelson Interferometer Na Lamp-1SOHINI KAYALNoch keine Bewertungen

- Unit-I: Introduction To J2EEDokument29 SeitenUnit-I: Introduction To J2EEsurakshaNoch keine Bewertungen

- Demographically Similar EntriesDokument1 SeiteDemographically Similar EntriesTahsildar MydukurNoch keine Bewertungen

- Iraqi Code for Reinforced Concrete StructuresDokument71 SeitenIraqi Code for Reinforced Concrete Structuresmamandawe50% (2)

- Models - Rf.bowtie Antenna OptimizationDokument14 SeitenModels - Rf.bowtie Antenna OptimizationbkmmizanNoch keine Bewertungen

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen