Beruflich Dokumente

Kultur Dokumente

Introduction To Petroleum Engineering - Lecture 7

Hochgeladen von

shanecarlOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Introduction To Petroleum Engineering - Lecture 7

Hochgeladen von

shanecarlCopyright:

Verfügbare Formate

BEng (Hons) Petroleum Engineering

Course: Introduction To Petroleum Engineering Instructor Dr. Tarek Darwich

Introduction to Petroleum Engineering

Course Outlines:

What is Petroleum Engineering? The Life Cycle of Oil and Gas projects, Origin, formation and accumulation of Petroleum, Oil & Gas Exploration, Appraisal of Oil & Gas Discoveries, Development of Oil & Gas Discoveries, Producing Oil & Gas Fields, Transportation of Oil & Gas, The Petroleum Industry & the Environment, Petroleum Economics.

Year 2012 - 2013

Introduction to Petroleum Engineering

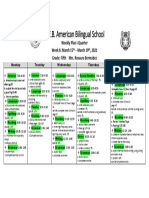

Weekly News

Year 2012 - 2013

Introduction to Petroleum Engineering

Weekly News

Year 2012 - 2013

Introduction to Petroleum Engineering

Drilling Well Profiles

Year 2012 - 2013

Introduction to Petroleum Engineering

Typical Drilling Time Depth Curve

Year 2012 - 2013

Introduction to Petroleum Engineering

Main Components of Drilling Rigs

-

Power System Hoisting System Rotary System Circulating System Well Control and Monitoring System

Year 2012 - 2013

Introduction to Petroleum Engineering

Drilling Rig Power System

Most power is consumed by:

Hoisting System Circulation System

Total power requirements 500 to 3000 HP

Diesel engines compose the majority of power sources on rotary rigs. Natural gas or gasoline engines are getting more popular. The minimum power requirement is around 10 HP every 100 ft depth

Year 2012 - 2013

Introduction to Petroleum Engineering

Drilling Rig Hoisting System

Hoisting system is used to lower or raise the drill string, casing string and other subsurface equipment into or out of the hole.

The principal components are:

Derrick and Substructure Block and tackle system Draw works

The Derrick

A structure of steal beams or tubes that can be completely dismantled and reassembled. Provides vertical height to raise sections of pipe. Provides support to the crown block

Year 2012 - 2013

Introduction to Petroleum Engineering

Drilling Rig Hoisting System

The main components of the Block and Tackle System are:

The Crown Block The Travelling Block The Drilling Line

The main function is to provide a mechanical advantage which permits easier handling of large loads.

Draw works provide the hoisting and the braking power required to raise or lower the heavy string of pipes.

Year 2012 - 2013

Introduction to Petroleum Engineering

Drilling Rig Rotary System

Wells are rotation. drilled by pipe and bit

This system following:

Swivel Kelly Rotary Drive Rotary table Drill Pipe Drill Collar Bit

mainly

includes

the

The swivel supports the weight of the drill string and permits rotation.

Year 2012 - 2013

Introduction to Petroleum Engineering

Drilling Rig Rotary System

The kelly is either square or hexagonal to be gripped easily. It is connected to the drill pipes. The kelly transmits the motion of the rotary table to the drill pipes. Rotary drive provides the power to rotate the rotary table. Rotary table supports the weight of the drill string and permits rotation.

Year 2012 - 2013

Introduction to Petroleum Engineering

Rotary Drilling Bottom Hole Behaviour

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit

The drilling bit is the cutting tool which is made up on the end of the drillstring.

The bit drills through the rock by scraping, chipping, gouging or grinding the rock at the bottom of the hole. Drilling fluid is circulated through passage ways in the bit to remove the drilled cuttings.

There are many variations in the design of drill bits.

The bit selected for a application will depend formation being drilled. particular on the

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit

The drilling bit performance is function of several operating parameters such as:

The weight on bit (WOB) Rotations per minutes (RPM) Mud Properties Hydraulic Efficiency

Three main types of drilling bits:

Drag bits Roller Cone Bits Diamond Bits

Drag bits were the first used in rotary drilling but no longer in common use.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit Roller Cone Bits

A roller cone bit is made up of 3 main parts:

The cones The bearings The body of the bit

Each cone has concentric rows of teeth that interfit with the rows of teeth in the adjacent cones. The teeth can be made of:

Steel machined in the cone Tungsten carbide inserts cold-pressed into holes drilled in the cone.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit Roller Cone Bits

A roller cone bit is made up of 3 main parts:

The cones The bearings The body of the bit

Each cone has concentric rows of teeth that interfit with the rows of teeth in the adjacent cones. The teeth can be made of:

Steel machined in the cone Tungsten carbide inserts cold-pressed into holes drilled in the cone.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit Roller Cone Bits

Bits with steel teeth are used when:

spudding in a well, in a soft formation, at high rotational speeds and where bed thickness makes insert bits not economic.

Bits for soft formations are designed with long, widely spaced teeth to help penetrate in the formation and tear off larger cuttings.

The bits for medium and medium-hard formations have more closely spaced teeth.

The tungsten-carbide insert bits are used to drill very hard abrasive formations. These bits are more expensive.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit Diamond Bits

There are 3 types of diamond bits depending on the nature of the cutting element

With natural diamond With PDC (polycrystaline diamond compact cutters) With TSP (with thermally stable polycrystaline diamond compact cutters).

Diamond is the hardest known mineral. Its compressive strength is approximately 80,000 bar (tungsten carbide 50,000 bar and steel 15,000 bar).

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit Coring Bits

A coring bit does not drill out the centre of the hole but allows this central portion (the core) to pass through the round opening of the bit and into the core barrel.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit Coring Bits

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit Coring Barrel

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drilling Bit Cores

Year 2012 - 2013

Introduction to Petroleum Engineering

Bit Selection

The goal of bit selection is to obtain the lowest cost per foot. The cost per foot can be calculated by using the equation:

Where C is the overall cost per foot, $/ft; Cb is the cost of the bit, $; Cr is the cost of operating the rig

$/hr; tb is the rotating time with bit on bottom, hours; tt is the round trip time, including connection time, hours; to is the other time, which is not rotating time or trip time, hours; and DD is the total depth as a given total time, ft.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drill String

The drill string is a assemblage of hollow pipes of circular section, extending from the surface to the bottom of the hole. It has three functions:

It takes the drilling bit to the bottom of the hole, while transmitting its rotation and its vertical load to it. It permits the circulation of the drilling fluids to the bottom of the hole It guides and controls the trajectory of the hole.

Starting from the top, the drill string consists of:

A kelly Drill pipes Drill Collars Number of accessory components (e.g. stabilisers, reamers, jars, downhole motors, .) The bit

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drill Pipes

The drill pipes are hollow steel pipes of various types with two tool joints welded at their ends.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drill Pipes Classification

Drill pipes are standardised according to API standards.

They are classified on the basis of their: length, outside diameter, linear weight and their steel grade.

The most common drill pipes are the following:

3.5 (13.3 lb/ft) 4.5 (16.6 lb/ft) 5.0 (19.5 lb/ft)

The grade of the steel is indicated by a letter , indicating the type of material, followed by a number which indicates the minimum yield strength.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Tool Joints of Drill pipes

It is the enlarged and threaded ends of drillpipes. These components are separate from the pipe body and welded into the pipe at the manufacturers facilities. The tool joints provide high-strength, high-pressure threaded connections that are sufficiently robust to survive the rigors of drilling and numerous cycles of tightening and loosening at threads. The tool joints are usually made of steel that has been treated to a higher strength than the steel of the tube body. The tool joints can be threaded a number of times and they should be protected.

Year 2012 - 2013

Introduction to Petroleum Engineering

The Drill Collars

The drill collar is defined as a heavy, tubular connector between drill pipe and a bit.

In drilling operations, the top part of the drill string is in tension while the lower part is in compression; the lengths of the two sections depends on the weight applied on the bit.

Thin-walled drill pipes cannot withstand compression. They may bend and break under axial compression. Therefore, the lower part of the drill string is assembled of heavy pipes. Drill collars were once a few feet long and weighed 400 or 500 pounds. Today because of the increased bit pressure and rapid rotation, collars are made up in 1000-foot lengths and weigh 50 to 100 pounds. The most common diameters of drill collars are: 9.5-in, 8-in and 6.5-in.

Year 2012 - 2013

Introduction to Petroleum Engineering

Drill Collars & Drill Pipes

Drill Pipes

Drill Collars

Year 2012 - 2013

Introduction to Petroleum Engineering

The Heavy Weight Drill Pipes

Connection of pipes of very different diameters lead to concentration of tensions and to a fatigue in the areas where cross section varies. This coincides with the location of threading which is a weak point. To avoid the danger of breaks, a short stretch of heavy weight drill pipes is inserted. This allows drill pipes and drill collars to be connected without any abrupt diameter changes. The heavy-wall drill pipes are normally made with the same outside diameter as the drill pipes, but with a smaller inside diameter. In practice, they are drill pipes with thick walls, having a linear weight two or three times greater.

Year 2012 - 2013

Introduction to Petroleum Engineering

Drill String Accessory Equipment

The drill string is very often fitted with accessory items which serve to resolve technical problems due to the wide variety of drilling conditions. The most common accessory items of equipment are stabilisers, reamers, jars and shock-absorbers. Stabilisers are placed along the bottom hole assembly (BHA), in between the drill collars, to make the string more rigid in the presence of the instability due to combined compressive, buckling and bending stresses. Stabilizers are fundamental for controlling the borehole trajectory both in vertical and in directional wells.

Year 2012 - 2013

Introduction to Petroleum Engineering

Drill String Accessory Equipment

Stabilizers consist of a body to which rib blades are applied, expanding the outside diameter of the tool to the nominal diameter of the bit. By changing the composition of the BHA, and in particular the positioning of the stabilizers, the mechanical behaviour of the drill string can be varied, which is useful in controlling the directional drilling operations.

Year 2012 - 2013

Introduction to Petroleum Engineering

Drill String Accessory Equipment

Reamers are special stabilisers with roller cutters instead of blades. Mounted on the rollers, there are usually 3 to 6 steel cutters or tungsten carbide inserts. Reamers serve the purpose of reaming wall of the hole, taking it to the nominal diameter of the bit. Eliminating the small variations in diameter means an elimination of any possible stepped profile that might be in the hole, which could make: the application of the weight on the bit uncertain or cause problems with running-in the casing. Reamers are used chiefly in drilling through streaks of hard and abrasive

Year 2012 - 2013

Introduction to Petroleum Engineering

Drill String Accessory Equipment

Jars are mechanical devices used downhole to deliver an impact load to another downhole component, especially when that component is stuck. There are two primary types, hydraulic and mechanical jars. While their respective designs are quite different, their operation is the same. Energy is stored in the drillstring and suddenly released by the jar when it fires.

Shock Absorbers is a device placed above the bit to reduce the axial vibrations generated during drilling, which are harmful for both the bit and the drill pipes. These devices are necessary when the vibrations are strong enough to be visible at the surface. In deep wells, the vibrations might not be visible at the surface. In this case other signals are observed, such as slow penetration rate and a particular bit wear pattern.

Year 2012 - 2013

Introduction to Petroleum Engineering

Drill String Specification in the well Programme

Year 2012 - 2013

Introduction to Petroleum Engineering

Drill String Useful Links

- Drilling Good & short overview - http://www.youtube.com/watch?v=nlSKA7PkSzo

- Drill Collars: - http://www.youtube.com/watch?v=g1LE3IMAfY8 - Openhole Fishing: - http://www.youtube.com/watch?v=7-WqVgksKtk - Chesapeak Drilling - http://www.youtube.com/watch?v=fBQCQ6HL2Yw&feature= Year 2012 - 2013 endscreen

Das könnte Ihnen auch gefallen

- Beng (Hons) Petroleum Engineering: Course: Introduction To Petroleum Engineering Instructor Dr. Tarek DarwichDokument16 SeitenBeng (Hons) Petroleum Engineering: Course: Introduction To Petroleum Engineering Instructor Dr. Tarek DarwichshanecarlNoch keine Bewertungen

- Introduction To Petroleum Engineering - Lecture 6Dokument20 SeitenIntroduction To Petroleum Engineering - Lecture 6shanecarlNoch keine Bewertungen

- Introduction To Petroleum Engineering - Lecture 8Dokument41 SeitenIntroduction To Petroleum Engineering - Lecture 8shanecarlNoch keine Bewertungen

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Von EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Bewertung: 5 von 5 Sternen5/5 (2)

- Introduction To Petroleum Engineering Final - Formation Evaluation - DSTDokument27 SeitenIntroduction To Petroleum Engineering Final - Formation Evaluation - DSTshanecarlNoch keine Bewertungen

- Introduction To Petroleum Engineering - Lecture 3 - 12-10-2012 - Final PDFDokument19 SeitenIntroduction To Petroleum Engineering - Lecture 3 - 12-10-2012 - Final PDFshanecarlNoch keine Bewertungen

- Introduction To Petroleum Engineering - Lecture 11 - CementingDokument17 SeitenIntroduction To Petroleum Engineering - Lecture 11 - CementingshanecarlNoch keine Bewertungen

- Introduction To Petroleum Engineering - Lecture 2Dokument22 SeitenIntroduction To Petroleum Engineering - Lecture 2shanecarlNoch keine Bewertungen

- Beng (Hons) Petroleum Engineering: Course: Introduction To Petroleum Engineering Instructor Dr. Tarek DarwichDokument8 SeitenBeng (Hons) Petroleum Engineering: Course: Introduction To Petroleum Engineering Instructor Dr. Tarek DarwichshanecarlNoch keine Bewertungen

- Introduction To Petroleum Engineering - Field Appraisal and DevelopmentDokument26 SeitenIntroduction To Petroleum Engineering - Field Appraisal and DevelopmentshanecarlNoch keine Bewertungen

- Introduction To Petroleum Engineering - Lecture 13 Final - Formation Evaluation - Well LoggingDokument30 SeitenIntroduction To Petroleum Engineering - Lecture 13 Final - Formation Evaluation - Well LoggingshanecarlNoch keine Bewertungen

- Introduction To Petroleum Engineering - Lecture 4 - 19-10-2012 - Final PDFDokument16 SeitenIntroduction To Petroleum Engineering - Lecture 4 - 19-10-2012 - Final PDFshanecarl0% (1)

- Wellbore Completion ConceptsDokument20 SeitenWellbore Completion ConceptsAngel NgoNoch keine Bewertungen

- Petroleum Production Engineering IDokument119 SeitenPetroleum Production Engineering IMurtezNoch keine Bewertungen

- Overview of Drilling Operations MAY 2011 SEMDokument48 SeitenOverview of Drilling Operations MAY 2011 SEMdatug100% (1)

- Introduction To Petroleum Engineering Field ProductionDokument28 SeitenIntroduction To Petroleum Engineering Field Productionshanecarl100% (1)

- 11 CL-1.Primary Cementing 1Dokument45 Seiten11 CL-1.Primary Cementing 1Eslam Atif AzkolNoch keine Bewertungen

- 07-Hoan Thien Gieng Optimize PDFDokument93 Seiten07-Hoan Thien Gieng Optimize PDFGiang Nguyen NinhNoch keine Bewertungen

- Gas HydratesDokument16 SeitenGas HydratesMehmet KırgözoğluNoch keine Bewertungen

- Lecture 1 Well Planning BDokument17 SeitenLecture 1 Well Planning BAryan RajNoch keine Bewertungen

- Tubing SelectionDokument51 SeitenTubing SelectionImam Zulkifli SNoch keine Bewertungen

- Well CementingDokument8 SeitenWell CementingNima MoradiNoch keine Bewertungen

- Introduction To Petroleum Engineering - Final - Oil and Gas TransportationDokument12 SeitenIntroduction To Petroleum Engineering - Final - Oil and Gas TransportationshanecarlNoch keine Bewertungen

- Logging While DrillingDokument37 SeitenLogging While Drillingdriller22Noch keine Bewertungen

- Completion Design (#2)Dokument57 SeitenCompletion Design (#2)Sayaf SalmanNoch keine Bewertungen

- 2 - Directional Well DrillingDokument105 Seiten2 - Directional Well DrillingAli AbdullahNoch keine Bewertungen

- Drilling Engineering Lecture 2Dokument63 SeitenDrilling Engineering Lecture 2shanecarl100% (1)

- Production LoggingDokument27 SeitenProduction Logginghooman_teh100% (1)

- Flowing WellsDokument18 SeitenFlowing WellsJorge RidezNoch keine Bewertungen

- Formation DamageDokument36 SeitenFormation Damagestaph23100% (1)

- Reservoir Engineering 1 (Introduction)Dokument15 SeitenReservoir Engineering 1 (Introduction)okpaire lawsonNoch keine Bewertungen

- 1 1 PetroleumgeologyDokument30 Seiten1 1 PetroleumgeologyJEAN ALARCONNoch keine Bewertungen

- Openhole CompletionsDokument9 SeitenOpenhole CompletionsShaktim DuttaNoch keine Bewertungen

- Part V Filtration ControlDokument24 SeitenPart V Filtration ControlMohamed SadekNoch keine Bewertungen

- Drilling Programme TemplateDokument15 SeitenDrilling Programme TemplateaMRHAGGAHNoch keine Bewertungen

- Introduction of Gravel Pack With Inflow Control Completions in BrazilDokument26 SeitenIntroduction of Gravel Pack With Inflow Control Completions in BrazilMujtabaNoch keine Bewertungen

- Well Planning and DesignDokument7 SeitenWell Planning and DesignCyril PintoNoch keine Bewertungen

- Formation DamageDokument46 SeitenFormation Damageali100% (3)

- 1 Casing DesignDokument73 Seiten1 Casing DesignHasril Fauzul AziNoch keine Bewertungen

- Well Logging 2016Dokument84 SeitenWell Logging 2016Ary Muhamad ramdaniNoch keine Bewertungen

- Casing Setting Depth SelectionDokument33 SeitenCasing Setting Depth Selectionمصطفى مجدي100% (1)

- Non-Consolidating Plugging Material For Wellbore and AnnulusDokument18 SeitenNon-Consolidating Plugging Material For Wellbore and AnnulusSLACKENGINEERNoch keine Bewertungen

- Offshore Well Construction - Casing DesignDokument77 SeitenOffshore Well Construction - Casing DesigntduyhaoNoch keine Bewertungen

- Module 3b - Reservoir Drive Mechanisms and Intro WaterfloodingDokument63 SeitenModule 3b - Reservoir Drive Mechanisms and Intro WaterfloodingJamelia Herbert100% (1)

- Drilling Fluids For Drilling of Geothermal Wells - Hagen HoleDokument8 SeitenDrilling Fluids For Drilling of Geothermal Wells - Hagen HoleAdil AytekinNoch keine Bewertungen

- Well Completion IntroductionDokument21 SeitenWell Completion IntroductionJonathan ShimNoch keine Bewertungen

- Coiled Tubing Cleanout OperationDokument54 SeitenCoiled Tubing Cleanout OperationRick Raynold ClaudiusNoch keine Bewertungen

- 3.5 Horizontal Well Completions PDFDokument29 Seiten3.5 Horizontal Well Completions PDFJohn CooperNoch keine Bewertungen

- CementingDokument53 SeitenCementingUgochukwu Fidelis100% (1)

- Exploiting the Digital Oilfield: 15 Requirements for Business ValueVon EverandExploiting the Digital Oilfield: 15 Requirements for Business ValueBewertung: 5 von 5 Sternen5/5 (1)

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceVon EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssuranceNoch keine Bewertungen

- Offshore Gas Hydrates: Origins, Development, and ProductionVon EverandOffshore Gas Hydrates: Origins, Development, and ProductionNoch keine Bewertungen

- Streamline Numerical Well Test Interpretation: Theory and MethodVon EverandStreamline Numerical Well Test Interpretation: Theory and MethodNoch keine Bewertungen

- Microbial Enhancement of Oil Recovery - Recent AdvancesVon EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesNoch keine Bewertungen

- Low Salinity and Engineered Water Injection for Sandstone and Carbonate ReservoirsVon EverandLow Salinity and Engineered Water Injection for Sandstone and Carbonate ReservoirsNoch keine Bewertungen

- Practical Petroleum Geochemistry for Exploration and ProductionVon EverandPractical Petroleum Geochemistry for Exploration and ProductionNoch keine Bewertungen

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsVon EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNoch keine Bewertungen

- Rich Dad Balance-SheetDokument1 SeiteRich Dad Balance-SheetshanecarlNoch keine Bewertungen

- Learning Plan AX Project ManagerDokument2 SeitenLearning Plan AX Project Managerpdfme123Noch keine Bewertungen

- Rich Dad Balance-SheetDokument1 SeiteRich Dad Balance-SheetshanecarlNoch keine Bewertungen

- Petroleum Production Engineering - Lecture 2 - Production From Undersaturated Oil Reservoirs - FinalDokument23 SeitenPetroleum Production Engineering - Lecture 2 - Production From Undersaturated Oil Reservoirs - FinalshanecarlNoch keine Bewertungen

- l3 QuestionDokument2 Seitenl3 QuestionshanecarlNoch keine Bewertungen

- 1.0 Introduction To Formation Evaluation Log AnalysisDokument3 Seiten1.0 Introduction To Formation Evaluation Log AnalysisshanecarlNoch keine Bewertungen

- 제8차 전력수급기본계획Dokument51 Seiten제8차 전력수급기본계획김명근Noch keine Bewertungen

- Real Time Manufacturing' Using Oracle Cloud 13: A Manufacturing Execution System by WiproDokument18 SeitenReal Time Manufacturing' Using Oracle Cloud 13: A Manufacturing Execution System by WiproSatya NekkantiNoch keine Bewertungen

- The Influence of Social Media On Crowd Behavior and The Operational EnvironmentDokument78 SeitenThe Influence of Social Media On Crowd Behavior and The Operational EnvironmentangryTXNoch keine Bewertungen

- Conductivity Type of Extrinsic Semiconducting Materials: Standard Test Methods ForDokument6 SeitenConductivity Type of Extrinsic Semiconducting Materials: Standard Test Methods ForRob GridleyNoch keine Bewertungen

- A Study On Pushover Analysis Using Capacity Spectrum Method Based On Eurocode 8Dokument13 SeitenA Study On Pushover Analysis Using Capacity Spectrum Method Based On Eurocode 8ephNoch keine Bewertungen

- Powerpoint TrainingDokument22 SeitenPowerpoint TrainingDenise SuNoch keine Bewertungen

- Eng8Quarter1Week1 2Dokument6 SeitenEng8Quarter1Week1 2Duero-Hadjilatip KayeNoch keine Bewertungen

- Non-Parametric TestsDokument1 SeiteNon-Parametric TestssdvdsvNoch keine Bewertungen

- Karma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Dokument37 SeitenKarma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Lars JensenNoch keine Bewertungen

- Janice C. Vergel: ObjectiveDokument3 SeitenJanice C. Vergel: ObjectiveRency Reiz JhaniceNoch keine Bewertungen

- GALCIT 6-Inch Shock Tube: Bryan SchmidtDokument14 SeitenGALCIT 6-Inch Shock Tube: Bryan SchmidtNitesh Kumar PatelNoch keine Bewertungen

- Final Differential Equations (PDF)Dokument88 SeitenFinal Differential Equations (PDF)Tina ShahNoch keine Bewertungen

- Gep Primary Water Resource Aug12 NSWDokument50 SeitenGep Primary Water Resource Aug12 NSWNitin AroraNoch keine Bewertungen

- Karatina University: University Examinations 2017/2018 ACADEMIC YEARDokument4 SeitenKaratina University: University Examinations 2017/2018 ACADEMIC YEARKimondo KingNoch keine Bewertungen

- Quiz 1 Distribusi Plus JawabanDokument6 SeitenQuiz 1 Distribusi Plus JawabandimasfupNoch keine Bewertungen

- Sheena HSMDokument8 SeitenSheena HSMdesign12Noch keine Bewertungen

- 2 ID FansDokument43 Seiten2 ID Fansshubham vermaNoch keine Bewertungen

- Circuflow 5200 Operating InstructionsDokument24 SeitenCircuflow 5200 Operating InstructionsalexNoch keine Bewertungen

- 10D Unit-Coral Reefs PDFDokument14 Seiten10D Unit-Coral Reefs PDFIWAN KUNCORONoch keine Bewertungen

- Lesson Plan in Mathematics Grade9Dokument6 SeitenLesson Plan in Mathematics Grade9Abegail VillanuevaNoch keine Bewertungen

- Dist Census Book Latur PDFDokument770 SeitenDist Census Book Latur PDFMP100% (1)

- Types of Speeches and Speech StyleDokument1 SeiteTypes of Speeches and Speech StyleSai RiveraNoch keine Bewertungen

- Thomson Catalog CompressedDokument210 SeitenThomson Catalog CompressedCharlesNoch keine Bewertungen

- Bitacora 5th Week #6Dokument1 SeiteBitacora 5th Week #6Onelbi RamosNoch keine Bewertungen

- A Comparative Study of Indian and Western Music FormsDokument6 SeitenA Comparative Study of Indian and Western Music FormsSophieNoch keine Bewertungen

- FNDWRR PDFDokument5 SeitenFNDWRR PDFngole ngoleNoch keine Bewertungen

- Seal Kit Seal KitDokument61 SeitenSeal Kit Seal KitМаксим Стратила0% (1)

- Acer V193 Service ManualDokument46 SeitenAcer V193 Service Manualagun92Noch keine Bewertungen

- Variables That Affect Teachers' Attitudes Towards Disability and Inclusive Education in Mumbai, IndiaDokument12 SeitenVariables That Affect Teachers' Attitudes Towards Disability and Inclusive Education in Mumbai, IndiaSumaiya HossainNoch keine Bewertungen

- Edi WowDokument11 SeitenEdi WowfantasighNoch keine Bewertungen