Beruflich Dokumente

Kultur Dokumente

Asgmnt Pneu Eng Starting

Hochgeladen von

BookMaggot0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten17 Seitenasgmnt pneu eng starting.ppt

Originaltitel

asgmnt pneu eng starting.ppt

Copyright

© Attribution Non-Commercial (BY-NC)

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenasgmnt pneu eng starting.ppt

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten17 SeitenAsgmnt Pneu Eng Starting

Hochgeladen von

BookMaggotasgmnt pneu eng starting.ppt

Copyright:

Attribution Non-Commercial (BY-NC)

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 17

4 Aeroplane 3

PNEUMATIC STARTING SYSTEM

To rotate engine to the rpm range where starting can be

accomplished.

Controlled by two start switches (located on the

forward overhead panel)

two pneumatic starters two starter valves

associated pneumatic plumbing

Consists

of

CENTER INSTRUMENT

PANEL

FORWARD OVERHEAD

PANEL

Air pressure in the pneumatic manifold

Engine accelerate to starting speed & engine start

Starter rotate & transmitted to the N2 compressor

through the accessory drive gear system

Low pressure heat the pneumatic starter

turbine blades

Start switch supply electrical power to open the

starter valve

Start switch

Control the system

4-position rotary switches

Other than ground start position

switch remain in its original

position until another selection is

made.

Electrical power source

* 28 -volt dc battery bus

* 115-volt ac transfer bus

* 115-volt ac standby bus

GRD, OFF, CONT and FLT

3 separate

compressed

air sources:

-APU

-Ground carts

-Cross-bleed air

+ Lightweight turbine-type air motor

+ Converts kinetic energy starting torque

+ Use low pressure air and electrical power for starter operation.

+ 5 basic parts:

PNEUMATIC STARTER

Scroll assembly

Turbine wheel

Reduction gear assembly

Engaging mechanism

Output shaft

Starter valve

open

admit air to

the inlet

connection

passes through the

starter vanes (starter

scroll ass.)

air directed radially

inward ( through

turbine wheel )

give high

speed

rotation

Exhaust air passes

air outlet screen or

turbine wheel

containment ass.

(reduction gear)

transmit high

speed, low torque

low speed,

high torque

Transmitted

to output

shaft

Transmitted

to the N

2

compressor

.

speed of output shaft >

speed of internal gear hub

clutch mechanism

provide automatic

disengagement

cutout switch mechanism

(actuated by centrifugal

force) closed starter valve

automatically when output

shaft reaches

predetermined cutout speed

Controls airflow to the pneumatic starter during engine

starting.

Operated pneumatically and solenoid- controlled.

Consists of two assemblies:

STARTER VALVE

Valve body assembly

Piston type pneumatic

actuator assembly

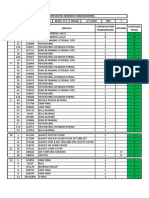

PNEUMATIC STARTING SYSTEM CIRCUIT

ENGINE STARTING USING

AUXILIARY POWER UNIT

- Pack valves and wing thermal anti-ice valves closed.

- Applicable engine bleed valve open.

- Bleed air isolation valve switch in AUTO.

- Both air conditioning packs off.

- The APU bleed valve ON.

- Compressed air is supplied to the starter to rotate the N2

compressor of the engine.

ENGINE STARTING USING

EXTERNAL AIR SOURCE

^ Depends on the external low pressure air source

connected to the ground pneumatic connection.

^ Procedure for starting is same as using the APU

except that bleed air valve for the applicable engine

must be opened manually if ac power is not

available.

ENGINE STARTING USING

ENGINE CROSS BLEED AIR

+ Can be done by using 8th-stage bleed air from the

operating engine.

+ The operating engine must operate at approximately

80% N2 rpm.

+ The procedure for starting is the same as using the

APU.

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- D12D EngineDokument130 SeitenD12D EngineZaw Than Hteik100% (1)

- Ob Di I Data InterpretationDokument8 SeitenOb Di I Data InterpretationMohamed WahiebNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- D13 500T, EU6HT - Eng - 01 - 310999630Dokument3 SeitenD13 500T, EU6HT - Eng - 01 - 310999630ESCC OfficeNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- ScaniaDokument22 SeitenScaniazahar22286% (7)

- CUMMINS - b3.9-c116 Parts Catalog cpl2351 DynapacDokument83 SeitenCUMMINS - b3.9-c116 Parts Catalog cpl2351 DynapacLord Eskar100% (1)

- New Holland Eh215 Crawler ExcavatorDokument653 SeitenNew Holland Eh215 Crawler ExcavatorcarlosNoch keine Bewertungen

- Parts Manual Perkins 404c-22Dokument136 SeitenParts Manual Perkins 404c-22Julio Ramirez100% (4)

- Overviewpartno PDFDokument48 SeitenOverviewpartno PDFAbomazen Galal100% (1)

- Volvo TWD1031Dokument422 SeitenVolvo TWD1031hoi100% (1)

- I - T - I ENGINEERS HANDBOOK I M 451145214 PDFDokument193 SeitenI - T - I ENGINEERS HANDBOOK I M 451145214 PDFcpîndaru100% (1)

- PinoutDokument5 SeitenPinout819680% (1)

- Vector Mechanics For Engineers-STATICSDokument15 SeitenVector Mechanics For Engineers-STATICSBookMaggot0% (1)

- Final Ignition System QuizDokument30 SeitenFinal Ignition System QuizMelzXinXajSandoyNalua100% (2)

- Symptoms of A Blown Head GasketDokument5 SeitenSymptoms of A Blown Head GasketSandeep Swami G Elugu100% (2)

- Cummins KTA50-G3Dokument16 SeitenCummins KTA50-G3Teodoro Cornelius AltuveNoch keine Bewertungen

- TurbochargerDokument5 SeitenTurbochargerToua Yaj100% (1)

- 1Dokument1 Seite1BookMaggotNoch keine Bewertungen

- 15Dokument5 Seiten15BookMaggotNoch keine Bewertungen

- Weekly Schedule SMC - EduDokument2 SeitenWeekly Schedule SMC - EduDavid BayerNoch keine Bewertungen

- Why Choose MBA MSC BUSDokument1 SeiteWhy Choose MBA MSC BUSBookMaggotNoch keine Bewertungen

- Composites SelectionDokument2 SeitenComposites SelectionBookMaggotNoch keine Bewertungen

- 17) What Is The Symbol of The Field Effect Transistor?Dokument4 Seiten17) What Is The Symbol of The Field Effect Transistor?BookMaggotNoch keine Bewertungen

- Understanding The Concept of The Gear Ratio: 1.27 Inches / 2 0.635 InchesDokument1 SeiteUnderstanding The Concept of The Gear Ratio: 1.27 Inches / 2 0.635 InchesBookMaggotNoch keine Bewertungen

- Cover LetterDokument2 SeitenCover LetterBookMaggotNoch keine Bewertungen

- Aircraft Refueling System Is A Refuelling Equipment For AircraftDokument1 SeiteAircraft Refueling System Is A Refuelling Equipment For AircraftBookMaggotNoch keine Bewertungen

- Three Pointer AltimetersDokument1 SeiteThree Pointer AltimetersBookMaggotNoch keine Bewertungen

- Cover Letter!Dokument1 SeiteCover Letter!BookMaggotNoch keine Bewertungen

- Anaki 2Dokument1 SeiteAnaki 2BookMaggotNoch keine Bewertungen

- QuestionaireDokument7 SeitenQuestionaireBookMaggotNoch keine Bewertungen

- The Silent EmergencyDokument5 SeitenThe Silent EmergencyBookMaggotNoch keine Bewertungen

- Project p-37Dokument2 SeitenProject p-37BookMaggotNoch keine Bewertungen

- 737sec1 PDFDokument10 Seiten737sec1 PDFBookMaggotNoch keine Bewertungen

- System DescriptionDokument10 SeitenSystem DescriptionBookMaggotNoch keine Bewertungen

- Seat Pitch Position On Two Seats, One Behind The Other - It Is NOT The Legrest Area As SomeDokument3 SeitenSeat Pitch Position On Two Seats, One Behind The Other - It Is NOT The Legrest Area As SomeBookMaggotNoch keine Bewertungen

- System DescriptionDokument2 SeitenSystem DescriptionBookMaggotNoch keine Bewertungen

- Defuel Aircraft: New Zealand Qualifications Authority 2006Dokument4 SeitenDefuel Aircraft: New Zealand Qualifications Authority 2006Arie WibowoNoch keine Bewertungen

- Typical Aircraft Charging CircuitDokument1 SeiteTypical Aircraft Charging CircuitBookMaggotNoch keine Bewertungen

- Assignment Fire 1Dokument14 SeitenAssignment Fire 1BookMaggotNoch keine Bewertungen

- RECOMMENDATIONSDokument4 SeitenRECOMMENDATIONSBookMaggotNoch keine Bewertungen

- PENTINGDokument5 SeitenPENTINGBookMaggotNoch keine Bewertungen

- Assignment CabinDokument5 SeitenAssignment CabinBookMaggotNoch keine Bewertungen

- RecipDokument5 SeitenRecipBookMaggotNoch keine Bewertungen

- Toefl 2Dokument8 SeitenToefl 2sangho,wooNoch keine Bewertungen

- The Problems of Instrument Part On Jet Streaming AircraftDokument2 SeitenThe Problems of Instrument Part On Jet Streaming AircraftBookMaggotNoch keine Bewertungen

- Toefl 3Dokument8 SeitenToefl 3sangho,wooNoch keine Bewertungen

- 633GC Service ManualDokument78 Seiten633GC Service Manualmichael.vielkind.rbwNoch keine Bewertungen

- Recon 08cb HhpblockDokument11 SeitenRecon 08cb HhpblockO mecanicoNoch keine Bewertungen

- H2ADDokument27 SeitenH2ADTatiana MirandaNoch keine Bewertungen

- 200aetl 2000Dokument0 Seiten200aetl 2000Ray Cepeda MenaNoch keine Bewertungen

- Page 1Dokument804 SeitenPage 1H Aries OñaNoch keine Bewertungen

- Diesel Cycle For Mechanical EngineersDokument21 SeitenDiesel Cycle For Mechanical Engineerszega5394Noch keine Bewertungen

- Respuestos para El AutomovilDokument4 SeitenRespuestos para El AutomovilMarcos CarrazcoNoch keine Bewertungen

- Inyección Golf mk5Dokument32 SeitenInyección Golf mk5Andres QuinteroNoch keine Bewertungen

- Swaraj Tractor EngineDokument7 SeitenSwaraj Tractor EngineHarmanjit SinghNoch keine Bewertungen

- Workshop Manual: Engine Series 3 - 4 LDDokument48 SeitenWorkshop Manual: Engine Series 3 - 4 LDNenadStojicNoch keine Bewertungen

- LkjpojpDokument149 SeitenLkjpojpErick BranteNoch keine Bewertungen

- MF 34 2003Dokument335 SeitenMF 34 2003lasieNoch keine Bewertungen

- Schema Elettrico MTS1200Dokument1 SeiteSchema Elettrico MTS1200Superleggera upmapNoch keine Bewertungen

- DBGFC 431-?'dif$: ModelDokument2 SeitenDBGFC 431-?'dif$: Modeljohnny sabinNoch keine Bewertungen

- EASA TCDS IM E 002 - GE90 Series - Issue3 - 15112017Dokument16 SeitenEASA TCDS IM E 002 - GE90 Series - Issue3 - 15112017Ranto GunawanNoch keine Bewertungen