Beruflich Dokumente

Kultur Dokumente

Manufacturing Technology: Unit - I

Hochgeladen von

karanmarwahaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manufacturing Technology: Unit - I

Hochgeladen von

karanmarwahaCopyright:

Verfügbare Formate

MANUFACTURING TECHNOLOGY

UNIT I

ELECTRICAL RESISTANCE WELDING

ELECTRICAL RESISTANCE WELDING

Introduction

Resistance welding uses the application of electric current and mechanical pressure to create a weld between two pieces of metal. Weld electrodes conduct the electric current to the two pieces of metal as they are forged together. The welding cycle must first develop sufficient heat to raise a small volume of metal to the molten state. This metal then cools while under pressure until it has adequate strength to hold the parts together. The current density and pressure must be sufficient to produce a weld nugget, but not so high as to expel molten metal from the weld zone.

ELECTRICAL RESISTANCE WELDING

Operating Principle

Parts to be welded (usually sheet metal) are placed in between

two opposing copper electrodes

When alternating current (A/C) is passed through the electrodes ,the electrical resistance at the metal joints becomes very high. Heat generated by electrical resistance to current flow at junction to be welded by means of applying pressure to squeeze parts between electrodes Pressure is applied to the contact zone until the current is turned off in order to obtain a strong weld.

ELECTRICAL RESISTANCE WELDING

Equipment

Schematic illustration of Electrical Resistance Welding

ELECTRICAL RESISTANCE WELDING

Equipment

Electrical Resistance Welding Process

ELECTRICAL RESISTANCE WELDING

Operating Principle in Detail

Parts inserted between electrodes Electrodes close, force applied Current on

Current off

Electrodes opened

ELECTRICAL RESISTANCE WELDING

Types of Resistance Welding Resistance Spot Welding

ELECTRICAL RESISTANCE WELDING

Resistance Spot Welding Process Detail

ELECTRICAL RESISTANCE WELDING

Operating Principle

Resistance welding process in which fusion of faying surfaces of a lap joint is achieved at one location by opposing electrodes

Used to join sheet metal parts using a series of spot welds Widely used in mass production of automobiles, appliances, metal furniture, and other products made of sheet metal

ELECTRICAL RESISTANCE WELDING

Resistance Seam Welding

Resistance Seam Welding is modification of spot welding wherein the electrodes are replaced by rotating wheels or rollers

The electrically conducting rollers produce a spot weld

RSEM can produce a continuous seam & joint that is liquid and gas tight

ELECTRICAL RESISTANCE WELDING

Resistance Seam Welding

ELECTRICAL RESISTANCE WELDING

Resistance Projection Welding

RPW is developed by introducing high electrical

resistance at a joint by embossing one or more projections on the surface to be welded

The

electrodes

exert

pressure

to

compress

the

projections

Nuts and bolts can be welded to sheet and plate by this process

Metal baskets, oven grills, and shopping carts can be made by RPW

ELECTRICAL RESISTANCE WELDING

Resistance Projection Welding

ELECTRICAL RESISTANCE WELDING

Resistance Projection Welding Process steps

start of operation, contact between parts is at Projections

When current is applied, weld nuggets similar to spot

welding are formed at the projections.

ELECTRICAL RESISTANCE WELDING

Heat Generated in the weld may be expressed as

Q = K R I2 T

Where,

K: constant less than 1 related to heat losses.

I : Current.

R: Resistance of ionized air gap.

T : Welding time.

ELECTRICAL RESISTANCE WELDING

Process Parameters

The welding current welding temperatures Electrode materials

Electrode geometry

Electrode pressing force

weld current and weld time.

ELECTRICAL RESISTANCE WELDING

Advantages

High speed welding Easily automated Suitable for high rate production Economical

ELECTRICAL RESISTANCE WELDING

Limitations

Initial equipment costs Lower tensile and fatigue strengths Lap joints add weight and material

ELECTRICAL RESISTANCE WELDING

Applications

Industries: automotive, aircraft, farm equipment, petroleum and natural gas

END

Das könnte Ihnen auch gefallen

- Electron Resistance WeldingDokument20 SeitenElectron Resistance Weldingsai prasadNoch keine Bewertungen

- WELDINGDokument94 SeitenWELDINGharshaNoch keine Bewertungen

- Module-1: Electric Welding byDokument17 SeitenModule-1: Electric Welding byveena bhatNoch keine Bewertungen

- Resistance WeldingDokument45 SeitenResistance WeldingAntony SiregarNoch keine Bewertungen

- Welding & Joining ProcessesDokument5 SeitenWelding & Joining ProcessesKetan TiwariNoch keine Bewertungen

- Esw & PMDokument28 SeitenEsw & PMSandipan SarmaNoch keine Bewertungen

- Manufacturing Technology: Unit - IDokument12 SeitenManufacturing Technology: Unit - Iapi-271354682Noch keine Bewertungen

- Resistance WeldingDokument22 SeitenResistance WeldingLOKENDRA91100% (2)

- Welding PrincipleDokument61 SeitenWelding PrincipleRishu GroverNoch keine Bewertungen

- Resistance WeldingDokument21 SeitenResistance WeldingAyush KumarNoch keine Bewertungen

- Electric WeldingDokument56 SeitenElectric WeldingKilaru Sai KiranNoch keine Bewertungen

- Resistance WeldingDokument9 SeitenResistance WeldingAhmed AbconoNoch keine Bewertungen

- 3-2 Spot WeldingDokument29 Seiten3-2 Spot WeldingNaram AppannaNoch keine Bewertungen

- Chapter 5 Metal Joinig ProcessesDokument88 SeitenChapter 5 Metal Joinig Processesdagimawgchew777Noch keine Bewertungen

- F Arcwelding 131118222251 Phpapp02Dokument42 SeitenF Arcwelding 131118222251 Phpapp02hassan aliNoch keine Bewertungen

- Welding: Welding Is A Process of Metal Joining by Applying Heat and Sometime PressureDokument41 SeitenWelding: Welding Is A Process of Metal Joining by Applying Heat and Sometime PressureJith Viswa100% (1)

- Welding and Fabrication NoteDokument54 SeitenWelding and Fabrication NoteluminiousNoch keine Bewertungen

- Resistance WeldingDokument22 SeitenResistance WeldingGarden005Noch keine Bewertungen

- Resistance WeldingDokument24 SeitenResistance WeldingSenthil Kumar K LNoch keine Bewertungen

- Resistance WeldingDokument24 SeitenResistance WeldingSenthil Kumar K LNoch keine Bewertungen

- Plasma CuttingDokument229 SeitenPlasma CuttingTilak MoundekarNoch keine Bewertungen

- Arc Welding in DetailDokument34 SeitenArc Welding in DetailSohen PatelNoch keine Bewertungen

- Welding LectureDokument101 SeitenWelding Lecturesumit sengarNoch keine Bewertungen

- 1585680360EEE 552 Slides-Pt3Dokument14 Seiten1585680360EEE 552 Slides-Pt3ksrmuruganNoch keine Bewertungen

- Resistance Seam WeldingDokument16 SeitenResistance Seam Weldingkkpkk100% (1)

- 6,7-Forge Welding, Resistance WeldingDokument13 Seiten6,7-Forge Welding, Resistance WeldingRamu AmaraNoch keine Bewertungen

- Resistance Welding: Anil Kr. Garikapati Asst. Prof. DbsitDokument22 SeitenResistance Welding: Anil Kr. Garikapati Asst. Prof. DbsitAnil Kumar GarikapatiNoch keine Bewertungen

- Welding Technology Lecture Notes by DR - Behzad PDFDokument354 SeitenWelding Technology Lecture Notes by DR - Behzad PDFAnonymous L9LWVE100% (7)

- Metal JoiningDokument62 SeitenMetal Joiningbhavna agarwalNoch keine Bewertungen

- Sonargaon University Shop 160 Welding - 2: Prepared by Zayed AhmedDokument19 SeitenSonargaon University Shop 160 Welding - 2: Prepared by Zayed Ahmedদুর্জয় দুর্বারNoch keine Bewertungen

- MF F222 Joining ProcessesDokument104 SeitenMF F222 Joining ProcessesKislay TiwaryNoch keine Bewertungen

- Esw and Plasma Arc WeldingDokument36 SeitenEsw and Plasma Arc WeldingaravindanilNoch keine Bewertungen

- Resistance Welding ProcessesDokument63 SeitenResistance Welding ProcessesJay DaveNoch keine Bewertungen

- Welding ProcessDokument25 SeitenWelding ProcessMayankNoch keine Bewertungen

- Arc WeldingDokument40 SeitenArc Welding20G062 NALVETHA BNoch keine Bewertungen

- Welding of MetalsDokument21 SeitenWelding of MetalsmangalamtestingbureaNoch keine Bewertungen

- Different Types of WeldingDokument4 SeitenDifferent Types of WeldingSALOOP T SNoch keine Bewertungen

- On Resistance WeldingDokument18 SeitenOn Resistance WeldingMadhup Kulshrestha100% (1)

- Welding-Of-Metals-PPT Amar BhargavDokument23 SeitenWelding-Of-Metals-PPT Amar BhargavSagar BhargavNoch keine Bewertungen

- Basics in WeldingDokument63 SeitenBasics in WeldingK JeevanNoch keine Bewertungen

- Welding ProcessDokument81 SeitenWelding ProcessTsegayNoch keine Bewertungen

- Electric WeldingDokument19 SeitenElectric WeldingRaghupatruni SowmyaNoch keine Bewertungen

- Fundamentals of Vehicle Dynamics by Thomas D GillespieDokument99 SeitenFundamentals of Vehicle Dynamics by Thomas D GillespieYogesh Chandrawanshi0% (1)

- Resistance WeldingDokument18 SeitenResistance WeldingAnand JainNoch keine Bewertungen

- Manufacturing Technology-I: Joining ProcessDokument43 SeitenManufacturing Technology-I: Joining ProcessheartyseeNoch keine Bewertungen

- Arc Welding1Dokument92 SeitenArc Welding1Kavipriyan KaviNoch keine Bewertungen

- Welding Types Procedures ParametersDokument156 SeitenWelding Types Procedures ParametersVinodh Kumar YallaNoch keine Bewertungen

- Smaw and Tig WeldingDokument46 SeitenSmaw and Tig WeldingRajesh Kumar Ravi100% (1)

- Welding: Asif Hussain Assistant Professor UMT Lahore PakistanDokument20 SeitenWelding: Asif Hussain Assistant Professor UMT Lahore PakistanNawaz RafiqueNoch keine Bewertungen

- Introduction To Welding and NDT: Rajneesh Vachaspati Assistant Director Npti-Hptc, NangalDokument83 SeitenIntroduction To Welding and NDT: Rajneesh Vachaspati Assistant Director Npti-Hptc, NangalRajneesh VachaspatiNoch keine Bewertungen

- Joining Part2Dokument27 SeitenJoining Part2Dune StarlightNoch keine Bewertungen

- Arc WeldingDokument43 SeitenArc WeldingHitarth ChudasamaNoch keine Bewertungen

- Unit Ii Resistance Welding ProcessesDokument49 SeitenUnit Ii Resistance Welding ProcessesparthibankNoch keine Bewertungen

- Chapter 3-Electric WeldingDokument32 SeitenChapter 3-Electric WeldingAMAR CHAND MEENANoch keine Bewertungen

- Welding TechnologyDokument218 SeitenWelding Technologywbl_200789% (9)

- Soldering Electronic Components 2nd EditionVon EverandSoldering Electronic Components 2nd EditionBewertung: 3 von 5 Sternen3/5 (2)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesVon EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNoch keine Bewertungen

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsVon EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNoch keine Bewertungen

- As1018 6 Sem 5Dokument2 SeitenAs1018 6 Sem 5api-271354682Noch keine Bewertungen

- 15as304 Air Breathing Propulsion SyllabusDokument2 Seiten15as304 Air Breathing Propulsion Syllabusapi-271354682Noch keine Bewertungen

- As1018 6 Sem 7Dokument2 SeitenAs1018 6 Sem 7api-271354682Noch keine Bewertungen

- As1018 6 Sem 6Dokument2 SeitenAs1018 6 Sem 6api-271354682Noch keine Bewertungen

- Air Breathing Propulsion Unit-1Dokument37 SeitenAir Breathing Propulsion Unit-1api-271354682Noch keine Bewertungen

- Gate Question and Answer For Aerospace by Vinothkumar AnnamalaiDokument138 SeitenGate Question and Answer For Aerospace by Vinothkumar Annamalaiapi-271354682Noch keine Bewertungen

- Propulsion2 QPDokument12 SeitenPropulsion2 QPapi-271354682100% (1)

- As1018 6 Sem 4Dokument5 SeitenAs1018 6 Sem 4api-271354682Noch keine Bewertungen

- Rocket Propulsion ct-1 2017 QPDokument5 SeitenRocket Propulsion ct-1 2017 QPapi-271354682100% (1)

- Assignment 3Dokument3 SeitenAssignment 3api-271354682Noch keine Bewertungen

- Rocket Propulsion Unit-2Dokument8 SeitenRocket Propulsion Unit-2api-271354682Noch keine Bewertungen

- Cycle Test 2 Rocket PropulsionDokument3 SeitenCycle Test 2 Rocket Propulsionapi-271354682Noch keine Bewertungen

- List of Rockets AssignmentDokument4 SeitenList of Rockets Assignmentapi-271354682Noch keine Bewertungen

- As0306 Propulsion IIDokument3 SeitenAs0306 Propulsion IIapi-271354682Noch keine Bewertungen

- Intake and Nozzle Problems NumericalDokument7 SeitenIntake and Nozzle Problems Numericalapi-271354682100% (1)

- Air Breathing Propulsion Unit-3Dokument22 SeitenAir Breathing Propulsion Unit-3api-271354682Noch keine Bewertungen

- Rocket Propulsion-2 ct-1 QP Key-2016Dokument3 SeitenRocket Propulsion-2 ct-1 QP Key-2016api-271354682Noch keine Bewertungen

- Program 1Dokument35 SeitenProgram 1api-271354682Noch keine Bewertungen

- Lab Manual Stud CP II To Be Used With The Right One 1Dokument21 SeitenLab Manual Stud CP II To Be Used With The Right One 1api-271354682Noch keine Bewertungen

- Rocket Propulsion Unit-4Dokument21 SeitenRocket Propulsion Unit-4api-271354682100% (1)

- Rocket Propulsion Unit-5Dokument44 SeitenRocket Propulsion Unit-5api-271354682Noch keine Bewertungen

- Rocket Propulsion Unit-3Dokument53 SeitenRocket Propulsion Unit-3api-271354682100% (4)

- Air Breathing Propulsion Unit-2Dokument54 SeitenAir Breathing Propulsion Unit-2api-271354682Noch keine Bewertungen

- Rocket Propulsion-2 ct-2 qp-2016Dokument5 SeitenRocket Propulsion-2 ct-2 qp-2016api-271354682Noch keine Bewertungen

- Rockets History and EvolutionDokument11 SeitenRockets History and Evolutionapi-271354682Noch keine Bewertungen

- Rocket Propulsion Unit-1Dokument47 SeitenRocket Propulsion Unit-1api-271354682100% (4)

- Choice of Blade Profile, Pitch and ChordDokument6 SeitenChoice of Blade Profile, Pitch and Chordapi-27135468260% (5)

- Numerical ProblemsDokument12 SeitenNumerical Problemsapi-271354682Noch keine Bewertungen

- Matching of Turbine and CompressorDokument2 SeitenMatching of Turbine and Compressorapi-271354682100% (5)

- FW12 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020Dokument2 SeitenFW12 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020 A106 283033 16"/7.92 Na Acc Acc Acc A105 W-1800126 16"/7.92 1/17/2020Muhammad firdaus rusliNoch keine Bewertungen

- KQ2 MMDokument21 SeitenKQ2 MMkrisornNoch keine Bewertungen

- TWI - Welding Procedure - Job Knowledge 39Dokument9 SeitenTWI - Welding Procedure - Job Knowledge 39tuanNoch keine Bewertungen

- PT Welding ReportDokument11 SeitenPT Welding ReportK38Aryya BhattacharyaCSBSNoch keine Bewertungen

- Wide Gap Brazing When Parts Don't Fit Together Well For BrazingDokument2 SeitenWide Gap Brazing When Parts Don't Fit Together Well For BrazingwalkerbhoNoch keine Bewertungen

- List of Welding ProcessesDokument5 SeitenList of Welding ProcessesFilipe CordeiroNoch keine Bewertungen

- Gas Flux WeldingDokument78 SeitenGas Flux WeldingyendikesumaNoch keine Bewertungen

- Intervention AssessmentDokument8 SeitenIntervention AssessmentAdrian MendezNoch keine Bewertungen

- Davidovits, (2013), Geopolymer CementDokument12 SeitenDavidovits, (2013), Geopolymer CementsunNoch keine Bewertungen

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDokument2 SeitenWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNoch keine Bewertungen

- Liquid Penetrant Examination: Qa/Qc DepartmentDokument1 SeiteLiquid Penetrant Examination: Qa/Qc DepartmentIma Yuni PasaningsihNoch keine Bewertungen

- MTC Catalog 2009 ENGLISCHDokument196 SeitenMTC Catalog 2009 ENGLISCHAsif JalgaonkarNoch keine Bewertungen

- 8.8 ISO 4762 / DIN 912: Socket Head Cap Screws, SteelDokument9 Seiten8.8 ISO 4762 / DIN 912: Socket Head Cap Screws, SteelVijayGowthamanNoch keine Bewertungen

- PT. Trakindo U: 320D FAL Toh EngineDokument1 SeitePT. Trakindo U: 320D FAL Toh Enginerahmat sanusiNoch keine Bewertungen

- Pivot SampleDokument38 SeitenPivot SampleKabacan ConvergenceNoch keine Bewertungen

- Aggregate & M SandDokument48 SeitenAggregate & M SandBijayNoch keine Bewertungen

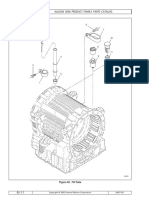

- Allison 3000 Product Family Parts CatalogDokument8 SeitenAllison 3000 Product Family Parts CatalogFilipposNoch keine Bewertungen

- UNF ThreadDokument4 SeitenUNF ThreadMUUTHUKRISHNANNoch keine Bewertungen

- P.No. Group N AWS No. Class Filler No (F. No.) A. No. Si No. Material Grade Filler Metal SFA NoDokument3 SeitenP.No. Group N AWS No. Class Filler No (F. No.) A. No. Si No. Material Grade Filler Metal SFA NoSitaram JhaNoch keine Bewertungen

- Open Frame Hand Crimp Tool Hx4: DatasheetDokument2 SeitenOpen Frame Hand Crimp Tool Hx4: Datasheetken liNoch keine Bewertungen

- Weidmüller - Crimping Tool CTI - Technical DataDokument3 SeitenWeidmüller - Crimping Tool CTI - Technical DatawilsonNoch keine Bewertungen

- Tee ReduceDokument163 SeitenTee ReduceEwaldo HidayatNoch keine Bewertungen

- Butt JointsDokument21 SeitenButt JointsRaj1-23Noch keine Bewertungen

- Sample Welding Map Project Kecil PDFDokument1 SeiteSample Welding Map Project Kecil PDFMuhammad Fitransyah Syamsuar Putra100% (1)

- Sample PQRDokument2 SeitenSample PQRudaysrp33% (3)

- Delphi DCM3.4 PDFDokument4 SeitenDelphi DCM3.4 PDFOsmar Augusto0% (1)

- UD20199B A Baseline Video Intercom Main Unit Quick Start Guide V2.2.3Dokument4 SeitenUD20199B A Baseline Video Intercom Main Unit Quick Start Guide V2.2.3avkt2005Noch keine Bewertungen

- Lab Report On Robotic WeldingDokument8 SeitenLab Report On Robotic WeldingSanatan ChoudhuryNoch keine Bewertungen

- Std-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)Dokument5 SeitenStd-Insp-0001 (Proceudre For Storage, Drying (Baking), Issue and Control of Welding Consumables)airbroomNoch keine Bewertungen

- Welding Machines Schedule of Loads PDF FreeDokument2 SeitenWelding Machines Schedule of Loads PDF FreeWar LockNoch keine Bewertungen