Beruflich Dokumente

Kultur Dokumente

Lean 3 TaktTime

Hochgeladen von

chethan626Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lean 3 TaktTime

Hochgeladen von

chethan626Copyright:

Verfügbare Formate

Building Lean Systems Takt Time

Origin of Takt Time

German engineers helped Japan build aircrafts in 30s. Takt is a German word for a musical meter. In TPS; Customer demand dictated the pace of operations on the shop floor. Takt Time: The concept of linking (external) customer demand to (internal) production resources. It is expressed in terms of the time available to make one unit to keep pace with customer demand.

Available Time per Period Takt Time Demand per Period

Lean Thinking: 3- Takt Time Ardavan Asef-Vaziri 6/4/2009 2

Takt Time: Hungama Insurance Co.

Demand is 20 policies/day. Net availability is 400 minutes/day. Takt Time = 400/20 = 20 There are four sub-processes; Data gathering / data entry (distribution), Risk analysis (underwriting) Computing the premium (rating), and Policy writing

Lean Thinking: 3- Takt Time

Ardavan Asef-Vaziri

6/4/2009

Load Balancing?

An operator can not be overloaded. Apply time studies to lower the time or breakdown the task. Loading each operator close to 100 percent may lead to infinite queue if the workload is highly variable (negative). keep operators loaded close to 100% to motivate them to find creative ways to reduce their cycle time to takt time (positive). If the operators are underutilized, work expands to fill the time available (negative). takt time goes down when demand increases. Then some operator may become overloaded. Subdivide tasks more finely, to load each operator close takt time. However, that would uniformly underutilize each operator. A better alternative is to have the first two operators loaded with tasks that add up to the takt time, leaving the third underloaded.

Ardavan Asef-Vaziri 6/4/2009 4

Lean Thinking: 3- Takt Time

Takt Time is a Measure of External Demand

The third operator could help if the others fall behind. S/he could be located at the end of the cell to perform material handling.

Lean Thinking: 3- Takt Time

Ardavan Asef-Vaziri

6/4/2009

Takt Time is a Measure of External Demand

If each operator is paced to takt time, over production will be automatically limited. Limiting overproduction prevents frequent stops and starts that inhibit a smooth flow. It's best to buffer variation with capacity, not inventory. It is incorrect stating that a machine has a takt time of five minutes. Takt time is a measure of external demand; it has nothing to do with machine capacity. Takt is time per piece, not pieces per time. Enterprise should match its (internal) resources to meet the (external) customer demand. takt time applies better to a flow shop, may not be very relevant in job shop, but still useful to determine the number of operators.

Ardavan Asef-Vaziri 6/4/2009 6

Lean Thinking: 3- Takt Time

How often should takt time be changed?

Too Frequent Chaos Not flexible to change Missed opportunities, Inventory buildup Distinguish between noise and real trends. Takt time could be reevaluated if the demand exceeds the set production rate for 5 consecutive days (Run Test). At Dell Assembly takt time is 15 secs per computer. It is accomplished through (capacity) running multiple assembly lines

Lean Thinking: 3- Takt Time

Ardavan Asef-Vaziri

6/4/2009

Internal vs. External Takt Time

Demand Production

130 120 110 100 90 80 0

10

15

20

25

30

Day

Takt Time allows to smooth external demand variation

Lean Thinking: 3- Takt Time Ardavan Asef-Vaziri 6/4/2009 8

Average Labor Content

Average labor content is the minimum number of workers to sustain operations.

Demand percentages for Hungama, Inc., Tasks

RUNS Jobs/Day

% of Total

RAPS

RAINS

RERUNS

4

10%

12

30%

6

15%

18

45%

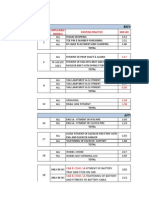

Operation times for Hungama, Inc. in (Minutes)

RUNS RAPS RAINS RERUNS

Distribution Underwriting

Rating Policy writing Total Labor

Lean Thinking: 3- Takt Time

58

43 72 67 240

50

40 65 0 155

44

23 68 55 190

28

19 75 50 172

6/4/2009 9

Ardavan Asef-Vaziri

Average Labor Content

Takt Time Net Availabili ty 400 10 minutes Demand 40

k

Average Labor Content (% of Model i )(Total labor content for Model i )

i 1

Average labor content = 0.10 (240) + 0.30 (155) + 0.15 (190) + 0.45(172) = 176.4 min

Minimum Manpower Reqirement

Average Labor Content Takt Time

176.4 Minimum Manpower Reqirement 17.6 18 10

Lean Thinking: 3- Takt Time Ardavan Asef-Vaziri 6/4/2009 10

Average Labor Content

ALC for Distribution = (0.10 x 58) + (0.30 x 50) + (0.15 x 44) + (0.45 x 28) = 40 minutes. Since Takt time is 10 min, the minimum number of operators allocated to Distribution task will be 4. (40/10 = 4)

A LC D istribution U nde rwriting Ra ting P olicy writing T ota l

Lean Thinking: 3- Takt Time

TT 10 10 10 10 10

M LR 4 3 7 4 18

6/4/2009 11

40 28.3 70.7 37.5 176

Ardavan Asef-Vaziri

Practice: Pleasant Valley Health Clinic

The Pleasant Valley Health Clinic treats patients with respiratory illnesses. It classifies patients according to four different types of respiratory problems (commonly referred to as Diagnostic Related Groups, or DRGs): Bronchiolitis (BRO), Pneumonia (PNE), Pharyngitis (PHA) and Sinusitis (SIN). The average number of patients treated per day are summarized below. The clinic works two shifts, from 7:00 am to 3 pm and from 3 pm to 11 pm. During a shift, the staff are provided a half hour lunch break and two rest breaks of 15 minutes each.

BRO 15

0.15

Patients / Day

PNE 24

0.24

PHA 25

0.25

SIN 36

0.36

Fraction of total

Lean Thinking: 3-Takt Time

Ardavan Asef-Vaziri

6/4/2009

12

Pleasant Valley Health Clinic: Task Durations

Each patient typically requires 4 process steps: Check-In (includes weigh-in, blood pressure check, etc.), Evaluation (by a physician), Testing (X-Rays, administering of respiratory instruments like Pulse Oximeters, etc.), and Assessment (diagnosis and future scheduling). The average task time for each process (in minutes) is given below:

Time (mininutes) Check-In Evaluation Testing Assessment Work Content BRO 30 20 45 15 110 PNE 30 15 40 15 100 PHA 30 10 15 10 65 SIN 30 12 15 10 67 Aggregate

30 13.42 25.5 11.95 80.87

Tasks 1, 3, and 4 are typically handled by RNs. Task 2 is handled by a physician. For simplicity, we assume that the arrival rates of patients are constant through both shifts.

Lean Thinking: 3-Takt Time Ardavan Asef-Vaziri 6/4/2009 13

Takt Time for Pleasant Valley Health Clinic

Average Work Content = 80.87 minutes. Daily demand; BRO: 15, PNE: 24, PHA: 25, SIN: 36. A total of 100. Time available in a day: 2 shift @ 8 hrs less 0.5 (lunch) - 0.5 (2 breaks) = 14 hours = 840 minutes Takt time = Time Available / Daily Demand = 840/100 = 8.40 minutes / reques Min. # of RNs required = 80.87/8.4 = 9.627 10

Lean Thinking: 3-Takt Time

Ardavan Asef-Vaziri

6/4/2009

14

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Option Selling WorkshopDokument10 SeitenOption Selling Workshopchethan626Noch keine Bewertungen

- Edgewonk's Math Cheat Sheet PDFDokument1 SeiteEdgewonk's Math Cheat Sheet PDFPrashant Tomar100% (1)

- 20 04 2020academic - PlanDokument2 Seiten20 04 2020academic - Planchethan626Noch keine Bewertungen

- Name: - Date: - Q.1 Match The Body PartsDokument5 SeitenName: - Date: - Q.1 Match The Body Partschethan626Noch keine Bewertungen

- Strike Call OI Put OI Cumulative Call Cumulative Put Total ValueDokument13 SeitenStrike Call OI Put OI Cumulative Call Cumulative Put Total Valuechethan626Noch keine Bewertungen

- ExcerciseDokument11 SeitenExcercisechethan626Noch keine Bewertungen

- 21-05-2020online Learning - Circular 1 PDFDokument8 Seiten21-05-2020online Learning - Circular 1 PDFchethan626Noch keine Bewertungen

- 21-05-2020online Learning - Circular 1 PDFDokument8 Seiten21-05-2020online Learning - Circular 1 PDFchethan626Noch keine Bewertungen

- Measurement Systems Analysis - How ToDokument72 SeitenMeasurement Systems Analysis - How Towawawa1100% (1)

- Factorial Analysis of Employee Satisfaction On Annual Performance Appraisal Practice at Tata Motors LTDDokument6 SeitenFactorial Analysis of Employee Satisfaction On Annual Performance Appraisal Practice at Tata Motors LTDchethan626Noch keine Bewertungen

- 1.05 Close Out ReportDokument5 Seiten1.05 Close Out ReportnsadnanNoch keine Bewertungen

- National Guard Black Belt Training: Unclassified / FouoDokument22 SeitenNational Guard Black Belt Training: Unclassified / Fouochethan626Noch keine Bewertungen

- Six Sigma ProjectDokument31 SeitenSix Sigma Projectchethan626Noch keine Bewertungen

- SSGB PreworkDokument16 SeitenSSGB Preworkchethan626Noch keine Bewertungen

- Mechanical EngineerDokument67 SeitenMechanical EngineersameerNoch keine Bewertungen

- Paper Id-14201326Dokument8 SeitenPaper Id-14201326chethan626Noch keine Bewertungen

- Investment ExamplesDokument25 SeitenInvestment Exampleschethan626Noch keine Bewertungen

- FmeaDokument10 SeitenFmeachethan626Noch keine Bewertungen

- Handout 07 - GMP Batches AB - Managerial Ethics - XLRI 2014 - The Ethics of Executive Moral ReasoningDokument48 SeitenHandout 07 - GMP Batches AB - Managerial Ethics - XLRI 2014 - The Ethics of Executive Moral Reasoningchethan626Noch keine Bewertungen

- BayesDokument1 SeiteBayesgopitheprinceNoch keine Bewertungen

- Ergo PDFDokument1 SeiteErgo PDFchethan626Noch keine Bewertungen

- Week1 PDFDokument10 SeitenWeek1 PDFahmedr25681Noch keine Bewertungen

- Week1 PDFDokument10 SeitenWeek1 PDFahmedr25681Noch keine Bewertungen

- Before Inversion: STN Applicable Models Existing Practice Min WCDokument4 SeitenBefore Inversion: STN Applicable Models Existing Practice Min WCchethan626Noch keine Bewertungen

- Human Factors and ErgonomicsDokument2 SeitenHuman Factors and Ergonomicschethan626Noch keine Bewertungen

- Aberdeen Cost of QualityDokument20 SeitenAberdeen Cost of Qualitychethan626Noch keine Bewertungen

- Defects Summary - L1Dokument32 SeitenDefects Summary - L1chethan626Noch keine Bewertungen

- Ergo IntroductionDokument12 SeitenErgo Introductionchethan626Noch keine Bewertungen

- Essay Intitutionlising of InnovationDokument3 SeitenEssay Intitutionlising of Innovationchethan626Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- DLL - English 5 - Q3 - W8Dokument8 SeitenDLL - English 5 - Q3 - W8Merlyn S. Al-osNoch keine Bewertungen

- GNDU Contract Jobs 2013 Advertisement PDFDokument8 SeitenGNDU Contract Jobs 2013 Advertisement PDFAnonymous zwCV8ZNoch keine Bewertungen

- Pipeline Construction InspecDokument48 SeitenPipeline Construction InspecAliDadKhan100% (2)

- STEEL STRUCTURES KHARGHAR SKYWALK AND NIFT INSTITUTE Ms PPT 2007Dokument30 SeitenSTEEL STRUCTURES KHARGHAR SKYWALK AND NIFT INSTITUTE Ms PPT 2007Harsh chhedaNoch keine Bewertungen

- Eurotuner February 2010 PDFDokument1 SeiteEurotuner February 2010 PDFJenniferNoch keine Bewertungen

- Pardoseli PVCDokument72 SeitenPardoseli PVCnasuemilNoch keine Bewertungen

- De Cuong On Thi HK2 Tieng Anh 10Dokument5 SeitenDe Cuong On Thi HK2 Tieng Anh 10hoangtouri2512Noch keine Bewertungen

- Summary Good To GreatDokument5 SeitenSummary Good To GreatAziz ur RehmanNoch keine Bewertungen

- Werling Optimal Trajectory Generationfor Dynamic Street Scenariosina Frenet FrameDokument8 SeitenWerling Optimal Trajectory Generationfor Dynamic Street Scenariosina Frenet FramehugoNoch keine Bewertungen

- Evaluation - Chemical Pit - 0Dokument8 SeitenEvaluation - Chemical Pit - 0Aiman AmirullahNoch keine Bewertungen

- CATEGORY - Green (III) Consent To EstablishDokument4 SeitenCATEGORY - Green (III) Consent To EstablishROOPDIP MUKHOPADHYAYNoch keine Bewertungen

- Precast Concrete ConstructionDokument37 SeitenPrecast Concrete ConstructionRuta Parekh100% (1)

- Samsung 932GW PDFDokument72 SeitenSamsung 932GW PDFSaidfa FaNoch keine Bewertungen

- As 4587-1999 Water Mist Fire Protection Systems - System Design Installation and CommissioningDokument10 SeitenAs 4587-1999 Water Mist Fire Protection Systems - System Design Installation and CommissioningSAI Global - APAC100% (1)

- Porphyry Tin Deposits in BoliviaDokument15 SeitenPorphyry Tin Deposits in Boliviasebastian tiriraNoch keine Bewertungen

- Report - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222Dokument23 SeitenReport - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222jawwadraja100% (1)

- Laws of ThermoDokument13 SeitenLaws of ThermofabyunaaaNoch keine Bewertungen

- L 1 Introduction To MorphologyDokument31 SeitenL 1 Introduction To MorphologyIftkhar GorsiNoch keine Bewertungen

- TEST Unit 5Dokument5 SeitenTEST Unit 5Giang Nguyen Thi ThuNoch keine Bewertungen

- 63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebDokument2 Seiten63-9378 - Rev-F - Ultra Puck - Datasheet - Web - 63-9378 - Rev-F - Ultra-Puck - Datasheet - WebAradhana AradhanaNoch keine Bewertungen

- Connecting Your Database and Auto Generate ID Using VB - Net 2008 and MySQL DatabaseDokument1 SeiteConnecting Your Database and Auto Generate ID Using VB - Net 2008 and MySQL DatabaseAgusWibowoNoch keine Bewertungen

- Climate Transition Finance Handbook Related Questions: 9 December 2020Dokument4 SeitenClimate Transition Finance Handbook Related Questions: 9 December 2020glenlcyNoch keine Bewertungen

- Communication Skills For Effective LeadershipDokument12 SeitenCommunication Skills For Effective LeadershipKovaNoch keine Bewertungen

- Virtual Screening of Natural Products DatabaseDokument71 SeitenVirtual Screening of Natural Products DatabaseBarbara Arevalo Ramos100% (1)

- Boolean Operators Literature ReviewDokument8 SeitenBoolean Operators Literature Reviewc5qz47sm100% (1)

- Painting and Weathering Unlocked PDFDokument91 SeitenPainting and Weathering Unlocked PDFWrensEye100% (6)

- QuestionnaireDokument5 SeitenQuestionnairePrisca FolorunsoNoch keine Bewertungen

- NA BR 1177 EN Dematic AutoStore SubsystemDokument8 SeitenNA BR 1177 EN Dematic AutoStore SubsystemDaniel Garnando KristianNoch keine Bewertungen

- Thermo 5th Chap17 P096Dokument19 SeitenThermo 5th Chap17 P096UTA - Std - Elvin ChantreNoch keine Bewertungen

- Adient Managment CSRDokument68 SeitenAdient Managment CSRClaudia PEÑANoch keine Bewertungen