Beruflich Dokumente

Kultur Dokumente

DC Motor Slides

Hochgeladen von

ashish_rewaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DC Motor Slides

Hochgeladen von

ashish_rewaCopyright:

Verfügbare Formate

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TITLE

ROTATING DC

MOTOR

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

OUTLINE

Theory

Rotating DC Motor Principle

Rotating DC Motor Theory

Rotating DC Motor Torque Taming

Rotating DC Motor Field Taming

Rotating DC Motor / Generator

Simple Rotating DC Motor

Rotating DC Motor Dissection

Rotating DC Motor Building at Home

Rotating DC Motor Regenerative Braking

Rotating DC Motor Brushless

Assignment

References

Summary

Fourier, Joseph (1768-1830)

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR PRINCIPLE

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR PRINCIPLE

Linear motors are good for certain tasks, but industrial

and transportation applications usually demand rotating

motion.

Movable metal bar

Magnetic flux density into page

External applied field

bat

V

+

R

I

v

app

B

Metal fixed rail

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR PRINCIPLE

The DC rotating motor is commonly

constructed with an armature on the rotor

and a field generated by a permanent

magnet instead of a stator winding.

Stator: non-moving coil

Rotor: rotating part

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR PRINCIPLE

motor, electric,

machine that converts electrical energy into mechanical

energy. When an electric current is passed through a wire

loop that is in a magnetic field, the loop will rotate and the

rotating motion is transmitted to a shaft, providing useful

mechanical work. The traditional electric motor consists of a

conducting loop that is mounted on a rotatable shaft. Current

fed in by carbon blocks, called brushes, enters the loop

through two slip rings. The magnetic field around the loop,

supplied by an iron core field magnet, causes the loop to turn

when current is flowing through it.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR PRINCIPLE

motor, electric,

In an alternating current (AC) motor, the current flowing in the loop

is synchronized to reverse direction at the moment when the plane of the

loop is perpendicular to the magnetic field and there is no magnetic force

exerted on the loop. Because the momentum of the loop carries it around

until the current is again supplied, continuous motion results. In alternating

current induction motors the current passing through the loop does not

come from an external source but is induced as the loop passes through

the magnetic field. In a direct current (DC) motor, a device known as a

split ring commutator switches the direction of the current each half

rotation to maintain the same direction of motion of the shaft. In any

motor the stationary parts constitute the stator, and the assembly

carrying the loops is called the rotor, or armature.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR PRINCIPLE

motor, electric,

As it is easy to control the speed of direct-current motors by varying the

field or armature voltage, these are used where speed control is necessary.

The speed of AC induction motors is set roughly by the motor construction

and the frequency of the current; a mechanical transmission must therefore

be used to change speed. In addition, each different design fits only one

application. However, AC induction motors are cheaper and simpler than

DC motors. To obtain greater flexibility, the rotor circuit can be connected to

various external control circuits. Most home appliances with small motors

have a universal motor that runs on either DC or AC. Where the expense is

warranted, the speed of AC motors is controlled by employing special

equipment that varies the power-line frequency, which in the United States

is 60 hertz (Hz), or 60 cycles per second.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR PRINCIPLE

motor, electric,

Brushless DC motors are constructed in a reverse fashion from the

traditional form. The rotor contains a permanent magnet and the

stator has the conducting coil of wire. By the elimination of brushes,

these motors offer reduced maintenance, no spark hazard, and better

speed control. They are widely used in computer disk drives, tape

recorders, CD drives, and other electronic devices. Synchronous

motors turn at a speed exactly proportional to the frequency. The very

largest motors are synchronous motors with DC passing through the rotor.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR PRINCIPLE

Terming this device a DC motor is not

entirely clear, in fact, the current in the

armature coil alternates in polarity, even

though the supply is DC.

Stator: non-moving coil

Rotor: rotating part

Armature coil

Brushes

WHY ?

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR THEORY

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE

Consider a rectangular coil rotating in a

uniform magnetic field B

Figures extracted from Lecture 22

Magnetic field and

current in loop

interact in such a way

as to generate a

torque on the loop.

Axis

r 2

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE

Lecture 22

97.315 Basic E&M and Power Engineering Topic: Magnetic dipole

THEORY THEORY

m

Side view

u

F

Pivot point

2

a

( ) u sin

2

IB a = I

a

a

I

Wire loop

I a m

2

=

( ) u sin B m

= I

B m

= I

TORQUE ON A

MAGNETIC

DIPOLE

Taken from Lecture 22

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE

Lecture 22

97.315 Basic E&M and Power Engineering Topic: Magnetic dipole

THEORY THEORY

m

Side view

u

F

Torque attempts to align dipole

moment with .

m

Pivot point

( ) u sin

2

2

a

F = I

F r

= I

2

a

Total torque

F => Magnetic force on

wire of length a

TORQUE ON A

MAGNETIC

DIPOLE

Taken from Lecture 22

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE

Lecture 22

97.315 Basic E&M and Power Engineering Topic: Magnetic dipole

THEORY THEORY

m

Side view

u

F

Pivot point

( ) u sin

2

2

a

F = I

2

a

F => Magnetic force on

wire of length a

IBa F =

Through postulate 1 for magnetic fields

( ) u sin

2

IB a = I

Then

TORQUE ON A

MAGNETIC

DIPOLE

d B I F d =

Taken from Lecture 22

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE

If current always

flows in the same

direction then loop

will only oscillate

rather than rotate

Axis

r 2

u

I

m

u

F

r

0

180

360

Unstable equilibrium

Stable equilibrium

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR TORQUE TAMING

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE TORQUE TAMING

We need to reverse the direction of the current on each half cycle.

u

I

0

180

360

Transform original torque

versus angle curve from:

u

I

0

180

360

TO

Now torque always applied in same

direction inducing loop to spin

continuously in same direction.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE TORQUE TAMING

This is accomplished by using a commutator (either mechanical or

electronic cycle).

u

I

0

180

360

How it Works.

Metal ring attached to shaft split in

two sections

Link to related site

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE TORQUE TAMING

The figure illustrates one method by which the commutation function might be

accomplished. Rather than hard wiring the current source to the coil, the current is

conducted through sliding contacts (brushes) connected to the current source. The

brushes ride on the ends of the coil wires, thus conducting current through the coil.

In this simplified motor, the brushes switch coil connections about once every 180

o

of rotation. Therefore, the direction of current flow remains fixed with respect to the

magnetic field.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE TORQUE

TAMING

The torque produced by this design momentarily goes to zero

every half cycle. Stall is possible, also start up may require a

small push. In addition to this the torque versus rotation angle is

not uniform

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE TORQUE TAMING

Link to related site

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE TORQUE TAMING

Link to related site

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE TORQUE TAMING

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR FIELD TAMING

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE FIELD TAMING

To obtain a more even

torque, the magnetic field

lines should look something

like:

F

And how do you get a magnetic field

with that shape?

B

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE FIELD TAMING

To obtain a more even

torque, the magnetic field

lines should look something

like:

B field lines follow the path of least reluctance, so the

curved poles create roughly a radial field pattern.

B

poles of magnet

Rotor

Redesign the permanent magnet poles.

Insert soft iron rotor

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE FIELD TAMING

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE FIELD TAMING

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE FIELD TAMING

B

Rotor

r

Recall slide 9 of this lecture for

parameters of the wire loop.

Motor dimensions:

Radius r

Depth

Torque in radial field

rBI 2 = I

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE FIELD TAMING

In a practical motor design, use many turns of wire on the rotor

(rather than just one) to increase the torque.

B

Rotor

r

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR PRINCIPLE FIELD TAMING

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR / GENERATOR

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR / GENERATOR

As the motor turns, a back emf is produced:

vB V

emf

2 =

velocity of the outer edge of the

rotor

r v e =

There are two conductors of length

in the loop.

B r V

emf

e 2 =

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR / GENERATOR

B r V

emf

e 2 =

Equivalent circuit

emf

V

bat

V

+

R

+

terminal

v

Expression of V

emf

Loop

Slide extracted from lecture 30 and modified for loop motor.

e

I

emf bat

V IR V + =

B r R

rB

V

bat

e 2

2

+

I

=

rBI 2 = I

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR / GENERATOR

B r R

rB

V

bat

e 2

2

+

I

=

Linear relation between

speed and torque

rB

V

bat

load no

2

=

e

e

I

R

V rB

bat

2

0

= I

= e

Current

flows in a

direction to

charge the

battery.

Motor

Slide extracted from lecture 30 and modified for loop motor.

Stall torque

Generator

Link

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

SIMPLE ROTATING DC MOTOR

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

SIMPLE ROTATING DC MOTOR

PURPOSE: To illustrate possibly the world's simplest motor.

DESCRIPTION: A small coil is mounted across the terminals of a battery as shown. The

enamel is scraped off half of the coil wire where it contacts the battery terminals. The magnet is

oriented such that when the coil is rotating it either pushes away or pulls toward the magnet in

the appropriate part of its cycle. The other half-cycle the enamel prevents the coil from being

activated; if it were it would counteract the torque which produces the desired rotation.

SUGGESTIONS:

REFERENCES: (PIRA unknown.)

EQUIPMENT: Mounted battery and rotation coil with carefully polished lead wires.

SETUP TIME: None.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

SIMPLE ROTATING DC MOTOR

ST. LOUIS MOTOR

PURPOSE: To demonstrate the structure and operation of a simple motor.

DESCRIPTION: This is a two-pole DC motor with a split-ring commutator and

permanent magnets. Operates with a 1.5 volt battery.

SUGGESTIONS:

REFERENCES: (PIRA 5K40.10)

EQUIPMENT: St. Louis motor.

SETUP TIME: None.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

THEORY

ROTATING DC MOTOR DISSECTION

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR DISSECTION

Link by clinking

on figure

"How Electric Motors Work" describes how an electric

motor works and explains the basic components found in

any simple DC electric motor. In this article we will take

apart an actual electric motor and see what's inside. The

motor being dissected is a simple electric motor that you

would typically find in a toy:

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR DISSECTION

You can see that this is a small motor about as big around as a dime. From the

outside you can see the steel can that forms the body of the motor, an axle, a

nylon end cap and two battery leads. If you hook the battery leads of the motor

up to a flashlight battery the axle will spin. If you reverse the leads it will spin in

the opposite direction. Here are two other views of the same motor. Note the

two slots in the side of the steel can in the second shot - their purpose will

become more evident in a moment:

The nylon end cap is held in place by two tabs that are part of the steel can. By

bending the tabs back you can free the end cap and remove it. Inside the end

cap are the motor's brushes. These brushes transfer power from the battery to

the commutator as the motor spins:

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR DISSECTION

The axle holds the armature and the commutator. As described in "How Electric

Motors Work", the armature is a set of electromagnets, in this case three. The

armature in this motor is a set of thin metal plates stacked together, with thin

copper wire coiled around each of the three poles of the armature. The two ends

of each wire (one wire for each pole) are soldered onto a terminal, and then each

of the three terminals is wired to one plate of the commutator. The figures below

make it easy to see the armature, terminals and commutator:

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR DISSECTION

The final piece of any DC electric motor is the field magnet. The

field magnet in this motor is formed by the can itself plus two

curved permanent magnets:

One end of each magnet rests against a slot cut into the can, and then the

retaining clip presses against the other ends of both magnets.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR DISSECTION

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR BUILDING AT HOME

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

While this motor is very crude and inefficient, it cost me less than $5.00 to build from

parts I mostly had around the house, and total construction time was under four hours.

The hardest part was winding the field magnet and the armature coils.

Note that you can click on many of the smaller images on this page to see larger

versions.

The wooden frame of the motor was constructed from various bits of scrap lumber I had

laying around. If you build your own, look through all of these pictures and you can rig

something up based on what YOU have laying around.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

I could have used permanent magnets for the fields on this motor,

but this is a section on electromagnetism - and I couldn't find

any. I made my field coil by winding 75 feet of 26 gauge

enameled magnet wire onto the "U" of a 2.5 in iron Muffler

clamp. Note the fence staple on the left to provide a route for the

wires. The coil is wound in several neat overlapping layers, with

a layer of electrical tape between each. Wind a layer, then wrap

with a single layer of electrical tape, and wind back over the coil

you have already wound. Just make sure that you always wind in

the same clockwise or counterclockwise direction in which you

started.

The arms of the "U" bolt are passed up through holes drilled in

the bottom of the wooden frame. The whole assembly is held in

place by gravity and by the nuts on the top of the frame

assembly.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

The bearings for the shaft are simply screw eyes

screwed in to the sides of the wooden frame. The

brushes, which will transfer current to the slip

rings in the commutator assembly are made from

22 gauge solid copper wire with a couple of inches

of the insulation stripped from each end. Note that

one is mounted on the top of one wooden cross

piece, while the other is mounted to the bottom of

the other. This wire must be stiff enough to hold a

shape, but not so stiff that it puts too much friction

on the commutator assembly.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

Wrap one layer of electrical tape around each half of the iron nail, then wind four

layers of 26 gauge enameled magnet wire and tape onto the iron nail, making sure

to always wind in the same direction. Simply cross over the 12 gauge wire shaft in

the center and continue each layer on the other side, as if the shaft were not there.

The armature is made from a section of iron nail

which was cut to fit cleanly between the arms of the

"U" bolt. Before winding the coil for the armature,

wrap one turn of 12 gauge solid copper insulated

house wiring around the very center of the nail. Bend

the wire in such a way that it comes straight off the

piece of nail, and that the nail is positioned in a ninety

degree angle to the wire. Place the nail and wire on a

chunk of waxed paper and place some two part epoxy

on the union to bind them together.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

The commutator in my motor is made from a section cut out of

a broken shovel handle. Drill a hole in the center into which

the wire shaft will fit fairly snugly, and cut a groove into each

of it's sides. Slide this onto the short end of the shaft. The next

step is to fashion the slip rings. I used a tuna fish can, and cut it

into 2 strips the width of the commutator using tin snips. The

ends of the strips should be folded down into the grooves in

each side of the commutator. Use a small screwdriver to fold

them neatly into the grooves in the wooden piece. It is

important that the slip rings are as round as possible when the

commutator is assembled, and that none of the metal extends

past the edges of the wooden part or your motor will not

function properly.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

Cut a small notch in the folded part of the slip rings so that you

have something to which you can attach the wires from the

armature. Using a small butane lighter, burn the insulation from

the ends of the armature wires and clean with a piece of steel

wool. You can solder the wires in place if you wish, but I

simply used some miniature alligator clips to hold it in place.

Snap the slip rings onto the wooden block, and wrap half of

them tightly with electrical tape to hold them in place. Make

sure that they are as round as possible, and that they do not

touch each other in the notches.

Make sure that the 12 gauge wire shaft is straight and even,

and that the slip rings on the commutator are as round as

possible. The gap between the slip rings should be at about a 90

degree angle to the armature assembly. Try spinning the shaft in

your fingers to be sure that the assembly is fairly well balanced.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

Slide the armature assembly into the front bearing

(a.k.a. a screw eye) from the center of the wooden

frame until the armature is against the frame. If the

other end of the wire shaft is too long to fit in the rear

screw eye, trim it off a bit. Insert the back end of the

shaft into the rear bearing, and slide the whole

assembly back until the slip rings line up with the

brushes.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

You should have to bend the brushes slightly outward to get the commutator

between them. If they don't touch the slip rings when you are done, slide the

assembly forward enough to bend them in toward the shaft, then gently slide

the commutator back between them.

There is not much to the electrical wiring of the motor - I did not even use

an on/off switch. The use of the terminal strip in the back of the motor is

optional, but does make life a lot easier. Apply power to the motor by

connecting a 12 volt lantern battery, and it should spin merrily away. If the

armature wants to lock in position, then you have the wires to the

commutator reversed, causing an opposite magnetic field. Even if you have

the magnetic poles in the correct orientation, to get the motor to run properly

you may have to disconnect the battery and adjust the position and tension

of the brushes. You can also slightly adjust the speed of the motor by

slightly rotating the commutator on the shaft so that you change the angle

between the armature and the field coils.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BUILDING AT HOME

If your motor still does not work properly, connect a couple of

"D" cell batteries (3 volts dc instead of 12) and manually turn

the shaft. You should be able to feel the magnetic fields as

resistance or attraction at certain points in the rotation and you

should then be able to figure out where the problem lies. Do

not leave the motor connected to the batter for very long or the

coils will get very hot, and the battery will get drained quickly,

due to the extremely poor efficiency of this design.

If you want your motor to work better than mine, and

possibly at a lower voltage, figure out how to reduce the

friction of the brushes, and use a more rigid shaft mounted in

bearings for the armature.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR LINKS

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR LINKS

Making DC Motors

Click picture to link

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR Regenerative

Braking

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR Regenerative Braking

Since the DC motor and a DC generator are virtually the same

machine mechanically, it was immediately realized that a train

could use its motors to act as generators and that this would provide

some braking effect if a suitable way could be found to dispose of

the energy. The idea formed that if the power could be returned to

the source, other trains could use it. Trains were designed therefore,

which could return current, generated during braking, to the supply

system for use by other trains. Various schemes were tried over

many years with more or less success but it was not until the

adoption of modern electronics that reliable schemes have been

available.

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

TEXT

ROTATING DC MOTOR BRUSHLESS

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BRUSHLESS

Brushless DC motors are referred to by many aliases: Brushless

permanent magnet, permanent magnet ac motors, permanent

magnet synchronous motors ect. The confusion arises because a

Brushless dc motor does not directly operate off a dc voltage

source. However, as we shall see, the basic principle of operation

is similar to a dc motor. A Brushless dc motor has a rotor with

permanent magnets and a stator with windings. It is essentially a

dc motor turned inside out. The brushes and commutator have

been eliminated and the windings are connected to the control

electronics. The control electronics replace the function of the

commutator and energize the proper winding.

As shown in the animation the winding are energized in a pattern which rotates around the stator. The

energized stator winding leads the rotor magnet, and switches just as the rotor aligns with the stator.

There are no sparks, which is one advantage of the bldc motor. The brushes of a dc motor have several

limitations; brush life, brush residue, maximum speed, and electrical noise. BLDC motors are

potentially cleaner, faster, more efficient, less noisy and more reliable. However, BLDC motors

require electronic control.

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BRUSHLESS

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BRUSHLESS

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BRUSHLESS

97.315 Basic E&M and Power Engineering Topic: DC Motors

Lecture 31 TEXT

ROTATING DC MOTOR BRUSHLESS

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

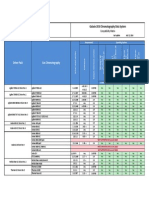

ASSIGNMENT

These questions are straight forward. Plug in the numbers and get your answer. Being able to

solve this type of question ensures you of at least a grade of 25% on a quiz or final exam

containing questions related to this lecture.

These questions require a few manipulations of equations or numbers before the answer can be

obtained. Being able to solve this type of question ensures you of at least a grade of 50% on a

quiz or final exam containing questions related to this lecture.

These questions are the most difficult and require a thorough understanding of the topic material

and also pull in topics from other lectures and disciplines. Being able to solve this type of

question ensures you an A grade on a quiz or final exam containing questions related to this

lecture.

These question are quite involved and requires a thorough understanding of the topic material.

Being able to solve this type of question ensures you of at least a grade of 75% on a quiz or final

exam containing questions related to this lecture.

25

50

75

100

75 100

These form excellent review questions when preparing for the quiz and final exam.

25 50 75

100

SELF EVALUATI ON SCALE

Lecture 31

97.315 Basic E&M and Power Engineering Topic: DC Motors

ASSIGNMENT

Know the properties of DC motors, ..

Lecture 31 ASSIGNMENT

A square coil, 0.60 m on a side, rotates about the x-axis

at w = 60 t rad/s in a uniform field B = 0.80 T in the

positive z direction. Find the induced voltage.

50

B

a

b

ab

V

w

DC Motors

Lecture 31 SUMMARY

DC Motors

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Script SweeneytoddDokument125 SeitenScript SweeneytoddAu Duong Tinh100% (15)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Clanbook TremereDokument111 SeitenClanbook TremereDaniel Alvarado100% (17)

- (Post Malone) Feeling WhitneyDokument2 Seiten(Post Malone) Feeling WhitneySaul GuerraNoch keine Bewertungen

- Fma 2014 2015Dokument118 SeitenFma 2014 2015AlexsanderMNoch keine Bewertungen

- Design, Modeling and Performance of Static Synchronous Series Compensator Regulated Self-Excited Induction GeneratorDokument7 SeitenDesign, Modeling and Performance of Static Synchronous Series Compensator Regulated Self-Excited Induction Generatorashish_rewaNoch keine Bewertungen

- 16 Vs PrasadDokument14 Seiten16 Vs Prasadashish_rewaNoch keine Bewertungen

- 06304821Dokument6 Seiten06304821ashish_rewaNoch keine Bewertungen

- 06342792Dokument4 Seiten06342792ashish_rewaNoch keine Bewertungen

- Lecture 1 SlideDokument38 SeitenLecture 1 Slideashish_rewaNoch keine Bewertungen

- Complementary Adaptive Control of Zeta Converters: Afshin Izadian, Senior Member, IEEE, and Pardis KhayyerDokument5 SeitenComplementary Adaptive Control of Zeta Converters: Afshin Izadian, Senior Member, IEEE, and Pardis Khayyerashish_rewaNoch keine Bewertungen

- Soft-switching active snubbers reduce losses in DC-DC convertersDokument13 SeitenSoft-switching active snubbers reduce losses in DC-DC convertersashish_rewaNoch keine Bewertungen

- 06327624Dokument14 Seiten06327624ashish_rewaNoch keine Bewertungen

- 06356718Dokument6 Seiten06356718ashish_rewaNoch keine Bewertungen

- FAN7535 PFC & Ballast Control IC: Features DescriptionDokument12 SeitenFAN7535 PFC & Ballast Control IC: Features Descriptionashish_rewaNoch keine Bewertungen

- Power Electronics: An SEO-Optimized Title for a Power Electronics DocumentDokument92 SeitenPower Electronics: An SEO-Optimized Title for a Power Electronics Documentashish_rewaNoch keine Bewertungen

- Ser-Par Opr of SCRsDokument15 SeitenSer-Par Opr of SCRsashish_rewaNoch keine Bewertungen

- Ele101 L2Dokument20 SeitenEle101 L2ashish_rewaNoch keine Bewertungen

- Phase Controlled-Rectifiers (AC-DC Coverters)Dokument172 SeitenPhase Controlled-Rectifiers (AC-DC Coverters)ashish_rewaNoch keine Bewertungen

- Design and Implementation of High Frequency AC-LED Driver With Digital DimmingDokument4 SeitenDesign and Implementation of High Frequency AC-LED Driver With Digital Dimmingashish_rewaNoch keine Bewertungen

- Finding affection and appreciationDokument19 SeitenFinding affection and appreciationRose JennetNoch keine Bewertungen

- Resume For SethDokument4 SeitenResume For Sethseth bixby daughertyNoch keine Bewertungen

- Dachshund Body PatternDokument25 SeitenDachshund Body PatternDanielaAlioneNoch keine Bewertungen

- National Artists of The PhilippinesDokument17 SeitenNational Artists of The PhilippinesDeniseNoch keine Bewertungen

- Thesis Parabolic Solar CollectorDokument4 SeitenThesis Parabolic Solar CollectorRajat AgarwalNoch keine Bewertungen

- Myths About ConstellationsDokument14 SeitenMyths About ConstellationssnezanaNoch keine Bewertungen

- All in The Family - 1x05 - Judging Books by Covers - DVDRip.enDokument44 SeitenAll in The Family - 1x05 - Judging Books by Covers - DVDRip.enSpeedyGonsalesNoch keine Bewertungen

- BTC - Autopilot - Method - MAKE - 700$-800$ - PER - WEEK - 2Dokument4 SeitenBTC - Autopilot - Method - MAKE - 700$-800$ - PER - WEEK - 2Aamir RehanNoch keine Bewertungen

- DSCG Core Rulebook Web PDFDokument24 SeitenDSCG Core Rulebook Web PDFJohann Piñon SalgadoNoch keine Bewertungen

- Digit 2 DonemusDokument6 SeitenDigit 2 DonemusDomenico PestilliNoch keine Bewertungen

- Small Sided Games ManualDokument70 SeitenSmall Sided Games Manualtimhortonbst83% (6)

- Joke StructureDokument2 SeitenJoke StructureMarcel Antonio100% (1)

- Tickets For Gardaland Amusement Park TiqetsDokument1 SeiteTickets For Gardaland Amusement Park Tiqetschichipster123Noch keine Bewertungen

- Chapter 7 Probability II Sample Space and EventsDokument7 SeitenChapter 7 Probability II Sample Space and Eventsleelee1127Noch keine Bewertungen

- CWS 315 2I en StudentManual 1 3 Days v03Dokument455 SeitenCWS 315 2I en StudentManual 1 3 Days v03Onurcan YahyaoğluNoch keine Bewertungen

- Infoblatt Skischulen Trends Port eDokument18 SeitenInfoblatt Skischulen Trends Port eAustrian National Tourism BoardNoch keine Bewertungen

- Smo0th CriminalDokument13 SeitenSmo0th CriminalSan Isidro Mps E-reklamoNoch keine Bewertungen

- What is Caption TextDokument10 SeitenWhat is Caption TextByma debyo PrayogoNoch keine Bewertungen

- Gas Turbine BookDokument246 SeitenGas Turbine Bookmpus0% (1)

- Galaxie 2010 Chromatography CompatibilityDokument3 SeitenGalaxie 2010 Chromatography CompatibilitymardonioandradeNoch keine Bewertungen

- PHILIPPINE LITERATURE TIMELINEDokument1 SeitePHILIPPINE LITERATURE TIMELINERICZYRECHRISTIAN TABIGO-ONNoch keine Bewertungen

- The Traveller: From The Game AquariaDokument18 SeitenThe Traveller: From The Game AquariaLuis FernandoNoch keine Bewertungen

- Tales of The MoonDokument1 SeiteTales of The MoondollybreastsNoch keine Bewertungen

- Jennifer Egan - Ask Me If I CareDokument14 SeitenJennifer Egan - Ask Me If I CarenightaguaNoch keine Bewertungen

- AdditionDokument26 SeitenAdditionilu593Noch keine Bewertungen

- Protestantism - Intertextuality - Challenge Universal Certainties or Truths - Broke of The Chronological OrderDokument2 SeitenProtestantism - Intertextuality - Challenge Universal Certainties or Truths - Broke of The Chronological OrderAgustina CampagnaNoch keine Bewertungen