Beruflich Dokumente

Kultur Dokumente

06A Lubricating Oils

Hochgeladen von

Bhupender Ramchandani0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten18 Seitenmarine

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenmarine

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten18 Seiten06A Lubricating Oils

Hochgeladen von

Bhupender Ramchandanimarine

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 18

Lubricating oils

Lubricating oil fractions extracted from

crude oil are a widely varying mixture of

straight and branched chain paraffinic,

napthenic aromatic hydrocarbons having

boiling points ranging from about 302

o

to

593

o

C. Some specialty lubricants may

have boiling point extremes of 777 and

815

o

C. The choice of grade of lubricating

oil base is determined by the expected

use.

General capabilities expected from an engine lubricant

1. Dispersivity or capacity to the cold parts of an engine clean

2. Detergency or capacity to keep hot parts of an engine clean

3. Thermal strength or capacity to withstand temperature

changes

4. Anti-oxidant or capacity to resist the action of oxygen

5. Anti-wear or capacity to contain wear

6. Anti-scuffing or capacity to preserve oil film even in the

presence of high pressures

7. Alkalinity reserve or capacity to neutralise acids formed

during combustion or other sources thereby preventing

corrosive wear

8. Demulsibility or capacity to separate contaminants

9. Resistance to hydrolysis or capacity to withstand the action

of water which can affect additives

10.Centrifugibility and filterability or capacity to separate

insoluble elements

11. Anti-rust, anti-corrosive and anti-foam are just some of the

other properties required

Properties ideal for bearings

1. Soluble for high speed fluid film

hydrodynamic lubrication, hence, low

viscosity with reduced oil film friction.

2. moderate bearing loads

3. improved heat transfer behavior

4. corrosion protection

5. cooling

6. low friction

7. good low temperature viscosity

8. good high temperature viscosity

Cylinder lub oil properties

Normal properties required are:

1. adequate viscosity at working temperature so that the oil

spreads over the liner surface to provide a tough film which

resists the scraper action of the piston rings

2. the oil must provide an effective seal between the rings and

liner

3. only a soft deposit must be formed when the oil burns

4. alkalinity level (total base number or TBN) must match the

acidity of the oil being burnt

5. detergent and dispersant properties are required in order to

hold deposits in suspension and thus keep surfaces clean

Behaviour depends upon the temperature of the liner, piston

crown and piston rings. TBN and detergency are closely

linked. This can have an adverse effect when running on

lighter fuels with lower sulphur content for any period of time.

Coke deposits are can increase.

Properties ideal for gear case

1. high film strength to prevent metal to metal contact.

Hence, high viscosity adhesive to resist sliding and

centrifugal forces

2. corrosion protection

3. cooling

4. reduces friction

5. good low tempo viscosity

6. good high tempo viscosity

The thicker the oil film the greater the cushioning

against shocks. Also less tendency for pit formation

by hydraulic action in cracks,

7. sound damping properties with cushioning effects

8. antifoam properties

Turbine oil

Compromise between above two

requirements

1. Generally a good quality refined mineral oil

derived from paraffanic base stock used with

various additives including EP additives for

highly loaded gearing.

2. Anti-foaming properties important

Additives

Improvements in lubricating oil over the last

twenty years have come about almost entirely

from the use of additives.

These are added for three main reasons;

1. to protect the lubricant in service by limiting the

chemical change and deterioration

2. To protect the mechanism from harmful combustion

products and malfunctioning lubricating oil

3. To improve existing physical properties and to

create new beneficial characteristics in the oil

Typical additives are; Barium, calcium, phosphorus,

Sulphur, chlorine, zinc

Oxidation inhibitor-increases oil and machinery life,

decreases sludge and varnish on metal parts

Corrosion inhibitor-protects against chemical attack of

alloy bearings and metal surfaces.

Antiwear improvers-protects rubbing surfaces

operating with this film boundary lubrication.

Detergent-tend to neutralise the deposits before

formation under high temperature and pressure

conditions, or as a result of using a fuel with high sulphur

content. The principle detergents are soaps and alkaline

metals, usually calcium (often referred to as 'metallo-

organic compounds'). They are usually ash forming and

spent additive will contribute to the insolubles loading of

a used oil. It should be noted that additives which do not

burn cleanly without ash tend to be avoided for use with

Cylinder Lubricating Oils.

Dispersant-used to disperse or suspend the deposits forming

contaminants. Typical dispersants, such as polyesters and

benzlamides, are usually clean burning. The molecules have a polar

charge at one end which attracts and holds the deposits

Alkaline agents-neutralises acids, these form the TBN of the oil and

includes additives such as the above dispersants and detergents.

An excess of acid neutralising alkalis are present in the oil and these

help to keep parts clean. Failure to keep an oil alkaline can lead to

damage to bearings due to acidic attack as well as increased liner

wear.

Rust inhibitors-

Pour point depressants-improves low temperature viscosity

Oiliness agent-reduces friction seizure point and wear rates

EP additives-increases film strength and load carrying capability

Antifoam agents-prevents stable bubble formation

Metal deactivators-prevent catalytic effects of metal

Antiseptic-bactericide.

Oxidation - Oxidation degrades the lube oil producing sludges,

varnishes and resins. Presence of moisture, and some metals

particularly copper tend to act as a catalyst. Once oxidation starts,

deterioration of the properties of the oil is rapid.

Recharging - When recharging no more than 10 % of the working

charge should be topped up due to heavy sludgeing that can occur

due to the heavy precipitation of the sludge.

EP additive oils - Can assist in healing of damaged gear surfaces

but should be used as a temporary measure only due to risk of side

effects

EMULSIFICATION - This occurs due to water contamination; also,

contamination with grease, fatty oils, varnish, paint and rust

preventers containing fatty products can also promote

emulsification. The presence of an emulsion can be detected by a

general cloudiness of the sample. Salt water emulsifies very easily

and should be avoided. Water entrained in the oil supplied to a

journal bearing can lead to loss of oil wedge, rub and failure. Fresh

water contamination whilst not in itself dangerous can lead to

rusting. The iron oxides catalyses the oil to form sludge's. The

additives in the oil can leach out to change the water into an

electrolyte. Salt water contamination is very serious as it causes tin

oxide corrosion, and also leads to electrochemical attack on the tin

matrix in the white metal. The sea water act as then electrolyte. A

major problem of water within a lub oil is where the mix enters a

bearing, here it is possible for the water to be flashed off collapsing

the oil wedge.

OIL ANALYSIS

Regular testing of crankcase lub oil is important to ensure that

deterioration has not taken place. The results of in service

deterioration could be a reduction in engine protection or actual

attack on working points by corrosive deposits. Oil samples are

generally tested every 3 to 4 months depending on the system and

experience. Shipboard testing is taking a rising prominence to allow

monitoring of oil condition between testing.

To ensure good representation, care should be taken where the

sample is drawn

Correct

Main supply line

inlet or outlet from lub oil cooler

Outlet from main lub oil pump

Incorrect

standpipes

purifier outlet

purifier direct sump suction

Samples should be drawn over a period of several minutes

Viscosity

The viscosity is the most important property of the oil. Oil

of correct viscosity will provide optimum film strength

with minimum friction losses and leakage.

The viscosity of a L.O. may fall due to fuel dilution if

running on gas oil, and rise if running on heavy f.o.

Viscosity may also increase due to heavy soot loading if

purifiers and filters not operating efficiently. Oil ageing

caused by oxidation and thermal degradation increases

viscosity.

A simple shipboard test is the Mobil flow stick where

drops of new and used oil are placed in separate

channels on an inclined 'stick'. The rate the oil flows

down the stick is proportional to its viscosity.

Water content

Initially determined by 'crackle' test. The

presence of Na and Mg in a 4:1 ratio indicates

salt water contamination.

Limits are laid down by the manufacturer, but as

a rule of thumb a limit of 0.2% should cause

investigation into source and remedial action at

0.5%

Gross contamination can be remedied by

placing the charge in a separate tank and

heating to 70

o

C and circulating through purifier.

Spectrometry

Indicates the presence of metal element composition and identifies

additive and contaminant levels.

Zinc(Zn),Phosphorus(P)- are components of many oils such as

diesel engine oils, hydraulic oils and gear oils, to enhance antiwear

and over properties of the oil

Calcium(Ca)- primarily a component of engine oils, provides

detergency,alkalinity and resistance to oxidation. Residual fuel

engine oils have higher Ca levels

Nickel(Ni)- Bearings, Valves, gear plating, fuel derivative

Barium(Ba)- Multi purpose additive, declining importance

Magnessium(Mg)- as for Ca, may also be due to sea water

contamination if found in Ratio of 1:4 of Na

Chromium(Cr)- Piston rings, hydraulic actuator cylinders

Manganese(Mn)- Cylinder wear

Aluminium(Al)- generally comes from wearing piston skirts, levels

rise where new piston fitted to old engine. Typically 10ppm, but rises

during bedding in. May also indicate the presence of catylytic fines

in residual fuels.

Iron(Fe), Molybdenum(Mo), Chromium(Cr)- metals alloyed for

piston ring etc, a rise in level may indicate ring pack/liner wear.

Copper(Cu), Lead(Pb) , Tin(Sn), Silver(Ag) - soft metals used in

the overlay of shell bearings, and phosphor bronze gears.Note that

high copper content can also occur when samples are drawn from

copper pipes which have not been flushed as well as gear wear.

Silicon(Si)- Indicates poor air filtration, possible fuel derivative

Sulphur(S)- May indicate the presence of clay based (bentonite)

greases

Sodium(Na)- With Mg indicates the presence of sea water

contamination, possible coolant system and fuel derivative

Vanadium(V)- Usually indicates the presence of fuel oil

Alkalinity and acidity

TBN-TOTAL BASE NUMBER- measure of alkaline additives available for

the neutralisation of acids from combustion products and oxidation. Level

governed by type of fuel.

For crosshead engines the TBN will tend to rise due to contamination by

liner lubrication, it should not be allowed to raise more than twice that of the

new charge.

As a guide, the TBN of fresh oil should be at least:

10 x fuel sulphur content (%) for trunk piston engines (10mgKOH/g)

20 x fuel sulphur content (%) for cyl oil in x-head engines (20mgKOH/g)

A simple shipboard go,no-go test is available for measuring the TBN, it

involves the addition of an indicator and acid reagent to a 30ml sample. The

quantify of acid reagent added is determined by the required level of TBN,

for TBN2.5 0.5ml are added, for TBN20 4ml is added. After three minutes

the colour is checked against a chart

Purple:Good level of TBN

Green:Borderline

Yellow:Low level of TBN

TAN-TOTAL ACID NUMBER-measure of organic acid and strong

acid content of oil. Where SAN is nil, the TAN represents the acidity

in the oil due to both the acids in the additives and the oxidation of

the hydrocarbons in the oil. The TAN of fresh oils varies with oil

type, and tends to climb with age. A high TAN may indicate that an

oil should be changed or freshened by top up. A high TAN may be

accompanied with increased viscosity.

SAN-STRONG ACID NUMBER-indicates the presence of strong,

highly corrosive (inorganic) acids, usually formed from combustion

products. If SAN is not zero the oil should be changed immediately

Oil cleanliness

IC-INDEX OF COMBUSTION-measures soot loading of oil

MD-MERIT OF DISPERSANCY-Ability of an oil to disperse

contaminants, such as soot, wear debris and water and thereby

carry them away from the critical areas. Measured by oil blot test

and should not be allowed to fall below 50

DP-DEMERIT POINTS- combination of IC and MD: the lower the

value, the healthier is the condition of the oil

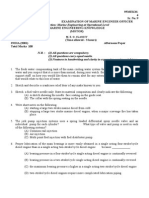

Shipboard water content test

The flask is filled to mark 'A' with

kerosene. A capsule of reagent (calcium

hydride) is added. Any water in the

kerosene will react with the calcium

hydride and any gas vented off. The

container is topped to mark 'B' with

sample oil. The screw valve and cap are

closed. The flask is inverted and shaken.

After 2 minutes the screw valve is

opened. The hydrogen produced by the

reaction between the reagent and water

exerts a pressure which forces the

kerosene through the open valve into the

graduated cylinder. The amount

discharged is proportional to the water

content in the oil sample. If the water

content is greater than 1.5% then the test

should be repeated this time using a

smaller sample by filling only to mark 'C'.

The second scale on the graduated

cylinder should then be used. If water is

detected its type, sea or fresh , should

then be determined by use of a special

reagent the water

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Isps CodeDokument10 SeitenIsps CodeBhupender RamchandaniNoch keine Bewertungen

- ArticrlDokument9 SeitenArticrlBhupender RamchandaniNoch keine Bewertungen

- P 57Dokument7 SeitenP 57Bhupender RamchandaniNoch keine Bewertungen

- Marine Engineering Study Materials: EFC InternationalDokument5 SeitenMarine Engineering Study Materials: EFC InternationalBhupender RamchandaniNoch keine Bewertungen

- Marine Engineering Study Materials: Videocon d2h HD OfferDokument7 SeitenMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniNoch keine Bewertungen

- ArticlDokument11 SeitenArticlBhupender RamchandaniNoch keine Bewertungen

- Marine Engineering Study Materials: Videocon d2h HD OfferDokument6 SeitenMarine Engineering Study Materials: Videocon d2h HD OfferBhupender RamchandaniNoch keine Bewertungen

- Marine Engineering Study Materials: Wall Paints in HD ShadesDokument7 SeitenMarine Engineering Study Materials: Wall Paints in HD ShadesBhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument2 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument3 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument2 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- 95MEP 4 Sr. No. 1Dokument2 Seiten95MEP 4 Sr. No. 1Bhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument3 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- 95 MEKM4 SR No2Dokument2 Seiten95 MEKM4 SR No2Bhupender RamchandaniNoch keine Bewertungen

- 95 MEKM4 SR No4Dokument3 Seiten95 MEKM4 SR No4Bhupender RamchandaniNoch keine Bewertungen

- 95 MEKM4 SR No.7Dokument3 Seiten95 MEKM4 SR No.7Bhupender RamchandaniNoch keine Bewertungen

- 95 MEKM4 SR No5Dokument3 Seiten95 MEKM4 SR No5Bhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument2 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument3 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- 95 MEKM4 SR No5Dokument3 Seiten95 MEKM4 SR No5Bhupender RamchandaniNoch keine Bewertungen

- 95MEKM4 SrNo10Dokument3 Seiten95MEKM4 SrNo10Bhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument3 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- 95 MEKM SR No.3Dokument3 Seiten95 MEKM SR No.3Bhupender RamchandaniNoch keine Bewertungen

- Mek 2001 Jan 95 SR - No.1Dokument3 SeitenMek 2001 Jan 95 SR - No.1Bhupender RamchandaniNoch keine Bewertungen

- 95MEKM4 SrNo6Dokument3 Seiten95MEKM4 SrNo6Bhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument4 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- 95MEKM4 SrNo8Dokument3 Seiten95MEKM4 SrNo8Bhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument4 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- 95MEKM4 SrNo2Dokument3 Seiten95MEKM4 SrNo2Bhupender RamchandaniNoch keine Bewertungen

- Function: Marine Engineering at Operational LevelDokument3 SeitenFunction: Marine Engineering at Operational LevelBhupender RamchandaniNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Caterpillar 3208 Marine EngineDokument9 SeitenCaterpillar 3208 Marine Enginevolkan korkmazNoch keine Bewertungen

- Chapter 4: Organic Chemistry: 1 Introduction (From Morrison and Boyd)Dokument17 SeitenChapter 4: Organic Chemistry: 1 Introduction (From Morrison and Boyd)DavidNoch keine Bewertungen

- Oil and Gas Regulatory Authority: (1) Sui Northern Gas Pipelines Limited (2) Sui Southern Gas Company LimitedDokument8 SeitenOil and Gas Regulatory Authority: (1) Sui Northern Gas Pipelines Limited (2) Sui Southern Gas Company LimitedpaldopalNoch keine Bewertungen

- Diesel Fuel MSDS PDFDokument7 SeitenDiesel Fuel MSDS PDFgeverett2765Noch keine Bewertungen

- Plant Layout & Fired HeatersDokument16 SeitenPlant Layout & Fired HeaterspetroloritoNoch keine Bewertungen

- API LIcenseDokument9 SeitenAPI LIcenseNadeem AnsariNoch keine Bewertungen

- GEA - Refrigeration in Oil & Gas Industry - tcm11-33981Dokument4 SeitenGEA - Refrigeration in Oil & Gas Industry - tcm11-33981Dhroov SharmaNoch keine Bewertungen

- 505 FM 01 S01Dokument18 Seiten505 FM 01 S01Are Gee100% (1)

- Learn About Oil and Gas SeparatorsDokument2 SeitenLearn About Oil and Gas SeparatorsOlivier Whettem0% (1)

- Maintenance Manual 447, 503, 582Dokument60 SeitenMaintenance Manual 447, 503, 582chacalextremeNoch keine Bewertungen

- DT40-DT45S (50 HZ)Dokument3 SeitenDT40-DT45S (50 HZ)Md ShNoch keine Bewertungen

- Global Toluene ConsumptionDokument2 SeitenGlobal Toluene ConsumptiontotpityiNoch keine Bewertungen

- Royal Purple Synfilm Recip LubricantDokument2 SeitenRoyal Purple Synfilm Recip LubricantMachineryengNoch keine Bewertungen

- Easypaisa Partnership With Fuel StationsDokument9 SeitenEasypaisa Partnership With Fuel Stationssmuzair110Noch keine Bewertungen

- Refining Process-AlkylationDokument20 SeitenRefining Process-AlkylationTusenkrishNoch keine Bewertungen

- PULSAR Service GuideDokument32 SeitenPULSAR Service GuidePersadaNoch keine Bewertungen

- Form As-1 SMPV Rules 2016Dokument2 SeitenForm As-1 SMPV Rules 2016Venugopal Sri100% (2)

- Columbia Bay Owners ManualDokument49 SeitenColumbia Bay Owners ManualZachary ZelinkaNoch keine Bewertungen

- P&ID - EngDokument7 SeitenP&ID - EngKanad PNoch keine Bewertungen

- Platts Asian Oil Products - Methodology&SpecificationGuideDokument29 SeitenPlatts Asian Oil Products - Methodology&SpecificationGuideStephen HohNoch keine Bewertungen

- Motor Deutz Tcd20122013 2v Operations Man 3123761Dokument80 SeitenMotor Deutz Tcd20122013 2v Operations Man 3123761Wilson Iñiguez100% (4)

- Manual 1008-1010Dokument12 SeitenManual 1008-1010Edgar Eduardo Tellez RuizNoch keine Bewertungen

- Ks Si 0010 en WebDokument0 SeitenKs Si 0010 en WebMoaed KanbarNoch keine Bewertungen

- Hemi EngineDokument23 SeitenHemi Enginesurendrabarwar7Noch keine Bewertungen

- Isx15 CM2250 4022234Dokument1 SeiteIsx15 CM2250 4022234Josuu Garcia100% (7)

- Fire Technology and Arson InvestigationDokument74 SeitenFire Technology and Arson InvestigationDonita BernardinoNoch keine Bewertungen

- Carbon Black: Professor Joe Greene Csu, ChicoDokument13 SeitenCarbon Black: Professor Joe Greene Csu, Chicojraman24Noch keine Bewertungen

- Energy Optimization of Crude Oil Distillation Using Different Designs of Pre-Flash DrumsDokument7 SeitenEnergy Optimization of Crude Oil Distillation Using Different Designs of Pre-Flash DrumsRicardoCamachoPerezNoch keine Bewertungen

- Hy Pro v1 Vac U Dry BrochureDokument3 SeitenHy Pro v1 Vac U Dry BrochureLuis100% (1)

- Harbour NotesDokument18 SeitenHarbour NotesTirumala Chakrapani EtiNoch keine Bewertungen