Beruflich Dokumente

Kultur Dokumente

Research Power Systems - M.E Project - Electrical Power Systems

Hochgeladen von

Senthil Kumar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

20 Ansichten6 SeitenEXPERT SYSTEMS AND SOLUTIONS

Center for Research Projects

Email: expertsyssol@gmail.com,

Cell:9952749533, 8608603634

www.researchprojects.info

Neyveli - Indra Nagar, Near to Neyveli Arch GATE Branches also at Chennai and Chidambaram

IEEE and Non IEEE based Projects For

Final year students of B.E in EEE, ECE, EIE, Mech, Automobile, Mechatronics ,

M.E (Power Systems)

M.E (Applied Electronics)

M.E (Power Electronics)

M.E (VLSI Design)

M.E ( Control Systems )

M.E ( Process Control )

Ph.D Electrical and Electronics.

Power Systems

Power Electronics

Students can assemble their hardware in our Research labs. Experts will be guiding the projects.

We provide you with

• Confirmation letter, Project Estimation, Completion Certificate

• Abstracts Block Diagram, Circuit Diagram of the project

• Supporting documents- notes

• Datasheets, Reference Papers

• Software tools and Real time support.

• Online Classes for Master degree and PhD Projects

• Journal Publication for researchers in Power systems and Power electronics

Short term and Online courses

• C and C++, Embedded C,

• MicroController 8051,PIC 16F877

• ARM 7 and ARM 9 Processors

• MATLAB Fundamental, MATLAB Simpower Systems,

• MATLAB Control systems

• MATLAB Fuzzy Toolbox

• MATLAB GA , ANN Toolbox

• Engineering MATHS MI, MII and MIII

POWER SYSTEMS PROJECTS

Deregulated Systems, Wind power Generation and Grid connection, Profit based Unit commitment, Economic dispatch, Using AI methods for Voltage stability FLC Control, Transformer Fault Identifications, SCADA in Power system Automation, FireFly Algorithm, PSO and QPSO , Genetic Algorithm, Fuzzy logic, Artifical Neural networks, PSCAD for Power systems.

POWER ELECTRONIC PROJECTS

Three phase inverter and converters, Buck Boost Converter Matrix Converter, Inverter and converter topologies, Fuzzy based control of Electric Drives, Optimal design of Electrical Machines, BLDC and SR motor Drives.

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenEXPERT SYSTEMS AND SOLUTIONS

Center for Research Projects

Email: expertsyssol@gmail.com,

Cell:9952749533, 8608603634

www.researchprojects.info

Neyveli - Indra Nagar, Near to Neyveli Arch GATE Branches also at Chennai and Chidambaram

IEEE and Non IEEE based Projects For

Final year students of B.E in EEE, ECE, EIE, Mech, Automobile, Mechatronics ,

M.E (Power Systems)

M.E (Applied Electronics)

M.E (Power Electronics)

M.E (VLSI Design)

M.E ( Control Systems )

M.E ( Process Control )

Ph.D Electrical and Electronics.

Power Systems

Power Electronics

Students can assemble their hardware in our Research labs. Experts will be guiding the projects.

We provide you with

• Confirmation letter, Project Estimation, Completion Certificate

• Abstracts Block Diagram, Circuit Diagram of the project

• Supporting documents- notes

• Datasheets, Reference Papers

• Software tools and Real time support.

• Online Classes for Master degree and PhD Projects

• Journal Publication for researchers in Power systems and Power electronics

Short term and Online courses

• C and C++, Embedded C,

• MicroController 8051,PIC 16F877

• ARM 7 and ARM 9 Processors

• MATLAB Fundamental, MATLAB Simpower Systems,

• MATLAB Control systems

• MATLAB Fuzzy Toolbox

• MATLAB GA , ANN Toolbox

• Engineering MATHS MI, MII and MIII

POWER SYSTEMS PROJECTS

Deregulated Systems, Wind power Generation and Grid connection, Profit based Unit commitment, Economic dispatch, Using AI methods for Voltage stability FLC Control, Transformer Fault Identifications, SCADA in Power system Automation, FireFly Algorithm, PSO and QPSO , Genetic Algorithm, Fuzzy logic, Artifical Neural networks, PSCAD for Power systems.

POWER ELECTRONIC PROJECTS

Three phase inverter and converters, Buck Boost Converter Matrix Converter, Inverter and converter topologies, Fuzzy based control of Electric Drives, Optimal design of Electrical Machines, BLDC and SR motor Drives.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

20 Ansichten6 SeitenResearch Power Systems - M.E Project - Electrical Power Systems

Hochgeladen von

Senthil KumarEXPERT SYSTEMS AND SOLUTIONS

Center for Research Projects

Email: expertsyssol@gmail.com,

Cell:9952749533, 8608603634

www.researchprojects.info

Neyveli - Indra Nagar, Near to Neyveli Arch GATE Branches also at Chennai and Chidambaram

IEEE and Non IEEE based Projects For

Final year students of B.E in EEE, ECE, EIE, Mech, Automobile, Mechatronics ,

M.E (Power Systems)

M.E (Applied Electronics)

M.E (Power Electronics)

M.E (VLSI Design)

M.E ( Control Systems )

M.E ( Process Control )

Ph.D Electrical and Electronics.

Power Systems

Power Electronics

Students can assemble their hardware in our Research labs. Experts will be guiding the projects.

We provide you with

• Confirmation letter, Project Estimation, Completion Certificate

• Abstracts Block Diagram, Circuit Diagram of the project

• Supporting documents- notes

• Datasheets, Reference Papers

• Software tools and Real time support.

• Online Classes for Master degree and PhD Projects

• Journal Publication for researchers in Power systems and Power electronics

Short term and Online courses

• C and C++, Embedded C,

• MicroController 8051,PIC 16F877

• ARM 7 and ARM 9 Processors

• MATLAB Fundamental, MATLAB Simpower Systems,

• MATLAB Control systems

• MATLAB Fuzzy Toolbox

• MATLAB GA , ANN Toolbox

• Engineering MATHS MI, MII and MIII

POWER SYSTEMS PROJECTS

Deregulated Systems, Wind power Generation and Grid connection, Profit based Unit commitment, Economic dispatch, Using AI methods for Voltage stability FLC Control, Transformer Fault Identifications, SCADA in Power system Automation, FireFly Algorithm, PSO and QPSO , Genetic Algorithm, Fuzzy logic, Artifical Neural networks, PSCAD for Power systems.

POWER ELECTRONIC PROJECTS

Three phase inverter and converters, Buck Boost Converter Matrix Converter, Inverter and converter topologies, Fuzzy based control of Electric Drives, Optimal design of Electrical Machines, BLDC and SR motor Drives.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

Motivation for the Research

The induction motors can be considered the larger users of

electrical energy. They are used both in industrial and commercial

sectors in a wide range of applications, such as: fans, compressors,

pumps, conveyor, winders, mills, transports, elevators, home

appliances and office equipments. In India, the electric motors used

in the industrial field consume typically the 60 to 70% of the total

adsorbed electrical energy. In the commercial sector, this percentage

is up to 35%.

With reference to industrial sector, a general purpose electrical

motor consumes about an annual quantity of electrical energy equal

to 5 times its purchase costs and the motor live can he evaluated

around 10 to 12 years. On the base of these considerations, it is

possible to obtain consistent energy saving if higher efficiency

motors are used in the final applications.

WORK FLOW

Efficiency Measurement using field

Experiments PSG -TECH

Design Parameters Optimizations

1 - PSO

2 GA

Finite Element based design optimization

Controller Design for optimal operation

Standard method for Efficiency

World-wide, there exist several standards for testing electric

machinery. For induction motors, the four most important are:

IEEE Standard 112-1996

IEC 34-2 and IEC 34-2A

JEC 37

IS 325

Several national standards are harmonized with regard to one of the

three general standards above. The NEMA MG-1- 1993 standard and the

Canadian standard C390 correspond to the IEEE standard, while in most of

the European countries; the standards are harmonized to IEC 34-2. JEC

stands for the Japanese standard. The efficiency value obtained from the

considered testing standards can differ by several percent, as will be shown

in the measurement results. Moreover, one standard can contain different

methods that do not necessarily lead to one firmly determined value.

In this project, international standards are used to evaluate the

efficiency of 3.7 KW, 4 pole three-phase induction motor and a logic based

energy optimizer is developed using the numerical values obtained from the

above standards.

MAGNET SOFTWARE FOR

DESIGN

MotorSolve represents a new and forward way of

looking at motor design and analysis.

Because it is based on finite element technology,

MotorSolve can provide details that other

software packages cannot.

While it possesses the same ease of use that

users of other packages are used to, MotorSolve

can deliver accurate and detailed results like the

color plot of flux density

FLUX DISTRIBUTION IN STEEL

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Ansi C37.47-2000 PDFDokument21 SeitenAnsi C37.47-2000 PDFIvanNoch keine Bewertungen

- FinalProgram Tencon05v2Dokument181 SeitenFinalProgram Tencon05v2api-3834272Noch keine Bewertungen

- IEEE STD 3002.8 - 2018: Power Systems AnalysisDokument79 SeitenIEEE STD 3002.8 - 2018: Power Systems AnalysisAldrin100% (1)

- IEEE C37.17 - 1997 American National Standard For Trip Devices For AC and General Purpose DC Low Voltage Power Circuit BreakersDokument13 SeitenIEEE C37.17 - 1997 American National Standard For Trip Devices For AC and General Purpose DC Low Voltage Power Circuit BreakersCatalina VásquezNoch keine Bewertungen

- Ann Fault Transformer Project Code - QuoteDokument2 SeitenAnn Fault Transformer Project Code - QuoteSenthil KumarNoch keine Bewertungen

- Expert Systems and Solutions: S. No Details-Specifications CostDokument1 SeiteExpert Systems and Solutions: S. No Details-Specifications CostSenthil KumarNoch keine Bewertungen

- Z - Source InverterDokument1 SeiteZ - Source InverterSenthil KumarNoch keine Bewertungen

- Quote Pscad Power SystemDokument1 SeiteQuote Pscad Power SystemSenthil KumarNoch keine Bewertungen

- Journal Prepration For PH.DDokument2 SeitenJournal Prepration For PH.DSenthil KumarNoch keine Bewertungen

- QUOTE BatteryDokument2 SeitenQUOTE BatterySenthil KumarNoch keine Bewertungen

- Nine Level Inverter Project - Hardware Project - B.Tech ProjectDokument1 SeiteNine Level Inverter Project - Hardware Project - B.Tech ProjectSenthil KumarNoch keine Bewertungen

- Journal Publication - QuoteDokument1 SeiteJournal Publication - QuoteSenthil KumarNoch keine Bewertungen

- Nine Level Inverter Project - Hardware Project - B.Tech ProjectDokument1 SeiteNine Level Inverter Project - Hardware Project - B.Tech ProjectSenthil KumarNoch keine Bewertungen

- Center For Research Projects - Power Systems - Power ElectronicsDokument13 SeitenCenter For Research Projects - Power Systems - Power ElectronicsSenthil KumarNoch keine Bewertungen

- M.E Power Electroncis ProjectDokument1 SeiteM.E Power Electroncis ProjectSenthil KumarNoch keine Bewertungen

- M.E ProjectDokument43 SeitenM.E ProjectSenthil KumarNoch keine Bewertungen

- Project Work in EngineeringDokument1 SeiteProject Work in EngineeringSenthil KumarNoch keine Bewertungen

- Real Power Loss Minimization, Power System Projects, M.E Project - 9952749533Dokument31 SeitenReal Power Loss Minimization, Power System Projects, M.E Project - 9952749533Senthil KumarNoch keine Bewertungen

- Jntu, HyderabadDokument34 SeitenJntu, HyderabadSenthil KumarNoch keine Bewertungen

- Projects EEE, ECE - Final YearDokument13 SeitenProjects EEE, ECE - Final YearSenthil KumarNoch keine Bewertungen

- Presentation 1Dokument22 SeitenPresentation 1Senthil KumarNoch keine Bewertungen

- PH.D Guidance in Power Systems For Journal PublicationDokument8 SeitenPH.D Guidance in Power Systems For Journal PublicationSenthil KumarNoch keine Bewertungen

- Electrified Bike Engine - EEE ProjectDokument39 SeitenElectrified Bike Engine - EEE ProjectSenthil KumarNoch keine Bewertungen

- Reactive Power EnhancementDokument20 SeitenReactive Power EnhancementSenthil KumarNoch keine Bewertungen

- M.E Power System ProjectDokument11 SeitenM.E Power System ProjectSenthil KumarNoch keine Bewertungen

- Jammer - B.E EEE ProjectDokument20 SeitenJammer - B.E EEE ProjectSenthil Kumar100% (1)

- Load Frequency Control - M.E Tech Project Code - 9952749533Dokument12 SeitenLoad Frequency Control - M.E Tech Project Code - 9952749533Senthil Kumar100% (1)

- Embedded Processor - Final Year ProjectsDokument23 SeitenEmbedded Processor - Final Year ProjectsSenthil KumarNoch keine Bewertungen

- 8051 TutorialsDokument10 Seiten8051 TutorialsSenthil KumarNoch keine Bewertungen

- M.E Projects PSEDokument37 SeitenM.E Projects PSESenthil KumarNoch keine Bewertungen

- Basic of DSP ProjectsDokument40 SeitenBasic of DSP ProjectsSenthil KumarNoch keine Bewertungen

- DSP ProjectDokument16 SeitenDSP ProjectSenthil KumarNoch keine Bewertungen

- Wireless ProjectsDokument9 SeitenWireless Projectssetsindia3735Noch keine Bewertungen

- WiFi 802.11Dokument24 SeitenWiFi 802.11BeyangAdinegaraNoch keine Bewertungen

- CV YangQuan Chen10SeptDokument56 SeitenCV YangQuan Chen10SeptAnjireddy ThatiparthyNoch keine Bewertungen

- ML TN NPU3C OverviewDokument1 SeiteML TN NPU3C OverviewJohn Doe50% (2)

- IEEE STD C37 123 2016 IEEE GuideDokument60 SeitenIEEE STD C37 123 2016 IEEE GuideUPP PAPUANoch keine Bewertungen

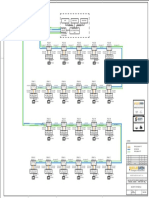

- Bsl1-Ele-032 Security System SLD .Rev 0Dokument1 SeiteBsl1-Ele-032 Security System SLD .Rev 0jdzarzalejoNoch keine Bewertungen

- Plant Engineering: Advanced Diploma ofDokument31 SeitenPlant Engineering: Advanced Diploma ofLazarus PhillipusNoch keine Bewertungen

- IEEE C62.92.1™-2016 - ErrataDokument4 SeitenIEEE C62.92.1™-2016 - ErrataDipankar ChakrabortyNoch keine Bewertungen

- Formato IEEEDokument6 SeitenFormato IEEEAngel David Torres MosqueraNoch keine Bewertungen

- IEEE 123 Node Test Feeder LetterheadDokument40 SeitenIEEE 123 Node Test Feeder LetterheadwilliamNoch keine Bewertungen

- Dollars Versus Diplomas: Find Your FireDokument52 SeitenDollars Versus Diplomas: Find Your FireMauricio ChávezNoch keine Bewertungen

- CH 14 Wireless LANs Multiple Choice Questions and Answers MCQ PDF - Data Communication and Networking PDFDokument13 SeitenCH 14 Wireless LANs Multiple Choice Questions and Answers MCQ PDF - Data Communication and Networking PDFMd MianNoch keine Bewertungen

- About Trilogic Program: Problem StatementDokument6 SeitenAbout Trilogic Program: Problem StatementMumbai AcademicsNoch keine Bewertungen

- Qualis Engenharias 3Dokument37 SeitenQualis Engenharias 3Cleibson AlmeidaNoch keine Bewertungen

- Tec 34731911Dokument10 SeitenTec 34731911vishalvsinghonlineNoch keine Bewertungen

- Debug 1214Dokument13 SeitenDebug 1214N1234mNoch keine Bewertungen

- Ethernet Mac Protocol PDFDokument2 SeitenEthernet Mac Protocol PDFEmilyNoch keine Bewertungen

- SoDokument157 SeitenSoLeonardoBernalNoch keine Bewertungen

- Ieee PSPB Operations ManualDokument3 SeitenIeee PSPB Operations ManualSamir Fassi FassiNoch keine Bewertungen

- Switches - Catalyst 9000 Index Sheet For Visio IconsDokument11 SeitenSwitches - Catalyst 9000 Index Sheet For Visio IconsmmihmNoch keine Bewertungen

- 9 Petroleum and Chemical Industry Conference Europe Electrical and Instrumentation ApplicationsDokument16 Seiten9 Petroleum and Chemical Industry Conference Europe Electrical and Instrumentation ApplicationsMohd_ADNoch keine Bewertungen

- Moduletek SFPDokument3 SeitenModuletek SFPDũng Đào TrungNoch keine Bewertungen

- LP DW Ubiquiti Di-Abril 13Dokument5 SeitenLP DW Ubiquiti Di-Abril 13Freling R. Ramirez BautistaNoch keine Bewertungen

- Ieee Switchgear PDFDokument42 SeitenIeee Switchgear PDFroberto herediaNoch keine Bewertungen

- Mediterranean Microwave Symposium 2022 - Call For PapersDokument2 SeitenMediterranean Microwave Symposium 2022 - Call For PapersMMS2022Noch keine Bewertungen

- PEL 20161201 Dec 2016Dokument76 SeitenPEL 20161201 Dec 2016RémiNoch keine Bewertungen

- Simulation Handbook PDFDokument862 SeitenSimulation Handbook PDFmharcosarmientoNoch keine Bewertungen