Beruflich Dokumente

Kultur Dokumente

Steam Turbine Product Solutions and Technology

Hochgeladen von

Machineryeng100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

843 Ansichten64 SeitenEngineered Steam Turbine Oct 01-Dresser Rand

Originaltitel

Engineered Steam Turbine Oct 01-Dresser Rand

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenEngineered Steam Turbine Oct 01-Dresser Rand

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

100%(3)100% fanden dieses Dokument nützlich (3 Abstimmungen)

843 Ansichten64 SeitenSteam Turbine Product Solutions and Technology

Hochgeladen von

MachineryengEngineered Steam Turbine Oct 01-Dresser Rand

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 64

1

STEAM TURBINE PRODUCTS

Sept. 26th, 2001

2

Steam Turbine Product

SOLUTIONS

ENERGY CONVERSION

LIFE CYCLE COST

FOCUS ON

3

Steam Turbine Product

APPLICATIONS

POWER GENERATION

COMPRESSORS DRIVE

PUMPS DRIVE

FANS DRIVE

4

Steam Turbine Product

MECHANICAL DRIVE TURBINES

STANDARD SINGLE STAGE

STANDARD MULTISTAGE

ENGINEERED MULTISTAGE

TURBINE GENERATORS

STANDARD TURBINE GENERATORS

ENGINEERED TURBINE GENERATORS

5

Maximum operating conditions of our SST range

(*) engineered product

TURBINE

FRAME

INLET

INCHES

EXHAUST

INCHES

STEAM

CONDITIONS

BARG -C - BARG

POWER

KW

SPEED

RPM

350 4 6 48-400-10 750 5000

500 6 8 48-440-10 2600 8000

500H 6 8 48-440-20 2600 12000

500 HA (*) 6 8 62-482-20 2600 15400

700 6 12 48-440-5 2600 6000

700LP 8 16 27-412-5 2600 6000

700S 4 12 103-482-5 2500 5300

700H 6 12 48-440-10 2600 5150

700HS 4 12 62-482-10 2500 5150

6

Typical single stage turbine cross section

7

From our SST range of

product

Steam Turbine Product

From our standard Z type

8

Steam Turbine Product

CHARACTERISTICS

POWER UP TO 80 MW

INLET PRESSURE UP TO 152 BARG

INLET TEMPERATURE UP TO 566 C

EXHAUST FLOW 25 t/h - 0.1 Bara - 16000 t/mn

90 t/h - 0.1 Bara - 11000 t/mn

400 t/h - 0.1 Bara - 4000 t/mn

9

Engineered mechanical drive turbines

CAPABILITY EXPERIENCE

POWER

70000 HP

52200 KW

51000 HP

38030 KW

SPEED 20000 RPM 15940 RPM

INLET PRESSURE

2200 PSIG

152 BARG

2000 PSIG

138 BARG

INLET TEMP.

1050 FTT

566 C

986 FTT

540 C

EXHAUST PRESSURE

800 PSIG

55 BARG

700 PSIG

48 BARG

EXTR/IND PRESSURE

1200 PSIG

82 BARG

685 PSIG

47 BARG

10

Typical multistage turbine cross section

11

Longitudinal section thru multistage steam turbine

12

Steam Turbine Product

13

High Speed Compressor Drive -

TT14

Back Pressure

18000 RPM

7000 hp

750 psig inlet

300 psig exhaust

51 inch span

14

High Speed Compressor Drive -

TT14

Condensing

17000 rpm

7000 hp

750 psig inlet

3.0 inches Hga

15

Steam Turbine Product

Finite element design

High pressure / High temperature

steam end casing

" Finger type design

16

High pressure / High temperature steam

end casing Finger type design

17

Steam Turbine Product

High pressure / High temperature design

nozzle ring

Diaphragms

18

Steam Turbine Product

19

Steam turbine Product

20

Upper multivalves casing for

condensing unit

21

Large exhaust end fabricated casing

22

View of lower half casing with

installed diaphragms

23

Tilting pad journal and thrust bearing design

24

For both the interstage and end gland packing we

utilizes a niresist nickel iron stationary packing ring

The packing rings are segmented in 4-90 segments

and are spring backed.

25

ROTOR

DESIGNED IN ACCORDANCE WITH API STANDARD 612

SPECIFICATIONS

ONE PIECE ALLOY FORGED CONSTRUCTION

INTEGRAL FLANGE COUPLING HUB

INTEGRAL THRUST COLLAR

PRESSURE EQUALIZATION HOLES

PROVISIONS FOR FIELD BALANCE

ULTRASONICALLY TESTED

HEAT STABILITY TESTED

STATIONARY SHAFT SEALING

MULTIPLANE DYNAMIC BALANCING PERFORMED DURING THE

BLADE INSTALLATION SEQUENCE

Steam Turbine Product

26

Steam Turbine Product

32 MW UNIT ROTOR

27

View of lower half casing with installed rotor

28

Free standing blade with

"Finger attachment" used on

last stages for large

condensing application

Part of our range of shrouded

blades riveted by packets using

dovetail design for attachment

Blades

30

Multivalves, lifted in sequence by individual cams.

The camshaft is actuated by the speed governor

through a powerfull oil opearted piston

32

COMPRESSOR DRIVES

MORE THAN 1600 UNITS INCLUDING ...

45 UNITS BETWEEN 7000 AND 15000 KW

55 UNITS BETWEEN 15000 AND 30000 KW

Steam Turbine Product

33

TURBO GENERATOR SET

MORE THAN 2400 UNITS INCLUDING ...

44 BACK PRESSURE UNITS ABOVE 7500 EKW

95 CONDENSING UNITS ABOVE 10000 EKW

Steam Turbine Product

34

Steam Turbine Product

TOTAL MANUFACTURED

IN FRANCE SINCE 1953

4980 SINGLE STAGE

425 MULTISTAGE

IN LE HAVRE SINCE 1985

715 SINGLE STAGE

68 MULTISTAGE

35

SynGas Compressor Drive

Turbine

36

Synthesis Gas Driver

40,000 HP

Double end drive

11,000 RPM

1,555 PSIG

935F extraction

/condensing

37

Syn Gas

Synthesis-Gas Steam Turbines

High Speed, High Power Drivers

Elevated Steam Conditions

Typically Drive Off Both Ends

Controlled Extraction

Simultaneous demand for

Maximum efficiency

Reliability

38

Ethylene Plant Turbine Drivers

39

Charge Gas

Drive Turbine

40

Steam Turbine Product

FEW REFERENCES

41

Tecnimont/Guangzhou (China) - Contract 1038 -

42

Technip/Leuna (Germany) - Contract 1044 -

43

FWCEE / Esso Port J erome ( France ) - Contract 1046 -

44

FWCEE / Esso Port J erome ( France ) - Contract 1048 -

45

Krebs / FCC J ordan / Bin Qasim ( Pakistan ) - Contract 1053 -

46

M.D.D / Tecnimont / IBN Rush ( S.ARABIA ) - Contract 1051 -

OTHER MECHANICAL DRIVE

47

N.P / F.W.C.E.E / Exxon B.V Rotterdam (Nederlands)

- Contract 1055 -

OTHER MECHANICAL DRIVE

48

M.D.D / Amoco ( Taiwan ) - Contract UE25841 -

OTHER MECHANICAL DRIVE

49

Krebs / Indo J ordan ( J ordanie ) - Contract 1045 -

TURBO GENERATOR SET

50

Krebs / UIOM Pau ( France ) - Contract 1047 -

TURBO GENERATOR SET

51

TNEE / UIOM Toulouse ( France ) - Contract 1049 -

TURBO GENERATOR SET

52

FWCEE / UIOM Valorsul ( Portugal ) - Contract 1050 -

TURBO GENERATOR SET

53 Von Roll / UIOM Vert Le Grand-Evry ( France ) - Contract 1052 -

TURBO GENERATOR SET

54

Serete / UIOM Gien ( France ) - Contract 1054 -

TURBO GENERATOR SET

55

Mon Loisir ( Mauritius ) - Contract 1059 -

TURBO GENERATOR SET

56

Arco Petroleum / Carson CA ( USA ) - Contract UE 23611 -

TURBO GENERATOR SET

Standard Steam Turbines

58

Steam Turbine Technology

Product Upgrades and Revamps

Advanced Flowpath Construction

Condensing Stage Developments

Axial Exhaust

Mechanical Steam Seals

Retractable Labyrinth Seals

Syngas Drive Turbines

59

Product Upgrades

Over 30 separate product upgrades available

for all DR steam turbine brands and models

Major Categories

Improved sealing technology

Controls

Power & efficiency

Reliability and Life Extension

Visit DR Website: http://www.dresser-

rand.com/steam/upgrades_steam.htm

60

Revamps and Uprates

Major increase in power or speed or change in

conditions of service

Recent Examples

Cracked gas compressor drive

35% power uprate (40,536 KW, originally 29,900 KW)

Ethylene compressor drive

47% power uprate (10,399 KW, originally 7,090 KW)

Ethylene compressor drive

35% power uprate (22,480 KW, originally 16,200 KW)

Visit DR Website: http://www.dresser-rand.com/steam/revamps.htm

61

Retractable Labyrinth Seals

Principle

At low stage pressures, seal segments are held open by

springs

Rising stage pressures close seals in sequence

Closing pressures tailored to stage pressures

Benefits

Reduce risk of damaging rubs during startup

Easier transit of critical speeds

Performance maintenance

62

Retractable Labyrinth Seals

DR seal design innovations

Spring loaded ball design

No loose pieces, simplified assembly

Simple installation, adjustment procedures

63

64

65

66

Das könnte Ihnen auch gefallen

- Steam Turbines For Pump DrivesDokument94 SeitenSteam Turbines For Pump DrivesFabbrox100% (9)

- Ansaldo - Steam - TurbinesDokument8 SeitenAnsaldo - Steam - TurbinesPratama Trendy LeoNoch keine Bewertungen

- Case Study On Dresser Rand Ethylene CompressorDokument18 SeitenCase Study On Dresser Rand Ethylene CompressorSDP02Noch keine Bewertungen

- Steam Turbine FFCDokument31 SeitenSteam Turbine FFCTaha KhanNoch keine Bewertungen

- Industrial Steam TurbineDokument28 SeitenIndustrial Steam TurbineReza AndriantonYa Ndud100% (2)

- Reciprocating Compressor Rod Position Rod Drop Whats The DifferenceDokument5 SeitenReciprocating Compressor Rod Position Rod Drop Whats The DifferenceMuhd Fadzlee ZNoch keine Bewertungen

- Steam Turbine Vibration Characteristics AnalysisDokument24 SeitenSteam Turbine Vibration Characteristics AnalysisVirgilio100% (1)

- Steam Turbine Q & ADokument47 SeitenSteam Turbine Q & Asrikanth9555100% (1)

- Training - Flowserve Apm Pump CW Pump Part3Dokument4 SeitenTraining - Flowserve Apm Pump CW Pump Part3hasan099Noch keine Bewertungen

- Num g17 Centrifugal CompressorDokument43 SeitenNum g17 Centrifugal CompressorMadan Yadav100% (3)

- Everything You Need to Know About Steam TurbinesDokument69 SeitenEverything You Need to Know About Steam TurbinesNgo Van Tan100% (2)

- Bowed Rotor Straightening WebVersion Dec 29 2010Dokument2 SeitenBowed Rotor Straightening WebVersion Dec 29 2010elrajilNoch keine Bewertungen

- Fundamentos de Compresores, Curvas PerformanceDokument116 SeitenFundamentos de Compresores, Curvas Performancejowar100% (3)

- CompressorDokument118 SeitenCompressorsjois_hs100% (1)

- 4 532583864623736914 PDFDokument8 Seiten4 532583864623736914 PDFMuhammad Riaz Ur RehmanNoch keine Bewertungen

- Steam Turbine PDFDokument122 SeitenSteam Turbine PDFKanzanah Pettarani100% (3)

- Troubleshooting Turbine Steam Path Damage MechanismsDokument40 SeitenTroubleshooting Turbine Steam Path Damage MechanismsMas Zuhad100% (1)

- 5 Reciprocating Compressor SelectionDokument27 Seiten5 Reciprocating Compressor SelectionGuido Mariano GonzalezNoch keine Bewertungen

- 04 SRL MaintenanceDokument94 Seiten04 SRL Maintenancerana usman100% (1)

- Steam Purity Considerations For New TurbinesDokument46 SeitenSteam Purity Considerations For New Turbinesomertrik100% (1)

- Turbine Supervisory InstrumentsationDokument52 SeitenTurbine Supervisory InstrumentsationKarthi KeyanNoch keine Bewertungen

- Intro To Centrifugal Compressor ComponentsDokument7 SeitenIntro To Centrifugal Compressor ComponentsMuhammad Ridhwan100% (2)

- Steam Turbine - Q & A 1Dokument104 SeitenSteam Turbine - Q & A 1rahul_choubey_9100% (6)

- GE Gas TurbineTheoryDokument62 SeitenGE Gas TurbineTheorysalamadel100% (1)

- Introduction to Steam Turbines for Power GenerationDokument95 SeitenIntroduction to Steam Turbines for Power Generationlnw lnw100% (2)

- Steam Turbine Code TypesDokument140 SeitenSteam Turbine Code Typesfreehandbook286% (7)

- Chapter 5 Steam TurbineDokument78 SeitenChapter 5 Steam TurbineGloria Del Carmen MuñozNoch keine Bewertungen

- Steam Turbine BasicsDokument15 SeitenSteam Turbine BasicsDilip YadavNoch keine Bewertungen

- Generator Control and Protection System PDFDokument159 SeitenGenerator Control and Protection System PDFAdetunji Taiwo100% (1)

- 04 Sundyne Presentation Fscontrol SystemDokument27 Seiten04 Sundyne Presentation Fscontrol SystemjoseellargoNoch keine Bewertungen

- Cent. Comp. For Trainee EngrsDokument141 SeitenCent. Comp. For Trainee EngrsInaam Ur Rehman100% (1)

- STI Reciprocating CompressorDokument29 SeitenSTI Reciprocating CompressorfazzlieNoch keine Bewertungen

- Compressors, An Introduction: © Siemens AG 2008. All Rights ReservedDokument63 SeitenCompressors, An Introduction: © Siemens AG 2008. All Rights ReservedMuhammad Saad KhanNoch keine Bewertungen

- Steam Turbine Control and Safety - 51229 - D PDFDokument8 SeitenSteam Turbine Control and Safety - 51229 - D PDFharis tambunan100% (1)

- Steam TurbineDokument25 SeitenSteam TurbineMajid Sattar100% (1)

- Siement Turbine Over Hauling ProcedureDokument75 SeitenSiement Turbine Over Hauling Procedurerajurajangam100% (2)

- Tilting Pad BearingDokument11 SeitenTilting Pad BearingDharmendra JainNoch keine Bewertungen

- T&C ContrlDokument78 SeitenT&C ContrlSTABNoch keine Bewertungen

- MHI Latest Large Frame Gas Turbine GTCC Power PlantDokument45 SeitenMHI Latest Large Frame Gas Turbine GTCC Power Plantluriah100% (2)

- Axial PositionDokument23 SeitenAxial PositionArif Insurgent67% (3)

- Forsthoffer’s Component Condition MonitoringVon EverandForsthoffer’s Component Condition MonitoringBewertung: 4 von 5 Sternen4/5 (2)

- Large Capacity Supercritical SetsDokument55 SeitenLarge Capacity Supercritical Setsbidyut100100% (5)

- Gas TurbineDokument93 SeitenGas TurbineShubhankit Porwal100% (2)

- CCGTDokument74 SeitenCCGTAbhishek Prakash SrivastavaNoch keine Bewertungen

- Doosan Steam TurbinesDokument24 SeitenDoosan Steam TurbinesUhrin Imre0% (1)

- TM2500 BrochureDokument8 SeitenTM2500 BrochuregustiramadaniNoch keine Bewertungen

- A64 Service Lube S PDFDokument8 SeitenA64 Service Lube S PDFCruzado Vilca AmesquitaNoch keine Bewertungen

- Fossil Fired Programs: 350 - 450 MW RatingDokument16 SeitenFossil Fired Programs: 350 - 450 MW Ratingmunendra_muni9896Noch keine Bewertungen

- Overiew of Comb Cycle Rev 6.0 - Part 1Dokument73 SeitenOveriew of Comb Cycle Rev 6.0 - Part 1SamNoch keine Bewertungen

- High-Efficiency CCGT Power PlantDokument188 SeitenHigh-Efficiency CCGT Power PlantAbbas_Makki94% (16)

- Brochure Gas Turbine SGT-300 For Power GenerationDokument4 SeitenBrochure Gas Turbine SGT-300 For Power GenerationIvo SilvaNoch keine Bewertungen

- Turboexpander CompressorsDokument5 SeitenTurboexpander CompressorsNuri LealNoch keine Bewertungen

- SGT 400Dokument4 SeitenSGT 400pramodtryNoch keine Bewertungen

- New Concepts in Supercritical TurbinesDokument37 SeitenNew Concepts in Supercritical TurbinesSushil Lamba100% (1)

- Hermetically Sealed Pumps Ensure Refrigerant Safety and EfficiencyDokument24 SeitenHermetically Sealed Pumps Ensure Refrigerant Safety and EfficiencyWaseem HassanNoch keine Bewertungen

- Principles of Power GenerationDokument94 SeitenPrinciples of Power GenerationAmi A HaNoch keine Bewertungen

- 01 Portable Nitrogen UnitsDokument8 Seiten01 Portable Nitrogen UnitsbracioNoch keine Bewertungen

- Ledeen Actuator General Catalogue - Entire LineDokument24 SeitenLedeen Actuator General Catalogue - Entire LineJair LamasNoch keine Bewertungen

- 24 - New Gen Strategy Ultra-Supercritical TechnlgyDokument21 Seiten24 - New Gen Strategy Ultra-Supercritical TechnlgySultan MahamudNoch keine Bewertungen

- Gas Compression Driver and Compressor OptionsDokument62 SeitenGas Compression Driver and Compressor OptionsRadu BabauNoch keine Bewertungen

- Manual Best Management PortsDokument156 SeitenManual Best Management PortsAchraf DouiriNoch keine Bewertungen

- Seal Design GuideDokument119 SeitenSeal Design GuideaytepeNoch keine Bewertungen

- JC Gasket CranfoilDokument2 SeitenJC Gasket CranfoilMachineryengNoch keine Bewertungen

- ESA Best Available Techniques Issue 1Dokument4 SeitenESA Best Available Techniques Issue 1vprochockyNoch keine Bewertungen

- Api 617 CameronDokument31 SeitenApi 617 CameronMachineryengNoch keine Bewertungen

- Steam TurbinesDokument8 SeitenSteam Turbinesspalaniyandi100% (1)

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDokument25 SeitenHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- Lip Seal Installation PDFDokument11 SeitenLip Seal Installation PDFMachineryengNoch keine Bewertungen

- SOP Templates 03Dokument1 SeiteSOP Templates 03MachineryengNoch keine Bewertungen

- Seal Design For High Pressure Offshore-Morton & EvansDokument10 SeitenSeal Design For High Pressure Offshore-Morton & EvansMachineryengNoch keine Bewertungen

- Compressor MountingDokument41 SeitenCompressor MountingjmacarroNoch keine Bewertungen

- SOP Number Insert Number: Standard Operating ProcedureDokument2 SeitenSOP Number Insert Number: Standard Operating ProcedureLawNoch keine Bewertungen

- Norsok ST 2001Dokument131 SeitenNorsok ST 2001mamounsdNoch keine Bewertungen

- Hsg253 The Safe Isolation of Plant and EquipmentDokument81 SeitenHsg253 The Safe Isolation of Plant and EquipmentRichard HollidayNoch keine Bewertungen

- Borsig BZM - 2016 - EngDokument84 SeitenBorsig BZM - 2016 - EngMachineryengNoch keine Bewertungen

- Creating A World That Doesnt BreakdownDokument23 SeitenCreating A World That Doesnt BreakdownmersiumNoch keine Bewertungen

- BORSIG ZM Compression - Innovative Solutions for Process Gas CompressionDokument16 SeitenBORSIG ZM Compression - Innovative Solutions for Process Gas CompressionMachineryengNoch keine Bewertungen

- Compressor Performance Test Procedure Shaybah Rev.2 BorsigDokument23 SeitenCompressor Performance Test Procedure Shaybah Rev.2 BorsigMachineryengNoch keine Bewertungen

- HA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FDokument25 SeitenHA Series Hydraulic Amplifier Electrical - Installation Operation Manual - Rev FMachineryeng0% (1)

- UtilityDokument8 SeitenUtilityAmit JainNoch keine Bewertungen

- Compressor Turbo-Air API a4-IRDokument12 SeitenCompressor Turbo-Air API a4-IRMachineryengNoch keine Bewertungen

- BORSIG Valve PresentationDokument18 SeitenBORSIG Valve PresentationMachineryengNoch keine Bewertungen

- Pit Ot Tube Pump TechnologyDokument12 SeitenPit Ot Tube Pump TechnologymariasofiarossiNoch keine Bewertungen

- Perf Improv To Aches Rev 0Dokument16 SeitenPerf Improv To Aches Rev 0Poncho RmzNoch keine Bewertungen

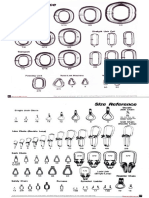

- Lifiting Chain Size Referance PDFDokument1 SeiteLifiting Chain Size Referance PDFMachineryengNoch keine Bewertungen

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresDokument1 SeiteBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraNoch keine Bewertungen

- Lifts and Hoists Maintenance Tasks PDFDokument19 SeitenLifts and Hoists Maintenance Tasks PDFMachineryengNoch keine Bewertungen

- Selection of Material Nace - H2S - Technical Paper PDFDokument21 SeitenSelection of Material Nace - H2S - Technical Paper PDFajaysharma_1009Noch keine Bewertungen

- SVS.435 Steam Turbine Control UpgradesDokument4 SeitenSVS.435 Steam Turbine Control UpgradesMachineryengNoch keine Bewertungen

- International Journal of Organizational Innovation Final Issue Vol 5 Num 4 April 2013Dokument233 SeitenInternational Journal of Organizational Innovation Final Issue Vol 5 Num 4 April 2013Vinit DawaneNoch keine Bewertungen

- Business Ethics and Social ResponsibilityDokument16 SeitenBusiness Ethics and Social Responsibilitytitan abcdNoch keine Bewertungen

- GE Oil & Gas Emails Discuss Earthing Cable SpecificationsDokument6 SeitenGE Oil & Gas Emails Discuss Earthing Cable Specificationsvinsensius rasaNoch keine Bewertungen

- Detect3D Fire and Gas Mapping Report SAMPLEDokument29 SeitenDetect3D Fire and Gas Mapping Report SAMPLEAnurag BholeNoch keine Bewertungen

- Cleavage (Geology) : Structural Geology Petrology MetamorphismDokument4 SeitenCleavage (Geology) : Structural Geology Petrology MetamorphismNehaNoch keine Bewertungen

- gr9mmc2015 2018 Mtap Grade 9Dokument12 Seitengr9mmc2015 2018 Mtap Grade 9Lawrence Leones100% (1)

- Early Christian Reliquaries in The Republic of Macedonia - Snežana FilipovaDokument15 SeitenEarly Christian Reliquaries in The Republic of Macedonia - Snežana FilipovaSonjce Marceva50% (2)

- HL Essay RubricDokument2 SeitenHL Essay Rubricapi-520941535Noch keine Bewertungen

- Buck ConverterDokument31 SeitenBuck Converterbalak144Noch keine Bewertungen

- Consent To Electronic CommunicationsDokument2 SeitenConsent To Electronic CommunicationsVilmarie RiveraNoch keine Bewertungen

- Sally Su-Ac96e320a429130Dokument5 SeitenSally Su-Ac96e320a429130marlys justiceNoch keine Bewertungen

- Astrolada - Astrology Elements in CompatibilityDokument6 SeitenAstrolada - Astrology Elements in CompatibilitySilviaNoch keine Bewertungen

- Writing Patterns NotesDokument2 SeitenWriting Patterns NoteslwitsfadontNoch keine Bewertungen

- REINFORCED CONCRETE DESIGNDokument22 SeitenREINFORCED CONCRETE DESIGNEMIL JOHN P. ANTONIONoch keine Bewertungen

- Guidelines For Selecting Correct Hot Forging Die LubricantsDokument4 SeitenGuidelines For Selecting Correct Hot Forging Die LubricantsSrikar Shenoy100% (1)

- Shariese-Moore-Resume NonumberDokument1 SeiteShariese-Moore-Resume Nonumberapi-404271214Noch keine Bewertungen

- Hrm-Group 1 - Naturals Ice Cream FinalDokument23 SeitenHrm-Group 1 - Naturals Ice Cream FinalHarsh parasher (PGDM 17-19)Noch keine Bewertungen

- CONTINUOUS MECHANICAL HANDLING EQUIPMENT SAFETY CODEmoving parts, shall be fitted with interlocking deviceswhich prevent starting of the equipment when theseopenings are openDokument16 SeitenCONTINUOUS MECHANICAL HANDLING EQUIPMENT SAFETY CODEmoving parts, shall be fitted with interlocking deviceswhich prevent starting of the equipment when theseopenings are openhoseinNoch keine Bewertungen

- 10 Common Problems in The ClassroomDokument2 Seiten10 Common Problems in The ClassroomNonnie CamporedondoNoch keine Bewertungen

- William Shakespeare PDFDokument2 SeitenWilliam Shakespeare PDFmr.alankoNoch keine Bewertungen

- Semi Detailed LP in Math 8 Inductive Reasoning by Jhon Edward G. Seballos San Roque NHS BulalacaoDokument3 SeitenSemi Detailed LP in Math 8 Inductive Reasoning by Jhon Edward G. Seballos San Roque NHS BulalacaoRuth Matriano100% (2)

- Topographic Map of New WaverlyDokument1 SeiteTopographic Map of New WaverlyHistoricalMapsNoch keine Bewertungen

- Camaras PointGreyDokument11 SeitenCamaras PointGreyGary KasparovNoch keine Bewertungen

- Reviews On IC R 20Dokument5 SeitenReviews On IC R 20javie_65Noch keine Bewertungen

- BlockStack Top 21 Trends in Web3 1676290935Dokument9 SeitenBlockStack Top 21 Trends in Web3 1676290935Ahmed BachaNoch keine Bewertungen

- Cheatsheet HomebrewDokument1 SeiteCheatsheet HomebrewfredmnNoch keine Bewertungen

- CHAPTER 7development StrategiesDokument29 SeitenCHAPTER 7development StrategiesOngHongTeckNoch keine Bewertungen

- Training Manual W Appendix 3-20-14 RsDokument193 SeitenTraining Manual W Appendix 3-20-14 RsZakir Ullah100% (5)

- Lecture Nsche Engr Mafe SIWESDokument38 SeitenLecture Nsche Engr Mafe SIWESoluomo1Noch keine Bewertungen

- 17-185 Salary-Guide Engineering AustraliaDokument4 Seiten17-185 Salary-Guide Engineering AustraliaAndi Priyo JatmikoNoch keine Bewertungen