Beruflich Dokumente

Kultur Dokumente

Quality Circle-A Way To Quality Improvement

Hochgeladen von

Santanu Karar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

40 Ansichten16 SeitenQuality Cisrcle

Originaltitel

qualitycircle

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenQuality Cisrcle

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

40 Ansichten16 SeitenQuality Circle-A Way To Quality Improvement

Hochgeladen von

Santanu KararQuality Cisrcle

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 16

Quality Circle-

A way to Quality Improvement

INTRODUCTION

Quality circles were originally associated with Japanese management and

manufacturing techniques. The introduction of quality circles in Japan in the

postwar years was inspired by the lectures of W. Edwards Deming (1900-

1993), a statistician for the U.S. government.

Quality Circle is one of the employee participation methods. It implies

the development of skills, capabilities, confidence and creativity of the

people through cumulative process of education, training, work

experience and participation.

It also implies the creation of facilitative conditions and environment of

work, which creates and sustains their motivation and commitment

towards work excellence.

Quality Circles have emerged as a mechanism to develop and utilize

the tremendous potential of people for improvement in product quality

and productivity.

DEFINITION

Quality Circle is a small group of 6 to 12 employees doing similar

work who voluntarily meet together on a regular basis to identify

improvements in their respective work areas using proven

techniques for analysing and solving work related problems coming

in the way of achieving and sustaining excellence leading to mutual

upliftment of employees as well as the organisation.

It is "a way of capturing the creative and innovative power that lies

within the work force".

PHILOSOPHY

Quality Circles is a people building philosophy, providing self-motivation and

happiness in improving environment without any compulsion or monetary

benefits.

It represents a philosophy of managing people specially those at the grass root

level as well as a clearly defined mechanism and methodology for translating

this philosophy into practice and a required structure to make it a way of life.

It is bound to succeed where people are respected and are involved in

decisions, concerning their work life, and in environments where peoples

capabilities are looked upon as assets to solve work-area problems.

The Quality Circle philosophy calls for a progressive attitude on the part of the

management and their willingness to make adjustments, if necessary, in their

style and culture.

CONCEPT

The concept of Quality Circle is primarily based upon recognition of

the value of the worker as a human being, as someone who willingly

activises on his job, his wisdom, intelligence, experience, attitude

and feelings.

It is based upon the human resource management considered as

one of the key factors in the improvement of product quality &

productivity. Quality Circle concept has three major attributes:

Quality Circle is a form of participation management.

Quality Circle is a human resource development technique.

Quality Circle is a problem solving technique.

OBJECTIVE

The objectives of Quality Circles are multi-faced.

a) Change in Attitude

From "I dont care" to "I do care"

Continuous improvement in quality of work life through

humanisation of work.

b) Self Development

Bring out Hidden Potential of people

People get to learn additional skills.

c) Development of Team Spirit

Individual Vs Team "I could not do but we did it"

Eliminate inter departmental conflicts.

d) Improved Organizational Culture

Positive working environment.

Total involvement of people at all levels.

Higher motivational level.

Participate Management process.

TRAINING

Appropriate training for different sections of employees needs to

be imparted. Without a proper understanding of the real concept of

Quality Circles, both the workers and management might look at this

philosophy with suspicion. Each group should know beforehand the

commitments and implications involved as well as the benefit that

can be obtained from Quality Circles. Such training comprises of :

Brief orientation programme for top management.

Programme for middle level executives.

Training of facilitators.

Training for Circle leaders and members.

LAUNCHING QUALITY CIRCLES

The major prerequisite for initiating Quality Circles in any

organisation is the total understanding of, as well as complete

conviction and faith in the participative philosophy, on the part of the

top and senior management. The launching of Quality Circles

involves the following steps:

o Expose middle level executives to the concept

o Explain the concept to the employees and invite them to volunteer

as members of Quality Circles.

o Nominate senior officers as facilitators

o Form a steering committee.

o Arrange training of co-ordinators, facilitators in basics of

Quality Circle approach, implementation, techniques and

operation. Later facilitator may provide training to Circle

leaders and Circle members.

o A meeting should be fixed preferably one hour a week for the

Quality Circle to meet.

o Formally inaugurate the Quality Circle.

o Arrange the necessary facilities for the Quality Circle meeting

and its operation.

PROCESS OF OPERATION

The operation of quality circles involves a set of sequential steps as

under:

Problem identification: Identify a number of problems.

Problem selection : Decide the priority and select the problem to be

taken up first.

Problem Analysis : Problem is clarified and analysed by basic

problem solving methods.

Generate alternative solutions : Identify and evaluate causes and

generate number of possible alternative solutions.

Select the most appropriate solution : Discuss and evaluate the

alternative solutions by comparison in terms of investment and

return from the investment. This enables to select the most

appropriate solution.

Prepare plan of action : Prepare plan of action for converting the

solution into reality which includes the considerations "who, what,

when, where, why and how" of solving problems.

Present solution to management circle members present solution

to management fore approval.

Implementation of solution : The management evaluates the

recommended solution. Then it is tested and if successful,

implemented on a full scale.

Select the most appropriate solution : Discuss and evaluate the

alternative solutions by comparison in terms of investment and

return from the investment. This enables to select the most

appropriate solution.

Prepare plan of action : Prepare plan of action for converting the

solution into reality which includes the considerations "who, what,

when, where, why and how" of solving problems.

Present solution to management circle members present solution

to management fore approval.

Implementation of solution : The management evaluates the

recommended solution. Then it is tested and if successful,

implemented on a full scale.

BENEFITS AND LIMITATIONS OF

QUALITY CIRCLES

Advantages of quality circles

Increase Productivity

Improve Quality

Boost Employee Morale

Disadvantages/problems with QC

Inadequate Training

Unsure of Purpose

Not truly Voluntary

Lack of Management Interest

Quality Circles are not really empowered to make decisions.

CONCLUSION

Quality Circles are not limited to manufacturing firms only.

They are applicable for variety of organisations where there is scope

for group based solution of work related problems.

Quality Circles are relevant for factories, firms, schools, hospitals,

universities, research institutes, banks, government offices etc.

Thank You!!

Das könnte Ihnen auch gefallen

- 4809.quality of Work Life and Quality CirclesDokument4 Seiten4809.quality of Work Life and Quality CirclesAbhienav MishraNoch keine Bewertungen

- Quality Circle-A Way To Quality ImprovementDokument4 SeitenQuality Circle-A Way To Quality ImprovementratheeshrkrishnaNoch keine Bewertungen

- Quality CircleDokument7 SeitenQuality CirclePawan SharmaNoch keine Bewertungen

- Quality Circles: Shah & Anchor Kutchhi Engineering College Department of Management StudiesDokument19 SeitenQuality Circles: Shah & Anchor Kutchhi Engineering College Department of Management StudiesHetal SanghviNoch keine Bewertungen

- Quality Management System Process A Complete Guide - 2020 EditionVon EverandQuality Management System Process A Complete Guide - 2020 EditionNoch keine Bewertungen

- 10 Biology 1-16-07 Endocrine System Feedback SystemsDokument34 Seiten10 Biology 1-16-07 Endocrine System Feedback SystemsErivieNoch keine Bewertungen

- What Is Quality CircleDokument5 SeitenWhat Is Quality CirclesatishwarNoch keine Bewertungen

- Technology Transfer A Complete Guide - 2020 EditionVon EverandTechnology Transfer A Complete Guide - 2020 EditionNoch keine Bewertungen

- Good Distribution Practice A Complete Guide - 2020 EditionVon EverandGood Distribution Practice A Complete Guide - 2020 EditionNoch keine Bewertungen

- Training Management System A Complete Guide - 2020 EditionVon EverandTraining Management System A Complete Guide - 2020 EditionNoch keine Bewertungen

- Gastroenterology MEDTRANS SAMPLEDokument1 SeiteGastroenterology MEDTRANS SAMPLEMarisol Jane JomayaNoch keine Bewertungen

- Manufacturing Facilities A Complete Guide - 2019 EditionVon EverandManufacturing Facilities A Complete Guide - 2019 EditionNoch keine Bewertungen

- Lean and Kanban-Based: Software DevelopmentDokument42 SeitenLean and Kanban-Based: Software Developmentanafc1403Noch keine Bewertungen

- Artificial Intelligence AI Complete Self-Assessment GuideVon EverandArtificial Intelligence AI Complete Self-Assessment GuideNoch keine Bewertungen

- QC Circle TrainingDokument19 SeitenQC Circle TrainingpoonambhaskarNoch keine Bewertungen

- Continuous Improvement A Complete Guide - 2019 EditionVon EverandContinuous Improvement A Complete Guide - 2019 EditionNoch keine Bewertungen

- World Class Manufacturing, 16Dokument14 SeitenWorld Class Manufacturing, 16Santhilal S Pillai100% (1)

- Managing the Training Function For Bottom Line Results: Tools, Models and Best PracticesVon EverandManaging the Training Function For Bottom Line Results: Tools, Models and Best PracticesBewertung: 3 von 5 Sternen3/5 (1)

- Course Title: Total Quality Management (TQM)Dokument26 SeitenCourse Title: Total Quality Management (TQM)Nikilaa ManoharanNoch keine Bewertungen

- Customer Satisfaction Levels A Complete Guide - 2020 EditionVon EverandCustomer Satisfaction Levels A Complete Guide - 2020 EditionBewertung: 1 von 5 Sternen1/5 (1)

- Error Proofing BasicsDokument16 SeitenError Proofing BasicsJohn OoNoch keine Bewertungen

- Thesis Process Maps (10 Mins)Dokument67 SeitenThesis Process Maps (10 Mins)Ray SefianeNoch keine Bewertungen

- Job AnalysisDokument5 SeitenJob AnalysisFaisal RasheedNoch keine Bewertungen

- Juran'S Trilogy-Planning, Control, ImprovementDokument18 SeitenJuran'S Trilogy-Planning, Control, ImprovementJoannah RiveraNoch keine Bewertungen

- Q4 HOPE 2 - Module 5Dokument10 SeitenQ4 HOPE 2 - Module 5May Ann GodezanoNoch keine Bewertungen

- Kano Model PDFDokument5 SeitenKano Model PDFdanielmugaboNoch keine Bewertungen

- Policy Strategy and Goal DeploymentDokument21 SeitenPolicy Strategy and Goal DeploymentJennycil Abuso GanteNoch keine Bewertungen

- KaizenSession2 PDFDokument29 SeitenKaizenSession2 PDFGherman Claudiu100% (1)

- Total Quality Management (TQM) ToolsDokument84 SeitenTotal Quality Management (TQM) ToolsSameer_Khan_60Noch keine Bewertungen

- Planning and Decision MakingDokument132 SeitenPlanning and Decision MakingGleiza Two BaguioNoch keine Bewertungen

- 5SDokument12 Seiten5SJanzen BascoNoch keine Bewertungen

- Saqa SDFDokument6 SeitenSaqa SDFtangwanlu9177Noch keine Bewertungen

- Skill Matrix: By-Sneha Kanitkar (925) ARPI SHAHDokument15 SeitenSkill Matrix: By-Sneha Kanitkar (925) ARPI SHAHSneha KanitCar Kango100% (1)

- TPM Preview 3 PDF FreeDokument55 SeitenTPM Preview 3 PDF FreemajosehdNoch keine Bewertungen

- ZED PresentationDokument13 SeitenZED PresentationSatbir SinghNoch keine Bewertungen

- Operator Training PointsDokument2 SeitenOperator Training PointsDisha ShahNoch keine Bewertungen

- 17 Step TPS JisukenDokument18 Seiten17 Step TPS Jisukendonz_leNoch keine Bewertungen

- Chap 8 Tanner - Recruitment and SelectionDokument23 SeitenChap 8 Tanner - Recruitment and SelectionHopey Wan-KenobiNoch keine Bewertungen

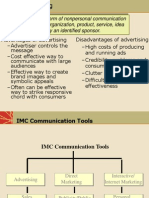

- Any Paid Form of Nonpersonal Communication About An Organization, Product, Service, Idea or Cause by An Identified SponsorDokument28 SeitenAny Paid Form of Nonpersonal Communication About An Organization, Product, Service, Idea or Cause by An Identified SponsorAbdul Rehman KalvaNoch keine Bewertungen

- Cost of QualityDokument4 SeitenCost of QualitynowsheenbdNoch keine Bewertungen

- BPR QuizDokument18 SeitenBPR QuizgigipapasNoch keine Bewertungen

- CARA NC Management Tool Instructions For Client: IATF OversightDokument8 SeitenCARA NC Management Tool Instructions For Client: IATF OversightAvinash CCMSNoch keine Bewertungen

- Inspection ControlDokument10 SeitenInspection ControlIvan D. RiveraNoch keine Bewertungen

- Root Cause Analysis: Presented By: Team: IncrediblesDokument21 SeitenRoot Cause Analysis: Presented By: Team: IncrediblesDinesh TyagiNoch keine Bewertungen

- Work Design and MeasurementDokument22 SeitenWork Design and MeasurementJanysse CalderonNoch keine Bewertungen

- Chap - 3 QC ToolsDokument12 SeitenChap - 3 QC ToolsSnehlata SarafNoch keine Bewertungen

- TPM Total Productive MaintenanceDokument7 SeitenTPM Total Productive MaintenanceBNoch keine Bewertungen

- Basic 7 Tools of Quality: Presentation By: Carla Scardino The Pennsylvania State UniversityDokument37 SeitenBasic 7 Tools of Quality: Presentation By: Carla Scardino The Pennsylvania State Universityjitenderbhati07Noch keine Bewertungen

- TQM - 601 Module 12 - Quality Method PDCA and PDSADokument17 SeitenTQM - 601 Module 12 - Quality Method PDCA and PDSA512781Noch keine Bewertungen

- Bench MarkingDokument21 SeitenBench MarkingRajiv DalelaNoch keine Bewertungen

- Business Plan: Plan: Detailed Proposal For Doing or Achieving Business Plan: A Business Plan Is A PlanningDokument13 SeitenBusiness Plan: Plan: Detailed Proposal For Doing or Achieving Business Plan: A Business Plan Is A PlanningDaniel Grabovsky100% (1)

- Why ISO 13485? - Awareness Presentation: Subtitle or PresenterDokument14 SeitenWhy ISO 13485? - Awareness Presentation: Subtitle or PresenterBulmaro SanchezNoch keine Bewertungen

- Swot Analysis: S W O TDokument38 SeitenSwot Analysis: S W O TA Sailesh ChandraNoch keine Bewertungen

- Risk Assessment: By: Satendra SinghDokument13 SeitenRisk Assessment: By: Satendra SinghVishwash GoyalNoch keine Bewertungen

- 5S - Check ListDokument3 Seiten5S - Check ListJayendra RajeshirkeNoch keine Bewertungen

- MBA Program Handbook 2018-2019Dokument31 SeitenMBA Program Handbook 2018-2019roshanfonseka62980% (1)

- Cambridge Pre-U: Classical Greek 9787/03Dokument7 SeitenCambridge Pre-U: Classical Greek 9787/03Maryam RehanNoch keine Bewertungen

- 7 - 19 AprilDokument30 Seiten7 - 19 AprilMaryam RehanNoch keine Bewertungen

- Cambridge Assessment International Education: Classical Greek 9787/01 May/June 2019Dokument18 SeitenCambridge Assessment International Education: Classical Greek 9787/01 May/June 2019Maryam RehanNoch keine Bewertungen

- 02 Oct 15Dokument88 Seiten02 Oct 15Maryam RehanNoch keine Bewertungen

- China: China'S Massive Defence Budget 2015: Implications For Indian Security - Indian AnalysisDokument8 SeitenChina: China'S Massive Defence Budget 2015: Implications For Indian Security - Indian AnalysisMaryam RehanNoch keine Bewertungen

- 005-Al Baqara 47-82Dokument13 Seiten005-Al Baqara 47-82Maryam RehanNoch keine Bewertungen

- 007-Al Baqara 104-141Dokument14 Seiten007-Al Baqara 104-141Maryam RehanNoch keine Bewertungen

- China: South China Sea: Satellite Imagery Shows Intensive Chinese BuildingDokument49 SeitenChina: South China Sea: Satellite Imagery Shows Intensive Chinese BuildingMaryam RehanNoch keine Bewertungen

- Math Answer KeyDokument1 SeiteMath Answer KeyMaryam RehanNoch keine Bewertungen

- Sample Answer Sheet: Roll No GradeDokument1 SeiteSample Answer Sheet: Roll No GradeMaryam RehanNoch keine Bewertungen

- Underwater Explosive Shock Testing UNDEX CM2000Dokument11 SeitenUnderwater Explosive Shock Testing UNDEX CM2000Maryam RehanNoch keine Bewertungen

- 2012 BCC SolutionDokument37 Seiten2012 BCC SolutionMaryam RehanNoch keine Bewertungen

- Ultra-Compact Multi-Format DVD Player Featuring Hdmi, 1080P Upscaling, Usb, and Divx PlaybackDokument2 SeitenUltra-Compact Multi-Format DVD Player Featuring Hdmi, 1080P Upscaling, Usb, and Divx PlaybackMaryam RehanNoch keine Bewertungen

- 2014 Beaver Computing Challenge Questions Answers, Explanations, and ConnectionsDokument36 Seiten2014 Beaver Computing Challenge Questions Answers, Explanations, and ConnectionsMaryam RehanNoch keine Bewertungen

- Bebras 2014 SIS RAE PosterDokument1 SeiteBebras 2014 SIS RAE PosterMaryam RehanNoch keine Bewertungen

- 2013 BCC SolutionDokument33 Seiten2013 BCC SolutionMaryam RehanNoch keine Bewertungen

- Mil STD 750fDokument19 SeitenMil STD 750fMaryam RehanNoch keine Bewertungen