Beruflich Dokumente

Kultur Dokumente

CURSOAD

Hochgeladen von

francofraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CURSOAD

Hochgeladen von

francofraCopyright:

Verfügbare Formate

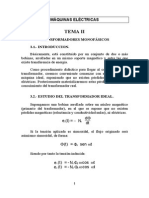

AD 2000

MERKBLTTER

CODE

Qu es el Cdigo AD?

Son reglas para la construccin de

recipientes a presin formuladas por el

ARBEITSGEMEINSCHAFT

DRUCKBEHLTER

Formada por siete sociedades alemanas que cumplen

con la directiva PED 97/23/EC del Parlamento

Europeo sobre Cdigos de Diseo de recipientes de

presin

Cmo est compuesto el Cdigo AD?

El Cdigo AD est compuesto por 8 captulos

alfabticos dedicados a los aspectos del

diseo, construccin y ensayo de los

recipientes de presin

A continuacin se copian de la versin en ingls

del AD los contenidos de cada parte

Parte G Estructura, gestin

En esta parte se establece lo siguiente:

1. El tipo de equipo que se disea segn la Directiva Europea

2. La estructura del Cdigo (reglas de diseo, fabricacin,

prueba, materiales, instalacin y marcas)

3. Las siete empresas que configuran el AD

4. Las 8 partes del Cdigo

5. Contenidos, desviaciones y requisitos adicionales

6. Gua para instrumentar cambios en el AD

7. Donde encontrar la ultima versin (VdTV)

8. Validez de lo publicado (inmediata)

Parte B Diseo

Parte HP Ensayos

Parte W Materiales

Estn disponibles copias de todas las

secciones B, HP y W requeridas para

los problemas comunes de diseo de

equipos de plantas de proceso

A Equipment, installation and marking

A 1 Safety devices against excess pressure Bursting safety devices

A 2 Safety devices against excess pressure Safety valves

A 4 Accessory housings

A 401 Pressure vessel equipment Marking

A 403 Pressure vessel equipment Equipment for detecting and limiting

pressure and temperature

A 404 Pressure vessel equipment Accessories

A 5 Openings, closures and closure elements

A 5 App. 1 Directives for the arrangement of manholes and inspection ports

A 5 App. 2 Guidelines for component testing of clamp-bolts

A 6 Safety devices against excess pressure MCR-safety devices

B Design

B 0 Design of pressure vessels

B 1 Cylindrical and spherical shells subjected to internal overpressure

B 1 App.1 Design of tube bends

B 2 Conical shells subjected to internal and external overpressure

B 3 Domed ends subject to internal or external pressure

B 4 Dished heads

B 5 Unstayed and stayed flat ends and plates

B 5/1 Design of plain rectangular tubes and sectional headers

B 6 Cylindrical shells subjected to external overpressure

B 7 Boltings

B 8 Flanges

B 9 Openings in cylindrical, conical and spherical shells

B 10 Thick walled cylindrical shells subject to internal pressure

B 13 Single-ply bellows expansion joints

G Fundamentals

G 1 AD 2000-Regulations Structure, Application and Method

Guidelines

G 2 List of all standards, quoted in the AD 2000 body of

regulations

HP Manufacture and testing

HP 0 General principles of design, manufacture and associated tests

HP 1 Design and construction

HP 2/1 Procedure qualification testing for joining processes; Procedure

qualification testing for welded joints

HP 3 Welding supervisors; welders

HP 4 Test supervisors and testers in non-destructive testing

HP 5/1 Manufacture and testing of joints Principles of welding practice

HP 5/2 Manufacture and testing of joints Production testing of welds, Testing

of base metal after postweld heat treatment

HP 5/3 Manufacture and testing of joints Non-destructive testing of welded

joints

HP 5/3 App. 1 Non-destructive testing of welded joints Minimum requirements

for non-destructive testing methods

HP Manufacture and testing (cont.)

HP 7/1 Heat treatment General principles

HP 7/2 Heat treatment Ferritic steels

HP 7/3 Heat treatment Austenitic steels

HP 7/4 Heat treatment Aluminum and aluminum alloys

HP 8/1 Testing of pressings made from steel, aluminum and aluminum alloys

HP 8/2 Testing of steel sections

HP 30 Performance of pressure tests

HP 100R Construction regulations Metal piping

HP 110R Construction regulations Piping made of glass reinforced

thermosetting plastics (GRP) with and without liner

HP 120R Construction regulations Thermoplastic piping

HP 511 Design examination

HP 512 Final testing and pressure testing

HP 512R Construction regulations Design examination, final testing and

pressure testing of piping

HP Special pressure vessels

HP 801 No. 10 Spray pressure vessels

HP 801 No. 11 Open vessels heated by steam jackets for cooking preserves,

confectionery and meat products

HP 801 No. 13 Storage containers for beverages

HP 801 No. 14 Pressure vessels in refrigerating and heat-pumping plant

HP 801 No. 15 Pressure vessels subjected to pulsating stresses

HP 801 No. 18 Pressure vessels for fire extinguishers and vessels forfire-

extinguishing agents

HP 801 No. 19 Pressure vessels with lining or masonry lining

HP 801 No. 23 Vehicle containers for liquid, granular and powdery materials

HP 801 No. 25 Liquefied gas storage vessel installation

HP Special pressure vessels (cont.)

HP 801 No. 26 Pressure vessels for gases or gas mixtures with operating

temperatures below -10 C

HP 801 No. 27 Pressure vessels for gases and mixtures in the liquid state

HP 801 No. 29 Rotating steam-heated cylinders

HP 801 No. 30 Autoclaves for masonry blocks

HP 801 No. 34 Ammonia storage vessels

HP 801 No. 37 Heat transfer installations

HP 801 No. 38 Experimental autoclaves

HP 801 No. 39 Pressure vessels in isostatic presses

N Non-metallic materials

N 1 Pressure vessels in glass fibre reinforced

thermosetting plastics

N 2 Pressure vessels made of electro-graphite and

hard burned carbon

N 4 Pressure vessels made of glass

N 4 App. 1 Assessment of defects in walls of

pressure vessels made of glass

S Special cases

S 1 Simplified analysis for cyclic loading

S 2 Analysis for cyclic loading

General verification of stability for pressure vessels

S 3/0 General verification of stability for pressure vessels Basic principles

S 3/1 General verification of stability for pressure vessels Vessels on skirt supports

S 3/2 General verification of stability for pressure vessels Verification of load-carrying

capacity for horizontal vessels on saddle supports

S 3/3 General verification of stability for pressure vessels Vessels with domed ends on

feet

S 3/4 General verification of stability for pressure vessels Vessels with support brackets

S 3/5 General verification of stability for pressure vessels Vessels with ring supports

S 3/6 General verification of stability for pressure vessels Vessels with nozzles subject to

additional loadings

S 3/7 General verification of stability for pressure vessels Allowing for thermals stresses in

heat exchangers with solid headers

S 4 Evaluation of stresses determined by way of calculation and experimental stress

analysis

W Materials

W 0 General principles for materials

W 1 Flat products of unalloyed and alloy steels

W 2 Austenitic steels

W 3/1 Cast iron with lamellar graphite (grey cast iron), non-alloy and low alloy

W 3/2 Cast iron materials; Spheroidal -graphite cast iron, non-alloy and low alloy

W 3/3 Cast iron materials; Austenitic cast iron with lamellar graphite

W 4 Tubes made from non-alloyed and alloy steels

W 5 Cast steel

W 6/1 Aluminum and aluminum alloys; Wrought materials

W 6/2 Copper and copper alloys

W 7 Bolts and nuts made from ferritic steels

W 8 Clad steels

W 9 Steels flanges

W 10 Materials for low temperatures; Ferrous materials

W 12 Seamless hollow components made from non-alloyed and alloy steels for pressure

vessel shells

W 13 Forgings and rolled components made of non-alloyed and alloy steels

Z Additional notes

Z 1 Guidelines for meeting the essential safety

requirements of the Pressure Equipment Directive

when using AD 2000-Merkbltter on pressure

vessels, piping und fittings

Z 2 Guidelines for carrying out a systematic analysis

of hazards

Das könnte Ihnen auch gefallen

- Clases de Hysys 7 OptimizerDokument62 SeitenClases de Hysys 7 OptimizerMaría Alejandra Ayude100% (1)

- Introducción a la simulación de procesos químicos con HYSYSDokument28 SeitenIntroducción a la simulación de procesos químicos con HYSYScharleeincNoch keine Bewertungen

- Int ImpropiasDokument21 SeitenInt ImpropiasfrancofraNoch keine Bewertungen

- Calibración.Dokument13 SeitenCalibración.francofraNoch keine Bewertungen

- Tema 1 UahDokument29 SeitenTema 1 UahcorcoaNoch keine Bewertungen

- Espectrofotometria de Absorcion MolecularDokument4 SeitenEspectrofotometria de Absorcion Molecularangus a.Noch keine Bewertungen

- LaplaceDokument78 SeitenLaplaceMauricio Calle CNoch keine Bewertungen

- Tablas Datos Termoquimicos PDFDokument2 SeitenTablas Datos Termoquimicos PDFfrancofraNoch keine Bewertungen

- Maquinas Corriente ContinuaDokument38 SeitenMaquinas Corriente ContinuaginesciudadrealNoch keine Bewertungen

- Transformada de FourierDokument3 SeitenTransformada de FourierGerman ItuNoch keine Bewertungen

- Corrosion de SuelosDokument13 SeitenCorrosion de SuelosfrancofraNoch keine Bewertungen

- Filosofia Parte 1Dokument124 SeitenFilosofia Parte 1Pablo Villaverde100% (9)

- TP Fotometria de LlamaDokument3 SeitenTP Fotometria de LlamafrancofraNoch keine Bewertungen

- Soluciones Reguladoras de PHDokument9 SeitenSoluciones Reguladoras de PHJhoel MadeniNoch keine Bewertungen

- Funciones de PesoDokument29 SeitenFunciones de PesoMagali MustaineNoch keine Bewertungen

- Métodos Potenciométricos: Electrodos de Referencia y Electrodos IndicadoresDokument12 SeitenMétodos Potenciométricos: Electrodos de Referencia y Electrodos IndicadoresAkiré Aki100% (1)

- Int ImpropiasDokument21 SeitenInt ImpropiasfrancofraNoch keine Bewertungen

- Soluciones de Anfolitos PDFDokument8 SeitenSoluciones de Anfolitos PDFRossy MoralNoch keine Bewertungen

- Ejemplo Calculo BaseDokument3 SeitenEjemplo Calculo BasefrancofraNoch keine Bewertungen

- AD B3 CabezalesDokument10 SeitenAD B3 CabezalesfrancofraNoch keine Bewertungen

- Tanques APIDokument34 SeitenTanques APIfrancofraNoch keine Bewertungen

- AD-B1 Envolventes, Presión InteriorDokument3 SeitenAD-B1 Envolventes, Presión InteriorfrancofraNoch keine Bewertungen

- Perfiles Laminados y Tubos EstructuralesDokument44 SeitenPerfiles Laminados y Tubos Estructuralesfederrr100% (1)

- AD-B0 Diseño Por PresiónDokument8 SeitenAD-B0 Diseño Por PresiónfrancofraNoch keine Bewertungen

- Efectos Símicos - CIRSOC 103Dokument9 SeitenEfectos Símicos - CIRSOC 103francofraNoch keine Bewertungen

- Contrato Nom e InnomDokument5 SeitenContrato Nom e InnomEDS11Noch keine Bewertungen

- Asme 2010Dokument40 SeitenAsme 2010francofraNoch keine Bewertungen

- Electrodos RevestidosDokument7 SeitenElectrodos RevestidosAlexander RomeroNoch keine Bewertungen

- Resistencia de MaterialesDokument24 SeitenResistencia de MaterialesfrancofraNoch keine Bewertungen

- Lanzadoras de Mortero MasterDokument3 SeitenLanzadoras de Mortero MasterOscar Enrique Blandon MirandaNoch keine Bewertungen

- Procedimiento de Limpieza y PinturaDokument37 SeitenProcedimiento de Limpieza y PinturaVicoqNoch keine Bewertungen

- Presupuesto Eléctrico Edificio V PDFDokument1 SeitePresupuesto Eléctrico Edificio V PDFJosé CorreaNoch keine Bewertungen

- Fregaderos+inox MEPAMSADokument6 SeitenFregaderos+inox MEPAMSAfran41960aguirreNoch keine Bewertungen

- Problemas Tema 3 PDFDokument3 SeitenProblemas Tema 3 PDFdmorenocNoch keine Bewertungen

- Catalogo Productos Itahua PDFDokument21 SeitenCatalogo Productos Itahua PDFGabriel Vera0% (1)

- MET-1100 Metalurgia GeneralDokument4 SeitenMET-1100 Metalurgia GeneralIVANAGUDELONoch keine Bewertungen

- Estirado en Frio y CalienteDokument5 SeitenEstirado en Frio y CalienteEdison UshiñaNoch keine Bewertungen

- Ensayo de Charpy y DurezaDokument18 SeitenEnsayo de Charpy y Durezaismael_pantoja_9Noch keine Bewertungen

- Proceso de CizalladoDokument7 SeitenProceso de CizalladoJonathan ChoraNoch keine Bewertungen

- Unidad 1 Mant Gest PesDokument11 SeitenUnidad 1 Mant Gest PesRicardoMoranNoch keine Bewertungen

- Protocolo de Enfierradura y Moldaje PSDDokument2 SeitenProtocolo de Enfierradura y Moldaje PSDRamon Gajardo MuñozNoch keine Bewertungen

- Cinta MétricaDokument3 SeitenCinta MétricaBeatriz PonsNoch keine Bewertungen

- Introducción al sistema periódico: propiedades de los metales alcalinos y halógenosDokument6 SeitenIntroducción al sistema periódico: propiedades de los metales alcalinos y halógenosEdison RamosNoch keine Bewertungen

- Soldadura MIG-MAG: Procesos, Materiales y EquipoDokument13 SeitenSoldadura MIG-MAG: Procesos, Materiales y EquipoAlvaro Gonza HuallaNoch keine Bewertungen

- Fase 1 InventarioDokument6 SeitenFase 1 InventarioAlex Cong ArtazaNoch keine Bewertungen

- Catalogo HogarDokument68 SeitenCatalogo HogarZuriñe EguiluzNoch keine Bewertungen

- Norgren ValvulasDokument69 SeitenNorgren ValvulasJair ValenciaNoch keine Bewertungen

- Tratamiento Termico A Engranaje HelicoidalDokument8 SeitenTratamiento Termico A Engranaje HelicoidalyencamiNoch keine Bewertungen

- SoldaduraDokument8 SeitenSoldadurafelix effioNoch keine Bewertungen

- Prac 1018juan, Alonso, LaloDokument40 SeitenPrac 1018juan, Alonso, LaloMiguel Angel López NavarreteNoch keine Bewertungen

- Calculo de Consumo de Material de SoldaduraDokument17 SeitenCalculo de Consumo de Material de SoldaduraJastenJesusNoch keine Bewertungen

- Corrosión IntergranularDokument12 SeitenCorrosión IntergranularHelder Daniel Cutire SotoNoch keine Bewertungen

- Antecedentes HipotesisDokument6 SeitenAntecedentes HipotesisnandoNoch keine Bewertungen

- LPU Obra Varias Proyectos - OA - Obras Adecuaciones 3G - Formato CotizacionDokument376 SeitenLPU Obra Varias Proyectos - OA - Obras Adecuaciones 3G - Formato CotizacionDorman SilvaNoch keine Bewertungen

- Informe de Dureza RockwellDokument8 SeitenInforme de Dureza RockwellKiara Zela OscoNoch keine Bewertungen

- Puntos Extra sm4Dokument5 SeitenPuntos Extra sm4Eder GonzalezNoch keine Bewertungen

- Elaboración de Guiso Tradicional de Hongo HuitlacocheDokument5 SeitenElaboración de Guiso Tradicional de Hongo HuitlacocheMari Acuca RabeloNoch keine Bewertungen

- 10133-63130lacor 1Dokument1 Seite10133-63130lacor 1Alfredo De La Hoz GuarinNoch keine Bewertungen

- Engranje: L L R R F HDokument2 SeitenEngranje: L L R R F HAdolfo SotoNoch keine Bewertungen