Beruflich Dokumente

Kultur Dokumente

Coal-Water Slurry Presentation2

Hochgeladen von

cumpio4254280 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

188 Ansichten19 Seitenpower point presentation for coal water slurry

Originaltitel

Coal-water Slurry Presentation2

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenpower point presentation for coal water slurry

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

188 Ansichten19 SeitenCoal-Water Slurry Presentation2

Hochgeladen von

cumpio425428power point presentation for coal water slurry

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 19

A New Kind of Fuel For Industrial

Boilers, Kilns & Furnaces

1. INTRODUCTION:

Coal slurry is a new type of low pollution

substitute fuel to comply with the Clean Air

Act for industrial heat and power generation

application.

Coal slurry is made from 65-70% of different

grains of coal powder and 30-35% of water

with approximately 1% of additive prepared

and mixed in proprietary process. It retains

the original physical character of solid coal

and more importantly, it poses the liquidity

(flow ability, mobility) and stability of heavy

fuel oil characteristic.

Like heavy fuel oil, it can easily be loaded,

stored and distributed via pipe line. Slurry

coal can attain high combustion rate of 98%

while solid coal can only attain a combustion

rate of 90-93%, and lower for the solid coal.

2. CHARACTERISTICS OF COAL SLURRY:

Compared with the traditional solid coal and

the fuel oil, Coal Slurry has many excellent

characteristics, bringing the social

environmental protection benefit and

enterprises economic benefit directly.

The density is high, rheology is good and it

can be stored for a long-term without

deposition. So it can be delivered or feed

through pumps thru pipes and burned with

atomization similar to the fuel oil. It can

replace the fuel completely in the boiler

industry, industrial kiln and the power station

boiler, its comprehensive economic cost is

much lower than burning the fossil fuel

greatly.

2. CHARACTERISTICS OF COAL SLURRY:

(CONTINUE)

Its combustion rate increase from 70-80% of

the coal to more than 98%. The carbon

percentage is slag reduce from 13.7% of the

coal to less than 2 %. Therefore, it fully

represents the characteristics of

environmental protection and energy saving.

Coal Slurry is transported and stored in tank

similar to the fossil fuel which reduces the

contamination of solid coal during the

transportation and the storage area. There is

no danger in the storage and transportation

because of its physical chemistry

composition characteristics.

2. CHARACTERISTICS OF COAL SLURRY:

(CONTINUE)

Since its combustion rate reach more than

98%, the discharged slag is reduced

significantly, compared with solid coal-

burning boiler, which not only reduces the

total coal area of the boiler house but also

enhances the circumjacent environment.

Since it is burnt automatically in a liquid state

within the system, the working environment

and condition is greatly enhanced compared

with the traditional solid coal-burning. It stops

the smell of lampblack and coom basically in

the boiler building with the special Coal

Water Slurry combustion technique.

3. BENEFIT OF USING COAL SLURRY:

Approximately two (2) tons of coal slurry can

replace one (1) ton of heavy oil and the price is

approximately less by 25% of the bunker fuel.

Coal slurry ash contain is much less than

burning solid coal directly.

Coal slurry can be loaded in a tank for delivery

and storage, therefore eliminating the

secondary ash pollution, resulting from solid

coal transport. This is will not only prevent solid

coal losses and environmental problems during

transportation, it also greatly reduces storage

space for the fuel.

COAL SLURRY IS THE 21 CENTURY FUEL

THAT CONTRIBUTES TO ENERGY

CONSERVATION AND ENVIRONMENTAL

PROTECTION

4. TECHNICAL DATA COMPARISON

Subject Coal Slurry Standard Coal Heavy

Fuel

Heating Value Kcal/kg 4,200 7,000 9,600

Price (PhP)/kg 1,200 800-900 5,000

Unit Price/Heating Value (PhP/Kcal)

0.286 0.114 0.521

Combustion Efficiency 98-99 65-75 98-99

Environmental Compliance Comply Not Comply Comply

Government Policy Encourage Restricted Not Encourage

5. COMPARISON OF INDUSTRIAL BOILER STEAM COST:

Boiler Heating Heat Combustion Fuel Unit Price Consumption

Type Cost per Value Efficiency Rate Type PhP per Kg Kg Steam

Steam

Pesos-Kcal % % per kg Kg

Slurry (China Coal+RP coal)

216 4,200 83-84 98 Slurry 1,200 0.180

Heavy Fuel

425 9,600 84 98 Bunker-C 30,000 0.085

Saving .. 34.18%

Note:

1. Heavy Fuel Boiler need pre heating and auxiliary system which incurred additional

production cost.

2. Crown Power can guaranty 30% of saving for the package services to provide the Coal

Slurry Boiler and Slurry Fuel.

3. The data is based on a HaiZhong 15 tons slurry boiler

6. COMPARISON OF INDUSTRIAL BOILER:

Subject Coal Slurry Standard Coal Heavy Fuel

Total System Cost Lowest Next to Slurry More Expensive

Fuel Raw Material Source Local Available Local Available Not Locally

Available

Fuel Storage Fuel Tank Ware House Fuel Tank

Storage Space Fuel Tank Size Bigger Space Fuel Tank Size

Storage Environment Clean An Issue Clean

Delivery Losses None Yes None

Boiler House Pollution None Yes None

Operation Simple Need More Attention Simple

Manpower Less More Less

Fuel Control Easy Need More Attention Easy

Quality Control Easy Not Easy Easy

Ash Emission Less More Less

Environmental Compliance Comply Not Comply Comply

Government Policy Encourage Restricted Not Encourage

PROPOSED COAL WATER SLURRY PLANT

Das könnte Ihnen auch gefallen

- Poster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselDokument1 SeitePoster For Optimisation of The Conversion of Waste Cooking Oil Into BiodieselcxmzswNoch keine Bewertungen

- Comsol - Models.heat - Tin Melting FrontDokument16 SeitenComsol - Models.heat - Tin Melting Frontntr_mn4408Noch keine Bewertungen

- 8 - Energy Balance of Solar CollectorsDokument27 Seiten8 - Energy Balance of Solar Collectorsftsebeek6164Noch keine Bewertungen

- GT-Power Exercise 2 Instructions - 2018Dokument15 SeitenGT-Power Exercise 2 Instructions - 2018ManuelLentiNoch keine Bewertungen

- Glutaraldehyde Bulk HandlingDokument4 SeitenGlutaraldehyde Bulk HandlingnubblerNoch keine Bewertungen

- Renewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantDokument36 SeitenRenewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantfaizanNoch keine Bewertungen

- Purge Gas Purification and Recovery in Ammonia Plants: Process DescriptionDokument5 SeitenPurge Gas Purification and Recovery in Ammonia Plants: Process DescriptionFerdian AziziNoch keine Bewertungen

- Report Rafael Damar ArjanggiDokument28 SeitenReport Rafael Damar ArjanggiRafael DamarNoch keine Bewertungen

- GMFIX Code DocumentsDokument63 SeitenGMFIX Code Documentsclarklipman100% (1)

- Flash Drum Design Che 4253 - Design I CheDokument5 SeitenFlash Drum Design Che 4253 - Design I CheDiliniNoch keine Bewertungen

- Techno-Economic Modelling and Cost Functions of CO Capture ProcessesDokument11 SeitenTechno-Economic Modelling and Cost Functions of CO Capture ProcessesAlex MarkNoch keine Bewertungen

- Transat Particles in PipesDokument17 SeitenTransat Particles in Pipesمحمد توفيق عراقيNoch keine Bewertungen

- LPG vs CNG - Comparing liquefied petroleum gas and compressed natural gasDokument3 SeitenLPG vs CNG - Comparing liquefied petroleum gas and compressed natural gasMuhammad Arham100% (1)

- Solved - A Stage Extraction Process Is Depicted in Fig. P9.13. I...Dokument3 SeitenSolved - A Stage Extraction Process Is Depicted in Fig. P9.13. I...Galuh Saputra 5Noch keine Bewertungen

- CFD SimulationDokument39 SeitenCFD SimulationSambhav JainNoch keine Bewertungen

- DIAGRAM MODELINGDokument2 SeitenDIAGRAM MODELINGSiti MaisarahNoch keine Bewertungen

- Lecture 28 Modeling of GTDokument59 SeitenLecture 28 Modeling of GTCindy CarvalhoNoch keine Bewertungen

- Brine SelectionDokument1 SeiteBrine SelectionKarthikeyan SankarrajanNoch keine Bewertungen

- CFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserDokument27 SeitenCFD Model of Active Flow Control by Jets in A Two-Dimensional DiffuserK PedersenNoch keine Bewertungen

- 6.C.b Industrial Waste Incineration GB2009Dokument21 Seiten6.C.b Industrial Waste Incineration GB2009AgungGhaniKramawijayaNoch keine Bewertungen

- Mfix MPPIC Doc PDFDokument20 SeitenMfix MPPIC Doc PDFMuhammad Adnan LaghariNoch keine Bewertungen

- BLOOM ENERGY Final PresentationDokument6 SeitenBLOOM ENERGY Final PresentationAlagappan AngamuthuNoch keine Bewertungen

- Combustion Modelling Tutorial Using ANSYS CFXDokument61 SeitenCombustion Modelling Tutorial Using ANSYS CFXVISHWA GANDHINoch keine Bewertungen

- Process Flow Diagram - Nitric AcidDokument1 SeiteProcess Flow Diagram - Nitric AcidAsma NasserNoch keine Bewertungen

- Design, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed CombustionDokument9 SeitenDesign, Process Simulation and Construction of An Atmospheric Dual Fluidized Bed Combustionapi-3799861Noch keine Bewertungen

- WINSEM2021-22 CHE2006 TH VL2021220501413 Reference Material I 11-03-2022 Module-5 CombustionDokument63 SeitenWINSEM2021-22 CHE2006 TH VL2021220501413 Reference Material I 11-03-2022 Module-5 Combustionswastik vijayNoch keine Bewertungen

- An Analytical Study On Heat Transfer Performance ofDokument18 SeitenAn Analytical Study On Heat Transfer Performance ofsanchez_1256Noch keine Bewertungen

- CFD Analysis of Biomass Downdraft GasifierDokument4 SeitenCFD Analysis of Biomass Downdraft GasifierArup DasNoch keine Bewertungen

- Role of CFD in SCR NOX Reduction PerformanceDokument8 SeitenRole of CFD in SCR NOX Reduction PerformanceMadusuthanan SababathyNoch keine Bewertungen

- Aspen For Chem RXN PART 2Dokument50 SeitenAspen For Chem RXN PART 2hakita86Noch keine Bewertungen

- Combustion Modeling: Industry SolutionsDokument4 SeitenCombustion Modeling: Industry SolutionsDimitri KaboreNoch keine Bewertungen

- Fluent-Intro 17.0 Module09 BestPractices PDFDokument43 SeitenFluent-Intro 17.0 Module09 BestPractices PDFHennry Anderson Zumaran SanchezNoch keine Bewertungen

- Numerical Simulation of Coal Gasification in Entrained Flow Gasifiers With CoalFoamDokument27 SeitenNumerical Simulation of Coal Gasification in Entrained Flow Gasifiers With CoalFoamoregano2000Noch keine Bewertungen

- 3.2 Design Parameters and CalculationsDokument9 Seiten3.2 Design Parameters and CalculationsMasAmirahNoch keine Bewertungen

- Create and Customize Your Physical ModelsDokument30 SeitenCreate and Customize Your Physical Modelsraul19rsNoch keine Bewertungen

- Shaftseal Chapter2 PDFDokument20 SeitenShaftseal Chapter2 PDFImmanuel AutomatonNoch keine Bewertungen

- Tutorial MultiphaseInterFoamDokument21 SeitenTutorial MultiphaseInterFoamAnonymous 9pln4v92SNoch keine Bewertungen

- 37 - 4 - Washington DC - 08-92 - 1855 PDFDokument9 Seiten37 - 4 - Washington DC - 08-92 - 1855 PDFMohamadMostafaviNoch keine Bewertungen

- Hybrid Recuperator Saves Energy for Glass ArtisansDokument21 SeitenHybrid Recuperator Saves Energy for Glass ArtisansSubrata DasNoch keine Bewertungen

- A PPT Presentation On Rankine Based Heat Recovery System in Heavy Vehicles by Er. Moien Muzaffar BhatDokument14 SeitenA PPT Presentation On Rankine Based Heat Recovery System in Heavy Vehicles by Er. Moien Muzaffar BhatMoienNoch keine Bewertungen

- Desa2011 PDFDokument5 SeitenDesa2011 PDFTayyabIsmailNoch keine Bewertungen

- Fuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andDokument46 SeitenFuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andSandhya SundarNoch keine Bewertungen

- Assignment 3Dokument2 SeitenAssignment 3KejriRajNoch keine Bewertungen

- Arora S IOD Chapter 2Dokument40 SeitenArora S IOD Chapter 2Ivan100% (1)

- Heat - Mass Balance at ULCOS PDFDokument3 SeitenHeat - Mass Balance at ULCOS PDFROWHEITNoch keine Bewertungen

- EES Code For Transient SystemDokument2 SeitenEES Code For Transient SystemDhrupad Parikh0% (1)

- Modelling Soot Formation During Biomass Gasification2020Renewable and Sustainable Energy ReviewsDokument13 SeitenModelling Soot Formation During Biomass Gasification2020Renewable and Sustainable Energy ReviewsLuiza L. Dos AnjosNoch keine Bewertungen

- EconomiserDokument19 SeitenEconomiserGaurav KumarNoch keine Bewertungen

- ME 401 Internal Combustion Engines AssignmentDokument7 SeitenME 401 Internal Combustion Engines AssignmentRysul Kabir100% (1)

- Maximizing Biomass Resources with Small Scale Gas Turbine PowerDokument7 SeitenMaximizing Biomass Resources with Small Scale Gas Turbine PowerpradeepdeceNoch keine Bewertungen

- Simulation of Compressors With The Help of An Engineering EquatiDokument9 SeitenSimulation of Compressors With The Help of An Engineering EquatiFernandoFloresNoch keine Bewertungen

- A Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Dokument20 SeitenA Major Project ON Biodiesel Production From Waste Cooking Oil (Literature and Planning)Ankur SemleNoch keine Bewertungen

- 2500 KW Forced Draft Cooling TowerDokument2 Seiten2500 KW Forced Draft Cooling Towerleojay24Noch keine Bewertungen

- Khan 2000Dokument18 SeitenKhan 2000HIMANSHU YADAVNoch keine Bewertungen

- Residualstresslaserwelding 141216211007 Conversion Gate02Dokument18 SeitenResidualstresslaserwelding 141216211007 Conversion Gate02mostafaNoch keine Bewertungen

- Fraccionamiento y AbsorciónDokument36 SeitenFraccionamiento y AbsorciónWilder GanozaNoch keine Bewertungen

- CFD vs empirical flare calculationsDokument15 SeitenCFD vs empirical flare calculationsRicardo BecNoch keine Bewertungen

- Chlorine: International Thermodynamic Tables of the Fluid StateVon EverandChlorine: International Thermodynamic Tables of the Fluid StateNoch keine Bewertungen

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectVon EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectNoch keine Bewertungen

- Practical Chemical Thermodynamics for GeoscientistsVon EverandPractical Chemical Thermodynamics for GeoscientistsNoch keine Bewertungen

- Telequip Inc. bid proposal review September 2015Dokument1 SeiteTelequip Inc. bid proposal review September 2015cumpio425428Noch keine Bewertungen

- Storm Surge Typhoon RubyDokument5 SeitenStorm Surge Typhoon Rubycumpio425428Noch keine Bewertungen

- Typical Outloading SystemDokument1 SeiteTypical Outloading Systemcumpio425428Noch keine Bewertungen

- Barchart SteleronDokument4 SeitenBarchart Steleroncumpio425428Noch keine Bewertungen

- 30,000 DWT Dolomite Outloading FacilityDokument2 Seiten30,000 DWT Dolomite Outloading Facilitycumpio425428Noch keine Bewertungen

- Outloading SystemDokument1 SeiteOutloading Systemcumpio425428Noch keine Bewertungen

- Auxin Price Itugon (Sangilo) Rev. 3Dokument3 SeitenAuxin Price Itugon (Sangilo) Rev. 3cumpio425428Noch keine Bewertungen

- Jetty Draft SurveyDokument1 SeiteJetty Draft Surveycumpio425428Noch keine Bewertungen

- PPA Panganiban PortDokument1 SeitePPA Panganiban Portcumpio425428Noch keine Bewertungen

- Proposed Outloading Facilities of OreDokument1 SeiteProposed Outloading Facilities of Orecumpio425428Noch keine Bewertungen

- Auxin Price MargaritaDokument2 SeitenAuxin Price Margaritacumpio425428Noch keine Bewertungen

- Abcumpio MJV DP BillingDokument1 SeiteAbcumpio MJV DP Billingcumpio425428Noch keine Bewertungen

- Letter Cash Advances of MonsantoDokument2 SeitenLetter Cash Advances of Monsantocumpio425428Noch keine Bewertungen

- Rice Mill Final Set-up2-ModelDokument1 SeiteRice Mill Final Set-up2-Modelcumpio425428Noch keine Bewertungen

- Weight of Steel PlateDokument1 SeiteWeight of Steel Platecumpio425428Noch keine Bewertungen

- Weight Per Course Tank ADokument1 SeiteWeight Per Course Tank Acumpio425428Noch keine Bewertungen

- Fire Protection Labor Cost Final (Riofil Ref)Dokument2 SeitenFire Protection Labor Cost Final (Riofil Ref)cumpio425428Noch keine Bewertungen

- Adsorption Tank DesignDokument4 SeitenAdsorption Tank Designcumpio425428Noch keine Bewertungen

- 12.5 Ton Per Hour Sugar RefineryDokument1 Seite12.5 Ton Per Hour Sugar Refinerycumpio425428Noch keine Bewertungen

- Price Proposal For Pulp SamplerDokument2 SeitenPrice Proposal For Pulp Samplercumpio425428Noch keine Bewertungen

- CCF02212015 0001Dokument1 SeiteCCF02212015 0001cumpio425428Noch keine Bewertungen

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDokument7 SeitenYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf Printercumpio425428Noch keine Bewertungen

- Ore Asia Thickener QuoteDokument2 SeitenOre Asia Thickener Quotecumpio425428Noch keine Bewertungen

- CC F 02262015Dokument1 SeiteCC F 02262015cumpio425428Noch keine Bewertungen

- A.B. Cumpio Engineering Services: Agro Power PhilippinesDokument3 SeitenA.B. Cumpio Engineering Services: Agro Power Philippinescumpio425428Noch keine Bewertungen

- SDP of Dump PitDokument1 SeiteSDP of Dump Pitcumpio425428Noch keine Bewertungen

- TVI Venture Nickel Outloading Facilities-ModelDokument1 SeiteTVI Venture Nickel Outloading Facilities-Modelcumpio425428Noch keine Bewertungen

- CC F 02112015Dokument1 SeiteCC F 02112015cumpio425428Noch keine Bewertungen

- Affidavit of LossDokument1 SeiteAffidavit of LossNowhere Man100% (1)

- Bangladesh Turbo GeneratorDokument1 SeiteBangladesh Turbo Generatorcumpio425428Noch keine Bewertungen

- ABSCESSDokument35 SeitenABSCESSlax prajapatiNoch keine Bewertungen

- Classification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialsDokument5 SeitenClassification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialssivaenotesNoch keine Bewertungen

- M-LVDT: Microminiature Displacement SensorDokument2 SeitenM-LVDT: Microminiature Displacement Sensormahdi mohammadiNoch keine Bewertungen

- Dimensional Data: For Valves and ActuatorsDokument52 SeitenDimensional Data: For Valves and ActuatorsPaulNoch keine Bewertungen

- The Girls Center: 2023 Workout CalendarDokument17 SeitenThe Girls Center: 2023 Workout Calendark4270621Noch keine Bewertungen

- Week 6 Blood and Tissue FlagellatesDokument7 SeitenWeek 6 Blood and Tissue FlagellatesaemancarpioNoch keine Bewertungen

- Board Review Endocrinology A. ApiradeeDokument47 SeitenBoard Review Endocrinology A. ApiradeePiyasak NaumnaNoch keine Bewertungen

- Manual de Referencia PlanmecaDokument288 SeitenManual de Referencia PlanmecaJorge Escalona Hernandez100% (2)

- Parasitology Lecture Hosts, Symbiosis & TransmissionDokument10 SeitenParasitology Lecture Hosts, Symbiosis & TransmissionPatricia Ann JoseNoch keine Bewertungen

- LabyrinthDokument4 SeitenLabyrinthAyezaZuberyNoch keine Bewertungen

- Nitric OxideDokument20 SeitenNitric OxideGanesh V GaonkarNoch keine Bewertungen

- Full SyllabusDokument409 SeitenFull SyllabusSanthana BharathiNoch keine Bewertungen

- Gebauer 2012Dokument26 SeitenGebauer 2012Seán GallagherNoch keine Bewertungen

- BCM Continuous ImprovementDokument22 SeitenBCM Continuous ImprovementnikoNoch keine Bewertungen

- Genetics ProblemsDokument50 SeitenGenetics ProblemsTasneem SweedanNoch keine Bewertungen

- Cell City ProjectDokument8 SeitenCell City ProjectDaisy beNoch keine Bewertungen

- of Types of Nuclear ReactorDokument33 Seitenof Types of Nuclear Reactormandhir67% (3)

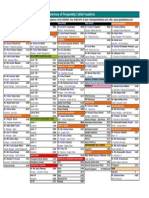

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDokument1 SeiteDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoNoch keine Bewertungen

- AZ ATTR Concept Test Clean SCREENERDokument9 SeitenAZ ATTR Concept Test Clean SCREENEREdwin BennyNoch keine Bewertungen

- Life Sciences Part 1 CSIR JRF NET GATE DBT PDFDokument132 SeitenLife Sciences Part 1 CSIR JRF NET GATE DBT PDFPavani Reddy68% (22)

- Medpet Pigeon ProductsDokument54 SeitenMedpet Pigeon ProductsJay Casem67% (3)

- Consumer Behaviour: Group ProjectDokument5 SeitenConsumer Behaviour: Group ProjectAanchal MahajanNoch keine Bewertungen

- New Microsoft Excel WorksheetDokument4 SeitenNew Microsoft Excel WorksheetRaheel Neo AhmadNoch keine Bewertungen

- PERSONS Finals Reviewer Chi 0809Dokument153 SeitenPERSONS Finals Reviewer Chi 0809Erika Angela GalceranNoch keine Bewertungen

- EcoLettsandSOM, Dulvy Et Al 2004Dokument25 SeitenEcoLettsandSOM, Dulvy Et Al 2004Nestor TorresNoch keine Bewertungen

- Impact of Energy Consumption On The EnvironmentDokument9 SeitenImpact of Energy Consumption On The Environmentadawiyah sofiNoch keine Bewertungen

- ItilDokument11 SeitenItilNarendar P100% (2)

- Soal Upk B Inggris PKBM WinaDokument11 SeitenSoal Upk B Inggris PKBM WinaCuman MitosNoch keine Bewertungen

- Bentel J408Dokument64 SeitenBentel J408Bojan MarkovicNoch keine Bewertungen

- Soal UTS Bahasa Inggris SMP Semester Genap Tahun Ajaran 2020Dokument5 SeitenSoal UTS Bahasa Inggris SMP Semester Genap Tahun Ajaran 2020awan MustofaNoch keine Bewertungen