Beruflich Dokumente

Kultur Dokumente

ABS

Hochgeladen von

Isman SyarifCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ABS

Hochgeladen von

Isman SyarifCopyright:

Verfügbare Formate

ANTI LOCK BRAKING SYSTEM

Introduction

Wheel lockup during braking causes skidding

which in turn cause a loss of traction and

vehicle control

This reduces the steering ability to change

direction. So the car slides out of control

With ABS system, the driver can brake hard,

take the evasive action and still be in control

of the vehicle in any road condition at any

speed and under any load.

Concept of ABS

A skidding wheel (where the tire contact

patch is sliding relative to the road) has less

traction than a non-skidding wheel

By keeping the wheels from skidding while

you slow down, anti-lock brakes benefit you

in two ways:

You'll stop faster, and you'll be able to steer

while you stop

comparison

Simple hydraulic braking system

A simple braking system

consists of a master

cylinder, and four wheel

cylinders

When the brake pedal is

pressed the piston in the

master cylinder forces the

liquid out of the cylinder.

This liquid presses the two

pistons in the wheel

cylinders outwards. These

two pistons push the brake

shoes out words.

Master cylinder

When the pedal is pressed

the primary piston moves to

the left .

when it crosses the bypass

port the liquid is forced

along the pipe lines to the

wheel cylinders.

When the pedal is released

the primary piston is moved

back wards .it is the spring,

which pushes the piston

back wards

Principles of ABS

The skidding and lack of

control was caused by the

locking of wheels.

The release and reapply of

the brake pedal will avoid

the locking of the wheels

which in turn avoid the

skidding.

This is exactly what an

antilock braking system

does.

Pressure modulation

When the brake pedal is pumped or pulsed the

pressure is quickly applied and released at the wheels.

This is called pressure modulation. Pressure

modulation works to prevent the wheel locking.

ABS can modulate the pressure to the brake as often

as 15 times per seconds

ABS precisely controls the slip rate of the wheels to

ensure maximum grip force from the tyre and it there

by ensures maneuverability and stability of the vehicle

Slip rate

During ABS operation, the

target slip rate can be

from 10 to 30%.

0% slip means the wheel

is rolling freely, while 100

% means the wheel is

fully locked.

A slip rate of 25 % means

the velocity of a wheel is

25 % less than that of a

freely rolling wheel at the

same vehicle speed

ABS components

Hydraulic components

1. Accumulator

An accumulator is used to store hydraulic fluid to

maintain high pressure in the brake system and provide

the residual pressure for power assisted braking

2. Antilock hydraulic control valve assembly

This assembly controls the release and application of

the brake system pressure to the wheel brake

assemblies .

It may be of integral type and non integral type

3. Booster pump

The booster pump is an assembly of an electric motor and

pump. The booster pump is used to provide pressurized

hydraulic fluid ABS

4. Booster/Master cylinder assembly

It is referred as the hydraulic unit, contains the valves and

pistons needed to modulate hydraulic pressure in the wheel

circuit during the ABS operations

5. Fluid accumulator

accumulator temporarily stored brake fluid that is removed

from the wheel brake unit during ABS cycle. This fluid is then

used by pump to build pressure for the brake hydraulic

system.

6. Hydraulic control unit

This assembly contains solenoid valve, fluid accumulator, pump

and electric motor. The unit may have one pump and one motor or

it have one motor and two pumps.

7. Main Valve

This is a two position valve and is also controlled by ABS control

module and is open only in the ABS mode.

8. Modulator unit

The modulator unit controls the flow of pressurized brake fluid to

the individual wheel circuits. Normally the modulator is made up of

solenoid that open and close valves

9. Solenoid valves

The solenoid valves are located in the modulator unit and are

electrically operated by signals from the control module

Electrical\ electronic components

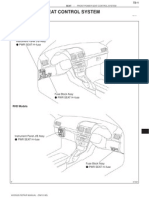

1. ABS control module fig

This small computer is normally mounted inside the trunk on

the wheel housing ,mounted to the master cylinder or is part

of the hydraulic control unit. It monitors system operation and

controls antilock function when needed

2. Brake pedal sensor

The antilock brake pedal sensor switch is normally closed.

when the brake pedal exceeds the antilock brake pedal

sensor switch setting during an antilock stop , the antilock

brake control module senses that the antilock brake pedal

sensor switch is open

3. Wheel speed sensor fig

It is mounted near the different toothed ring . as the rings

teeth rotate past the sensor an ac voltage is generated

Types of antilock brake systems

Four channel, four sensor ABS

This is the best scheme. there is speed sensor on all four

wheels and a separate valve for all the four wheels.

Three channel , three sensor ABS

This scheme is commonly found on pick up trucks with four

wheels ABS, has a speed sensor and a valve for each of the

front wheels, with one valve and one sensor for both rear

wheels.

One channel , one sensor ABS

it has one valve ,which controls both rear wheels , and one

speed sensor, located in the rear axle .

Four wheel system

The hydraulic circuit for this type of system is

an independent four channel type. One for

each wheel. The hydraulic control unit is a

separate unit

The system prevents wheel lock up during an

emergency stop by modulating brake

pressure

Operation

fig

Advancements

AUTOMATIC TRACTION CONTROL

(ATC)

AUTOMATIC STABILITY CONTROL

AUTOMATIC TRACTION CONTROL (ATC)

Automatic traction control

systems apply the brakes when

a drive wheel attempts to spin

and lose traction.

The system works best when

one drive wheel is working on a

good traction surface and the

other is not.

The system also works well

when the vehicle is accelerating

on slippery road surfaces,

especially when climbing hills.

AUTOMATIC STABILITY CONTROL

Stability control systems

momentarily apply the

brakes at any one wheel to

correct over steer or under

steer.

The control unit receives

signals from the typical

sensors plus a yaw, lateral

acceleration (G-force) and a

steering angle sensor

ESP

Advantages

It allows the driver to maintain directional stability

and control over steering during braking

Safe and effective

Automatically changes the brake fluid pressure at

each wheel to maintain optimum brake performance.

ABS absorbs the unwanted turbulence shock waves

and modulates the pulses thus permitting the wheel

to continue turning under maximum braking

pressure.

Disadvantages

It is very costly

Maintenance cost of a car equipped with

ABS is more.

Conclusion

Statistics show that approximately 40 % of

automobile accidents are due to skidding.

These problems commonly occur on vehicle

with conventional brake system which can be

avoided by adding devices called ABS

If there is an ABS failure, the system will

revert to normal brake operation. Normally

the ABS warning light will turn on and let the

driver know there is a fault

Wheel speed sensor

Back

ABS control module

Back

Back

Das könnte Ihnen auch gefallen

- HMC Accident Repair Getz BodyDokument6 SeitenHMC Accident Repair Getz BodyAnon BoletusNoch keine Bewertungen

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesVon EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNoch keine Bewertungen

- Camshaft Sensor 2.4 MitsubishiDokument14 SeitenCamshaft Sensor 2.4 MitsubishiJoselorenzo Torres ANoch keine Bewertungen

- 250-1859 Rostra - Com Cruise ControlDokument12 Seiten250-1859 Rostra - Com Cruise ControlimirzacNoch keine Bewertungen

- Porsche Transmission DTC Diag&Troubleshooting PDFDokument38 SeitenPorsche Transmission DTC Diag&Troubleshooting PDFThibault ChapelNoch keine Bewertungen

- Front Shock Absorber With Coil Spring: OverhaulDokument28 SeitenFront Shock Absorber With Coil Spring: OverhaulMusat Catalin-MarianNoch keine Bewertungen

- Daewoo Nubira 1997-2004 General InformationDokument29 SeitenDaewoo Nubira 1997-2004 General InformationHenry SilvaNoch keine Bewertungen

- VW Passat B4 - Steering Column, Steering Column Tube and Steering WheelDokument12 SeitenVW Passat B4 - Steering Column, Steering Column Tube and Steering WheelNPNoch keine Bewertungen

- Peugeot All Models Wiring Diagrams - GeneralDokument30 SeitenPeugeot All Models Wiring Diagrams - GeneralLoki_YONoch keine Bewertungen

- Daewoo Service Manual Tail Lamp MatizDokument12 SeitenDaewoo Service Manual Tail Lamp Matizjulio797Noch keine Bewertungen

- 306 ArticlesDokument80 Seiten306 ArticlesSalie BehardienNoch keine Bewertungen

- HowStuffWorks - Benefits of Hill-Start ControlDokument3 SeitenHowStuffWorks - Benefits of Hill-Start ControlfrapedNoch keine Bewertungen

- Seat - PoweredDokument39 SeitenSeat - PoweredMusat Catalin-MarianNoch keine Bewertungen

- XK8 CATS SuspensionDokument6 SeitenXK8 CATS Suspensionjuha_teuvonnen100% (1)

- Electric Power Steering Line CardDokument2 SeitenElectric Power Steering Line Card刘牛Noch keine Bewertungen

- ASNU CatalogDokument82 SeitenASNU CataloggnndelimaNoch keine Bewertungen

- Timing Cover 190EDokument8 SeitenTiming Cover 190ESergio Belmar CrisostoNoch keine Bewertungen

- Aygo MMT ResetDokument3 SeitenAygo MMT ResetAlan Ghon100% (2)

- Sienna SparkPlug RemovalDokument17 SeitenSienna SparkPlug Removalazeemm1Noch keine Bewertungen

- LSD Manual PDFDokument13 SeitenLSD Manual PDFHector Muñoz SepulvedaNoch keine Bewertungen

- FaultMemoryList VIN7-B914278 PDFDokument2 SeitenFaultMemoryList VIN7-B914278 PDFZakaria ElNoch keine Bewertungen

- DSB 240LHDokument96 SeitenDSB 240LHGuillermo HernandezNoch keine Bewertungen

- Current Flow Diagram Seats Heating VW Golf 5Dokument5 SeitenCurrent Flow Diagram Seats Heating VW Golf 5Marius NeaguNoch keine Bewertungen

- WiringDokument561 SeitenWiringMario ZentenoNoch keine Bewertungen

- Guided Procedure: 2048 - Clutch Pedal Switch Set Too LowDokument1 SeiteGuided Procedure: 2048 - Clutch Pedal Switch Set Too LowMessi EmetievNoch keine Bewertungen

- Front Suspension PDFDokument19 SeitenFront Suspension PDFspeedkar9Noch keine Bewertungen

- I10 - 2014 PDFDokument6 SeitenI10 - 2014 PDFPatricio ValenciaNoch keine Bewertungen

- VW AG4 (097 / 01N) : Ganzeboom Transmission Parts & Torque ConvertersDokument2 SeitenVW AG4 (097 / 01N) : Ganzeboom Transmission Parts & Torque ConvertersMustafa KoperNoch keine Bewertungen

- Nissan X-Trail 32. Manual - Part 167Dokument3 SeitenNissan X-Trail 32. Manual - Part 167Grenyher Nieves SanchezNoch keine Bewertungen

- 017 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - On VehicleDokument98 Seiten017 - Automatic Transmission - 6T70 (M7U M7W) - Repair Instructions - On VehicleGedas GvildysNoch keine Bewertungen

- Installation Instructions 30-5130Dokument8 SeitenInstallation Instructions 30-5130alexcus1539Noch keine Bewertungen

- Auto Gear Shift Technology (AGS) or Auto Manual Transmission (AMT)Dokument5 SeitenAuto Gear Shift Technology (AGS) or Auto Manual Transmission (AMT)Ahmed YousfiNoch keine Bewertungen

- General Information: Section 0BDokument3.772 SeitenGeneral Information: Section 0BLeandro Lcar AutomotivoNoch keine Bewertungen

- 406 Coupe PDFDokument137 Seiten406 Coupe PDFNeverfeelsorryNoch keine Bewertungen

- Electricalcomponentlocations 131222071900 Phpapp02Dokument91 SeitenElectricalcomponentlocations 131222071900 Phpapp02petcucatalinnNoch keine Bewertungen

- 2002 Peugeot 307 SWDokument137 Seiten2002 Peugeot 307 SWClaude SefakoNoch keine Bewertungen

- 301 - D6AX09WGP0!20!27!09!2019 - Informations - Fault Code U1F2E 87 (Built-In Systems Interface)Dokument1 Seite301 - D6AX09WGP0!20!27!09!2019 - Informations - Fault Code U1F2E 87 (Built-In Systems Interface)Mohammed Awwal NdayakoNoch keine Bewertungen

- Daewoo Matiz - Hydraulic BrakesDokument14 SeitenDaewoo Matiz - Hydraulic BrakesadrianNoch keine Bewertungen

- Optra hv2401-1Dokument32 SeitenOptra hv2401-1FabricioNoch keine Bewertungen

- 5sfe Timing Belt DYIDokument14 Seiten5sfe Timing Belt DYIchasquareNoch keine Bewertungen

- VW Passat B5 1.8T Timing Belt Replacement DIYDokument26 SeitenVW Passat B5 1.8T Timing Belt Replacement DIYaweed100% (1)

- ConnectorQuickReferenceGuide PDFDokument2 SeitenConnectorQuickReferenceGuide PDFBoleslaw ZarasNoch keine Bewertungen

- Advanced Chassis and Body Control Systems-Part2Dokument60 SeitenAdvanced Chassis and Body Control Systems-Part2aliNoch keine Bewertungen

- CHEVROLET (DAEWOO) Lacetti (J200) 1.8 16V F18D3: Timing Belt: Removal/installationDokument7 SeitenCHEVROLET (DAEWOO) Lacetti (J200) 1.8 16V F18D3: Timing Belt: Removal/installationJuan Jesus FernandesNoch keine Bewertungen

- Chasis Electrical SystemDokument5 SeitenChasis Electrical SystemMirko Aldair Ramos CamposNoch keine Bewertungen

- New Features - c59 Transmission PDFDokument2 SeitenNew Features - c59 Transmission PDFIvan Torres VillalobosNoch keine Bewertungen

- Nissan Murano Engine Air Intake DuctDokument8 SeitenNissan Murano Engine Air Intake DuctenkcyongNoch keine Bewertungen

- 3587ADokument45 Seiten3587Aainginer100% (2)

- Captiva 2008 Out Speed Sensor ReemplacementDokument3 SeitenCaptiva 2008 Out Speed Sensor ReemplacementJose Luis Velasquez RomeroNoch keine Bewertungen

- Petrol Engine Twin Camshaft Setting-Locking Tool KitsDokument9 SeitenPetrol Engine Twin Camshaft Setting-Locking Tool KitsCristian CernaNoch keine Bewertungen

- Hyundai Excel X2 1989-1998 Air Conditioning PDFDokument53 SeitenHyundai Excel X2 1989-1998 Air Conditioning PDFAamir Nasir KhanNoch keine Bewertungen

- Engine IdentificationDokument47 SeitenEngine Identificationgerber damianNoch keine Bewertungen

- B10a8 Air Bag PDFDokument6 SeitenB10a8 Air Bag PDFDaniel Garcia100% (1)

- SML Isuzu Luxury Bus LT134Dokument1 SeiteSML Isuzu Luxury Bus LT134Sukhdeep100% (1)

- Data Sheet Nissan NavaraDokument1 SeiteData Sheet Nissan NavaraSebastián Valencia100% (1)

- 2021 Kia Sorento 116225Dokument700 Seiten2021 Kia Sorento 116225Tien Nguyen TatNoch keine Bewertungen

- Anti Lock Braking SystemDokument29 SeitenAnti Lock Braking SystemRaghavendra RaghavNoch keine Bewertungen

- My PPT AbsDokument27 SeitenMy PPT AbsTigerSrinivasanNoch keine Bewertungen

- Antilock Braking System PDFDokument35 SeitenAntilock Braking System PDFjatinshukla431Noch keine Bewertungen

- Improvement of Thermal Efficiency by Recovery of Heat From Ic Engine ExhaustDokument22 SeitenImprovement of Thermal Efficiency by Recovery of Heat From Ic Engine ExhaustPravin DeshmaneNoch keine Bewertungen

- Mahindra Bolero Maxx Pik Up HD BrochureDokument4 SeitenMahindra Bolero Maxx Pik Up HD BrochurePravin DeshmaneNoch keine Bewertungen

- Hydraulic Pneumatic BrakesDokument14 SeitenHydraulic Pneumatic Brakesabyzen100% (1)

- Automobile TiresDokument6 SeitenAutomobile TiresPravin DeshmaneNoch keine Bewertungen

- Advanced Safety System in AutomobilesDokument26 SeitenAdvanced Safety System in AutomobilesPravin DeshmaneNoch keine Bewertungen

- Advanced Safety System in AutomobilesDokument26 SeitenAdvanced Safety System in AutomobilesPravin DeshmaneNoch keine Bewertungen

- Six Stroke EngineDokument21 SeitenSix Stroke Engineinder_sandhuNoch keine Bewertungen

- Energy Forms and ChangesDokument44 SeitenEnergy Forms and Changesdoudouthekiller100% (1)

- 336392214Dokument5 Seiten336392214Pravin DeshmaneNoch keine Bewertungen

- Vapour Compression RefrigerationDokument38 SeitenVapour Compression RefrigerationArvind75% (4)

- CNCDokument31 SeitenCNCPravin DeshmaneNoch keine Bewertungen

- CompressorsDokument51 SeitenCompressorsReza RahmanudinNoch keine Bewertungen

- Air CompressorDokument31 SeitenAir CompressorEr Bali Pandhare33% (3)

- Ankur Seeds Pvt. LTD.: (0712) 2726148, 2725117, Fax No.: (0712) 2723455Dokument3 SeitenAnkur Seeds Pvt. LTD.: (0712) 2726148, 2725117, Fax No.: (0712) 2723455Pravin DeshmaneNoch keine Bewertungen

- Emission Control On IC EngineDokument18 SeitenEmission Control On IC Enginetarunskumar89% (19)

- Ankur Seeds Pvt. LTD.: (0712) 2726148, 2725117, Fax No.: (0712) 2723455Dokument3 SeitenAnkur Seeds Pvt. LTD.: (0712) 2726148, 2725117, Fax No.: (0712) 2723455Pravin DeshmaneNoch keine Bewertungen

- Agronomic EvaluationDokument10 SeitenAgronomic EvaluationnaraganahalliyogenNoch keine Bewertungen

- Planting RiceDokument14 SeitenPlanting RicePravin DeshmaneNoch keine Bewertungen

- Planting RiceDokument14 SeitenPlanting RicePravin DeshmaneNoch keine Bewertungen

- Simulation of Haulage Performance of 2WD Agricultural Tractor in Visual BasicDokument87 SeitenSimulation of Haulage Performance of 2WD Agricultural Tractor in Visual BasicPravin DeshmaneNoch keine Bewertungen

- 4 Project Planning WorksheetDokument2 Seiten4 Project Planning WorksheetPravin DeshmaneNoch keine Bewertungen

- PDF Articles 1 10Dokument35 SeitenPDF Articles 1 10Ahmed TrabelsiNoch keine Bewertungen

- Trimitra Asri TamaDokument9 SeitenTrimitra Asri TamaRecky PahleviNoch keine Bewertungen

- Drive Train: Catalog Data SheetDokument3 SeitenDrive Train: Catalog Data SheetGustavo MosqueraNoch keine Bewertungen

- Functional Requirements of 8 Transportation Systems in A Building.Dokument40 SeitenFunctional Requirements of 8 Transportation Systems in A Building.Umar Faruq AfokeNoch keine Bewertungen

- AR-WIM BrochureDokument2 SeitenAR-WIM BrochureFidaNoch keine Bewertungen

- Magazine - Diesel - Power - July - 2016Dokument188 SeitenMagazine - Diesel - Power - July - 2016robertoNoch keine Bewertungen

- Use Only: Operator ManualDokument66 SeitenUse Only: Operator ManualСергейNoch keine Bewertungen

- FMVSS 121Dokument83 SeitenFMVSS 121linh caca huynhNoch keine Bewertungen

- Filter Assy-Engine Oil 2630002752Dokument1 SeiteFilter Assy-Engine Oil 2630002752Smart Parts ExportsNoch keine Bewertungen

- Manual John Deere Gator XUV 850DDokument2 SeitenManual John Deere Gator XUV 850Djoel blancoNoch keine Bewertungen

- Cavalry US Field ManualDokument356 SeitenCavalry US Field ManualRyan ThomasNoch keine Bewertungen

- 1 (B) Advance - Aansoekvorm - Application Form - MasterDokument7 Seiten1 (B) Advance - Aansoekvorm - Application Form - MasterbesterkailaNoch keine Bewertungen

- Oem20cross20ref20paper208 08 1B.220143602Dokument104 SeitenOem20cross20ref20paper208 08 1B.220143602Adriana100% (1)

- Gasoline-Powered Forklift / Specification SheetDokument8 SeitenGasoline-Powered Forklift / Specification SheetLuis A DuarteNoch keine Bewertungen

- Name: Teacher: Date: Score:: Distance, Rate, and Time Word ProblemsDokument2 SeitenName: Teacher: Date: Score:: Distance, Rate, and Time Word ProblemsChunlyNoch keine Bewertungen

- Ergonomics As A Concept: For More Notes, Presentations, Project Reports VisitDokument19 SeitenErgonomics As A Concept: For More Notes, Presentations, Project Reports Visitkamdica91% (11)

- CVT CalculationsDokument7 SeitenCVT CalculationsNimitesh SinghNoch keine Bewertungen

- Fabrication Propeller Shaft Using in Two WheelerDokument4 SeitenFabrication Propeller Shaft Using in Two WheelerSURESHNoch keine Bewertungen

- Maintenance Hub Reduction PDFDokument22 SeitenMaintenance Hub Reduction PDFrachmat ary wibowoNoch keine Bewertungen

- 1.0 PM (IPte) Hilux Price ListDokument1 Seite1.0 PM (IPte) Hilux Price ListdddNoch keine Bewertungen

- Dispatch TrainingDokument4 SeitenDispatch TrainingAbdirahman AbdirizaqNoch keine Bewertungen

- AWD+COM - IVECO-Daily-4x4 (4seitig) - ENDokument3 SeitenAWD+COM - IVECO-Daily-4x4 (4seitig) - ENn.kettou.86Noch keine Bewertungen

- Models FA and FB: IDENTIFICATION INFORMATION ................................................ 1-2Dokument4 SeitenModels FA and FB: IDENTIFICATION INFORMATION ................................................ 1-2Komatsu Perkins HitachiNoch keine Bewertungen

- A Message To Hyundai Fork Lift Truck OperatorsDokument106 SeitenA Message To Hyundai Fork Lift Truck OperatorsDarwin Yarleque FloresNoch keine Bewertungen

- E-Mail:: (EBS Gen3 MID136 - 4x2)Dokument3 SeitenE-Mail:: (EBS Gen3 MID136 - 4x2)nikitaNoch keine Bewertungen

- Forklift Safety TrainingDokument22 SeitenForklift Safety TrainingSteve DonardNoch keine Bewertungen

- Danymics - Homeworks - Chapter 3 Kinetics of Particles - Energy and Momentum MethodsDokument3 SeitenDanymics - Homeworks - Chapter 3 Kinetics of Particles - Energy and Momentum MethodsRed DemonsNoch keine Bewertungen

- "Goldhofer" Hydraulic Platform Trailer 10 Axles With Prime Mover 1 UnitDokument1 Seite"Goldhofer" Hydraulic Platform Trailer 10 Axles With Prime Mover 1 UnitPriyoNoch keine Bewertungen

- ICU3 To ICU3S Replacement Guidelines: General InformationDokument10 SeitenICU3 To ICU3S Replacement Guidelines: General Informationmahamane zakari salifou kallamNoch keine Bewertungen

- 3CX 4CX IssueDokument26 Seiten3CX 4CX IssueMez Nacer0% (1)