Beruflich Dokumente

Kultur Dokumente

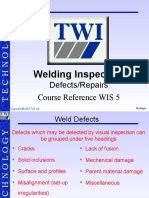

Defect Training

Hochgeladen von

dedikartiwa_dkCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Defect Training

Hochgeladen von

dedikartiwa_dkCopyright:

Verfügbare Formate

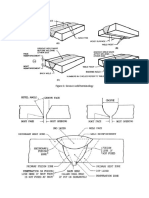

Cold lap is a condition where the weld filler metal does not properly fuse with

the base metal or the previous weld pass material (interpass cold lap). The arc

does not melt the base metal sufficiently and causes the slightly molten puddle

to flow into the base material without bonding.

Cap Undercut

Intermittent

Cap Undercut

Intermittent

Slag

Inclusion

Arc Strike

Porosity

Lack of

fusion

Cap Undercut

Intermittent

Arc Strike

Incomplete Filled Groove

Porosity is the result of gas entrapment in the solidifying metal. Porosity can take many

shapes on a radiograph but often appears as dark round or irregular spots or specks

appearing singularly, in clusters, or in rows. Sometimes, porosity is elongated and

may appear to have a tail. This is the result of gas attempting to escape while the

metal is still in a liquid state and is called wormhole porosity. All porosity is a void in

the material and it will have a higher radiographic density than the surrounding area

Lack of Sidewall Fusion

Incomplete Filled Groove

Overlap and Excess Cap Height Full Weld Length

Surface Slag

Porosity

Lack of Sidewall

Fusion

Cluster porosity is caused when flux coated electrodes are contaminated with

moisture. The moisture turns into a gas when heated and becomes trapped

in the weld during the welding process. Cluster porosity appear just like

regular porosity in the radiograph but the indications will be grouped close

together.

Cap Undercut

Intermittent

Cap Undercut

Intermittent

Slag

Inclusion

Arc Strike

Porosity

Lack of

fusion

Cap Undercut

Intermittent

Arc Strike

Incomplete Filled Groove

Slag inclusions are nonmetallic solid material entrapped in weld metal

or between weld and base metal. In a radiograph, dark, jagged

asymmetrical shapes within the weld or along the weld joint areas

are indicative of slag inclusions.

Cap Undercut

Intermittent

Cap Undercut

Intermittent

Slag

Inclusion

Arc Strike

Porosity

Lack of

fusion

Cap Undercut

Intermittent

Arc Strike

Incomplete Filled Groove

Incomplete penetration (IP) or lack of penetration (LOP) occurs when the weld metal

fails to penetrate the joint. It is one of the most objectionable weld discontinuities.

Lack of penetration allows a natural stress riser from which a crack may propagate.

The appearance on a radiograph is a dark area with well-defined, straight edges that

follows the land or root face down the center of the weldment.

Linear misalignment

Lack of root penetration

Mechanical damage

Lack of root penetration

Burn through

Lack of root fusion

Poor stop/start

Arc strike

Lack of root fusion

+ poor stop/start

Incomplete fusion is a condition where the weld filler metal does not

properly fuse with the base metal. Appearance on radiograph:

usually appears as a dark line or lines oriented in the direction of the

weld seam along the weld preparation or joining area.

Arc strike

Spatter

Lack of root

fusion

Lack of root

fusion

Root undercut intermittent

Lack of root

fusion

Lack of root

fusion

Spatter

Internal concavity or suck back is a condition where the weld metal has

contracted as it cools and has been drawn up into the root of the weld. On a

radiograph it looks similar to a lack of penetration but the line has irregular

edges and it is often quite wide in the center of the weld image.

Internal or root undercut is an erosion of the base metal next to the root of

the weld. In the radiographic image it appears as a dark irregular line offset

from the centerline of the weldment. Undercutting is not as straight edged

as LOP because it does not follow a ground edge.

Root undercut

intermittent

Ground flush root

Lack of penetration intermittent

Arc strike

External or crown undercut is an erosion of the base metal next to

the crown of the weld. In the radiograph, it appears as a dark

irregular line along the outside edge of the weld area.

Mechanical damage

Cap undercut

Cap undercut

Spatter/irregular cap profile

Offset or mismatch are terms associated with a condition where two pieces being

welded together are not properly aligned. The radiographic image shows a noticeable

difference in density between the two pieces. The difference in density is caused by

the difference in material thickness. The dark, straight line is caused by the failure of

the weld metal to fuse with the land area

Linear misalignment

Lack of root penetration

Mechanical damage

Lack of root penetration

Burn through

Lack of root fusion

Poor stop/start

Arc strike

Lack of root fusion

+ poor stop/start

Inadequate weld reinforcement is an area of a weld where the thickness of weld metal deposited is

less than the thickness of the base material. It is very easy to determine by radiograph if the weld

has inadequate reinforcement, because the image density in the area of suspected inadequacy

will be higher (darker) than the image density of the surrounding base material.

Longitudinal

Crack

Surface slag & Spatter

Cap Undercut

Incomplete

Filled Groove +

Lack of

Sidewall

Fusion

Slag Inclusion

Incomplete Filled Groove

+ Lack of Sidewall Fusion

+ Cap Undercut

Intermittent

Excess weld reinforcement is an area of a weld that has weld metal added in

excess of that specified by engineering drawings and codes. The

appearance on a radiograph is a localized, lighter area in the weld. A visual

inspection will easily determine if the weld reinforcement is in excess of that

specified by the engineering requirements.

Lack of Sidewall Fusion

Incomplete Filled Groove

Overlap and Excess Cap Height Full Weld Length

Surface Slag

Porosity

Lack of Sidewall

Fusion

Cracks can be detected in a radiograph only when they are propagating in a direction

that produces a change in thickness that is parallel to the x-ray beam. Cracks will

appear as jagged and often very faint irregular lines. Cracks can sometimes appear

as "tails" on inclusions or porosity.

Longitudinal

Crack

Surface slag & Spatter

Cap Undercut

Incomplete

Filled Groove +

Lack of

Sidewall

Fusion

Slag Inclusion

Incomplete Filled Groove

+ Lack of Sidewall Fusion

+ Cap Undercut

Intermittent

Tungsten inclusions. Tungsten is a brittle and inherently dense material used

in the electrode in tungsten inert gas welding. If improper welding

procedures are used, tungsten may be entrapped in the weld.

Radiographically, tungsten is more dense than aluminum or steel, therefore

it shows up as a lighter area with a distinct outline on the radiograph.

Oxide inclusions are usually visible on the surface of material being

welded (especially aluminum). Oxide inclusions are less dense than

the surrounding material and, therefore, appear as dark irregularly

shaped discontinuities in the radiograph.

Linear Misalignment

Plate corrosion

Lack of Root Fusion

Poor Stop/Start

Surface Slag

Parent material

gas cavities

Crater pipe

Surface slag

Burn-Through results when too much heat causes excessive weld metal to penetrate

the weld zone. Often lumps of metal sag through the weld, creating a thick globular

condition on the back of the weld. These globs of metal are referred to as icicles. On

a radiograph, burn-through appears as dark spots, which are often surrounded by

light globular areas (icicles).

Linear misalignment

Lack of root penetration

Mechanical damage

Lack of root penetration

Burn through

Lack of root fusion

Poor stop/start

Arc strike

Lack of root fusion

+ poor stop/start

Das könnte Ihnen auch gefallen

- Weld Radio GraphsDokument30 SeitenWeld Radio Graphsvenkatesh0% (1)

- Radiography Weld Defects GuideDokument50 SeitenRadiography Weld Defects GuideWisüttisäk Peäröön100% (2)

- Radiographic DefectsDokument20 SeitenRadiographic Defectshappysekhon86100% (1)

- Common weld discontinuities and defects guideDokument28 SeitenCommon weld discontinuities and defects guideAmyNoch keine Bewertungen

- Radiography PresentationDokument28 SeitenRadiography PresentationmqasimqasimNoch keine Bewertungen

- RT Interpretation-SignedDokument7 SeitenRT Interpretation-Signedhamdi hamdiNoch keine Bewertungen

- Defects in Fusion WeldingDokument83 SeitenDefects in Fusion WeldingBalakumar100% (1)

- Radiograph Interpretation (RT Film Interpretation)Dokument10 SeitenRadiograph Interpretation (RT Film Interpretation)Abu HurairaNoch keine Bewertungen

- Welding Imperfection and Material InspectionDokument62 SeitenWelding Imperfection and Material Inspectionintfarha10Noch keine Bewertungen

- Identify Welding Defects & DiscontinuitiesDokument21 SeitenIdentify Welding Defects & DiscontinuitiesJoanna AprilNoch keine Bewertungen

- Radiography InterpretationDokument13 SeitenRadiography InterpretationBhavin SukhadiyaNoch keine Bewertungen

- X-ray Films Reveal Welding DiscontinuitiesDokument12 SeitenX-ray Films Reveal Welding DiscontinuitiesAlienshowNoch keine Bewertungen

- RT Film InterpretationDokument20 SeitenRT Film InterpretationMOhammed PatelNoch keine Bewertungen

- Weld Defects AgfaDokument20 SeitenWeld Defects AgfaDinesh Radhakrishnan100% (1)

- Radiographic Testing: Basic Principles and TechniquesDokument48 SeitenRadiographic Testing: Basic Principles and TechniquesArjun LalitNoch keine Bewertungen

- Radiography Interpretation PDFDokument220 SeitenRadiography Interpretation PDFVijay Kumar100% (1)

- CSWIP Practical Plate AnswersDokument31 SeitenCSWIP Practical Plate AnswersSha Zha100% (1)

- Defects Hydrogen Cracks IdentificationDokument5 SeitenDefects Hydrogen Cracks Identificationarif maulanafNoch keine Bewertungen

- Casting DefectsDokument35 SeitenCasting DefectsYaser Mohamed AbasNoch keine Bewertungen

- Radiography TestDokument20 SeitenRadiography Testkrishna_pipingNoch keine Bewertungen

- MCQS .... CSWIP Questions and AnswersDokument67 SeitenMCQS .... CSWIP Questions and AnswersAli Kashif100% (1)

- Fundamentals of Visual InspectionDokument49 SeitenFundamentals of Visual InspectionsusanwebNoch keine Bewertungen

- Visual Weld Exam TrainingDokument64 SeitenVisual Weld Exam Trainingcarlos100% (1)

- Welding Inspection: Defects/Repairs Course Reference WIS 5Dokument54 SeitenWelding Inspection: Defects/Repairs Course Reference WIS 5verall_averusNoch keine Bewertungen

- Defects and Discontinuities GuideDokument77 SeitenDefects and Discontinuities GuideAnonymous 7ibtVlNoch keine Bewertungen

- Visual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)Dokument29 SeitenVisual Testing: - Asme - Section 5 (NDT) - Section 5 - Article 9 (VT)MAXX ENGINEERS100% (1)

- RT Technique Evaluation Dwsi of 1 Inch Dia PipeDokument3 SeitenRT Technique Evaluation Dwsi of 1 Inch Dia Pipemusaismail8863Noch keine Bewertungen

- @coating Book - Aramco Inspection HandbookDokument126 Seiten@coating Book - Aramco Inspection HandbookUmair AhmadNoch keine Bewertungen

- Radiographic Interpreter: Weld Defect Exercise Part 2Dokument12 SeitenRadiographic Interpreter: Weld Defect Exercise Part 2Nicko Arya Dharma100% (1)

- WeldingDokument9 SeitenWeldingkiraneluruNoch keine Bewertungen

- A General Review of The Causes and Acceptance of Shape ImperfectionsDokument7 SeitenA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekNoch keine Bewertungen

- Bend Test Acceptance CriteriADokument1 SeiteBend Test Acceptance CriteriAGowrisanthosh PalikaNoch keine Bewertungen

- MODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsDokument7 SeitenMODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsNsidibe Michael EtimNoch keine Bewertungen

- Macro Inspection Part IIDokument16 SeitenMacro Inspection Part IImohammed dallyNoch keine Bewertungen

- Aluminium Alloys: Weldability of Materials Job Knowledge 21Dokument3 SeitenAluminium Alloys: Weldability of Materials Job Knowledge 21kevin herryNoch keine Bewertungen

- Module 4 Weld Geometry and Welding Symbols-1Dokument87 SeitenModule 4 Weld Geometry and Welding Symbols-1Miki JaksicNoch keine Bewertungen

- RT Film Interpretation (Image - Guide)Dokument88 SeitenRT Film Interpretation (Image - Guide)sananth80100% (10)

- Welding Defects and Imperfections Identification GuideDokument35 SeitenWelding Defects and Imperfections Identification GuideAdil Hasanov100% (1)

- Radiography Weld Defects GuideDokument50 SeitenRadiography Weld Defects GuideAdilMunir100% (2)

- Welding Variables Guide: Effects of Current, Voltage, Speed & MoreDokument34 SeitenWelding Variables Guide: Effects of Current, Voltage, Speed & MoremilindNoch keine Bewertungen

- Radiographic Interpreter: Weld Defect Exercise Part 3Dokument12 SeitenRadiographic Interpreter: Weld Defect Exercise Part 3Nicko Arya Dharma100% (3)

- Using Welding Inspection ToolsDokument9 SeitenUsing Welding Inspection ToolsVinoth RajendraNoch keine Bewertungen

- Pipeline Inspector 1667834732Dokument57 SeitenPipeline Inspector 1667834732Dhani de EngineurNoch keine Bewertungen

- WPS PresentationDokument27 SeitenWPS PresentationSenthil Kumar50% (2)

- Casting DefectsDokument5 SeitenCasting DefectsGurjinder SinghNoch keine Bewertungen

- CSWIP 3.2 LATEST WIS10-Mar-2011Dokument303 SeitenCSWIP 3.2 LATEST WIS10-Mar-2011Mohamed Faris100% (8)

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- RADIOGRAPHY FILM INTERPRETATION GUIDEDokument16 SeitenRADIOGRAPHY FILM INTERPRETATION GUIDERavindra S. Jivani100% (1)

- RT Interpretation DefectsDokument12 SeitenRT Interpretation Defectsbenergy84Noch keine Bewertungen

- Helpful RT Article and PhotosDokument8 SeitenHelpful RT Article and Photosponnivalavans_994423Noch keine Bewertungen

- Radiograph InterpretationDokument12 SeitenRadiograph InterpretationnithingrmeNoch keine Bewertungen

- Defect-TrainingDokument16 SeitenDefect-TrainingSubhashNoch keine Bewertungen

- Photos of Defects Found in RadiographyDokument14 SeitenPhotos of Defects Found in RadiographyKavipriyan KaviNoch keine Bewertungen

- Welding FLAWSDokument86 SeitenWelding FLAWSrohitbhat2345Noch keine Bewertungen

- Radiograph Interpretation - WeldsDokument6 SeitenRadiograph Interpretation - WeldsPercy Morales RamirezNoch keine Bewertungen

- Radiographic DefectsDokument20 SeitenRadiographic DefectsUsman AhmedNoch keine Bewertungen

- Welding DefectsDokument15 SeitenWelding DefectsAYUSH TRIVEDI100% (1)

- Welding Inspection Guide: Identifying Defects & Making RepairsDokument40 SeitenWelding Inspection Guide: Identifying Defects & Making RepairsAbdulateaf SattiNoch keine Bewertungen

- Radiographic Film Interpretation - Presentation-1 PDFDokument87 SeitenRadiographic Film Interpretation - Presentation-1 PDFvirat virat90% (10)

- WeldingDokument41 SeitenWeldinggigiphiNoch keine Bewertungen

- Standards For Material Handling, Storage, and DisposalDokument13 SeitenStandards For Material Handling, Storage, and Disposaljeb13Noch keine Bewertungen

- Movement JointsDokument4 SeitenMovement JointsArnold TunduliNoch keine Bewertungen

- Control Rods of Rubber Flexible JointDokument2 SeitenControl Rods of Rubber Flexible Jointdedikartiwa_dkNoch keine Bewertungen

- MP&MH 2012 (Apr-Nov)Dokument1 SeiteMP&MH 2012 (Apr-Nov)dedikartiwa_dkNoch keine Bewertungen

- Removal of Expansion Join's Bolts & Nuts: No. Photos Before Photos After No. Photos Photos AfterDokument3 SeitenRemoval of Expansion Join's Bolts & Nuts: No. Photos Before Photos After No. Photos Photos Afterdedikartiwa_dkNoch keine Bewertungen

- Collar TypeDokument1 SeiteCollar Typededikartiwa_dkNoch keine Bewertungen

- Pipe Flow Friction Factor CalculationsDokument14 SeitenPipe Flow Friction Factor Calculationsdedikartiwa_dkNoch keine Bewertungen

- ViskositasDokument1 SeiteViskositasnawrim_sugaNoch keine Bewertungen

- Quality Measurement Tool & Tester ListDokument1 SeiteQuality Measurement Tool & Tester Listdedikartiwa_dkNoch keine Bewertungen

- Request For Field InspectionDokument1 SeiteRequest For Field Inspectiondedikartiwa_dkNoch keine Bewertungen

- TIASA - Thermal Insulation HandbookDokument58 SeitenTIASA - Thermal Insulation HandbookSirGawain99Noch keine Bewertungen

- LPG Air Mixing 2 A3Dokument1 SeiteLPG Air Mixing 2 A3ambientinstal instalNoch keine Bewertungen

- Kaeser ASD SeriesDokument5 SeitenKaeser ASD SeriesSachith VidanapathiranaNoch keine Bewertungen

- 21 TSRT PR 21 Mechanical PrecommissionngDokument8 Seiten21 TSRT PR 21 Mechanical Precommissionngdedikartiwa_dkNoch keine Bewertungen

- Measuring Petroleum StandardsDokument101 SeitenMeasuring Petroleum StandardsJonathan Narh-DometeyNoch keine Bewertungen

- Rp150 Juta Penawaran Harga Tank RO 230x340Dokument2 SeitenRp150 Juta Penawaran Harga Tank RO 230x340dedikartiwa_dkNoch keine Bewertungen

- Underground LPG SDokument1 SeiteUnderground LPG Sdedikartiwa_dkNoch keine Bewertungen

- Pressure Drop Excel VB FormatDokument4 SeitenPressure Drop Excel VB Formatsiva242245Noch keine Bewertungen

- Piping Identification and Valve Tagging PDFDokument5 SeitenPiping Identification and Valve Tagging PDFdedikartiwa_dkNoch keine Bewertungen

- Velocity Profile Circular PipeDokument4 SeitenVelocity Profile Circular Pipededikartiwa_dkNoch keine Bewertungen

- Road Vehicle Safety TalkDokument12 SeitenRoad Vehicle Safety Talkdedikartiwa_dkNoch keine Bewertungen

- Piping Identification and Valve Tagging StandardDokument6 SeitenPiping Identification and Valve Tagging Standardmanox007Noch keine Bewertungen

- SDS - Aluflex - Marine - Protective - English (Uk) - United KiDokument5 SeitenSDS - Aluflex - Marine - Protective - English (Uk) - United KiAndres Fitria FarrelNoch keine Bewertungen

- Calibration Checklist for Monitoring DevicesDokument1 SeiteCalibration Checklist for Monitoring Devicesdedikartiwa_dkNoch keine Bewertungen

- Equipment Commissioning ChecklistDokument20 SeitenEquipment Commissioning ChecklistDheeraj Yadav100% (2)

- SDS - Barrier - Comp. B - Marine - Protective - Indonesian (IdDokument7 SeitenSDS - Barrier - Comp. B - Marine - Protective - Indonesian (Iddedikartiwa_dkNoch keine Bewertungen

- SDS - Alkydprimer - Marine - Protective - English (Uk) - UniteDokument6 SeitenSDS - Alkydprimer - Marine - Protective - English (Uk) - UniteAndres Fitria FarrelNoch keine Bewertungen

- Pipe Sizes Chart Nominal Outside DiametersDokument1 SeitePipe Sizes Chart Nominal Outside Diametersdedikartiwa_dkNoch keine Bewertungen

- RIT Pipe Lmnabeling Painting and Valve Tag Standard 03 01 2013Dokument3 SeitenRIT Pipe Lmnabeling Painting and Valve Tag Standard 03 01 2013dedikartiwa_dkNoch keine Bewertungen

- Piping Identification and Valve Tagging PDFDokument5 SeitenPiping Identification and Valve Tagging PDFdedikartiwa_dkNoch keine Bewertungen

- NG22 282 CST PSL 100011 - Revc0Dokument9 SeitenNG22 282 CST PSL 100011 - Revc0Theophilus OrupaboNoch keine Bewertungen

- Cleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and SystemsDokument13 SeitenCleaning, Descaling, and Passivation of Stainless Steel Parts, Equipment, and SystemsLuis Fernando Castrillón MadrigalNoch keine Bewertungen

- NAS1581 GenuineAircraftHardwareDokument2 SeitenNAS1581 GenuineAircraftHardwareBogdan RusuNoch keine Bewertungen

- Anodic ProtectionDokument30 SeitenAnodic ProtectionLuis Eduardo PereiraNoch keine Bewertungen

- Astm A105Dokument5 SeitenAstm A105mahamad AziNoch keine Bewertungen

- Betamate 2090Dokument4 SeitenBetamate 2090José Antonio CuberoNoch keine Bewertungen

- JUNE 2022 Surplus Record Machinery & Equipment DirectoryDokument718 SeitenJUNE 2022 Surplus Record Machinery & Equipment DirectorySurplus Record100% (1)

- Gia Cong CokhiDokument55 SeitenGia Cong CokhitranngNoch keine Bewertungen

- Cryptic CalendarDokument61 SeitenCryptic CalendarGabriel Antonio NájeraNoch keine Bewertungen

- BS EN 10283-2010 耐腐蚀钢铸件Dokument20 SeitenBS EN 10283-2010 耐腐蚀钢铸件Txus Nieto100% (1)

- Flange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening ProcedureDokument10 SeitenFlange Bolt Torque Sequence and Torque Table - A Complete Bolt Tightening ProcedureNavasNoch keine Bewertungen

- Stoody 104TJ SAW005Dokument1 SeiteStoody 104TJ SAW005Juaros LeonNoch keine Bewertungen

- CH 14Dokument29 SeitenCH 14Amrik SinghNoch keine Bewertungen

- How the Rubber Band Outsold the BeatlesDokument2 SeitenHow the Rubber Band Outsold the BeatlesManisha ChawlaNoch keine Bewertungen

- Kushwaha 2013Dokument11 SeitenKushwaha 2013Abhishek GadhwalNoch keine Bewertungen

- Combustion Chambers PDFDokument1 SeiteCombustion Chambers PDFkosmc123Noch keine Bewertungen

- Exhaust and Pollution Control SystemDokument24 SeitenExhaust and Pollution Control SystemOne Love Jah LoveNoch keine Bewertungen

- Atlas Copco: Stationary Air CompressorsDokument100 SeitenAtlas Copco: Stationary Air CompressorsJavier LópezNoch keine Bewertungen

- Protek Composite Wear PadDokument1 SeiteProtek Composite Wear PadWilliam ChipanaNoch keine Bewertungen

- Building Construction WoodDokument30 SeitenBuilding Construction WoodDaryl Gomez Timatim100% (1)

- Rosan Insert CatalogueDokument59 SeitenRosan Insert CatalogueRussell GouldenNoch keine Bewertungen

- Lecture 5 Paper and Paperboard Packaging For StudentsDokument14 SeitenLecture 5 Paper and Paperboard Packaging For StudentsQuoc KhanhNoch keine Bewertungen

- Permatex - 80036Dokument1 SeitePermatex - 80036David Martinez VillarroelNoch keine Bewertungen

- Astmb 248 MDokument12 SeitenAstmb 248 MwiroNoch keine Bewertungen

- Isobutylene by MTBE Decomposition-CD TECHDokument2 SeitenIsobutylene by MTBE Decomposition-CD TECHDrVedprakash Mishra100% (1)

- Dowty Oring SizesDokument67 SeitenDowty Oring SizesluismcmcNoch keine Bewertungen

- Grade 12 FOODFISH TVL Q3WK5-6Dokument20 SeitenGrade 12 FOODFISH TVL Q3WK5-6Mario Reynaldo CicatNoch keine Bewertungen

- 8620 Steel DatasheetDokument1 Seite8620 Steel DatasheetLuis ReyesNoch keine Bewertungen

- HIGH SPEED TOOL STEELS CHEMICAL COMPOSITIONS AND FEATURESDokument11 SeitenHIGH SPEED TOOL STEELS CHEMICAL COMPOSITIONS AND FEATUREScadcamtaiNoch keine Bewertungen

- Product Data Sheet: Bisalloy Protection 400 SteelDokument1 SeiteProduct Data Sheet: Bisalloy Protection 400 SteelAli TalebiNoch keine Bewertungen