Beruflich Dokumente

Kultur Dokumente

Material Properties

Hochgeladen von

nareshvijayan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten22 SeitenCollege presentation on material properties in brief

Copyright

© © All Rights Reserved

Verfügbare Formate

PPTX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCollege presentation on material properties in brief

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten22 SeitenMaterial Properties

Hochgeladen von

nareshvijayanCollege presentation on material properties in brief

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPTX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 22

Materials are defined by their properties and their properties

determine their uses. We have lots of material properties to

define a material and those are listed below with their

category

1. Acoustical properties

2. Atomic properties

3. Chemical properties

4. Electrical properties

5. Environmental properties

6. Magnetic properties

7. Manufacturing properties

8. Mechanical properties

9. Optical properties

10. Radiological properties

11. Sensorial properties

12. Thermal properties

The above mentioned categories have their own set

of list which is studied in detail below..

Overview

Acoustical properties

Acoustical absorption

Speed of sound

Atomic properties

Atomic mass

Atomic number- applies to pure elements only

Atomic weight - applies to individual isotopes or

specific mixtures of isotopes of a given element.

Chemical properties

Corrosion resistance

Hygroscopy

pH

Reactivity

Specific internal surface area

Surface energy

Surface tension

Electrical properties

Conductivity

Dielectric constant

Dielectric strength

Electrical conductivity

Permeability

Permittivity

Piezoelectric constants

Seebeck coefficient

Environmental properties

Embodied energy

Embodied water

RoHS compliance

There are a variety of other properties to consider in an

environmental impact assessment that effect the ecological

or human environment that may be difficult to quantify

(unlike most of the properties listed on this page) including

pollution (extraction, transportation, manufacture),

scarcity/abundance, habitat destruction, renewability,

recyclability, wars fought over materials, labor exploitation,

etc. These can be subjective, dependent on context, or

inadequately measured

Magnetic properties

Curie Point

Diamagnetism

Hysteresis

Permeability

Manufacturing properties

Castability

Extruding temperature and pressure

Hardness

Machinability rating

Machining speeds and feeds

Mechanical properties

Compressive strength

Density

Ductility

Fatigue limit

Flexural modulus

Flexural strength

Fracture toughness

Hardness

Plasticity (physics)

Poisson's ratio

Shear modulus

Shear strain

Shear strength

Softness

Specific modulus

Specific weight

Tensile strength

Yield strength

Young's modulus

Coefficient of friction(also

depends on surface

finish)

Coefficient of restitution

Optical properties

Absorptivity

Color

Luminosity

Photosensitivity

Reflectivity

Refractive index

Scattering

Transmittance

Radiological properties

Neutron cross-section

Specific activity

Sensorial properties

Brightness

Smell

Softness

Warmth

Thermal properties

Auto ignition temperature

Binary phase diagram

Boiling point

Coefficient of thermal

expansion

Critical temperature

Curie point

Emissivity

Eutectic point

Flammability

Flash point

Glass transition temperature

Heat of fusion

Heat of vaporization

Inversion temperature

Melting point

Phase diagram

Pyrophoricity

Solidus

Specific heat

Thermal conductivity

Thermal diffusivity

Thermal expansion

Seebeck coefficient

Triple point

Vapor Pressure

Vicat softening point

Of that all, the most important properties that we

consider in our domain is mechanical and

manufacturing properties and, lets see each of

them in detail

Manufacturing Properties

Castability :

Its the casting property that defines how easy a

part can be casted.

The main attributes that control the quality of

casting is the part volume, surface area, and the

number of features.

The design that reduces the castability are:

Undercuts ,interior cavities due to tooling complexions.

Sudden changes in wall thickness because of

turbulence during filling, fillets are used to rectify it.

Non planar parting line which increases tooling

complexions.

Making highly accurate casting will also reduce the

castablity.

To increase the castablity we should have a very

good design intend. Here in casting we have to use

drafts, fillets, less complex features for a good

castablity

Hardness:

Its the measure of material resistance towards

different forces.

It also depends on lot other properties like ductility,

plasticity, etc

We have 3 types of hardness that is measured so

far, that is

Scratch:

It measures the fracture resistance due

to friction from a sharp object

Indentation:

It measures the fracture resistance due

to a constant compression load from a sharp object

Rebound:

Its also called as dynamic hardness

which is measured my dropping a diamond tipped

hammer on the sample to measure the bounce

height, this is related with the elasticity

Machinability rating :

Machinability is nothing but a property of a

material that defines how easy a metal can be

machined..

There is no standard way of quantifying the

machinablity but still there are few ways like

machinability rating which is determined by

American Iron and Steel Institute (AISI). It is

determined my running a turning test at

180sfpm(surface feet per minute) and comparing to

a constant and they are rated with percentage.

The constant is B112steel with 160brinell.

The rating is determined by considering tool life,

cutting speed and surface finish. The normal rating

for a material to have a good machinability property

is 100 % which is assigned to B112steel.

Mechanical properties:

Compressive strength:

The ability of a material to withstand compression

force.

Hard materials have higher compressive strength

whereas the soft material has lower compressive

strength.

Tensile strength(ultimate strength):

Its a opposite of compressive strength, in which the

material have to withstand the stress that is

produced when it is stretched.

It is measured by tensile test and the highest point

of the stress and strain curve is the ultimate tensile

strength.

The value does not depend on the size of the

sample material. And the unit of measurement is

Pascal.

Density(mass density):

It is defined as the mass per unit volume.

Sometimes the values of it changes according to the

materials temperature and pressure but mostly all

the materials are measured in standard

temperature pressure(STP).

The unit of density is kg/m

3

Specific weight:

This is same as density but here it is weight per unit

volume.

The unit is N/m

3

Fatigue limit:

Fatigue limit or fatigue strength or endurance limit

is the value of the stress at which the material tend

to break or fail.

Shear strength:

It is the Strength of the material against the failure

due to shear load.

Poissons ratio:

Whenever a material is compressed in one direction

it tends to expand in other two direction, this is

called poissons effect and the measure of this is

called poisson ratio.

Poisson effect is mainly helpful in pipe flow analysis.

Yield strength:

Yield strength or yield point of a material is the

value of stress above which the material deforms

plastically.

Below this yield point the material tends to be in

elastic form in which the material regains its

position if it is stressed and released, which is

termed as elasticity.

And plasticity is a permanent form after which the

material does not regain its position even after the

stress is release.

Ductility:

Its the property of the material which can able to

deform under a tensile stress.

Example of this is, ability of a material to form into

wire.

Malleability:

This is the property in which the material has the

ability to deform, in compressive stress.

Example of this is, ability of a material to form into

sheet by hammering or some other process.

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Temple FACILITY Circular Slab DesignDokument1 SeiteTemple FACILITY Circular Slab Designselvakumar sNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Govt - Engineering College, Barton Hill, Thiruvananthapuram Second Series Test-S7 Mechanical Engineering Refrigeration & Air ConditioningDokument3 SeitenGovt - Engineering College, Barton Hill, Thiruvananthapuram Second Series Test-S7 Mechanical Engineering Refrigeration & Air ConditioningRakesh NairNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- FXZ1 (FRT, ZH) : Halogen FreeDokument4 SeitenFXZ1 (FRT, ZH) : Halogen FreeMario LuvineriNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Aparatos y Metodos para Mantener La Circulación Constante Durante La Perforación.Dokument9 SeitenAparatos y Metodos para Mantener La Circulación Constante Durante La Perforación.Raul BlancoNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Name: Franz Eric C. Disquitado Section: BSCE-1A Civil Engineering OrientationDokument2 SeitenName: Franz Eric C. Disquitado Section: BSCE-1A Civil Engineering OrientationFranz Eric DisquitadoNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Literature SurveyDokument6 SeitenLiterature SurveyMekhaile PjNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Cold Storage SeminarDokument20 SeitenCold Storage SeminarmsshahenterNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Rules BNBC 2020Dokument23 SeitenRules BNBC 2020ibti nabilNoch keine Bewertungen

- Reparación de Motor Volvo D12D: Inversión Segura A Un Menor CostoDokument2 SeitenReparación de Motor Volvo D12D: Inversión Segura A Un Menor CostoRoberto CornejoNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Residential Driveways Encroachmentsencroachment S: Regulations For Driveway and Encroachment Control 8-1Dokument4 SeitenResidential Driveways Encroachmentsencroachment S: Regulations For Driveway and Encroachment Control 8-1luke elbertNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Limits To The Scope of The Warranty of Fitness For PurposeDokument1 SeiteLimits To The Scope of The Warranty of Fitness For PurposeWilliam TongNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- EEMUA 159 Reading ChecklistDokument3 SeitenEEMUA 159 Reading ChecklistbacabacabacaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

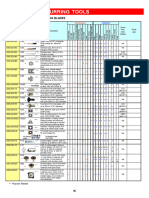

- "Shaviv" Deburring ToolsDokument1 Seite"Shaviv" Deburring ToolsRino SutrisnoNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Carbon FiberDokument30 SeitenCarbon FiberAarizMalik100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- SS Cable Ties Catalog PDFDokument2 SeitenSS Cable Ties Catalog PDFNimish TaterhNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Typical Design Calculations of PierDokument40 SeitenTypical Design Calculations of PierAjayvidyanand Sharma100% (1)

- Md. Sadiqul Hasan CVDokument3 SeitenMd. Sadiqul Hasan CVnewaz2010Noch keine Bewertungen

- Construction Drawing: Propose Operator WorkstationDokument1 SeiteConstruction Drawing: Propose Operator WorkstationWAN CHANDNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Conexiones y Aplicaciones Estructurales de Compuestos Poliméricos Reforzados Con Fibra para Infraestructura Civil en Entornos AgresivosDokument15 SeitenConexiones y Aplicaciones Estructurales de Compuestos Poliméricos Reforzados Con Fibra para Infraestructura Civil en Entornos Agresivosjose mauricio muñoz bolivarNoch keine Bewertungen

- Super Duplex Stainless Steel PipesDokument3 SeitenSuper Duplex Stainless Steel Pipeskumar sandeepNoch keine Bewertungen

- 2.2.3 - DQR - PST Capacity-Rev B1Dokument7 Seiten2.2.3 - DQR - PST Capacity-Rev B1Sudip ShresthaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Schedule DDokument19 SeitenSchedule DwangruiNoch keine Bewertungen

- Calculation of Thermal Bridges in Various European CountriesDokument7 SeitenCalculation of Thermal Bridges in Various European CountriesbatteekhNoch keine Bewertungen

- ICREC 2015 - Dobson Rammed EarthDokument8 SeitenICREC 2015 - Dobson Rammed EarthAndresNoch keine Bewertungen

- Development Proposal For 101 Brady Street in Allegan, MichiganDokument19 SeitenDevelopment Proposal For 101 Brady Street in Allegan, MichiganWWMTNoch keine Bewertungen

- Flange Coupling Lab PDFDokument25 SeitenFlange Coupling Lab PDFAli Raza MalikNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Viscount Rotational Moulding Iviscount - Rotational - Moulding - Infrastructure - Catalogue - Railnfrastructure Catalogue RailDokument2 SeitenViscount Rotational Moulding Iviscount - Rotational - Moulding - Infrastructure - Catalogue - Railnfrastructure Catalogue RailredchaozNoch keine Bewertungen

- Composite Repair PDFDokument13 SeitenComposite Repair PDFNarendra PalandeNoch keine Bewertungen

- Smart Materials in Civil EngineeringDokument8 SeitenSmart Materials in Civil EngineeringRavikiranSharmaSrkNoch keine Bewertungen

- Analysis of Flexible Pavements Using IIT Pave: Harish G RDokument4 SeitenAnalysis of Flexible Pavements Using IIT Pave: Harish G RAyush KumarNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)