Beruflich Dokumente

Kultur Dokumente

Fired Heaters - GET

Hochgeladen von

Fasil Paruvanath0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten25 SeitenFired Heaters - GET

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenFired Heaters - GET

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

54 Ansichten25 SeitenFired Heaters - GET

Hochgeladen von

Fasil ParuvanathFired Heaters - GET

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 25

FIRED HEATERS

Chemical reactions and processes take place at high

temperatures and hence heat sources are required.

Various sources of heat

Direct fired heaters

Steam heaters

Thermal fluid heaters, e.g., Dowtherm

Electrical heaters

Fluid In

Fluid Out

DIRECT FIRED HEATER

Steam to various users

including turbines,

charge heaters,

Reboilers etc.

Condensate return

to boilers

Fluid In

Fluid Out

to

heat

exchangers

THERMAL FLUID HEATER

Fluid In

Fluid Out

Electrical Power IN

RADIATION

ZONE

FUEL OIL

FUEL GAS

STEAM

CONVECTION

ZONE

STACK

DAMPER

NATURAL DRAFT FIRED HEATER

AIR

RADIATION

ZONE

FUEL OIL

FUEL GAS

STEAM

PLENUM

CHAMBER

CONVECTION

ZONE

STACK

FD FAN

DAMPER

FORCED DRAFT FIRED HEATER

AIR FROM ATMOS.

RADIATION

ZONE

FUEL OIL

FUEL GAS

STEAM

PLENUM

CHAMBER

CONVECTION

ZONE

STACK

ID FAN

FD FAN

DAMPER

BALANCED

DRAFT FIRED

HEATER

RADIATION

ZONE

FUEL OIL

FUEL GAS

STEAM

PLENUM

CHAMBER

CONVECTION

ZONE

STACK

AIR PREHEATER

ID FAN

FD FAN

DAMPER

STEAM

APH

BOTTOM OR UPFIRED

SIDE OR END FIRED

TOP OR DOWNFIRED

CYLINDRICAL HEATER WITH VERTICAL COIL

SECTION

Arbor type

Inlet header

Outlet header

U tube

FINNED TUBES - CONVECTION

STUDDED TUBES - CONVECTION

Bare

tubes

150mm TO

200mm thick

castable

refractory

Bottom

floor

200mm

thick

castable

refractory

with one

layer of

brick

lining

1300 - 1600 C

800 - 900 C

350 - 450 C

CERAWOOL

LINING CAN

BE APPLIED

INSTEAD OF

REFRACTORY

DETAIL OF CERAWOOL LINING

Heater steel

external

shell

Bitumastic

paint coating

SS304 foil 0.2mm thick for

corrosion resistance

25mm thick cerawool

pads laid one after another.

Cerawool blankets hold

down bolts

Cerawool is not used in

furnaces with oil fired burners.

Cost is high

Burner floor

refractory

Air

register

Fuel gas

Fuel oil

Pilot

burner

Burner

tile

BURNER ASSEMBLY

METALLURGY OF TUBES

Depends on the fluid inside and the temperature to which the

fluid is to be heated

Tube metallurgy Max. temp (C)

Carbon steel 540

1.25% Cr - 0.5%Mo 595

2.25% Cr - 1%Mo 650

5%Cr-1%Mo 650

9%Cr-0.5%Mo 705

SS304,SS316,SS321,SS347815

HK40(25Cr-20Ni) 1010

For any selected metallurgy of tubes the design life shall be

minimum 100 000 hours

Metallurgy of tube supports

Tube metallurgy Max. temp (C)

Carbon steel 427 C

2.25%Cr-1%Mo 649

19%Cr-9%Ni 816

25%Cr-12%Ni (Plate) 871

25%Cr-12%Ni (cast) 982

25%Cr-20%Ni(Plate) 871

25%Cr-20%Ni(Cast) 1093

50%Cr-50%Ni 982

If the fuel oil has more than 100ppm vanadium then the

supports shall be 50%Cr-50%Ni or refractory lined for

corrosion resistance purposes.

IMPORTANT DOCUMENTS TO BE REFERRED

Process licensor datasheet

Vendor datasheet

API 560 - Fired heaters for general refinery services

API 530 - Calculation of heater tube thickness

Equipment drawings for individual heater for more details

END

RADIATION

ZONE

FUEL OIL

FUEL GAS

STEAM

PLENUM

CHAMBER

CONVECTION

ZONE

STACK

AIR PREHEATER

ID FAN

FD FAN

DAMPER

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Goforth Diathesis-Stress Model FinalDokument3 SeitenGoforth Diathesis-Stress Model FinalmaretadekaNoch keine Bewertungen

- Influence LinesDokument5 SeitenInfluence LinessushilkumarNoch keine Bewertungen

- Environmental Product Declaration: Power Transformer Trafostar 63 MvaDokument4 SeitenEnvironmental Product Declaration: Power Transformer Trafostar 63 MvaFasil ParuvanathNoch keine Bewertungen

- Are Structures Cheat Sheet 1Dokument5 SeitenAre Structures Cheat Sheet 1priodeep chowdhuryNoch keine Bewertungen

- NAFEMS BooksDokument4 SeitenNAFEMS Booksds_srinivas50% (2)

- Beam Cantilever ComDokument15 SeitenBeam Cantilever ComHareesh GrNoch keine Bewertungen

- 30.design and Analysis of A Automobile FrameDokument1 Seite30.design and Analysis of A Automobile FrameFasil ParuvanathNoch keine Bewertungen

- ConclusionDokument1 SeiteConclusionFasil ParuvanathNoch keine Bewertungen

- Strength Calculation of Clamping Structure FinalDokument3 SeitenStrength Calculation of Clamping Structure FinalFasil ParuvanathNoch keine Bewertungen

- Module 1 Lecture 3 FinalDokument12 SeitenModule 1 Lecture 3 Finaltejap314Noch keine Bewertungen

- 16 - Chapter 6Dokument5 Seiten16 - Chapter 6Fasil ParuvanathNoch keine Bewertungen

- List of Abbrevations I List of Figures III List of Tables VIII 1Dokument3 SeitenList of Abbrevations I List of Figures III List of Tables VIII 1Fasil ParuvanathNoch keine Bewertungen

- 7.1 Finite Element Simulation of Chassis DesignDokument5 Seiten7.1 Finite Element Simulation of Chassis DesignFasil ParuvanathNoch keine Bewertungen

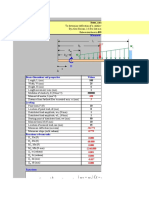

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Parameter Changes - ConfigDokument1 SeiteParameter Changes - ConfigFasil ParuvanathNoch keine Bewertungen

- Climate Change Affect ChilldrenDokument5 SeitenClimate Change Affect ChilldrenFasil ParuvanathNoch keine Bewertungen

- Graphics - Software OpengGLDokument2 SeitenGraphics - Software OpengGLFasil ParuvanathNoch keine Bewertungen

- (BS ISO 128-40 - 2001) - Technical Drawings. General Principles of Presentation. Basic Conventions For Cuts and Sections PDFDokument14 Seiten(BS ISO 128-40 - 2001) - Technical Drawings. General Principles of Presentation. Basic Conventions For Cuts and Sections PDFFasil Paruvanath100% (1)

- Climate Change Affect ChilldrenDokument5 SeitenClimate Change Affect ChilldrenFasil ParuvanathNoch keine Bewertungen

- Ease in Ease of Doing BusinessDokument4 SeitenEase in Ease of Doing BusinessFasil ParuvanathNoch keine Bewertungen

- List of Tables: Table Title No. NoDokument2 SeitenList of Tables: Table Title No. NoFasil ParuvanathNoch keine Bewertungen

- 13 ReferencesDokument9 Seiten13 ReferencesAbdelrahman MagdyNoch keine Bewertungen

- 7.1 Finite Element Simulation of Chassis DesignDokument5 Seiten7.1 Finite Element Simulation of Chassis DesignFasil ParuvanathNoch keine Bewertungen

- Pass Format From Police StationDokument1 SeitePass Format From Police StationThe Indian Express83% (6)

- Stress ManagementDokument10 SeitenStress ManagementRishabh MehtaNoch keine Bewertungen

- ConclusionDokument1 SeiteConclusionFasil ParuvanathNoch keine Bewertungen

- 03 AbstractsDokument3 Seiten03 AbstractsFasil ParuvanathNoch keine Bewertungen

- Pippin PDFDokument6 SeitenPippin PDFFasil ParuvanathNoch keine Bewertungen

- Lenovo s30 Manual PDFDokument1 SeiteLenovo s30 Manual PDFFasil ParuvanathNoch keine Bewertungen

- Practitioners GuideDokument5 SeitenPractitioners GuideNarina Avi SeptiyantiNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Tutorium Refrigeration SolutionDokument20 SeitenTutorium Refrigeration SolutionwanpudinNoch keine Bewertungen

- Me2134 2Dokument18 SeitenMe2134 2FlancNoch keine Bewertungen

- Vorticity Transport Equation From NavierDokument2 SeitenVorticity Transport Equation From NavierBen0% (1)

- Orifice Sizing API and ASMEDokument2 SeitenOrifice Sizing API and ASMEGanda SamosirNoch keine Bewertungen

- Manual Secador Refrigerativo RCDokument160 SeitenManual Secador Refrigerativo RCElena IbarraNoch keine Bewertungen

- Charging Heat Pumps and AirsDokument15 SeitenCharging Heat Pumps and Airsrohitkb09Noch keine Bewertungen

- EE Notes FULLDokument56 SeitenEE Notes FULLAnonymous Q4MsQANoch keine Bewertungen

- FM Complex Engineering ProblemDokument13 SeitenFM Complex Engineering ProblemCh TalhaNoch keine Bewertungen

- PS400 Bolted Plastic Pump: Engineering Operation & Maintenance ManualDokument28 SeitenPS400 Bolted Plastic Pump: Engineering Operation & Maintenance ManualJosmir KerneNoch keine Bewertungen

- Innovative Vapor-CompressionDokument13 SeitenInnovative Vapor-CompressionCj MoLanoNoch keine Bewertungen

- Production of Ethylene GlycolDokument15 SeitenProduction of Ethylene Glycoldrami9475% (4)

- Lip Thickness For Reduction of Supersonic Jet LengthDokument34 SeitenLip Thickness For Reduction of Supersonic Jet LengthmadhanNoch keine Bewertungen

- Henrys Law NotesDokument3 SeitenHenrys Law NotesayushNoch keine Bewertungen

- Chemical Injection PDFDokument4 SeitenChemical Injection PDFermusat100% (1)

- Treatment Techniques For The Recycling of Bottle Washing Water in The Soft Drinks IndustryDokument6 SeitenTreatment Techniques For The Recycling of Bottle Washing Water in The Soft Drinks Industrynermeen ahmedNoch keine Bewertungen

- Method Statement of Hydrostatic TestDokument28 SeitenMethod Statement of Hydrostatic TestMassimo FumarolaNoch keine Bewertungen

- Heat Pump - Refrigeration and LiquefactionDokument72 SeitenHeat Pump - Refrigeration and LiquefactionhananNoch keine Bewertungen

- #4, - RAMA NIVAS - , Ground Floor 3rd Temple Road, Malleshwaram Bangalore - 56003Dokument15 Seiten#4, - RAMA NIVAS - , Ground Floor 3rd Temple Road, Malleshwaram Bangalore - 56003GAMING AND TECH ZONENoch keine Bewertungen

- Sepuran® N System 6": in NM /H at 7 Barg 25°CDokument2 SeitenSepuran® N System 6": in NM /H at 7 Barg 25°CsanjaigNoch keine Bewertungen

- Hydraulic Unit: C P B M 0 0 0 - 2Gh - 1Dokument14 SeitenHydraulic Unit: C P B M 0 0 0 - 2Gh - 1MoshMedNoch keine Bewertungen

- Hydraulic System, V80/V90 - 1.8/2.0 MW: History of This DocumentDokument33 SeitenHydraulic System, V80/V90 - 1.8/2.0 MW: History of This DocumentHUNGNoch keine Bewertungen

- Yamaha Outboard Fuel FiltersDokument2 SeitenYamaha Outboard Fuel FiltersMarine Parts ChinaNoch keine Bewertungen

- Selecting and Measuring Pipe & Fittings: Thread Type CompatibilityDokument1 SeiteSelecting and Measuring Pipe & Fittings: Thread Type CompatibilityITLHAPNNoch keine Bewertungen

- PS220/PS230 Bolted Metal Pump: Engineering Operation MaintenanceDokument28 SeitenPS220/PS230 Bolted Metal Pump: Engineering Operation MaintenanceJuan Mac LeanNoch keine Bewertungen

- Factory Acceptance Test: Action ReportDokument1 SeiteFactory Acceptance Test: Action ReportmahipalNoch keine Bewertungen

- Fundamentals of Reservoir Rock PropertiesDokument234 SeitenFundamentals of Reservoir Rock PropertiesRobert Lorez50% (2)

- Chapter - 9 (PPT WaterDokument17 SeitenChapter - 9 (PPT Waterhabib panaNoch keine Bewertungen

- Atomization For Spray Drying Unanswered Questions and Industrial NeedsDokument6 SeitenAtomization For Spray Drying Unanswered Questions and Industrial NeedsNicolas Pardo AlvarezNoch keine Bewertungen

- 2.1 Purpose of The GCTDokument6 Seiten2.1 Purpose of The GCTsml mptNoch keine Bewertungen

- Surge CalculationsDokument21 SeitenSurge CalculationsSri DharNoch keine Bewertungen