Beruflich Dokumente

Kultur Dokumente

Dr. Pham Huynh Tram Department of ISE Phtram@hcmiu - Edu.vn

Hochgeladen von

Ngọc Nhung VũOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dr. Pham Huynh Tram Department of ISE Phtram@hcmiu - Edu.vn

Hochgeladen von

Ngọc Nhung VũCopyright:

Verfügbare Formate

Dr.

Pham Huynh Tram

Department of ISE

phtram@hcmiu.edu.vn

Review of basic probability & statistics

- Probability

- Types of data

- Describing data

Stabilizing and improving a process with control

charts

- Needs of control chart

- Structure of control chart

- Rules of identifying out-of-control point

- Possible mistakes un using control chart

Example: a bin contains 4000 screws; 2000 are good and

2000 are defective

What is the probability of drawing a defective screw?

- Classical probability

- Relative frequency probability

- Difference?

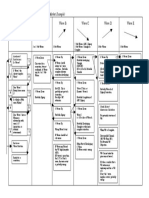

Sub-

group

No. of

defective

Fraction of

defective

Cummulative

no. of

defective

Cummulative

no. of screw

Cummulative

of fraction

1

2

3

4

5

6

7

Subgroup size :50

Pupose of collecting data?

Attribute data

- Classificaion of items into categories. Eg.: grade A, B, C

- Counts of the number of items in a given category or a

proportion in a given category

- Counts of the number of occurrences per unit. Eg.: no. of

defects per batch, no. of sales per month

Variables (measurment) data

- Measurement of a characteristic. Eg.: length of time to

resolve customer complaint, weights of boxes of detergent

- Computation of Numerical Value from two or more

measurements of variables data. Eg.: computation of a

rectangular containe, km per litre for each truck

For frequency distribution

Tabular displays

Graphical displays

- Histogram (variable data)

- Bar chart (attribute data)

- Ogive

- Run chart

The number of intervals

influences the pattern, shape, or spread

of your Histogram.

The width of the bar chart has no

significance

Run chart

Measures of central tendency:

Mean, median, mode, proportion

Measures of variability

Range, Standard diviation

Measures of shape

Skewness, kurtosis

Mode = 16

The mode is the most frequently occurring value. It is the value

with the highest frequency.

Given a data set:

9, 10, 6, 12, 16, 14, 19, 20, 14, 15, 22, 24, 13, 16, 17, 5, 17, 18,

19, 18, 16, 22

The mean of a set of observations is their

average - the sum of the observed values divided

by the number of observations.

Population Mean

Sample Mean

=

=

x

N

i

N

1

x

x

n

i

n

=

=

1

Range

Difference between maximum and minimum values

Variance

Mean

*

squared deviation from the mean

Standard Deviation

Square root of the variance

-

Definitions of population variance and sample variance differ slightly.

Population Variance Sample Variance

( )

N

N

x

x

N

x

N

i

N

i

N

i

2

1

1

2

1

2

2

|

.

|

\

|

=

=

=

o

2

o o =

( )

1

1

2

1

1

2

1

2

2

|

.

|

\

|

=

=

=

n

n

x

x

n

x x

s

n

i

n

i

n

i

2

s s=

Find the sample mean and sample variance for

the following series of data:

Value

21

12

34

22

17

18

43

28

56

34

12

Practice with Calculator !!

Skewness

Measure of asymmetry of a frequency distribution

Skewed to left

Symmetric or unskewed

Skewed to right

Kurtosis

Measure of flatness or peakedness of a frequency

distribution

Platykurtic (relatively flat)

Mesokurtic (normal)

Leptokurtic (relatively peaked)

Skewed to left

6 0 0 5 0 0 4 0 0 3 0 0 2 0 0 1 0 0

3 0

2 0

1 0

0

x

F

r

e

q

u

e

n

c

y

Mean < median < mode

Mean = median = mode

6 0 0 5 0 0 4 0 0 3 0 0 2 0 0 1 0 0

x

3 0

2 0

1 0

0

F

r

e

q

u

e

n

c

y

Symmetric

Mode < median < mean

6 0 0 5 0 0 4 0 0 3 0 0 2 0 0 1 0 0

x

3 0

2 0

1 0

0

F

r

e

q

u

e

n

c

y

Skewed to right

3 . 7 2 . 9 2 . 1 1 . 3 0 . 5 - 0 . 3 - 1 . 1 - 1 . 9 - 2 . 7 - 3 . 5

7 0 0

6 0 0

5 0 0

4 0 0

3 0 0

2 0 0

1 0 0

0

X

F

r

e

q

u

e

n

c

y

Platykurtic - flat distribution

4 3 2 1 0 - 1 - 2 - 3 - 4

5 0 0

4 0 0

3 0 0

2 0 0

1 0 0

0

X

F

r

e

q

u

e

n

c

y

Mesokurtic - not too flat and not too peaked

Leptokurtic - peaked distribution

1 0 0 - 1 0

2 0 0 0

1 0 0 0

0

Y

F

r

e

q

u

e

n

c

y

Normal distribution

Calculate probability

Skewed distribution

Unknown distribution

K = 1

K=2

K=3

6826 . 0 ) 1 1 ( = + < < o o X P

9544 . 0 ) 2 2 ( = + < < o o X P

9973 . 0 ) 3 3 ( = + < < o o X P

1

1

2

1

1

4

3

4

75%

1

1

3

1

1

9

8

9

89%

1

1

4

1

1

16

15

16

94%

2

2

2

= = =

= = =

= = =

At least of the elements of any distribution

lie within k standard deviations of the mean

|

.

|

\

|

2

1

1

k

At

least

Lie

within

Standard

deviations

of the mean

2

3

4

Control charts are constructed by drawing samples and

taking measurements of a process characteristics. Each set

of measurements is called a subgroup

Control charts help to

- identify and differentiate between common causes and

special causes of variation

- determine a processs capability

Process is stable if it only exhibits common cause variation

When a process is stable, continuous improvement helps to

bring the centerline of the process closer to a desired level

(nominal) by reducing the magnitude of common cause

variations

-Centerline: drawn at the average value of all the plotted data.

-Control Limits (UCL, LCL): set at a distance of 3 sigma above and 3

sigma below the centerline. They indicate variation from the centerline

* Difference between control limits and specification limits?

27

29

30

31

32

Rule 5: 8 or more successive values continually increase

or decrease

Rule 6: unusual small number of runs above and below

center line are present ( a sawtooth pattern)

Rule 7: 13 consecutive points fall in zone C

Over adjustment

Process should be adjusted not on the basis of time-to-

time observations, but on the basis of information

provided by a statistical control chart

Funnel experiment

Under adjustment

Lack of attention when the process is out of control and

no effort is made to provide neccesary regulation

*Also, becareful on false out-of control signal

Defect prevention: atribute chart

P chart, mp chart, c chart, u chart

Continuous improvement: variable control chart

X bar chart, R chart, MR chart, s chart

Das könnte Ihnen auch gefallen

- Statistical Quality Control: Simple Applications of Statistics in TQMDokument57 SeitenStatistical Quality Control: Simple Applications of Statistics in TQMHarpreet Singh PanesarNoch keine Bewertungen

- Statistical Process Control (Control Chart)Dokument32 SeitenStatistical Process Control (Control Chart)Risad ChoudhuryNoch keine Bewertungen

- 2 Mean Median Mode VarianceDokument29 Seiten2 Mean Median Mode VarianceBonita Mdoda-ArmstrongNoch keine Bewertungen

- M6 - Basic StatisticsDokument66 SeitenM6 - Basic StatisticsAzer Asociados SacNoch keine Bewertungen

- X-Bar and S Charts: NCSS Statistical SoftwareDokument26 SeitenX-Bar and S Charts: NCSS Statistical Softwareanon_123371106100% (1)

- Discriptive StatisticsDokument50 SeitenDiscriptive StatisticsSwathi JanardhanNoch keine Bewertungen

- Introduction SPCDokument28 SeitenIntroduction SPCmixarimNoch keine Bewertungen

- Unit Iii - Statistical Process Control: TQM Tools (Seven Tools of Quality) 1. Pareto Diagram 2. Flow DiagramDokument11 SeitenUnit Iii - Statistical Process Control: TQM Tools (Seven Tools of Quality) 1. Pareto Diagram 2. Flow DiagramKabilan KabilNoch keine Bewertungen

- Process Capability Analysis OverviewDokument46 SeitenProcess Capability Analysis Overviewpaneer selvamNoch keine Bewertungen

- QC TRNGDokument55 SeitenQC TRNGSamNoch keine Bewertungen

- Variation: The Presence of VariationDokument17 SeitenVariation: The Presence of VariationHarris ChackoNoch keine Bewertungen

- Basic 1Dokument60 SeitenBasic 1Rajesh DwivediNoch keine Bewertungen

- Gsoe9810 Week 9Dokument30 SeitenGsoe9810 Week 9Handy PratamaNoch keine Bewertungen

- Statistical Quality Control 2Dokument34 SeitenStatistical Quality Control 2Tech_MXNoch keine Bewertungen

- Statistical Inference: Prepared By: Antonio E. Chan, M.DDokument227 SeitenStatistical Inference: Prepared By: Antonio E. Chan, M.Dश्रीकांत शरमाNoch keine Bewertungen

- Error and Uncertainty: General Statistical PrinciplesDokument8 SeitenError and Uncertainty: General Statistical Principlesdéborah_rosalesNoch keine Bewertungen

- SPC TrainingDokument80 SeitenSPC TrainingRubelio JaimesNoch keine Bewertungen

- Have You Ever : Shot A Rifle? Played Darts? Played Basketball?Dokument39 SeitenHave You Ever : Shot A Rifle? Played Darts? Played Basketball?foofoolNoch keine Bewertungen

- Ken Black QA ch03Dokument61 SeitenKen Black QA ch03Rushabh Vora0% (1)

- 7 QC Tools: Check-Sheet Cause and Effect Pareto Histogram Control Chart Scatter Plot StratificationDokument55 Seiten7 QC Tools: Check-Sheet Cause and Effect Pareto Histogram Control Chart Scatter Plot StratificationNilesh RathoreNoch keine Bewertungen

- Chapter 1 - SPCDokument56 SeitenChapter 1 - SPChyde2520015754Noch keine Bewertungen

- Statistical AnalysisDokument23 SeitenStatistical AnalysisMohammad Sabir HussainNoch keine Bewertungen

- Measures of VariationDokument32 SeitenMeasures of VariationInjamam AlamNoch keine Bewertungen

- Data Types:: Basic StatisticsDokument23 SeitenData Types:: Basic StatisticsmaheshsakharpeNoch keine Bewertungen

- CPK - Vs PPMDokument21 SeitenCPK - Vs PPMazadsingh1100% (1)

- Introduction To SPC (Statistical Process Control)Dokument80 SeitenIntroduction To SPC (Statistical Process Control)ross3mrNoch keine Bewertungen

- Variance and Standard DeviationDokument16 SeitenVariance and Standard Deviationmehtab sanaNoch keine Bewertungen

- Statistical QCDokument57 SeitenStatistical QCJigar NagvadiaNoch keine Bewertungen

- TQM - Statistical Process ControlDokument93 SeitenTQM - Statistical Process ControlAjitNoch keine Bewertungen

- Chapter 3Dokument23 SeitenChapter 3MomedNoch keine Bewertungen

- Lecture-2 Descriptive Statistics-Box Plot Descriptive MeasuresDokument47 SeitenLecture-2 Descriptive Statistics-Box Plot Descriptive MeasuresOmar SibghatNoch keine Bewertungen

- A Concise Presentation: Mr. Deepak SarangiDokument20 SeitenA Concise Presentation: Mr. Deepak SaranginikunjNoch keine Bewertungen

- Topic 2 Frequency Distribution and Data Presentation, Measures of Central Tendency and DispersionDokument46 SeitenTopic 2 Frequency Distribution and Data Presentation, Measures of Central Tendency and DispersionKishoNoch keine Bewertungen

- SPC PresentationDokument45 SeitenSPC Presentationdanaka007Noch keine Bewertungen

- Presentation 3Dokument26 SeitenPresentation 3Levi PogiNoch keine Bewertungen

- Lectures 8 9 10Dokument185 SeitenLectures 8 9 10AzmiHafifiNoch keine Bewertungen

- Unit 8 TextbookDokument47 SeitenUnit 8 TextbookSteve Bishop0% (2)

- Quantitative Techniques 1Dokument37 SeitenQuantitative Techniques 1nprash123Noch keine Bewertungen

- Bus173 Chap03Dokument42 SeitenBus173 Chap03KaziRafiNoch keine Bewertungen

- A Concise Presentation: Mr. Deepak SarangiDokument20 SeitenA Concise Presentation: Mr. Deepak SarangiGAJENDRA KUMARNoch keine Bewertungen

- 06-14-PP CHAPTER 06 Continuous ProbabilityDokument81 Seiten06-14-PP CHAPTER 06 Continuous ProbabilityNawarajPokhrelNoch keine Bewertungen

- Lecture On C - ChartDokument20 SeitenLecture On C - Chart191329Noch keine Bewertungen

- Lecture09 (Assessing Normality)Dokument32 SeitenLecture09 (Assessing Normality)Elaine LieuNoch keine Bewertungen

- Quantitative Tech in BusinessDokument20 SeitenQuantitative Tech in BusinessHashir KhanNoch keine Bewertungen

- 5.2 Process Capability Analysis Rev2ADokument8 Seiten5.2 Process Capability Analysis Rev2APollyNoch keine Bewertungen

- g11 10 StatisticsDokument49 Seiteng11 10 Statisticsapi-235269401Noch keine Bewertungen

- 06control Chart 1Dokument37 Seiten06control Chart 1Ashok SubramaniamNoch keine Bewertungen

- Determing Statistical Significance of Skewness 121104Dokument2 SeitenDeterming Statistical Significance of Skewness 121104IMSQANoch keine Bewertungen

- Compilation of Lessons and ActivitiesDokument37 SeitenCompilation of Lessons and ActivitiesMara M. LabanderoNoch keine Bewertungen

- Click To Add Text Dr. Cemre ErciyesDokument69 SeitenClick To Add Text Dr. Cemre ErciyesJade Cemre ErciyesNoch keine Bewertungen

- Probability and Statistics in EngineeringDokument24 SeitenProbability and Statistics in EngineeringasadNoch keine Bewertungen

- What Is Data? Data Is A Set of Values of Subjects With Respect To Qualitative or Quantitative VariablesDokument10 SeitenWhat Is Data? Data Is A Set of Values of Subjects With Respect To Qualitative or Quantitative Variablesvinothkumar441Noch keine Bewertungen

- 3.numerical Descriptive TechniquesDokument69 Seiten3.numerical Descriptive TechniquesHaris KhalidNoch keine Bewertungen

- 3 - Control Charts For VariablesDokument54 Seiten3 - Control Charts For VariablesWilliam BautistaNoch keine Bewertungen

- 06control Chart 1Dokument37 Seiten06control Chart 1abishank09100% (1)

- Practical Engineering, Process, and Reliability StatisticsVon EverandPractical Engineering, Process, and Reliability StatisticsNoch keine Bewertungen

- This is The Statistics Handbook your Professor Doesn't Want you to See. So Easy, it's Practically Cheating...Von EverandThis is The Statistics Handbook your Professor Doesn't Want you to See. So Easy, it's Practically Cheating...Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Recognition, Information Search, Evaluation of Alternatives, Purchase Decision, Post Purchase BehaviorDokument4 SeitenRecognition, Information Search, Evaluation of Alternatives, Purchase Decision, Post Purchase BehaviorNgọc Nhung VũNoch keine Bewertungen

- Logistics Section 02 Locating FacilityDokument48 SeitenLogistics Section 02 Locating FacilityNgọc Nhung VũNoch keine Bewertungen

- Not Good Survey QuestionairesDokument2 SeitenNot Good Survey QuestionairesNgọc Nhung VũNoch keine Bewertungen

- Chapter 7 PDFDokument22 SeitenChapter 7 PDFNgọc Nhung VũNoch keine Bewertungen

- Logistics Section 01 IntroductionDokument40 SeitenLogistics Section 01 IntroductionNgọc Nhung Vũ100% (2)

- Don't Like Clickbait? Don't ClickDokument10 SeitenDon't Like Clickbait? Don't ClickNgọc Nhung VũNoch keine Bewertungen

- Application ID: 001790 Secret Key: Caef6bfaDokument1 SeiteApplication ID: 001790 Secret Key: Caef6bfaNgọc Nhung VũNoch keine Bewertungen

- Internship OutlineDokument5 SeitenInternship OutlineNgọc Nhung VũNoch keine Bewertungen

- CEO Also Be The Chairman of The BoardDokument5 SeitenCEO Also Be The Chairman of The BoardNgọc Nhung VũNoch keine Bewertungen

- Chap 8 Technology Affect Business EthicDokument2 SeitenChap 8 Technology Affect Business EthicNgọc Nhung VũNoch keine Bewertungen

- Research Proposal SampleDokument3 SeitenResearch Proposal SampleNgọc Nhung Vũ100% (1)

- On Cac Ham ExcelDokument4 SeitenOn Cac Ham ExcelNgọc Nhung VũNoch keine Bewertungen

- Midterm Report: International UniversityDokument16 SeitenMidterm Report: International UniversityNgọc Nhung VũNoch keine Bewertungen

- Commands Guide Tutorial For SolidWorks 2012Dokument64 SeitenCommands Guide Tutorial For SolidWorks 2012Jelena Misimovic100% (1)

- Solution Manual Elements of Modern Algebra 8Th Edition by Gilbert Isbn 1285463234 9781285463230 Full Chapter PDFDokument36 SeitenSolution Manual Elements of Modern Algebra 8Th Edition by Gilbert Isbn 1285463234 9781285463230 Full Chapter PDFmichelle.lowe753100% (15)

- Title: Performance OF Digital Communication System Corrupted by Noise ObjectivesDokument16 SeitenTitle: Performance OF Digital Communication System Corrupted by Noise ObjectivesAzie BasirNoch keine Bewertungen

- Traction Versus Slip in A Wheel-Driven Belt Conveyor: Mechanism and Machine TheoryDokument10 SeitenTraction Versus Slip in A Wheel-Driven Belt Conveyor: Mechanism and Machine TheoryWashington MoraisNoch keine Bewertungen

- Solved According To Your Preferences Do The Following Pairs of ProductsDokument1 SeiteSolved According To Your Preferences Do The Following Pairs of ProductsM Bilal SaleemNoch keine Bewertungen

- Tesis Aan Putra, M.pd.Dokument338 SeitenTesis Aan Putra, M.pd.Rizki KurniashihNoch keine Bewertungen

- Algorithm Analysis Cheat Sheet PDFDokument2 SeitenAlgorithm Analysis Cheat Sheet PDFGabriele GattiNoch keine Bewertungen

- PRT - Unit-1-Lect-3Dokument22 SeitenPRT - Unit-1-Lect-3Sri VatsaanNoch keine Bewertungen

- 8 2 Angle Bisectors of TrianglesDokument8 Seiten8 2 Angle Bisectors of Trianglesapi-332361871Noch keine Bewertungen

- Two Way AnnovaDokument18 SeitenTwo Way Annovaomee purohitNoch keine Bewertungen

- 2.1 Random Variables 2.1.1 Definition: PX PX XDokument13 Seiten2.1 Random Variables 2.1.1 Definition: PX PX XMichael Hsiao100% (1)

- Chapter III Torsion 3.4Dokument2 SeitenChapter III Torsion 3.4Joshua John JulioNoch keine Bewertungen

- Space and TimeDokument36 SeitenSpace and TimeravindraNoch keine Bewertungen

- Structured Mathematical Modeling of Industrial BoiDokument22 SeitenStructured Mathematical Modeling of Industrial BoiAndrey CaroNoch keine Bewertungen

- Well Testing and Interpretation For Horizontal WellsDokument6 SeitenWell Testing and Interpretation For Horizontal Wellsmiguel_jose123Noch keine Bewertungen

- Hypothesis Testing in The Multiple Regression PDFDokument23 SeitenHypothesis Testing in The Multiple Regression PDFShabbir WahabNoch keine Bewertungen

- Calculus I ProjectDokument9 SeitenCalculus I Projectapi-495320622Noch keine Bewertungen

- Designing Toll PlazaDokument8 SeitenDesigning Toll PlazaFrancisco Javier Moreno FierrosNoch keine Bewertungen

- Microsoft Word - Bollinger Bands TutorialDokument13 SeitenMicrosoft Word - Bollinger Bands Tutorialadoniscal100% (1)

- Circular BeamDokument24 SeitenCircular BeamSyed Sikandar ShahNoch keine Bewertungen

- Corrective WaveDokument1 SeiteCorrective WaveMoses ArgNoch keine Bewertungen

- Research Aptitude TestDokument14 SeitenResearch Aptitude TestMaths CTNoch keine Bewertungen

- TheModelEngineersHandbook TubalCainDokument226 SeitenTheModelEngineersHandbook TubalCainDan Agu100% (21)

- Modeling and Simulation of Surface Roughness: Rajendra M. PatrikarDokument8 SeitenModeling and Simulation of Surface Roughness: Rajendra M. PatrikarMEHDI FARROKHINoch keine Bewertungen

- C2 TrigonometryDokument10 SeitenC2 TrigonometryAmina DollyNoch keine Bewertungen

- ANSYS TurboGrid Users GuideDokument144 SeitenANSYS TurboGrid Users GuideAndrés Edisson ÁguilaNoch keine Bewertungen

- Delphi XE2 Foundations - Part 1 - Rolliston, ChrisDokument160 SeitenDelphi XE2 Foundations - Part 1 - Rolliston, ChrisJoel Quezada100% (2)

- Presentation Introduction To FEA Using ProMechanicaDokument40 SeitenPresentation Introduction To FEA Using ProMechanicasusanwebNoch keine Bewertungen

- Chapter 2 - DataDokument10 SeitenChapter 2 - DataDR NORHISAM BULOTNoch keine Bewertungen