Beruflich Dokumente

Kultur Dokumente

Combo

Hochgeladen von

Fasil ParuvanathCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Combo

Hochgeladen von

Fasil ParuvanathCopyright:

Verfügbare Formate

Gas Tungsten Arc Welding

By L D Poyyara

GTAW

Fusion Welding Process

Arc Between Non-Consumable Tungsten

Rod And Work

Arc & Weld Pool Shielded By Argon

Filler Wire Separately Added To Weld Pool

Welding Torch & Tungsten Rod Cooled by

Flow OF Argon / Cooling Water

Shielding Gas

Inert Gas - Argon , Helium

Common Shielding Gas Argon

When Helium Is Used Called Heli Arc Welding

When Argon Is Used Called Argon Arc Welding

Inert Gas Prevents Contamination Of Molten Metal

It Prevents Oxidation Of Tungsten Rod

It Ionizes Air Gap and Stabilizes Arc

It Cools Welding Torch & Tungsten Rod

Equipment & Accessories

+

Argon Gas In

Flow Meter

Welding Cable & Cooling

Water In Tube

HF Unit &

Water Cooling

System

Argon Cylinder

Pressure Regulator

Cooling Water In

Cooling Water Out

Argon Shielding

Tungsten Rod

Power Source

Work

Arc

+

High Frequency

Connection

Solenoid

Valve

Ceramic Cup

Pedal Switch

Gas Lens

GTAW Equipment &

Accessories

Power Source Inverter, Thyrester,Rectifier,

Generator

High Frequency Unit

Water Cooling System

Welding Torch- (Ceramic Cup, Tungsten Rod,

Collet, Gas-lens)

Pedal Switch

Argon Gas Cylinder

Pressure Gauge, Regulator, Flow Meter

Earthing Cable With Clamp

Types Of GTAW Power Source

Inverter- DC

Thyrester DC

Motor Generator DC

Rectifier DC

Transformer AC (For Aluminium Welding Only)

Power Source

Provides Electric Energy Arc Heat

Drooping Characteristic

OCV Appx. 90V,

Current Range 40 A to 300 A ( Capacity Of M/s)

Arc Voltage 18V to 26V

Characteristic Of GTAW

Power Source

A

Vertical

Curve

V1

V2

A1 A2

Drooping Constant Current

V

High Frequency Unit

Provides High Voltage Electric Energy With

Very high Frequency 10000 Cycles / Sec.

Initiates low energy Arc / Spark & Ionize Air

Gap.

Electrically charges Air Gap For welding

Current to Jump Across the Tungsten Tip &

BM to Form An Arc.

HF Gets Cut Off, Once Welding Arc Struck.

Water Cooling System

Provides Cooling Water To Welding Torch.

Cools Tungsten Rod, Torch handle & Welding

Cable.

Cooling Water Returns through Flexible Tube

Which Carries welding cable within.

GTAW TORCH

Tungsten Rod

Ceramic Cup

Arc

Argon Gas Inlet

Cooling Water Outlet

Cooling Water Inlet Tube with cable

Base Metal

Torch Handle

Cap with collet For

Holding Tungsten

Argon Shielding Gas

Earthing Cable

Pedal Switch

Switches system

on And off in

sequence

When Pedal Pressed

Solenoid valve opens, Argon gas

flows

High Frequency current jumps from

tungsten rod generating sparks

Welding current flows generating an

arc across tungsten rod and work.

High frequency gets cut off from the

system & welding continues.

When Pedal Released

1 Current gets cut off, Arc extinguishes

2 Gas flow remains for few more

seconds before it stops.

Argon Gas Cylinder- Pressure

Regulator + Flow Meter

Cylinder Stores Argon

At High Pressure

Regulator Regulates

Cylinder Pressure to

Working Pressure

Flow Meter Controls

Flow Rate

Argon Cylinder

Flow Meter

Pressure Regulator

Flow Regulator

Pressure gauges

Cylinder Valve

Connection To Torch

Shielding Gas

Argon - Purity 99.95%

Impure Argon Results In Porosities

Purity Verified by Fusing BQ CS plate

Leakage of Argon in Torch Results in

Porosity.

Check Leakage by Closing the Ceramic

Cup With Thump

Argon Gas Cylinder

Light Blue In Colour

Full Cylinder Pressure: 1800 psi ( 130 Kgs / Cm

2

)

Volume Of Argon In Full Cylinder: 7.3 M

3

Commercial Argon (99.99%) Cost: Rs 70/- Per M

3

High Purity Argon (99.999) Cost: Rs 87/- Per M

3

Back Purging

Purging Gas Commercial

Argon or Nitrogen

Applicable to Single

Sided full penetration

Prevents oxidation of

root pass from opposite

side of weld

Essential for high alloy

steels, nonferrous

metals and alloys

Desirable For All

Material

Welding Torch

Root Pass

Purging Gas In

Purging

Gas Out

Purging

chamber

Filler Wire

Tools For GTAW

Head Screen

Hand gloves

Chipping Hammer

Wire Brush

Spanner Set

Tungsten Rod

Non Consumable Electrode.

Maintains Stable Arc

Tip to be Ground to a cone Shape of 60

to 30 angle

Thoriated Tungsten for General

Application, Zerconiated Tungsten for

Aluminium Welding

Sizes :- 2, 2.4 & 3 mm

Tungsten Rod

Ground to

50 ankle

Filler Wire

Added Separately to the weld pool.

Compatible to base metal

Used in cut length for manual welding.

Used from layer wound spool for

automatic welding.

Sizes :- 0.8, 1, 1.2, 1.6, 2, 2.4 & 3 mm

ASME Classification Of Filler Wire

SS Filler Wire:

SFA-5.9, ER 308, 308L, 316, 316L, 347, 309

LAS Filler Wire:

SFA 5.28, ER 70S A1, ER 80S B2, ER90S D2,

ER 80S Ni2

CS Filler Wire:

SFA- 5.18 , ER 70S2

C = 0.07%, Mn = 0.9% 1.4%, Si = 0.4 0.7%, P = 0.025%, S = 0.035%

Dos & Don'ts In GTAW

Always Connect

Electrode Ve

Keep Always Flow

Meter Vertical

Check & Confirm

Argon Purity

Clean Groove & Filler

wire With Acetone

Grind Tungsten Tip to

Point

Dont Strike Arc With

Electrode + Ve

Dont strike Arc Without

Argon Flow

Dont Strike Arc By

touching Tungsten Rod

Dont Touch Weld Pool

With Tungsten Rod

Dont Lift and break Arc

Dos Donts

Dos & Don'ts In GTAW

Break The Arc Only By

Pedal Switch

Lift The Torch only After

5 Sec Of Arc Break.

Ensure Pre Purging &

Post Purging of 5Sec

Ensure Argon Flow &

Water Circulation To

Torch

When Arc is Stopped

Dont Lift Torch

immediately.

Dont Weld With Blend

Tungsten Rod

Dont Weld With Argon

Leaking Torch

Dont Weld Without

Water Circulation

Dos Donts

Dos & Don'ts In GTAW

Provide Back Purging

For Single Sided Full

Penetration Welds

Use N

2

or Argon as

Back Purging Gas For

CS & LAS

Use Argon As Back

Purging Gas For SS &

Non Ferrous Alloys

Dont Weld Single Sided

Full Penetration Welds

Without Back Purging

Dont Use N

2

As Back

Purging Gas For Non

Ferrous Alloys

Dont Empty Ag

Cylinders Fully.

Dos Donts

Defects In GTAW

1. Cracks 2. Lack Of Fusion

3. Porosity 4. Undercut

5.Lack Of Penetration 6. Excess Penetration

7.Overlap 8. Suck Back

9. Under Flush 10. Burn Through

11. Tungsten Inclusion 11.Stray Arcing

Crack

Cause Remedy

1) Wrong Consumable

2) Wrong Procedure

3) Improper Preheat

4) Inadequate Thickness

In Root Pass

1) Use Right Filler Wire

2) Qualify Procedure

3) Preheat Uniformly

4) Add More Filler Wire

in root Pass

crack

Lack Of Fusion

Cause Remedy

1) Inadequate Current

2) Wrong Torch angle

3) Improper bead placement

1) Use Right Current

2) Train /Qualify welder

3) Train/Qualify Welder

Lack Of Fusion

Porosity

Cause Remedy

1) Impure Argon Gas

2) Argon Leak Within Torch

3) Defective Filler Wire

4) Wet surface of BM

5) Rusted / Pitted Filler wire

6) Improper Flow Of Argon

1) Replace Argon Cylinder

2) Replace Leaking Torch

3) Replace Filler Wire

4) Clean & Warm BM

5) Clean Filler Wire

6) Provide Gas lens

Porosity

. .

Undercut

Cause Remedy

1) Excess Current

2) Excess Voltage

3) Improper Torch angle

1) Reduce the Current

2) Reduce Arc length

3) Train & Qualify the Welder

Under cut

Lack Of Penetration*

Cause Remedy

1) Excess Root Face

2) Inadequate Root opening

3) Over size Filler Wire

4) Wrong Direction of Arc

5) Improper bead placement

6) Improper weaving technique

1) Reduce Root Face

2) Increase Root Opening

3) Reduce Filler Wire size

4) Train / Qualify Welder

5) Train / Qualify Welder

6) Train & Qualify Welder

LOP

* Applicable to SSFPW

Excess Penetration*

Cause Remedy

1)Excess root opening

2) Excess Current

3) Inadequate root face

4) Excess Weaving

5) Wrong Direction Of Arc

1) Reduce root gap

2) Reduce Current

3) Increase Root face

4) Train Welder

5) Train Welder

Excess Penetration

* Applicable to SSFPW

Overlap

Cause Remedy

1) Wrong Direction Of Arc

2) Inadequate Current

3) Excess Filler Wire

1) Train & Qualify Welder

2) Increase Current

3) Reduce Filler Metal

Overlap

Suck Back*

Cause Remedy

1) Excess weaving in root

2) Excess Current

3) Inadequate root face

4) Wrong Electrode angle

1) Reduce weaving

2) Reduce Current

3) Increase root face

4) Train / Qualify Welder

Suck Back

* Applicable to SSFPW in 4G, 3G & 2G

Under flush

Cause Remedy

1) Inadequate weld beads in

final layer

2) Inadequate understanding on

weld reinforcement

3) Wrong selection of filler wire

size

1) Weld some more beads

in final layer

2) Train / Qualify welder

3) Train / Qualify Welder

Under flush

Burn through*

Cause Remedy

1) Excess Current

2) Excess Root opening

3) Inadequate Root face

4) Improper weaving

1) Reduce the Current

2) Reduce root opening

3) Increase root face

4) Train / Qualify Welder

Burn trough

*Applicable to root pass

Tungsten Inclusion

Cause Remedy

1) Ineffective HF

2) Improper Starting of Arc

3) Tungsten Tip Comes in

Contact With Weld

1) Rectify HF Unit

2) Never Touch Weld

With Tungsten Rod

3) Train / Qualify welder

Tungsten Inclusion

Stray Arcing

Cause Remedy

1) HF Not In Operation

2) Inadequate Skill of Welder

1) Rectify HF Unit

2) Train the Welder

Arc Strikes

Thanks

Gas Metal Arc Welding

By L D Poyyara

What Is GMAW ?

A Fusion Welding Process Semi Automatic

Arc Between Consumable Electrode &Work

Arc Generated by Electric Energy From a Rectifier

/ Thyrester / Inverter

Filler Metal As Electrode Continuously fed From

Layer Wound Spool.

Filler Wire Driven to Arc By Wire Feeder through

Welding Torch

Arc & Molten Pool Shielded by Inert Gas through

Torch / Nozzle

Gas Metal Arc Welding

MIG Shielding Gas Ar / Ar + O2 / Ar + Co2

MAG Shielding Gas Co2

FCAW Shielding Gas Co2 With Flux cored

Wire

Note:- Addition of 1 5% of O2 or 5 10% of Co2 in Ar.

increases wetting action of molten metal

Power Source For MIG / MAG

Inverter- DC

Thyrester DC

Motor Generator DC

Rectifier DC

Characteristic Of GMAW Power

Source

Constant V / Linier Characteristic

Appx. Horizontal

Curve

V1

V2

A1 A2

A

V

Current & Polarity

DC- Electrode +Ve

Stable Arc

Smooth Metal Transfer

Relatively Low Spatter

Good Weld Bead Characteristics

DC- Electrode Ve, Seldom Used

AC- Commercially Not In use

Accessories Of GMAW

Power Source

Wire Feed Unit

Shielding Gas Cylinder, Pressure gauges/

Regulator, Flow meter ( Heater For Co2 )

Welding Torch

Water Cooling System (For Water cooled Torch)

Earthing Cable With Clam

Tools For GMAW

Head Screen With DIN 13 / 14 Dark Glass

Hand Wire Brush / Grinder With Wire Wheel

Cutting Pliers

Hand Gloves

Chipping Hammer / Chisel & hammer

Spanner Set

Cylinder Key

Anti-spatter Spray

Earthing Cable With Clamp

GMAW Torch

Torch Handle

Spring Conduit

Job

Arc

Gas Cup

Shielding Gas

Filler Wire - Electrode

Nozzle Tip

On / Off Switch

Equipment & Accessories

+

Wire Inside Spring Lining

Flow Meter

Welding Torch Wire Feeder

Shielding Gas

Cylinder

Pressure Regulator

Argon / Co2

Shielding

Power Source

With Inductance

Work

Arc

Solenoid

Valve

Copper Cup

Wire

Spool

Electrode /

Wire

Shielding Gas

Heater

(Only For

Co2)

Contact Tip

Switch

Torch With Cable Max. 3Mtr

Types Of Wire Feeding In

GMAW

Push Type

Wire fed in to The torch by Pushing through Flexible

Conduit From A Remote Spool

Pull Type

Feed Rollers Mounted on The Torch Handle Pulls the

Wire From A Remote spool

Self Contained

Wire Feeder & The Spool On the Torch

Function Of Shielding Gas In

GMAW

Prevents Air contamination of weld Pool

Prevents Contamination During Metal

Transfer

Increases fluidity of molten metal

Minimizes the spatter generation

Helps in even & uniform bead finish

Shielding Gases For GMAW

MIG: Argon Or Helium

For SS, CS, LAS & Non-ferrous Mt & Al

MIG: Ar + 1 to 2 % O2, Wire With Add. Mn & Si

For SS, CS, LAS & Non-ferrous Mt & Al

MIG: Ar + 5 to 20 % Co2 Wire With Add. Mn & Si

For SS, CS, LAS & Non-ferrous Mt & Al

MAG: Co2 With Solid Wire

For CS & LAS

FCAW: Co2 With Flux Cored Wire

For CS, LAS & SS Overlay

ASME Classification For CS

GMAW Wire

SFA 5.18 : - CS Solid Wire

ER 70 S 2, ER 70 S 3

ER 70 S 6, ER 70 S 7

SFA 5.20 :- CS Flux Cored Wire

E 71 T-1, E 71 T-2 ( Co2 Gas )

E 71 T-1M, E 71 T-2M ( Ar + Co2 Mix)

GMAW CS Wire

Generally Copper Coated

Prevents Oxidation / rusting in Storage

Promotes Electric Conductivity in Arcing

Available In Solid & Flux Cored

Size in mm 0.8, 1, 1.2, 1.6, 2, 2.4, 3

Manganese & Silicon ( Mn 1 2 %, Si Max 1%)

Act As Deoxidizing Agents

Eliminate Porosity

Increase Wetting Of Molten Pool

Metal Transfer In MIG

Short-Circuiting / Dip Transfer

Globular Transfer

Spray Transfer

Metal Transfer In MIG

Dip/Short Circuiting Globular

Spray

CS Solid Wire 1.2 mm

Above230A

24 35 V

120 to 250A

16 24 V

Up to 120A

14 22V

Co2 or Ar Co2 or Ar Only Ar / Ar+O2

Short-Circuiting / Dip Transfer

Wire In Contact With Molten Pool 20 to 200 times

per Second

Operates in Low Amps & Volts Less Deposition

Best Suitable for Out of Position Welding

Suitable for Welding Thin Sheets

Relatively Large opening of Root Can be Welded

Less Distortion

Best Suitable for Tacking in Set up

Prone to Get Lack of Fusion in Between Beads

Globular Transfer

Metal transferred in droplets of Size grater

than wire diameter

Operates in Moderate Amps & Volts

Better Deposition

Common in Co2 Flux Cored and Solid Wire

Suitable for General purpose Welding

Spray Transfer

Metal transferred in multiples of small droplets

100 to 1000 Droplets per Second

Metal Spray Axially Directed

Electrode Tip Remains pointed

Applicable Only With Inert Gas Shielding

Not With Co2

Operates in Higher Amps & Volts Higher

Deposition Rate

Not Suitable for Welding in Out of Position.

Suitable for Welding Deep Grooves

Pulsed Spray Welding

Power Source Provides Two different

Current LevelsBackground and Peakat

regular interval

Background & Peak are above and

below the Average Current

Best Suitable for Full Penetration Open

Root Pass Welding

Good Control on Bead Shape and Finish

Synergic Pulse GMAW

Parameters of Pulsed Current (Frequency,

Amplitude, Duration, Background Current)

Related to Wire feed Rate

One Droplet detaches with each pulse

An Electronic Control unit synchronizes wire feed

Rate with Pulse Parameters

Best Suitable for Most Critical Full Penetration

Open Root Pass Welding

Good Control on Open Root penetration, Bead

Shape and Finish

GMAW Process Variables

Current

Voltage

Travel Speed

Stick Out / Electrode Extension

Electrode Inclination

Electrode Size

Shielding Gas & Flow Rate

Welding Position

Parameter For 1.2 FC Wire

Current 200 to 240 A

Voltage 22-24

Travel Speed 150 to 250 mm / min

Stick Out / Electrode Extension 15 to 20 mm

Electrode Inclination Back Hand Technique

Shielding Gas Co2, 12 L/Hr

Parameter For 1.2 Solid Wire

Current 180 to 220 A

Voltage 20-22

Travel Speed 150 to 200 mm / min

Stick Out / Electrode Extension 10 to 20 mm

Electrode Inclination Back Hand Technique

Shielding Gas Co2 12 L/Hr

Results In Change Of Parameters

Increase In Current

More deposition, More Penetration, More BM Fusion

Increase In Voltage

More Weld Bead Width, Less Penetration, Less

Reinforcement, Excess Spatter

Increase In Travel Speed

Decrease in Penetration, Decrease in Bead Width,

Decrease In Gas Flow rate

Results In porosity

Long Stick Out / Electrode Extension

Excess Weld Deposit With Less Arc intensity, Poor Bead

Finish, Shallow Penetration

Common Defects In GMAW

1. Porosity 2. Spatters

3. Lack Of Fusion 4. Under Cut

5. Over Lap 6. Slag

7. Crack 8. Lack Of Penetration

9. Burn Through 10. Convex Bead

11. Unstable Arc 12. Wire Stubbing

Porosity

Cause Remedy

1) Less Mn & Si In Wire

2) Rusted / Unclean BM / Groove

3) Rusted wire

4) Inadequate Shielding Gas

1) Use High Mn & Si Wire

2) Clean & warm the BM

3) Replace the Wire

4) Check & Correct Flow Rate

Porosity

. .

Spatters

Cause Remedy

1) Low Voltage

2) Inadequate Inductance

3) Rusted BM surface

4) Rusted Core wire

5) Quality Of Gas

1) Increase Voltage

2) Increase Inductance

3) Clean BM surface

4) Replace By Rust Free wire

5) Change Over To Ar + Co2

Spatters

Lack Of Fusion

Cause Remedy

1) Inadequate Current

2) Inadequate Voltage

3) Wrong Polarity

4) Slow Travel Speed

5) Excessive Oxide On Joint

1) Use Right Current

2) Use Right Voltage

3) Connect Ele. + Ve

4) Increase Travel speed

5) Clean Weld Joint

Lack Of Fusion

Undercut

Cause Remedy

1) Excess Voltage

2) Excess Current

3) Improper Torch angle

4) Excess Travel Speed

1) Reduce Voltage

2) Reduce Current

3) Train & Qualify the Welder

4) Reduce Travel Speed

Under cut

Overlap

Cause Remedy

1) Too Long Stick Out

2) Inadequate Voltage

1) Reduce Stick Out

2) Increase the Voltage

Overlap

Slag

Cause Remedy

1) Inadequate Cleaning

2) Inadequate Current

3) Wrong Torch angle

4) Improper bead placement

1) Clean each bead

2) Use Right Current

3) Train / Qualify welder

4) Train / Qualify Welder

Slag

Crack

Cause Remedy

1) Incorrect Wire Chemistry

2) Too Small Weld Bead

3) Improper Preheat

4) Excessive Restrain

1) Use Right Wire

2) Increase wire Feed

3) Preheat Uniformly

4) Post heating or ISR

crack

Lack Of Penetration*

Cause Remedy

1) Too Narrow Groove Angle

2) Inadequate Root opening

3) Too Low Welding current

4) Wrong Torch angle

5) Puddle Roll In Front Of Arc

6) Long Stick Out

1) Widen The Groove

2) Increase Root Opening

3) Increase Current

4) Train / Qualify Welder

5) Correct Torch Angle

6) Reduce Stick Out

LOP

* Applicable to SSFPW

Burn through*

Cause Remedy

1) Excess Current

2) Excess Root opening

3) Inadequate Root face

4) Too Low Travel Speed

5) Quality Of Gas

1) Reduce the Current

2) Reduce root opening

3) Increase root face

4) Increase Speed

5) Use Ar + Co2

Burn trough

*Applicable to root pass

Convex Bead Finish

Cause Remedy

1) Low Current

2) Low Voltage

3) Low Travel Speed

4) Low Inductance

5) Too Narrow Groove

1) Increase Current

2) Increase Voltage

3) Increase Travel Speed

4) Increase Inductance

5) Increase Groove Width

Uneven bead finish

Unstable arc

Cause Remedy

1) Improper Wire Feed

2) Improper Gas Flow

3) Twisted Torch Conduit

1) Check Wire Feeder

2) Check Flow Meter

3) Straighten Torch Cab

Wire Stubbing

Cause Remedy

1) Too Low Voltage

2) Too High Inductance

3) Excess Slope

4) Too Long Stick Out

1) Increase Voltage

2) Reduce Inductance

3) Adjust Slope

4) Reduce Stick Out

Important Terminology used in

Critical Welding

Preheating

Post Heating or Dehydrogenation

Intermediate Stress leaving

Inter pass Temperature

Post Weld Heat Treatment

What Is Preheating?

Heating the base metal along the weld joint to a

predetermined minimum temperature immediately before

starting the weld.

Heating by Oxy fuel flame or electric resistant coil

Heating from opposite side of welding wherever possible

Temperature to be verified by thermo chalks prior to

starting the weld

Why Preheating?

Preheating eliminates possible cracking of weld and HAZ

Applicable to

Hardenable low alloy steels of all thickness

Carbon steels of thickness above 25 mm.

Restrained welds of all thickness

Preheating temperature vary from 75C to 200C

depending on hardenability of material, thickness & joint

restrain

How does Preheating Eliminate Crack?

Preheating promotes slow cooling of weld and

HAZ

Slow cooling softens or prevents hardening of

weld and HAZ

Soft material not prone to crack even in

restrained condition

What Is Post Heating?

Raising the pre heating temperature of the weld joint to a

predetermined temperature range (250 C to 350 C) for

a minimum period of time (3 Hrs) before the weld cools

down to room temperature.

Post heating performed when welding is completed or

terminated any time in between.

Heating by Oxy fuel flame or electric resistant coil

Heating from opposite side of welding wherever possible

Temperature verified by thermo chalks during the period

Why Post Heating?

Post heating eliminates possible delayed cracking

of weld and HAZ

Applicable to

Thicker hardenable low alloy steels

Restrained hardenable welds of all thickness

Post heating temperature and duration depends on

hardenability of material, thickness & joint

restrain

How does Post Heating Eliminate

Crack?

SMAW introduces hydrogen in weld metal

Entrapped hydrogen in weld metal induces

delayed cracks unless removed before cooling to

room temperature

Retaining the weld at a higher temperature for a

longer duration allows the hydrogen to come out

of weld

What Is Intermediate Stress Relieving?

Heat treating a subassembly in a furnace to a

predetermined cycle immediately on completion of

critical restrained weld joint / joints without

allowing the welds to go down the pre heat

temperature. Rate of heating, Soaking temperature,

Soaking time and rate of cooling depends on

material quality and thickness

Applicable to

Highly restrained air hardenable material

Why Intermediate Stress Relieving?

Restrained welds in air hardenable steel highly

prone to crack on cooling to room temperature.

Cracks due to entrapped hydrogen and built in stress

Intermediate stress relieving relieves built in stresses

and entrapped hydrogen making the joint free from

crack prone

What Is Inter- Pass Temperature?

The temperature of a previously layed weld bead

immediately before depositing the next bead over

it

Temperature to be verified by thermo chalk prior

to starting next bead

Applicable to

Stainless Steel

Carbon Steel & LAS with minimum impact

Why Inter Pass Temperature?

Control on inter pass temperature avoids over

heating, there by

Refines the weld metal with fine grains

Improves the notch toughness properties

Minimize the loss of alloying elements in

welds

Reduces the distortion

What Is Post Weld Heat Treatment?

Heat treating an assembly on completion of all

applicable welding, in an enclosed furnace with

controlled heating/cooling rate and soaking at a

specific temperature for a specific time.

Rate of heating, Soaking temperature, Soaking time

and rate of cooling depends on material quality and

thickness

Applicable to

All type of CS & LAS

Why Post Weld Heat Treatment?

Welded joints retain internal stresses within the

structure

HAZ of welds remains invariably hardened

Post Weld Heat Treatment relieves internal stresses

and softens HAZ. This reduces the cracking

tendency of the equipment in service

Thanks

Submerged Arc Welding

By L D Poyyara

Poyyara Consultants

SAW

Fusion Welding Process

Automatic / Semi Automatic

Arc Between Consumable Electrode And Work

Arc Covered Under granular Flux

Wire / Electrode Continuously Fed To Weld Pool

Wire / Arc Under Flux Moves Along The Groove

Wire, BM & Flux Close to Arc Melt Under Flux

On Cooling Weld Metal Solidifies

Molten Flux Forms Thick Slag Coating On Weld

Poyyara Consultants

SAW

Poyyara Consultants

+

Wire

Flux

Slag

Weld

Base Metal

Hopper

Power Source

Flux

+

Arc

Flux For SAW

Sodium Chloride

Potassium Chloride

Titanium Dioxide

Sodium Silicate

Deoxidizing Agents

Poyyara Consultants

Types Of Flux

Fused Flux

Agglomerated Flux

Neutral Flux

Active Flux

Poyyara Consultants

Types Of Flux

Neutral Flux

-Wire compatible to base metal

- Single flux suitable for several material

Active Flux

- Single flux suitable for specific application

- Wire may be different from base metal

- To be welded within the recommended parameters

Poyyara Consultants

Function Of Flux In SAW

Stabilizes Arc

Prevents contamination of weld metal

Cleans the weld from unwanted impurities

Increases Fluidity of molten metal

Generates inert gas shielding while metal transfers

Forms slag after melting & covers weld

Allows deposited metal to cool slowly

Compensates alloying elements Within the weld

Eliminates spatter generation

Helps in even & uniform bead finish

Poyyara Consultants

Baking Requirements For Flux

Spread the loose Flux in a Tray Of baking Oven

Identify The Tray With The Quality/Grade Of Flux

Bake Tray in an Oven Between 300 C to 350 C

Baking Time 2Hrs to 3 Hrs

Reduce the temperature to 100 C to 150 C

Hold the Flux at this temperature till use

Poyyara Consultants

Why Baking Flux?

To remove the moisture (H2O)

To avoid possible cracking of weld due

to H2

Poyyara Consultants

How Does Moist Flux Generate

Crack Within Weld?

Moist Flux introduce atomic hydrogen at high

temperature in weld

On cooling, atomic hydrogen try to form

molecules

The reaction results in stresses and fine cracks

Cracks occur within hardened metal - HAZ

Known as Hydrogen Embitterment or Under

Bead Crack or Delayed Crack

Poyyara Consultants

Reuse Of Flux

Flux May Be Reused Provided

- Weld Not Highly Critical In Impact / Chemistry

- Reuse Limited To Maximum Twice

- All Slag Particles Are sieved & Removed

- Rebaked If not Remained In Hot

- Minimum 50% Fresh Flux Well Mixed

- Customer Spec. Doesn't Prohibit The Same

Poyyara Consultants

Types Of Power Source

Thyrester DC

Rectifier DC

Motor Generator DC

Transformer - AC

Poyyara Consultants

Characteristic Of Power Source

Poyyara Consultants

Machine welding

Drooping Cons. A Linear Cons. V

V V

A

A

V1

V2

V2

V1

A2 A1

A2

A1

SAW Wire - Electrode

Consumable Electrode / Wire

Layer Wound On Spool / Coil

CS & LAS Wires Coated with Cu

Conducts Current and generates Arc

Chemistry Compatible To Base Metal

Grade Of Flux Can Be Same For CS & LAS

Wire melts & deposited as filler in joint

Poyyara Consultants

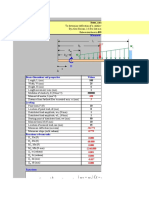

Typical Welding Parameter

Poyyara Consultants

Sr.

no

Wire

mm

Current A

Voltage

V

Speed

mm/min

Dep. Rate

Per Arc Hr

Wire & Flux

1 1.6 200-300 22-26 750-1500 3 4 kgs.

CS wire

+

Neutral

Flux

2 2 250-350 24-26 750-1250 3- 4.5 kgs.

4 2.5 300-350 25-27 750-1250 4 4.5 kgs.

5 3 400-500 28-30 500-100 5 5.5 kgs.

6 4 550-650 30-32 400-750 5.5 - 7 kgs.

7 5 600-800 30-34 350-700 6 - 8 kgs.

Important Terminology used in

Critical SAW

Preheating

Post Heating or Dehydrogenation

Intermediate Stress leaving

Inter pass Temperature

Post Weld Heat Treatment

Poyyara Consultants

What Is Preheating?

Heating the base metal along the weld joint

to a predetermined minimum temperature

immediately before starting the weld.

Heating by Oxy fuel flame or electric

resistant coil

Heating from opposite side of welding

wherever possible

Temperature to be verified by thermo chalks

prior to starting the weld

Poyyara Consultants

Why Preheating?

Preheating eliminates possible cracking of weld

and HAZ

Applicable to

-Hardenable low alloy steels of all thickness

-Carbon steels of thickness above 25 mm.

-Restrained welds of all thickness

Preheating temperature vary from 75C to 200C

depending on hardenability of material, thickness

& joint restrain

Poyyara Consultants

How does Preheating Eliminate

Crack?

Preheating promotes slow cooling of weld

and HAZ

Slow cooling softens or prevents hardening

of weld and HAZ

Soft material not prone to crack even in

restrained condition

Poyyara Consultants

What Is Post Heating?

Raising the pre heating temperature of the weld

joint to a predetermined temperature range (250

C to 350 C) for a minimum period of time (3 Hrs)

before the weld cools down to room temperature.

Post heating performed when welding is completed

or terminated any time in between.

Heating by Oxy fuel flame or electric resistant coil

Heating from opposite side of welding wherever

possible

Temperature verified by thermo chalks during the

period

Poyyara Consultants

Why Post Heating?

Post heating eliminates possible delayed

cracking of weld and HAZ

Applicable to

-Thicker hardenable low alloy steels

-Restrained hardenable welds of all

thickness

Post heating temperature and duration

depends on hardenability of material,

thickness & joint restrain

Poyyara Consultants

How does Post Heating Eliminate

Crack?

SAW introduces hydrogen in weld metal

Entrapped hydrogen in weld metal induces

delayed cracks unless removed before

cooling to room temperature

Retaining the weld at a higher temperature

for a longer duration allows the hydrogen to

come out of weld

Poyyara Consultants

What Is Intermediate Stress

Relieving?

Heat treating a subassembly in a furnace to

a predetermined cycle immediately on

completion of critical restrained weld joint /

joints without allowing the welds to go down

the pre heat temperature. Rate of heating,

Soaking temperature, Soaking time and rate

of cooling depends on material quality and

thickness

Applicable to

Highly restrained air hardenable material

Poyyara Consultants

Why Intermediate Stress

Relieving?

Restrained welds in air hardenable steel

highly prone to crack on cooling to room

temperature.

Cracks due to entrapped hydrogen and built

in stress

Intermediate stress relieving relieves built in

stresses and entrapped hydrogen making

the joint free from crack prone

Poyyara Consultants

What Is Inter- Pass Temperature?

The temperature of a previously layed weld

bead immediately before depositing the next

bead over it

Temperature to be verified by thermo chalk

prior to starting next bead

Applicable to

Stainless Steel

Carbon Steel & LAS with minimum

impact

Poyyara Consultants

Why Inter Pass Temperature?

Control on inter pass temperature avoids

over heating, there by

-Refines the weld metal with fine grains

-Improves the notch toughness properties

-Minimize the loss of alloying elements in

welds

-Reduces the distortion

Poyyara Consultants

What Is Post Weld Heat

Treatment?

Heat treating an assembly on completion of

all applicable welding, in an enclosed

furnace with controlled heating/cooling rate

and soaking at a specific temperature for a

specific time.

Rate of heating, Soaking temperature,

Soaking time and rate of cooling depends on

material quality and thickness

Applicable to

-All type of CS & LAS

Poyyara Consultants

Why Post Weld Heat Treatment?

Welded joints retain internal stresses within

the structure

HAZ of welds remains invariably hardened

Post Weld Heat Treatment relieves internal

stresses and softens HAZ. This reduces the

cracking tendency of the equipment in

service

Poyyara Consultants

Thanks

Shielded Metal Arc Welding

By L D Poyyara

What Is Welding ?

Process of joining metals / alloys

The process performed by Heat with or without

Pressure

Filler metal may or may not be used

The joint will be homogeneous

Classification Of Welding

1 Pressure Welding With Heat &

Pressure

2 Fusion Welding With Heat & mostly

with Filler

Pressure Welding Process

Metal parts heated to forging temperature

Heating by Oven, Oxy fuel flame or Electric

Resistance

Pressure applied on heated parts by

Hammer, Hydraulic Press or Mechanical

lever

The Parts remain permanent homogeneous

joint

Types Of Pressure Welding

Forge Welding

Resistance Butt / Flash Butt / Stud Welding

Resistance Spot Welding

Resistance Seam welding

Fusion Welding Process

Metal parts locally heated to melt along the joint.

Heating by oxy fuel flame or electric Arc.

Invariably filler metal added to molten pool.

On cooling, molten puddle solidifies to permanent

homogeneous joint.

Types Of Fusion Welding

Shielded Metal Arc Welding- SMAW

Gas Tungsten Arc Welding - GTAW

Gas Metal Arc Welding - MIG / MAG

Submerged Arc Welding SAW

Gas welding Oxy Fuel Gas

Electron Beam Welding - EBW

Thermit Welding

An electric Arc struck between

electrode and base metal joint

Base metal melts under arc

Electrode tip melts in drops and

transfers to molten pool of BM

Electrode with Arc moves along

the joint keeping constant arc

length

On cooling pool solidifies

Arc

Base Metal

Flux Coating

Core Wire

Pool

SMAW Process

Equipment, Accessories & tools

Power Source

Welding Cables, Holder & Earthing Clamp

Head Screen, Hand gloves, Chipping

Hammer & Wire Brush

Types Of Power Source

Inverter- DC

Thyrester DC

Motor Generator / Diesel Generator Set -DC

Rectifier DC

Transformer - AC

Characteristic Of Power Source

Manual welding Machine welding

Drooping Cons. A Linear Cons. V

V V

A

A

Vertical

Curve

Horizontal

Curve

V1

V2

A1 A2

V1

V2

A1 A2

Electrode

Consumable

Metallic Wire Coated with Flux

Conducts Current and generates Arc

Wire melts & deposited as filler in joint

Flux Coating On Electrode

Sodium Chloride

Potassium Chloride

Titanium Dioxide

Sodium Silicate

Ferrosilicon

Iron Powder

Alloying Elements

Binding Material

Function Of Flux In welding

Stabilizes Arc

Prevents contamination of weld metal

Cleans the weld from unwanted impurities

Increases fluidity of molten metal

Generates inert gas shielding while metal

transfers

Function Of Flux In welding

Forms slag after melting & covers weld

Allows deposited metal to cool slowly

Introduces alloying elements in the weld

Increases deposition efficiency

Minimizes the spatter generation

Helps in even & uniform bead finish

CS & LAS Electrode Sizes &

Recommended Currents

No

Core Wire in mm

Gage Current

Time required

for burning in

seconds

Average

electrodes

consumed in 8

Hrs shift

Dia Length

1 2 300 14 40 60 A 50-55 ---

2 2.5 350 12 60 85 A 60-65 ---

3 3.15 450 10 100 130 A 80 -85 120 - 140

4 4 450 8 130 180 A 85-90 110 - 120

5 5 450 6 150 210 A 90-95 80 - 90

6 6.3 450 4 240 250 A 95-100 60 -70

ASME Classification Of Electrodes

SFA 5.1

E 7018

E = Electrode

70 = UTS in 1000 psi ( 60/70/80/90/100/ 110)

1 = Position (1= all, 2= 1G, 1F & 2F, 3= 1G &

1F)

8 = Type of coating (0,1,2,3,5,6,8)

Baking Of Basic Coated Electrodes

Bake the loose electrodes in a baking Oven

Baking Temperature 250

C to 300

C

Baking Time 2Hrs to 3 Hrs

Reduce the temperature to 100

C to 150

C

Hold the electrodes at this temperature till use

Unused / left over electrodes to be re-baked

Why Baking?

To remove the moisture (H

2

O) from coating to

avoid possible cracking of weld

How Does Moist Electrode Generate

Crack Within Weld?

Moist electrodes introduce atomic hydrogen at high

temperature in weld

On cooling, atomic hydrogen try to form molecules

The reaction results in stresses and fine cracks

Cracks occur within hardened metal - HAZ

Known as Hydrogen Embrittlement , Under Bead

Crack, HIC, Delayed Crack

Important Terminologies used in Critical

Welding Operation

Preheating

Post Heating or Dehydrogenation

Intermediate Stress leaving

Inter pass Temperature

Post Weld Heat Treatment

What Is Preheating?

Heating the base metal along the weld joint to a

predetermined minimum temperature immediately

before starting the weld.

Heating by Oxy fuel flame or electric resistant coil

Heating from opposite side of welding wherever

possible

Temperature to be verified by thermo chalks prior to

starting the weld

Why Preheating?

Preheating eliminates possible cracking of weld and

HAZ

Applicable to

Hardenable low alloy steels of all thickness

Carbon steels of thickness above 25 mm.

Restrained welds of all thickness

Preheating temperature vary from 75

C to 200

C

depending on hardenability of material, thickness &

joint restraint

How does Preheating Eliminate Crack?

Preheating promotes slow cooling of weld and

HAZ

Slow cooling softens or prevents hardening of

weld and HAZ

Soft material not prone to crack even in

restrained condition

What Is Post Heating?

Raising the pre heating temperature of the weld joint to

a predetermined temperature range (250 C to 350 C)

for a minimum period of time (3 Hrs) before the weld

cools down to room temperature.

Post heating performed when welding is completed or

terminated any time in between.

Heating by Oxy fuel flame or electric resistant coil

Heating from opposite side of welding wherever

possible

Temperature verified by thermo chalks during the

period

Why Post Heating?

Post heating eliminates possible delayed cracking

of weld and HAZ

Applicable to

Thicker hardenable low alloy steels

Restrained hardenable welds of all

thickness

Post heating temperature and duration depends on

hardenability of material, thickness & joint

restrain

How does Post Heating Eliminate

Crack?

SMAW introduces hydrogen in weld metal

Entrapped hydrogen in weld metal induces

delayed cracks unless removed before cooling to

room temperature

Retaining the weld at a higher temperature for a

longer duration allows the hydrogen to come out

of weld

What Is Intermediate Stress Relieving?

Heat treating a subassembly in a furnace to a

predetermined cycle immediately on completion

of critical restrained weld joint / joints without

allowing the welds to go down the pre heat

temperature. Rate of heating, Soaking temperature,

Soaking time and rate of cooling depends on

material quality and thickness

Applicable to

Highly restrained air hardenable material

Why Intermediate Stress Relieving?

Restrained welds in air hardenable steel highly

prone to crack on cooling to room temperature.

Cracks due to entrapped hydrogen and built in stress

Intermediate stress relieving relieves built in

stresses and entrapped hydrogen making the joint

free from crack prone

What Is Inter- Pass Temperature?

The temperature of a previously layed weld bead

immediately before depositing the next bead over

it

Temperature to be verified by thermo chalk prior

to starting next bead

Applicable to

Stainless Steel

Carbon Steel & LAS with minimum impact

Why Inter Pass Temperature?

Control on inter pass temperature avoids over

heating, there by

Refines the weld metal with fine grains

Improves the notch toughness properties

Minimize the loss of alloying elements in welds

Reduces the distortion

What Is Post Weld Heat Treatment?

Heat treating an assembly on completion of all

applicable welding, in an enclosed furnace with

controlled heating/cooling rate and soaking at a

specific temperature for a specific time.

Rate of heating, Soaking temperature, Soaking

time and rate of cooling depends on material

quality and thickness

Applicable to

All type of CS & LAS

Why Post Weld Heat Treatment?

Welded joints retain internal stresses within the

structure

HAZ of welds remains invariably hardened

Post Weld Heat Treatment relieves internal

stresses and softens HAZ. This reduces the cracking

tendency of the equipment in service

Welding Terminologies used in

Qualifications

Heat In Put

Heat Effected Zone HAZ

Dilution

Overlap In Weld Overlay

Tempering Bead

What Is Heat In Put In Welding?

The extent of heat energy generated in Joules per

unit length while making each weld bead.

Heat In Put is the Function of Welding

Current, Arc Voltage, And the Welding Speed

It is measured in Joules -

Heat In Put In Joules / mm

= (A x V x 60) Travel Speed in mm / min

Why Control On Heat in Put?

Heat In put controls the grain size of weld

metal.

Lower the Heat in put finer the grain size.

Finer the Grain size Better the impact properties

Heat In Put Also controls Dilution, HAZ &

Geometry of Bead size

What Is Heat Affected Zone (HAZ)

A small volume of BM adjacent to weld fusion

line, which is totally changed in its structure due

to intense heat of each weld bead is known HAZ

Weld Zone

HAZ

Diluted BM

Diluted BM

Weld Zone

Fusion Line

What Is Significant Of HAZ

It is a part and parcel of weld joint

It is inevitable

It has properties different from BM & Weld

Metal

Weld Zone

HAZ

Diluted BM

Diluted BM

Weld Zone

Fusion Line

What Is Dilution In Weld

In all Fusion welding, a small portion of BM

very close to the welding heat gets melted and

added to weld zone / fusion zone. Dilution is

the ratio of molten base metal volume (Area)

to the volume ( Area) of total fusion zone

HAZ

Diluted BM

Weld / Fusion Zone

Fusion Line

% Dilution = (Area of Diluted BM Total Fused Area) 100

What Is Significant Of Dilution

Weld metal chemistry changes depending on

the extent of dilution

Chemical elements influence Physical properties

of the joint.

Weld chemistry influences corrosion resistance

of weld overlays

Weld Zone

HAZ

Diluted BM

Diluted BM

Weld Zone

Fusion Line

What Is Overlap In Weld Overlay?

The extent of covering or over lapping of

previous weld bead by the adjacent bead.

40 to 50 % Over Lap

Less Dilution More Dilution

10 to 15 % Over Lap

More Thickness

Less Thickness

What Is Significant Of Overlap In

Weld Overlay?

Overlap of 40 to 50% results in Less Dilution & more weld

overlay Thickness per layer

Less dilution results weld metal chemistry more towards filler

metal chemistry

40 to 50 % Over Lap 10 to 15 % Over Lap

Less Dilution More Dilution

More Thickness

Less Thickness

What Is Temper Bead Technique?

In a multi pass groove & Fillet Welds, each bead & its

HAZ are getting tempered (heat treated) by the welding

heat of the next bead.

Thus all beads & their HAZ, except those in last layer,

are tempered.

Temper beads are the specially & carefully welded

temporary beads on the top of final weld reinforcement

with out allowing to generate any HAZ within the BM.

Temper beads are to be ground flush with the required

reinforcement.

Temper Bead

Temper Bead T1 & T2 Not To Generate HAZ

In BM

Temper Beads To Be Ground Flush

T2 T1

2

1

3

3

4

4

5

5

T1 & T2 To be ground Flush

HAZ

Rqd. Reinforcement

Common Defects In SMAW

1. Cracks 2. Lack Of Fusion

3. Slag 4. Porosity

5. Pinhole 6. Piping

7. Undercut 8. Overlap

9. Lack Of Penetration 10. Excess Penetration

11. Spatters 12. Suck Back

13. Under Flush 14. Burn Through

15. Uneven Bead 16.Stray Arcing

Crack

Cause Remedy

1) Wrong Consumable

2) Wrong Procedure

3) Improper Preheat

4) Excessive Restrain

1) Use Right Electrode

2) Qualify Procedure

3) Preheat Uniformly

4) Post heating or ISR

crack

Lack Of Fusion

Cause Remedy

1) Inadequate Current

2) Wrong Electrode angle

3) Improper bead placement

1) Use Right Current

2) Train /Qualify welder

3) Train/Qualify Welder

Lack Of Fusion

Slag

Cause Remedy

1) Inadequate Cleaning

2) Inadequate Current

3) Wrong Electrode angle

4) Improper bead placement

1) Clean each bead

2) Use Right Current

3) Train / Qualify welder

4) Train / Qualify Welder

Slag

Porosity

Cause Remedy

1) Damp Electrode

2) Damaged coating

3) Wet surface of BM

4) Rusted core wire

1) Bake the electrodes

2) Replace the electrodes

3) Clean & warm the BM

4) Replace the electrodes

Porosity

. .

Pinhole

Cause Remedy

1) Damp Electrode

2) Damaged coating

3) Wet surface of BM/WM

4) Rusted core wire

1) Bake the electrodes

2) Replace the electrodes

3) Clean & warm the BM

4) Replace the electrodes

Pinhole

Piping

Cause Remedy

1) Damp Electrode

2) Damaged coating

3) Previous beads wet

4) Rusted core wire

1) Bake the electrodes

2) Replace the electrodes

3) Clean & warm the weld

4) Replace the electrodes

Piping

Undercut

Cause Remedy

1) Excess Current

2) Excess Voltage

3) Improper Electrode angle

4) Eccentric Coating

1) Reduce the Current

2) Reduce Arc length

3) Train & Qualify the Welder

4) Replace the electrode

Under cut

Overlap

Cause Remedy

1) Wrong Electrode Angle

2) Inadequate current

1) Train & Qualify welder

2) Increase the current

Overlap

Lack Of Penetration*

Cause Remedy

1) Excess Root Face

2) Inadequate Root opening

3) Over size electrode

4) Wrong Electrode angle

5) Improper bead placement

6) Improper weaving technique

1) Reduce Root Face

2) Increase Root Opening

3) Reduce electrode size

4) Train / Qualify Welder

5) Train / Qualify Welder

6) Train & Qualify Welder

LOP

* Applicable to SSFPW

Excess Penetration*

Cause Remedy

1) Excess root opening

2) Excess Current

3) Inadequate root face

4) Wrong Electrode angle

1) Reduce root gap

2) Reduce Current

3) Increase Root face

4) Train / Qualify Welder

Excess Penetration

* Applicable to SSFPW

Spatters

Cause Remedy

1) Excess Current

2) Excess Voltage

3) Wrong Polarity

4) Wet Electrodes

5) Rusted BM surface

6) Rusted Core wire

7) Eccentrics coating

1) Reduce to Right Current

2) Reduce Arc length

3) Correct the polarity

4) Use Baked electrodes

5) Clean BM surface

6) Replace the electrodes

7) Replace the electrodes

Spatters

Suck Back*

Cause Remedy

1) Excess weaving in root

2) Excess Current

3) Inadequate root face

4) Wrong Electrode angle

1)Reduce weaving

2) Reduce Current

3) Increase Root face

4) Train / Qualify Welder

Suck Back

* Applicable to SSFPW in 4G, 3G & 2G

Under Flush

Cause Remedy

1) Inadequate weld beads in

final layer

2) Inadequate understanding on

weld reinforcement requirement

3) Wrong selection of Electrode

size for final layer

1) Weld some more beads

in final layer

2) Train / Qualify welder

3) Train / Qualify Welder

Under flush

Burn through*

Cause Remedy

1) Excess Current

2) Excess Root opening

3) Inadequate Root face

4) Improper weaving

1) Reduce the Current

2) Reduce root opening

3) Increase root face

4) Train / Qualify Welder

Burn trough

*Applicable to root pass

Uneven Bead Finish

Cause Remedy

1) Improper bead

placement

2) Excess Voltage

3) Excess / inadequate

current

1) Train & Qualify the Welder

2) Reduce Arc length

3) Train & Qualify the Welder

Uneven bead finish

Stray Arcing

Cause Remedy

1) Wrong Arc Striking Practice

2) Inadequate Skill of Welder

1) Train the Welder

2) Train the Welder

Arc Strikes

Good Engineering Practices in

Shielded Metal Arc Welding

Good Engineering Practices In

SMAW

Do Welding with properly baked electrodes

Basic coated CS electrodes to be baked to

250

C to 300

C for two hours

Baked electrodes to be directly used on job or

to be retained in a hold over oven at 100

C to

150

C until use

Unused balance electrodes shall be returned to

baking oven

Do not weld with damp Electrodes

Do not try to heat electrodes by touching the

job (Short circuiting)

Do not use electrodes with damaged coating

Do not use electrodes with cracked coating

Do not bend the electrodes after holding it in

the holder

Good Engineering Practices In

SMAW

Do not weld on groove / surface with mill

scale or rusting

Prior to welding, clean the weld groove with

power wire wheel

Do not weld with unidentified electrodes

Do not leave balance electrodes unattended

on shop

Good Engineering Practices In

SMAW

All connections with earthing and welding

cables shall be tight fitted

Earthing clamp shall always be tightly

connected to the job

Burn the full length of electrode till 37 mm

stub length

Good Engineering Practices In

SMAW

Earthing cable shall directly connect to the

job with an earthing clamp.

Tacks for set up shall be minimum 5 times the

electrode diameter

Weaving shall be limited to three times the

electrode diameter.

Only trained & qualified welders shall be

employed for welding

Good Engineering Practices In

SMAW

Do not direct fan or blower to welding arc

Remove paint if any from the area near

welding

While welding in open, area shall be covered

to protect from rain water & breeze

Weld edge preparation shall be free from

serrations

Good Engineering Practices In

SMAW

Use poison plates between the job material &

structural supports.

Do not damage parent metal while removing

temporary supports.

Locations where from temporary supports are

removed shall be touched up by welding /

grinding and PT checked.

Good Engineering Practices In

SMAW

Remove visible defects from welds before

placing the subsequent beads

Do not weld over a visible crack

Electrodes kept out side more than 2 Hrs shall

be returned to baking oven

Maximum 15 electrodes at a time shall be

taken from oven for welding

Good Engineering Practices In

SMAW

When preheat is required, heat from opposite

side of welding.

Use temperature indicating crayons for

checking temperature

Do not Weld more than specified weld size-

Fillet / Reinforcement.

Good Engineering Practices In

SMAW

Safety Precautions in

Shielded Metal Arc Welding

Safety Precautions In SMAW

Welders shall use safety devises Hand

gloves, Head screen with right glass & Safety

shoes

Welders shall use full sleeve boiler suit

Use welding glass-DIN 11/12 up to 250

Amps and 13 above 250 Amps

Do not look at the arc with naked eyes

Do not throw Stubs on ground. They shall be

placed in stub collector.

Do not keep electrode in the holder when

work is not in progress

Do not touch the electrode held on holder and

the the job when the power source is on

Keep welding cables duly wound near power

source when no welding is done

Safety Precautions In SMAW

Do not breath welding fumes

When working in confined area, ensure

adequate ventilation / exhaust

Gas cutting torch / preheating burner shall not

be taken inside confined area unless the flame

is lit

When not in use, switch off the the power

source from electric supply

Safety Precautions In SMAW

Acetone / inflammable liquids (Chemical for

dye penetrant test) shall not be brought near

welding

Gas cutting unit / fuel gas cylinders shall be

away from welding area

Wet safety Shoes or wet hand gloves shall not

be worn while welding

Safety Precautions In SMAW

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Westermann Tables Materials Classification and PropertiesDokument86 SeitenWestermann Tables Materials Classification and PropertiesDipak88% (17)

- Surface Vehicle StandardDokument7 SeitenSurface Vehicle Standardwilian_coelho3309Noch keine Bewertungen

- A506 00 PDFDokument4 SeitenA506 00 PDFJohano AraújoNoch keine Bewertungen

- BGR 270 MVA 1-PH GT short circuit strength calculationDokument3 SeitenBGR 270 MVA 1-PH GT short circuit strength calculationFasil ParuvanathNoch keine Bewertungen

- Are Structures Cheat Sheet 1Dokument5 SeitenAre Structures Cheat Sheet 1priodeep chowdhuryNoch keine Bewertungen

- Is 513 StandardsDokument18 SeitenIs 513 StandardsEr Abhijeet Kamble0% (1)

- Designation: D7175 08Dokument16 SeitenDesignation: D7175 08Lupita RamirezNoch keine Bewertungen

- A480A480M-14b Standard Specification For General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and StripDokument27 SeitenA480A480M-14b Standard Specification For General Requirements For Flat-Rolled Stainless and Heat-Resisting Steel Plate, Sheet, and Striptjt4779100% (1)

- (BS ISO 128-40 - 2001) - Technical Drawings. General Principles of Presentation. Basic Conventions For Cuts and Sections PDFDokument14 Seiten(BS ISO 128-40 - 2001) - Technical Drawings. General Principles of Presentation. Basic Conventions For Cuts and Sections PDFFasil Paruvanath100% (1)

- Dictionary of MetallurgyDokument309 SeitenDictionary of MetallurgyADITYA_PATHAKNoch keine Bewertungen

- ASTM A36 DatasheetDokument4 SeitenASTM A36 DatasheetRene D. ArrietaNoch keine Bewertungen

- Beam Cantilever ComDokument15 SeitenBeam Cantilever ComHareesh GrNoch keine Bewertungen

- Environmental Product Declaration: Power Transformer Trafostar 63 MvaDokument4 SeitenEnvironmental Product Declaration: Power Transformer Trafostar 63 MvaFasil ParuvanathNoch keine Bewertungen

- Influence LinesDokument5 SeitenInfluence LinessushilkumarNoch keine Bewertungen

- Goforth Diathesis-Stress Model FinalDokument3 SeitenGoforth Diathesis-Stress Model FinalmaretadekaNoch keine Bewertungen

- Module 1 Lecture 3 FinalDokument12 SeitenModule 1 Lecture 3 Finaltejap314Noch keine Bewertungen

- 7.1 Finite Element Simulation of Chassis DesignDokument5 Seiten7.1 Finite Element Simulation of Chassis DesignFasil ParuvanathNoch keine Bewertungen

- NAFEMS BooksDokument4 SeitenNAFEMS Booksds_srinivas50% (2)

- 16 - Chapter 6Dokument5 Seiten16 - Chapter 6Fasil ParuvanathNoch keine Bewertungen

- Genetic Algorithm Optimizes Chassis Section Modulus for Load, StressDokument1 SeiteGenetic Algorithm Optimizes Chassis Section Modulus for Load, StressFasil ParuvanathNoch keine Bewertungen

- 30.design and Analysis of A Automobile FrameDokument1 Seite30.design and Analysis of A Automobile FrameFasil ParuvanathNoch keine Bewertungen

- Ease of Doing Business in India: Factors & ImprovementsDokument4 SeitenEase of Doing Business in India: Factors & ImprovementsFasil ParuvanathNoch keine Bewertungen

- Climate Change Affect ChilldrenDokument5 SeitenClimate Change Affect ChilldrenFasil ParuvanathNoch keine Bewertungen

- Pass Format From Police StationDokument1 SeitePass Format From Police StationThe Indian Express83% (6)

- 03 AbstractsDokument3 Seiten03 AbstractsFasil ParuvanathNoch keine Bewertungen

- Graphics - Software OpengGLDokument2 SeitenGraphics - Software OpengGLFasil ParuvanathNoch keine Bewertungen

- Parameter Changes - ConfigDokument1 SeiteParameter Changes - ConfigFasil ParuvanathNoch keine Bewertungen

- Climate Change Affect ChilldrenDokument5 SeitenClimate Change Affect ChilldrenFasil ParuvanathNoch keine Bewertungen

- Vehicle Chassis Optimization Using Genetic AlgorithmDokument3 SeitenVehicle Chassis Optimization Using Genetic AlgorithmFasil ParuvanathNoch keine Bewertungen

- Genetic Algorithm Optimizes Chassis Section Modulus for Load, StressDokument1 SeiteGenetic Algorithm Optimizes Chassis Section Modulus for Load, StressFasil ParuvanathNoch keine Bewertungen

- Stress ManagementDokument10 SeitenStress ManagementRishabh MehtaNoch keine Bewertungen

- List of Tables: Table Title No. NoDokument2 SeitenList of Tables: Table Title No. NoFasil ParuvanathNoch keine Bewertungen

- 7.1 Finite Element Simulation of Chassis DesignDokument5 Seiten7.1 Finite Element Simulation of Chassis DesignFasil ParuvanathNoch keine Bewertungen

- 13 ReferencesDokument9 Seiten13 ReferencesAbdelrahman MagdyNoch keine Bewertungen

- Lenovo s30 Manual PDFDokument1 SeiteLenovo s30 Manual PDFFasil ParuvanathNoch keine Bewertungen

- Pippin PDFDokument6 SeitenPippin PDFFasil ParuvanathNoch keine Bewertungen

- Practitioners GuideDokument5 SeitenPractitioners GuideNarina Avi SeptiyantiNoch keine Bewertungen

- E Electrical PDF 2011Dokument19 SeitenE Electrical PDF 2011Towkir AhmmadNoch keine Bewertungen

- ASTM A853 Alambre RecocidoDokument3 SeitenASTM A853 Alambre RecocidoLuisalbertobarNoch keine Bewertungen

- Borosil Pricelist 2015-16 - LRDokument263 SeitenBorosil Pricelist 2015-16 - LRN GANESAMOORTHY0% (1)

- 51CrV4 10083 06 ENG 01Dokument1 Seite51CrV4 10083 06 ENG 01ashkansoheylNoch keine Bewertungen

- Material SciencesDokument11 SeitenMaterial SciencesSafana SarwarNoch keine Bewertungen

- Lvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudDokument17 SeitenLvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudAnshu Tech100% (4)

- Hs Stainless SteelDokument12 SeitenHs Stainless SteelKrisna MahendraNoch keine Bewertungen

- Tool Steel - Material Selection Guide: High Speed SteelsDokument1 SeiteTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKNoch keine Bewertungen

- Specification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure VesselsDokument13 SeitenSpecification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure VesselsjscfNoch keine Bewertungen

- Advanced High Strength Steel (Ahss) Application GuidelinesDokument163 SeitenAdvanced High Strength Steel (Ahss) Application Guidelines366900100% (1)

- 317LDokument4 Seiten317LSuriyachai NiamsornNoch keine Bewertungen

- Closed-Book Practice-Ch 07 (2016!12!24)Dokument8 SeitenClosed-Book Practice-Ch 07 (2016!12!24)JuanNoch keine Bewertungen

- High Tensile Steel 4140Dokument2 SeitenHigh Tensile Steel 4140Sadullah TaşkınNoch keine Bewertungen

- 15heat Treatment of SteelsDokument42 Seiten15heat Treatment of SteelsFrafyadNoch keine Bewertungen

- Technical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Dokument5 SeitenTechnical Data Sheet Jindal Stainless Steel Grade JSL AUS (J1)Dudung SNoch keine Bewertungen

- A 960 - 02 Qtk2mc0wmkeDokument9 SeitenA 960 - 02 Qtk2mc0wmkesachinguptachdNoch keine Bewertungen

- Tratamente Termice F4Dokument6 SeitenTratamente Termice F4andreeaoana45Noch keine Bewertungen

- Astm A 960 - 03 - QTK2MC0WMWDokument9 SeitenAstm A 960 - 03 - QTK2MC0WMWEjat ISNoch keine Bewertungen

- Rotor Manufacturing Report: Heat Treatment ProcessesDokument3 SeitenRotor Manufacturing Report: Heat Treatment Processessumukha nadigNoch keine Bewertungen

- Innovative and Highly Productive Joining Technologies For Multi-Material Lightweight Car Body Structures PDFDokument9 SeitenInnovative and Highly Productive Joining Technologies For Multi-Material Lightweight Car Body Structures PDFS P Suganthi GaneshNoch keine Bewertungen

- Everything about case hardening steelDokument2 SeitenEverything about case hardening steelFrancisco Botelho Carlos100% (1)

- KMTL Cast Iron Turning Guide 32 65Dokument34 SeitenKMTL Cast Iron Turning Guide 32 65cristian111111Noch keine Bewertungen