Beruflich Dokumente

Kultur Dokumente

A Bearing Is A Device To Permit Constrained Relative Motion Between Two Parts, Typically Rotation or Linear Movement

Hochgeladen von

Sreedhar Madhana100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

83 Ansichten18 Seitencontains different types of rolling element bearings, Terminology and geometry of rolling bearings

Originaltitel

Rolling Bearings

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldencontains different types of rolling element bearings, Terminology and geometry of rolling bearings

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

83 Ansichten18 SeitenA Bearing Is A Device To Permit Constrained Relative Motion Between Two Parts, Typically Rotation or Linear Movement

Hochgeladen von

Sreedhar Madhanacontains different types of rolling element bearings, Terminology and geometry of rolling bearings

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 18

INTRODUCTION

A Bearing is a device to permit constrained relative motion between two

parts, typically rotation or linear movement.

When there is a relative motion between two machine parts, one of

which supports the others.The supporting member is called Bearing.

TERMINOLOGY

Inner race

Outer race

Inner and outer

diameters

Width

Geometry of Rolling Contact

Bearings

SELECTION OF BEARING

TYPE

Each bearing type displays characteristic properties, based on its design which makes it

more, or less appropriate for a given application

The most important factors to be considered when selecting a standard bearing type and

thus a facilitate an appropriate choice :

Available space

Loads

Misalignment

Precision

Speed

Quiet running

Stiffness

Axial displacement

Mounting and dismounting

Integral seals

LOADS

MAGNITUDE OF LOAD :-

The magnitude of the load is one of the factors that usually determines the size of the

bearing to be used. Generally, roller bearing are available to support heavier loads than

similar size ball bearing and bearings having a full compliment of rolling elements can

accommodate heavier loads than the corresponding caged bearing.

DIRECTION OF LOAD

Radial load :-

The load which comes perpendicular on the

shaft called redial load.

Cylindrical roller

bearing, needle roller bearing, and

toroidal roller bearing can only support

pure Radial loads.

DIRECTION OF LOAD

Axial load :-

The load which comes axis on the shaft

called Axial load.

Thrust ball bearing and four point contact

ball bearing are suitable for light or

moderate loads that are purely axial.

DIRECTION OF LOAD

Combined load :-

A combined load comprises a redial and an

axial load acting simultaneously

For combined loads, single and double row

angular contact ball bearing, and single

row taper roller bearing are most

commonly used, although deep groove

ball bearing and spherical roller bearing

are suitable.

SPEED

The permissible operating temperature limits the speed at which rolling

bearings can be operated. Bearing types with low friction and correspondingly

low heat generation inside the bearing are therefore the most suitable for

high - speed operation.

BALL BEARING

A Ball bearing is a common type

of rolling element bearing.

-Point contact; support radial

and axial loads.

ANGULAR CONTACT BALL

BEARING

Designed for axial loading;

used in pairs

These bearing are used where the thrust

load is equal to or greater than radial load.

THRUST BALL BEARING

Designed for pure

axial loading

This type comprises a row of balls

running between two flat groove washers

with balls track designed to absorbed

thrust load in one direction this does not

with stand any radial loads, also with this

is not suitable for higher speeds.

ROLLER BEARING

Roller bearings are used in rotary

applications to replace sliding movement

with low friction, rolling motion. The

principal types of roller bearings are

cylindrical, spherical, and tapered. In

general, roller bearings offer higher load

capacities than ball bearings of the same

size

CYLINDRICAL ROLLER BEARING

Supports high radial

loads; slower speed ratings

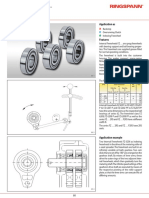

TAPERED ROLLER

BEARING

High radial and axial load

ratings; used in pairs

These bearings carry heavy loads

at moderate speed. There should

always be mounted in pairs with

opposed taper because in each

bearing the radial load produced an

axial component which needs

counter balance

SPHERICAL ROLLER BEARING

Allows for misalignment

These bearings are suitable for use with

independent support housing and

wherever there is possibility of a lack of

alignment. It can carry medium or heavy

redial or combined load.

NEEDLE ROLLER

BEARING

Thrust and radial types; typically

no inner race

These bearings are used in plans

where the speed in low or oscillation

takes place as in wrist pin, rocker arm,

universal joint etc.

Das könnte Ihnen auch gefallen

- Bearings: BEARING: It Is Device WhichDokument23 SeitenBearings: BEARING: It Is Device WhichPranjal Dogra100% (1)

- Lecture 1Dokument8 SeitenLecture 1Debabrat SaikiaNoch keine Bewertungen

- Engineering DrawingDokument41 SeitenEngineering DrawingKinfe MehariNoch keine Bewertungen

- Material Dan MetalurgiDokument32 SeitenMaterial Dan MetalurgiPrengki WijayaNoch keine Bewertungen

- Big Island Bliss - Anita CarminDokument3 SeitenBig Island Bliss - Anita CarminAnitaCarminNoch keine Bewertungen

- VolcanoDokument17 SeitenVolcanoanm1207Noch keine Bewertungen

- Calculus TestDokument3 SeitenCalculus TestMark EichenlaubNoch keine Bewertungen

- Lubrication of Wire RopeDokument14 SeitenLubrication of Wire RopegauthamNoch keine Bewertungen

- TrigonometryDokument60 SeitenTrigonometryjobeth_garcia10Noch keine Bewertungen

- Rolling Contact Bearings - DMEDokument28 SeitenRolling Contact Bearings - DMESumitNoch keine Bewertungen

- HHT FFT DifferencesDokument8 SeitenHHT FFT Differencesbubo28Noch keine Bewertungen

- Application of Nitrous Oxide in AutomobilesDokument14 SeitenApplication of Nitrous Oxide in AutomobilesmandykapoorNoch keine Bewertungen

- The Golden Ratio, Fibonacci Series and Continued FractionsDokument23 SeitenThe Golden Ratio, Fibonacci Series and Continued FractionsDr Srinivasan Nenmeli -KNoch keine Bewertungen

- Yield Stress Von MIses Stress Strength of Materials - Mechanics of MaterialsDokument3 SeitenYield Stress Von MIses Stress Strength of Materials - Mechanics of MaterialsGnabBangNoch keine Bewertungen

- Radio Frequency Identification (RFID) Opportunities For Mobile Telecommunication ServicesDokument18 SeitenRadio Frequency Identification (RFID) Opportunities For Mobile Telecommunication ServicesAmit NaikNoch keine Bewertungen

- Spoke Tension - The Definitive Guide To Spoke Tensioning - Spokecalc - IoDokument8 SeitenSpoke Tension - The Definitive Guide To Spoke Tensioning - Spokecalc - IoJose Luis Sabino100% (1)

- Leaf SpringDokument15 SeitenLeaf SpringAjay SengarNoch keine Bewertungen

- Post Pouring BeltDokument5 SeitenPost Pouring BeltlouiNoch keine Bewertungen

- Gear Ratio Calculations PDFDokument4 SeitenGear Ratio Calculations PDFrechingatuputamadreNoch keine Bewertungen

- Gear Teeth: Clocks and ShipsDokument16 SeitenGear Teeth: Clocks and ShipsČika BrkoNoch keine Bewertungen

- Linear Homogeneous Boundary Value Problems: Dr. P. DhanumjayaDokument19 SeitenLinear Homogeneous Boundary Value Problems: Dr. P. DhanumjayapurijatinNoch keine Bewertungen

- Static Analysis of A Bycycle FrameDokument24 SeitenStatic Analysis of A Bycycle FrameADARSH SINGHNoch keine Bewertungen

- 1 1 4 A PulleydrivessprocketsDokument4 Seiten1 1 4 A Pulleydrivessprocketsapi-30839565067% (3)

- Coupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, SeeDokument24 SeitenCoupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, Seerupesh8989Noch keine Bewertungen

- Quora MechanicalDokument14 SeitenQuora MechanicalRj SakthiNoch keine Bewertungen

- Design and Analysis Procedures For Shafts and Splines: Paul E. BurkeDokument21 SeitenDesign and Analysis Procedures For Shafts and Splines: Paul E. BurkeBalasrinivasan Murugan100% (3)

- Lab Report 5:: Compound PendulumDokument12 SeitenLab Report 5:: Compound PendulumAymen JavaidNoch keine Bewertungen

- How To Design With Precision BallscrewsDokument10 SeitenHow To Design With Precision BallscrewsRichard CapewellNoch keine Bewertungen

- Drive ShaftDokument8 SeitenDrive ShaftAkshat SharmaNoch keine Bewertungen

- Bearing ReliabilityDokument3 SeitenBearing ReliabilityWayu100% (1)

- Shaft Alignment Guide - E-Jan05Dokument12 SeitenShaft Alignment Guide - E-Jan05Brian FreemanNoch keine Bewertungen

- Lab ManualDokument25 SeitenLab ManualFarhan Khan NiaZi100% (1)

- Lecture Slides: Shigley's Mechanical Engineering DesignDokument108 SeitenLecture Slides: Shigley's Mechanical Engineering DesignHamza SultanNoch keine Bewertungen

- Tech-03 Springs-Roll Stiffness-4 PDFDokument9 SeitenTech-03 Springs-Roll Stiffness-4 PDFMibsão EsdrasNoch keine Bewertungen

- RequestDokument22 SeitenRequestOmar MuñozNoch keine Bewertungen

- NSK Rollneck Bearing ManualDokument36 SeitenNSK Rollneck Bearing ManualFaizNoch keine Bewertungen

- Self-Locking Gear - Design and Potential ApplicationsDokument7 SeitenSelf-Locking Gear - Design and Potential ApplicationsVikram BalajiNoch keine Bewertungen

- 1 Mechatronics OverviewDokument13 Seiten1 Mechatronics OverviewPaul WallsNoch keine Bewertungen

- Chapter 7 Rolling Contact Bearing-2Dokument33 SeitenChapter 7 Rolling Contact Bearing-2Abaziz Mousa OutlawZzNoch keine Bewertungen

- Design & Analysis of Steering System Drag Link Against Buckling Loads For Tipper ApplicationDokument7 SeitenDesign & Analysis of Steering System Drag Link Against Buckling Loads For Tipper ApplicationIJIERT-International Journal of Innovations in Engineering Research and TechnologyNoch keine Bewertungen

- Dynamic Analysis of Leaf SpringDokument9 SeitenDynamic Analysis of Leaf SpringTHEBESTNoch keine Bewertungen

- Optimization of Planetary Gear Box For High Reduction RatioDokument12 SeitenOptimization of Planetary Gear Box For High Reduction RatioNovriansyah BrianNoch keine Bewertungen

- Iowa Class - Armor ProtectionDokument3 SeitenIowa Class - Armor Protectionsworks69100% (1)

- 07 MolesDokument3 Seiten07 MoleshiepwinNoch keine Bewertungen

- Abstract Precision Gear Boxes and Geared Motors ReportDokument2 SeitenAbstract Precision Gear Boxes and Geared Motors Reportsandy17377Noch keine Bewertungen

- CH 11 SlidesDokument77 SeitenCH 11 SlidestasrifNoch keine Bewertungen

- F1 CARS ChassisDokument27 SeitenF1 CARS ChassisNikhil Goyal100% (2)

- Optimization of Gear To Improve Performance of GearboxDokument4 SeitenOptimization of Gear To Improve Performance of Gearboxijaert100% (1)

- Types of GearsDokument22 SeitenTypes of GearsAnonymous 2RbW9dNoch keine Bewertungen

- Screwthread and Gear MeasurementDokument19 SeitenScrewthread and Gear MeasurementseenuNoch keine Bewertungen

- Ptitchener Gearboxreport FullDokument25 SeitenPtitchener Gearboxreport Fullapi-244906204Noch keine Bewertungen

- Types of PendulumDokument5 SeitenTypes of PendulumExpertsmindEdu100% (2)

- Thesis On Ball BearingsDokument196 SeitenThesis On Ball BearingsSudheer Reddy TenaliNoch keine Bewertungen

- Foote-Jones Spiral Bevel Helical ReducerDokument21 SeitenFoote-Jones Spiral Bevel Helical Reducerbwelz100% (1)

- An Investigation of The Fatigue and Fretting PerformanceDokument19 SeitenAn Investigation of The Fatigue and Fretting PerformanceKrishna PrasadNoch keine Bewertungen

- Harmonic Drive GearingDokument22 SeitenHarmonic Drive GearingManoj Kumar SarangiNoch keine Bewertungen

- A Study On Tribological & Statistical Investigation of PTFE, Tin Bronze and White MetalDokument9 SeitenA Study On Tribological & Statistical Investigation of PTFE, Tin Bronze and White MetalIJRASETPublicationsNoch keine Bewertungen

- Design and Analysis of Wheel Assembly For FSAE F3 VehicleDokument4 SeitenDesign and Analysis of Wheel Assembly For FSAE F3 VehicleEditor IJTSRD100% (1)

- 20 Design of Helical Springs For Variable LoadDokument16 Seiten20 Design of Helical Springs For Variable LoadPRASAD326Noch keine Bewertungen

- Microstructure and Defects in NanomaterialsDokument32 SeitenMicrostructure and Defects in NanomaterialsSreedhar MadhanaNoch keine Bewertungen

- UnitDokument2 SeitenUnitSreedhar MadhanaNoch keine Bewertungen

- TH THDokument1 SeiteTH THSreedhar MadhanaNoch keine Bewertungen

- Indian GeographyDokument446 SeitenIndian GeographySreedhar Madhana100% (5)

- IC Engine Components (Autosaved)Dokument5 SeitenIC Engine Components (Autosaved)Sreedhar MadhanaNoch keine Bewertungen

- Nursery RhymesDokument3 SeitenNursery RhymesSreedhar Madhana100% (1)

- Sketch ModuleDokument6 SeitenSketch ModuleSreedhar MadhanaNoch keine Bewertungen

- Machine Drawing1Dokument11 SeitenMachine Drawing1Sreedhar MadhanaNoch keine Bewertungen

- Machine Design - IntroductionDokument9 SeitenMachine Design - IntroductionSreedhar MadhanaNoch keine Bewertungen

- S3SD/S4SD & Sb3Sd/Sb4Sd: Submersible Sewage Dual Seal PumpsDokument8 SeitenS3SD/S4SD & Sb3Sd/Sb4Sd: Submersible Sewage Dual Seal PumpsulisesgeNoch keine Bewertungen

- Screw Pumps ACG-UCGDokument11 SeitenScrew Pumps ACG-UCGmohamedNoch keine Bewertungen

- Internal Freewheels FZ : With Ball Bearing PropertiesDokument6 SeitenInternal Freewheels FZ : With Ball Bearing Propertiesmohammed kareemNoch keine Bewertungen

- Coal Feeding AreaDokument75 SeitenCoal Feeding AreaAamir HayatNoch keine Bewertungen

- RKB Bearings Catalogue Light BetaDokument352 SeitenRKB Bearings Catalogue Light BetaHector MaldonadoNoch keine Bewertungen

- SKF Bearings Master InterchangeDokument452 SeitenSKF Bearings Master InterchangeAamir AshinNoch keine Bewertungen

- Bearing Technology Topics TR-113059-V2Dokument149 SeitenBearing Technology Topics TR-113059-V2anesi67100% (2)

- Viking Serie 4197 Sec - 164!12!06screenDokument5 SeitenViking Serie 4197 Sec - 164!12!06screenneoNoch keine Bewertungen

- Die Set Engineering Handbook and CatalogDokument144 SeitenDie Set Engineering Handbook and CatalogEduardo Medel50% (2)

- Bearing TypesDokument33 SeitenBearing TypesFaisal TariqNoch keine Bewertungen

- ED261d01 Alta VelocidadDokument48 SeitenED261d01 Alta Velocidadoctavio lugoNoch keine Bewertungen

- Egger Impeller Brochure PDFDokument10 SeitenEgger Impeller Brochure PDFnbharath1988100% (1)

- Linear BearingDokument3 SeitenLinear BearingyahsooyNoch keine Bewertungen

- Bearing Units Catalog A-21000-IDokument374 SeitenBearing Units Catalog A-21000-Iardiansyah arfahNoch keine Bewertungen

- Bearing Replacement Guide UkDokument264 SeitenBearing Replacement Guide UkLeroyNoch keine Bewertungen

- Android Game Programming For DummiesDokument127 SeitenAndroid Game Programming For DummiesbillyNoch keine Bewertungen

- Main Shaft AssemblyDokument6 SeitenMain Shaft AssemblyFrancis MartinezNoch keine Bewertungen

- Catalog ZKL-ZRL PLC InfoDokument32 SeitenCatalog ZKL-ZRL PLC InfoVolodymyrNoch keine Bewertungen

- BearingDokument18 SeitenBearingBudhaditya Goswami89% (45)

- Ball TimkenDokument216 SeitenBall Timken5723820Noch keine Bewertungen

- Sintech Pumps For Sugar Processing PlantDokument18 SeitenSintech Pumps For Sugar Processing Plantsahildhingra100% (2)

- FAG Bearing DamageDokument91 SeitenFAG Bearing Damagesamir8albinoNoch keine Bewertungen

- Hub City Beveal Gear DrivesDokument5 SeitenHub City Beveal Gear DrivesJuan CaceresNoch keine Bewertungen

- NbnterehDokument459 SeitenNbnterehmeghasyamNoch keine Bewertungen

- Alfa Laval Complement To Service Manual SU Separation 01811064Dokument106 SeitenAlfa Laval Complement To Service Manual SU Separation 01811064André Heunis100% (1)

- Juntas EsfericasDokument12 SeitenJuntas EsfericasHenrique Ribeiro OliveiraNoch keine Bewertungen

- Project ReportDokument59 SeitenProject ReportKarthi M100% (2)

- MV Motor Publication Jan 2012Dokument16 SeitenMV Motor Publication Jan 2012safinditNoch keine Bewertungen

- Thrust Bearing Selector - InA-85-178Dokument94 SeitenThrust Bearing Selector - InA-85-178ebeNoch keine Bewertungen

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDokument3 Seiten1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishNoch keine Bewertungen