Beruflich Dokumente

Kultur Dokumente

BBA VI Semester Faculty J Vidhya

Hochgeladen von

Shahid KapoorOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BBA VI Semester Faculty J Vidhya

Hochgeladen von

Shahid KapoorCopyright:

Verfügbare Formate

ED

BBA VI semester

Module IV

Faculty J Vidhya

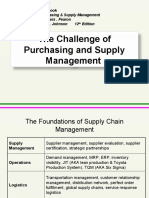

Module IV: Market and Materials

Management Analysis

Vendor development, vendor selection

decision factors,

methods of price determination, direct and

hidden cost in material management,

market development, market feasibility,

activities and

decisions in materials management

Kautilya in Arthasastra

Stores and purchase personnel should

definitely be expert in his job, adept in the art

of negotiations, intelligent, loyal to the

organisations goals, suppressing personal

greed.

Importance of Supplier Selection - 1

One of the most important processes performed in

organizations today is the evaluation, selection and continuous

measurement of suppliers.

Selecting a vendor is now as important a process as developing

new products.

Importance of Supplier Selection - 2

Supplier selection process is a multi-criteria problem, which includes both

qualitative and quantitative factors.

Purchasing commands a significant position in most organizations

sincepurchased parts, components, and supplies typically represent 40 to

60 percent of the sales of its end products.

Thus relatively small cost reductions gained in the acquisition of materials

can have a greater impact on profits.

Suppliers have a large and direct impact on the cost, quality,technology,

and time-to-market of new products.

Importance of Supplier Selection - 3

Organizations ability to produce a quality product at a reasonable cost

and in a timely manner is heavily influenced by its

supplierscapabilities.

Supplier selection is one of the key issues of SCM because the cost of

raw materials and component parts constitutes the main cost of a

product Management.

A sound supplier selection decision today can reduce or

prevent a host of problems tomorrow

Vendor Selection Decision Factors

Steps in Vendor Selection Process

Evaluating Needs and Defining Objectives

Gathering a Limited Pool of Vendors

Interviewing with Vendors

Selecting and Applying the Method

Evaluating Needs and Defining Objectives

What need you are looking to satisfy?

Increase product quality

Which evaluation categories you will use?

What are your business, technical and usability requirements?

What are the must requirements?

Max price, min performance, etc

How will you score the requirements?

OUTCOME: list of requirements, objective and criterias to

evaluate the vendors and the way to score different criterias

Gathering a Limited Pool of Vendors

Evaluating all potential vendors takes much

time

Basic screening and elimination due to lack of

must requirements

OUTCOME: vendors pool

Interviewing with Vendors

One by one interview with vendors

Gap analysis between your requirements,

objectives and vendor properties

Scoring each criteria

OUTCOME: criteria-score list for each vendor

Selecting and Applying the Method

Select one among various methods

AHP, fuzzy logic method, etc

Calculate overall vendor score using selected

method

Select the vendor with best score

Supplier Evaluation Criterias

The evaluation criterias are fundamental to choose the best

supplier. They are specific to each firm, because they vary

according to the needs.

The criteria exposed in the following slides are the most

common ones.*

Six categories of criteria selected

(*) We have analysed almost 30 texts in order to select the most

common criterias

Supplier Evaluation Criterias

The six classes for the suppliersevaluation

measurement:

FINANCIAL HEALTH

EXPERTISE

OPERATIONAL PERFORMANCE METRICS

BUSINESS PROCESSES & PRACTICES

ENABLING BEHAVIORS OR CULTURAL FACTORS

RISK FACTORS

Financial Health

In order to evaluate if a potential supplier is in good

financial position, a buyer can use indicators such as:

Sales

Profitability

Liquidity

ROI

Debt ratio

Transparency of finances

Expertise

The purchasing department of the firm should choose

its suppliers according to its capabilities:

Network capabilities

Quality and production capabilities (dedicated

level?)

Technical level compared to sector average

Spread of technical creation

Investment in R&D

Operational Performance

There are a large number of criteria in this category, such

as:

On-time delivery

Lead time

Responsiveness

Inventory management and control: reorder management, forecasting

capabilities

Order acceptance, processing & fulfillement

Customer service

Preventive maintenance

Hours of operators training in Total Quality Control (TQC) or JIT

Business Processes and Practices

How does supplier provide a product or service at the

best value, on time and exactly as required from the

buyers?

Best practice and quality based information.

This evaluation business can help get at the root causes of supplier

problems.

For example: is the quality standard of the products met by the

production process (preventing defection) or by inspecting the quality

of the products after production?

Behaviors and Cultural factors

The evaluation criteria of such a category focus on the

long term sustainability of potential suppliers:

What is the improvement culture of the supplier?

Are his information capabilities always up-to-

date?

What is his intention of coordination?

Risk Factors

A suppliers risks are risks for the buyer.

Indeed, if a supplier takes too much risk, it can

have a great impact on his customer.

Risk factors can be uncovered in the previous

criteria exposed, but also in criteria such as:

trade relations, currency exchange, insurance,

legislations.

Criteria Selection

In reality, these mesures of supplier performance are difficult

to obtain (financial publications, questionnaires, surveys, site

visits).

Whichever criteria chosen, the assessment system must be

optimal for good decision making.

Markov chain concept: the decision environment is dynamic,

i.e. there must be interaction between the cooperation

patterns and the supplier evaluation criteria.

Reasons for popularity of materials

management

The amount spent on materials is higher than other inputs

Materials offer considerable scope for reducing cost and improving profit

Improving return on investment depends on the effective utilisation of

materials.

Materials add value to product

Quality of end product depends on materials

Materials management assumes responsibility for whatever happens in

purchasing, storing, inventory or any other area connected with materials.

Need for preservation of scarce resources for posterity

Increasing demand for ensuring environmental safety

The efficiency of any organisation depends upon the availability of right

materials, in right quantity, at right time and at right price.

Materials are life-blood of mans development

Materials management involves planning,

programming, organising, directing,

controlling, and co-ordinating the various

activities concerning the materials. The

production managers found it necessary to

develop an organised body of knowledge on

this subject. The resulting set of related

disciplines is known as materials

management.

Materials Management

Materials are any commodities used directly or

indirectly in producing a product such as raw

materials, component parts or assemblies.

Materials management is the grouping of management

functions supporting the complete cycle of material

flow, from the purchase and internal control of

production materials to the planning and control of

work in process to the warehousing, shipping, and

distribution of the finished product.

Thomas F. Wallace & John R. Dougherty

Materials management is the management of

the flow of materials into an organisation to

the point, where, those materials are

converted into the firms end product(s)

Bailey & Farmer

The executive who engage in materials

management are concerned with three

basic activities: buying, storage of materials

and movement.

Functions of Materials Management

Materials planning and programming

Raw material purchase

Receiving, store keeping, and warehousing

Issuing of material

Inventory control

Value engineering

Transportation of materials

Vendor development

Vendor rating

Disposal of scrap and surpluses

Focus of Material Management

To procure right materials

In Right Quantity

Of Right Quality

At Right Time

From Right sources

At Right prices

5 Rs, principles of purchasing

Primary Objectives

Buying the best item at the lowest cost

Reduction in inventory cost and High inventory

turnover

Maintaining the flow of production

Maintaining the consistency of quality

Optimisation of acquisition and possession,

resulting in lower cost

Cordial relationship with suppliers

Maintaining good records

Contribution towards competitiveness

Personnel development

Secondary Objectives

Promotion of standardisation with suppliers

Development of reciprocal relations with

customers

Committees to decide on economic make or-

buy decisions

Development of inter departmental

relationships

Can undertake acquisitions

Advantages or benefits of M M

Material cost can be lowered ( Sales price can be

brought down to a reasonable level)

Controlling of indirect cost (such as materials

movement)

Risk of inventory loss minimised (theft, pilferage )

Reduction in loss of time of direct labour

Cost of material used in different department

ascertained

Control of manufacturing cycle

Material congestion in storage places avoided

Improvement in delivery of the product

Phases in M M

Planning (Plans for capacity or production

levels and required inventory levels

Material utilisation (efficiency of the flow of

materials through the plant)

Physical (storing, receiving and issuing of

materials and physical checking of inventory of

raw materials, work in process, finished goods,

record keeping)

Control or follow up (feedback and corrective

action involved)

Challenges of M M

Selection of appropriate vendors

Land and storage cost increase

Difficulty in forecasting demand accurately

Scarce capital for investment in materials

inventory

Diversification of product lines

Optimising time and quantity for products

Management of information

Direct & Indirect costs in MM

Examples of direct costs

Indirect costs

Examples of indirect costs

Main depts. Of M M

Materials planning

Purchase

Stores

Inventory control

Purchasing

Purchasing is to procure the materials,

supplies, tools, equipment etc.

5 Rs Material, Quantity, Source, Time, Price

Procurement purchase, material supervision and

management as inventory control, receiving and

salvage operations.

Vendor rating

It is a method to evaluate a vendor against

certain parameters, related to his supplies.

Factors considered:

Vendors are assessed on the basis of a wide

variety of factors or criteria which might include

but not limited to:

Price

Discounts received

Maintenance of specifications

Promptness of delivery

Freight and delivery charges

Service

Market information

Co-operation

Management competence

Credit terms

Cost reduction suggestions

Inventory plans

Financial position

Rating techniques

Categorical plan

Personnel from different division maintain

informal evaluation records

Purchasing , engineering, quality control, receiving

and inspection.

For each supplier , each person prepares a list of

performance factors important to him. At a

monthly meeting, each major supplier is

evaluated against the list and assigned an overall

group evaluation, like preferred, neutral, or

unsatisfactory.

Weighted point plan

The performance factors to be evaluated are

given weights, for example quality might be

weighted 25, delivery 20, price 30 and service

25.

Weights selected represent buyers judgement

about the relative importance of the

respective factors.

Quantitative terms

Critical incidents method

Record of events related to buyer vendor

relationships is maintained in each vendors

file. They reflect positive and negative aspect

of actual performance.

This kind of documentation useful in

discussing ways and means of improving

performance, acknowledging the existence of

good relationships, determining the

competence of a vendor, and if necessary

considering termination.

Checklist system

A simple checklist is used to evaluate the

vendors.

Check list may be something like

Reliability, technical capability, after sales service,

availability, buying convenience etc.

Ethics

Ethics is a segment of philosophy concerned

with values of human conduct.

Ethics refers to a code of conduct that guides

an individual in dealing with others.

Ethics relates to the social rules that influence

people to be honest in dealing with others.

Ethics in purchasing

Many decisions remain largely a matter of personal

judgement.

Purchase manager is the custodian of company funds,

responsible for their conservation and wise spending.

Because of his contacts, he is the custodian of companys

reputation for courtesy and fair dealing.

A high ethical standard of conduct is essential.

They are subjected to more temptations

Since they spend millions, they yield tremendous power and

are the objects of considerable attention from suppliers.

They are in an excellent position to be dishonest if they want

to.

But they have to be ethical

Value analysis ( value engineering)

Purchasing & methods engineering

This activity is aimed at modifying the specifications

of materials, parts, and products to reduce their

costs

Focus is on the value of the product- what function is

to be performed by the product- and how that value

can be achieved at the lowest cost.

Primary attention is devoted to the materials.

Suppliers suggest improvement & cost reduction

ideas.

Inventory Management

The term inventory includes materials raw, in

process, finished packaging, spares and others stocked

in order to meet an unexpected demand or

distribution in the future.

Inventory can be used to refer to the stock on hand at

a particular time, of raw materials, goods-in process

of manufacture, finished products, merchandise

purchased for resale, and the like, tangible assets

which can be seen, measured and counted. In

connection with financial statements and accounting

records, the reference may be to the amount assigned

to the stock of goods owned by an enterprise at a

particular time.

Types

Finished goods inventories

Stock in trade ready for shipment

Maintenance, Repair and Operating

inventories

- cutting tools , grinding wheels, jigs

Maintenance inventory

Electrical switches, fuses, lamps, lubricants, safety goggles

Stationary inventories

Canteen provisions, medical supplies, uniforms

Objectives of Inventory

To facilitate smooth operation of the

manufacturing process.

To minimise investment in inventory

To reduce material handling costs

Reasonable utilisation of people

Inventories are held to facilitate product display

and service to customers, batching in

production in order to take advantage of longer

production runs and provide flexibility in

production scheduling

Inventory costs

Ordering cost

Carrying cost

Out of stock or shortage cost

Capacity cost

Ordering Costs

Cost of placing an order with a vendor of

materials

Preparing a purchase order

Processing payments

Receiving and inspecting the material

Ordering from the plant

Machine set up

Start up scrap generated from getting a

production run started

Carrying costs

Costs connected directly with materials

Obsolescence

Deterioration

Pilferage

Financial costs

Taxes

Insurance

Storage

Interest

Capital costs

Interest on money invested in inventory

Interest on money in land and building

Storage space costs

Building rent

Depreciation

Cost of maintenance

Inventory service costs

Out of stock costs

Lost sales, transportation

Capacity costs

Overtime when capacity is low

Idle time when capacity is large

Benefits of Inventory management

Inventory control ensures an adequate supply of

materials, stores, etc. minimises stockouts and

shortages, and avoids costly interruptions in

operations.

It keeps down investments in inventories, inventory

carrying costs and obsolescence losses to the

minimum

It facilitates purchasing economies through the

measurement of requirements on the basis of

recorded experience

It eliminates duplication in ordering or in

replenishing stocks by centralising the source from

which purchase requisitions emanate

It permits a better utilisation of available stocks by

facilitating inter departmental transfers within a

company

It provides a check against loss of materials through

carelessness or pilferage

It facilitates cost accounting activities by providing a

means for allocating material costs to products,

departments or other operating accounts

It enables management to make cost and

consumption comparison between operations and

periods

It serves as a means for the location and

disposition of inactive and obsolete items of

stores

Perpetual inventory values provide a

consistent and reliable basis for preparing

financial statements.

Das könnte Ihnen auch gefallen

- Value Chain AnalysisDokument31 SeitenValue Chain AnalysisArvind Renganathan100% (1)

- Module 2: Procurement StrategiesDokument41 SeitenModule 2: Procurement StrategiesYemen YemenNoch keine Bewertungen

- Supplier DevelopmentDokument33 SeitenSupplier Developmentkarthick080288100% (2)

- Seepage CSM8 User ManualDokument24 SeitenSeepage CSM8 User ManualimamgantengsekaliNoch keine Bewertungen

- Fertilizer Industry Wastewater TreatmentDokument1 SeiteFertilizer Industry Wastewater TreatmentAnmol UpadhyayNoch keine Bewertungen

- Materials MGMTDokument43 SeitenMaterials MGMTdivyasahalNoch keine Bewertungen

- Men - Machines - Methods - Money - MaterialsDokument42 SeitenMen - Machines - Methods - Money - MaterialsAbhirup MukherjeeNoch keine Bewertungen

- Materials Management 1223701895922844 9Dokument48 SeitenMaterials Management 1223701895922844 9bitto100% (1)

- Business ManagementDokument48 SeitenBusiness ManagementmikeyizanainvincibleNoch keine Bewertungen

- Supplier Selection & Evaluation: BPT3133 - Procurement in Industrial ManagementDokument22 SeitenSupplier Selection & Evaluation: BPT3133 - Procurement in Industrial ManagementDr.Satish RadhakrishnanNoch keine Bewertungen

- The Challenge of Purchasing and Supply ManagementDokument48 SeitenThe Challenge of Purchasing and Supply ManagementWaseem Ahmed HingorjoNoch keine Bewertungen

- ProcurementDokument27 SeitenProcurementViVi TruongNoch keine Bewertungen

- Procurement and Purchasing.Dokument36 SeitenProcurement and Purchasing.Arif Shan100% (1)

- Chapter 15 - Purchasing and Supply Management V1 - 0Dokument26 SeitenChapter 15 - Purchasing and Supply Management V1 - 0Terilee PillayNoch keine Bewertungen

- P&S Lec 1Dokument18 SeitenP&S Lec 1nomanashrafNoch keine Bewertungen

- Chapter 15 - Purchasing and Supply Management V1 - 0Dokument27 SeitenChapter 15 - Purchasing and Supply Management V1 - 0sphesihlemkhize1204Noch keine Bewertungen

- Unit - IV Key Words Material ManagementDokument14 SeitenUnit - IV Key Words Material Managementsuganya.sNoch keine Bewertungen

- Supplier DevelopmentDokument33 SeitenSupplier Developmentsiva_4072Noch keine Bewertungen

- Supply Chain Management A Logistics Perspective 10Th Edition Coyle Solutions Manual Full Chapter PDFDokument36 SeitenSupply Chain Management A Logistics Perspective 10Th Edition Coyle Solutions Manual Full Chapter PDFsusan.ross888100% (11)

- SCM 04 - 06Dokument62 SeitenSCM 04 - 06Nasir HussainNoch keine Bewertungen

- Materials Management: Dr. K. K. Saju Professor Division of Mechanical Engineering Soe, CusatDokument78 SeitenMaterials Management: Dr. K. K. Saju Professor Division of Mechanical Engineering Soe, CusatRitwik AravindNoch keine Bewertungen

- Business Essentials Midterm ReviewerDokument20 SeitenBusiness Essentials Midterm ReviewerJulianne Marie CaasiNoch keine Bewertungen

- Sourcing DecisionsDokument24 SeitenSourcing DecisionsSimerdeep Singh50% (2)

- Supplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLDokument38 SeitenSupplier Evaluation and Selection: Laura AITER Cengiz ÇOKAY Güven GÜLsrkadaliNoch keine Bewertungen

- DPS 304 Sourcing Strategies & PoliciesDokument34 SeitenDPS 304 Sourcing Strategies & PoliciesSehar AdilNoch keine Bewertungen

- Different Corporate PoliciesDokument42 SeitenDifferent Corporate Policiesazeem dilawarNoch keine Bewertungen

- Unit ViiDokument21 SeitenUnit Viibesedegefub9131Noch keine Bewertungen

- Purchasing and Vendor Management Lecture 6Dokument34 SeitenPurchasing and Vendor Management Lecture 6dinesh9936115534100% (4)

- What Is Strategic Planning?Dokument21 SeitenWhat Is Strategic Planning?GukanandMVNoch keine Bewertungen

- Manufacturing Resource Planning: II To Distinguish From MRPDokument16 SeitenManufacturing Resource Planning: II To Distinguish From MRPJames Patrick TorresNoch keine Bewertungen

- SCM ch05Dokument84 SeitenSCM ch05Hasan RazaNoch keine Bewertungen

- Supply Chain Management and Purchasing Function (Continued) : Talal AbadiDokument44 SeitenSupply Chain Management and Purchasing Function (Continued) : Talal Abadijoel collinsNoch keine Bewertungen

- Logistics Management: Definition: Logistics Is The Process of StrategicallyDokument9 SeitenLogistics Management: Definition: Logistics Is The Process of StrategicallyashwinNoch keine Bewertungen

- 001 Introduction To SourcingDokument45 Seiten001 Introduction To SourcingNathaniel Nti waeNoch keine Bewertungen

- Log 5101: Strategic Supply Chain Management UNIT ONE: Introduction To Strategic Supply Chain ManagementDokument45 SeitenLog 5101: Strategic Supply Chain Management UNIT ONE: Introduction To Strategic Supply Chain ManagementNancy LyimoNoch keine Bewertungen

- Global SourcingDokument10 SeitenGlobal Sourcingmaddy5518Noch keine Bewertungen

- Sourcing Materials and ServicesDokument30 SeitenSourcing Materials and ServicesMikkay WongNoch keine Bewertungen

- Supplier SelectionDokument12 SeitenSupplier SelectionSimon Chege100% (2)

- Operations ManagementDokument121 SeitenOperations ManagementPrathmesh PatelNoch keine Bewertungen

- Module 3Dokument19 SeitenModule 3Sanak Aditya MannaNoch keine Bewertungen

- 21 Operations Management Module 1Dokument136 Seiten21 Operations Management Module 1RISHAV RAJ GUPTANoch keine Bewertungen

- MODULE-II Sourcing ManagementDokument14 SeitenMODULE-II Sourcing ManagementumeshNoch keine Bewertungen

- Chapter 13Dokument76 SeitenChapter 13Nikky Bless LeonarNoch keine Bewertungen

- 5 Supplier Selection and EvaluationDokument31 Seiten5 Supplier Selection and EvaluationAyush GuptaNoch keine Bewertungen

- Procurement & Materials Management - Strategy: Arvind Tiwari Guest Faculty IIFTDokument40 SeitenProcurement & Materials Management - Strategy: Arvind Tiwari Guest Faculty IIFTguru945Noch keine Bewertungen

- Learning Block 1: Supply Management and Procurement OverviewDokument63 SeitenLearning Block 1: Supply Management and Procurement OverviewBon-Boni Arnaiz100% (1)

- Module2 - Strategic ProcurementDokument13 SeitenModule2 - Strategic ProcurementTrixie De LaraNoch keine Bewertungen

- What Is Supply Chain and What Is Its Importance?Dokument6 SeitenWhat Is Supply Chain and What Is Its Importance?muhammad qasimNoch keine Bewertungen

- Supply Chain Planning and ControlDokument13 SeitenSupply Chain Planning and ControlRemigi CosmasNoch keine Bewertungen

- Vendor Selection and DevelopmentDokument12 SeitenVendor Selection and DevelopmentAsher RamishNoch keine Bewertungen

- Supplier Performance TopicDokument27 SeitenSupplier Performance TopicPeter MananaNoch keine Bewertungen

- Debritu AssignDokument5 SeitenDebritu Assigngetamesay assefaNoch keine Bewertungen

- MGMT2018M3 Sustainable Procurement - IntroductionDokument27 SeitenMGMT2018M3 Sustainable Procurement - IntroductionSohail TaujooNoch keine Bewertungen

- Chapter 1 Introduction To Supply Chain Management Supply Chain ManagementDokument18 SeitenChapter 1 Introduction To Supply Chain Management Supply Chain Management21-54712Noch keine Bewertungen

- SCM Mod1Dokument52 SeitenSCM Mod1mx plNoch keine Bewertungen

- Aguilar, Airalyn V. Balabala, Reivin T. Jala, Jacqueline M. Manalo, Renzo L. Palulan, Carlo A. Papa, Angelica B. Ustaris, Vince Jimwell MDokument53 SeitenAguilar, Airalyn V. Balabala, Reivin T. Jala, Jacqueline M. Manalo, Renzo L. Palulan, Carlo A. Papa, Angelica B. Ustaris, Vince Jimwell MRio Loraine SalandananNoch keine Bewertungen

- Mms - Marketing: II Year - III Semester Mumbai UniversityDokument40 SeitenMms - Marketing: II Year - III Semester Mumbai UniversityManas ChaturvediNoch keine Bewertungen

- The Accredited Supply Chain ProfessionalVon EverandThe Accredited Supply Chain ProfessionalBewertung: 5 von 5 Sternen5/5 (1)

- Seven Essentials of Supplier Quality Management A Concise Guide: A systematic approach in managing supplier towards delivering zero-defect material consistentlyVon EverandSeven Essentials of Supplier Quality Management A Concise Guide: A systematic approach in managing supplier towards delivering zero-defect material consistentlyBewertung: 4 von 5 Sternen4/5 (2)

- Logistics in Manufacturing, Supply Chain, and DistributionVon EverandLogistics in Manufacturing, Supply Chain, and DistributionNoch keine Bewertungen

- Quadrature Amplitude ModulationDokument10 SeitenQuadrature Amplitude ModulationSafirinaFebryantiNoch keine Bewertungen

- Nitrile RubberDokument1 SeiteNitrile RubberMohamedNoch keine Bewertungen

- BITS Herald Summer Issue 2013Dokument23 SeitenBITS Herald Summer Issue 2013Bits Herald100% (1)

- Casting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Dokument7 SeitenCasting: Definition, Types, Steps Involved in Casting, Advantages, Disadvantages, Importance (PDF)Munem ShahriarNoch keine Bewertungen

- Organic Chemistry 4th Edition Gorzynski Test BankDokument17 SeitenOrganic Chemistry 4th Edition Gorzynski Test Bankdigonousconcrewh2zxi100% (31)

- Iec 04Dokument10 SeitenIec 04Habeeb RahmanNoch keine Bewertungen

- Astm D 3241 - 02 - RdmyndetmdjbDokument13 SeitenAstm D 3241 - 02 - RdmyndetmdjbSamuel EduardoNoch keine Bewertungen

- Single Phase Induction MotorDokument5 SeitenSingle Phase Induction MotorSridhar SridharNoch keine Bewertungen

- Is 13935 2009 PDFDokument33 SeitenIs 13935 2009 PDFManojKumawatRjNoch keine Bewertungen

- Klauke - Bi-Metal Lugs & ConnectorsDokument6 SeitenKlauke - Bi-Metal Lugs & ConnectorsBiplab PaulNoch keine Bewertungen

- Physics Lab Experiment 6Dokument6 SeitenPhysics Lab Experiment 6Peter Sam CoNoch keine Bewertungen

- KNS2163 Week1Dokument32 SeitenKNS2163 Week1Nurul QurratuNoch keine Bewertungen

- Hydrostatic Force On Plane Surfaces: Experiment No. 03Dokument2 SeitenHydrostatic Force On Plane Surfaces: Experiment No. 03ChristopherHiladoNoch keine Bewertungen

- 02 February 1990Dokument108 Seiten02 February 1990Monitoring TimesNoch keine Bewertungen

- Quadrosense - ManualDokument22 SeitenQuadrosense - ManualdannraduNoch keine Bewertungen

- CHAPTER 8 Hazop StudyDokument7 SeitenCHAPTER 8 Hazop StudyNethiyaa50% (2)

- AGE10503, Gas ProcessingDokument34 SeitenAGE10503, Gas ProcessingiranmortezaNoch keine Bewertungen

- Instalación Zapata Case 9010Dokument5 SeitenInstalación Zapata Case 9010Miguel Angel Herrera MartinezNoch keine Bewertungen

- Alternative Sources of EnergyDokument6 SeitenAlternative Sources of EnergykageNoch keine Bewertungen

- HeiDokument1 SeiteHeiJose Nelson Moreno BNoch keine Bewertungen

- In ThoseDokument2 SeitenIn ThoseanggieNoch keine Bewertungen

- Larsen and Toubro RVNL Bid Document Rock Bolts PDFDokument240 SeitenLarsen and Toubro RVNL Bid Document Rock Bolts PDFSubhash Kedia100% (1)

- Minimal Requirements: Solaris InstallationDokument74 SeitenMinimal Requirements: Solaris InstallationsrinivasNoch keine Bewertungen

- Mathalino: E N W S G S V V V V V W W W D Γ Γ Γ Γ Γ Γ Γ Γ Ll Pl Li Pi GiDokument8 SeitenMathalino: E N W S G S V V V V V W W W D Γ Γ Γ Γ Γ Γ Γ Γ Ll Pl Li Pi GiLovely Joy ArdanielNoch keine Bewertungen

- Street Quality Identification Device (SQUID)Dokument6 SeitenStreet Quality Identification Device (SQUID)viviolaNoch keine Bewertungen

- C-Zone SDN BHD: Price List Effective 10 AUG 2019Dokument2 SeitenC-Zone SDN BHD: Price List Effective 10 AUG 2019Cikgu AlNoch keine Bewertungen

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDokument3 SeitenAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- 02 04 16 BPZ Transclinic 16i 4 Sprachen PRINTDokument144 Seiten02 04 16 BPZ Transclinic 16i 4 Sprachen PRINTjuanNoch keine Bewertungen