Beruflich Dokumente

Kultur Dokumente

Torishima Boiler Circulation Pumps Technical Data and Operating Range

Hochgeladen von

Krishnan Santhanaraj0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

190 Ansichten24 SeitenWet Stator motor pump

Originaltitel

1. BCP Technical & Operating Data

Copyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenWet Stator motor pump

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

190 Ansichten24 SeitenTorishima Boiler Circulation Pumps Technical Data and Operating Range

Hochgeladen von

Krishnan SanthanarajWet Stator motor pump

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 24

TORISHIMA

Boiler Circulation Pumps

HLAV

Contents

1. Technical Data

2. Operating Data

Training course 1

Technical Study

Date : 22. Jun. 2012

D

e

s

i

g

n

p

r

e

s

s

u

r

e

:

k

g

f

/

c

m

2

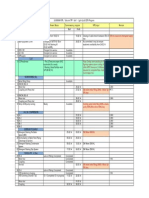

1.Technical Data

and Operating Range

Design pressure

Total head

Capacity

Design temperature

Sizes

Speed

Motor rating

Voltage

400

200

100

50

20

10 100 1000 7000

T

o

t

a

l

h

e

a

d

:

m

Capacity

Q : m

3

h

HLAV K type

HLV H type

HLAV C type

HLAV M type

HLV M type

326

255

224

133

102

100 200 300 330 375 420

Design Temperature : C

up to 326 kgf/cm

2

up to 320 m

up to 6,840 m

3

/h

up to 420 deg.C

2 to 16 in

2900,1450,3500,

1750 rpm

up to 2,500 kW

up to 11 kV

Tuticorin 2x500MW :

370 deg.C x 214 kg/cm

2

Tuticorin 2x500MW

2987 m

3

/h x 31.04 m

Sample data for Training

1-2. Torishima BCP :

Features - Benefits

(1) GENERAL DESIGN

Simple Structure

Maintenance free and high reliability

Easy start-up and shut-down operation.

Direct connection of the pump and pipeline

No foundation work and easy installation

Vertical suspension type design

Less plant space required

Pull-out system design

Easy installation, overhaul and inspection work.

Glandless

No Seal / No Leakage

Highly durable water- lubricated bearings

Maintenance free bearings

Variable type of casings

Spherical, volute or annular design

(2) PUMP DESIGN

(3) MOTOR DESIGN

Effective motor cooling circuit

Only low pressure cooling water is required

(High pressure cooling water is not needed)

Wet-type coil motor

High efficiency and reliability

High voltage application (up to 10kV)

Contributes to power saving for the whole plant

DIFFUSER

MOTOR COOLER

THRUST BEARING

CASE

THRUST BEARING

SEGMENT (UPPER)

PLAIN BEARING

(LOWER)

ROTOR

STATOR

HEAT BARRIER

MOTOR CASING

PLAIN BEARING

(UPPER)

PUMP CASING

IMPELLER

SHAFT

STUD BOLT

MOTOR WINDING

BEARING BRACKET

THRUST BEARING

PLATE

THRUST BEARING

SEGMENT (LOWER)

FILTER

Construction

of BCP

Simple Structure

Nozzle orientation

Suction nozzle is arranged axially

(end suction) and the discharge nozzle

radially.

The nozzle can be provided with

welding stub ends.

Nozzle

Direct connection of the pump and pipeline

Nozzle

Motor

Casing

Heat barrier

Bearings

This vertical pump is suspended in

the pipe line without any external supports.

No anchorage point in the piping system.

During overhauls, the pump casing can

remain attached to the pipe line.

The motor unit, together with the heat

barrier and the impeller, can be removed

from the casing after unscrewing the

tiebolts.

Vertical suspension type design

Pull- out system design

Casing

Casing

The motor casing is flange-jointed

to the pump casing.

Pump and motor pressure depends on

the system pressure.

Glandless design

Bearings

Bearings

The shaft is supported by two

self-lubricated plain bearings.

Thrust Bearing

Bearings

The axial thrust is balanced by a

self-lubricated thrust bearing.

Axial Bearing

Thrust bearing plate

in the form of

an auxiliary impeller

Thrust bearing

plate

Upper thrust

bearing segment

Lower thrust

bearing

segment

Axial Bearing

Phenolic Resin

SUS420J2

HCr Plated

Thrust Bearing

Bearings

The axial thrust is balanced by a

self-lubricated thrust bearing.

Highly- durable water- lubricated bearings

Casing

Spherical casing

Shape of Pump casing

Standard type

Volute casing Annular casing

Variable type of casings

Forged casing

Cast casing

Heat barrier

Heat barrier

A heat barrier is provided between

the pump and the motor.

The heat barrier prevents heat transfer

from the hot pump to the cold motor.

The heat barrier protects the motor

winding insulation.

Heat barrier cooling water also prevents

heat transfer especially stand-by mode

Insulation class : Y

Motor design temp. :

Max 90degC

Heat Barrier Cooling Water Line

Sectional view of Heat barrier

Motor

The motor is filled with water.

The HP cooling water inside the motor is

circulated by a thrust bearing plate.

The motor heat is transmitted to the LP

cooling water in the motor cooler.

Motor cooler

Stator

Rotor

Thrust bearing plate

Effective Motor Cooling Circuit

Motor winding

(Stator coil)

Insulation class : Y

Design temp. : 90 deg.C

Insulation material : Polyethylene

Wet- type Coil Motor

Filter

The filter keeps the HP cooling water clean.

Filter

2. Operating Data

2.1 Pump set

- Pump name Boiler Water Circulating Pump

- Number of sets per unit 3 set/unit

- Product number Tuticorin 2x500MW

AP930016/ AP930024

- Designation Glandless Circulating Pump

- Design pressure 214 kgf/cm

2

- Design temperature

- Pump 370 deg.C

- Motor 90 deg.C

- Hydrostatic test pressure 321 kgf/cm

2

Sample data for Training

2.2 Pump

- Type Vertical Glandless Centrifugal Pump

- Fluid pumped Boiler water

- Operating temperature 355.5 deg.C

- Capacity 2987 m

3

/h

- Total head 31.04 m

- NPSH req. 15 m

- Nominal size

- Suction nozzle OD457.2 mm

- Discharge nozzle OD371.5 mm

2. Operating Data

Sample data for Training

2.3 Motor

- Type Wet motor

- Nominal rating 350 kW

- Nominal speed 1,470 rpm

- Frequency 50 Hz

- Voltage 3,300 V

- Nominal current 89.7 A

- Starting current 539 A

- Insulation of motor winding PE2/PA

(cross link polyethylene/polyamide)

- Motor normal temp. 50 deg.C (at upper motor cavity)

- Motor alarm temp. 63 deg.C (at upper motor cavity)

- Motor trip temp. 66 deg.C (at upper motor cavity)

2. Operating Data

Sample data for Training

2.4 LP Cooling Water

- Heat Barrier

- Cooling water quantity required 30 L/min

- Inlet temperature 39 deg.C

- Cooling water pressure required Approx. 1 kgf/cm

2

- Motor Cooler (Over 400kW Torishima supply)

- Quantity of heat to be eliminated 41kW

- Cooling water quantity required 150 L/min

- Inlet temperature 39 deg.C

- Cooling water pressure required Approx. 1 kgf/cm

2

2. Operating Data

Sample data for Training

Das könnte Ihnen auch gefallen

- 13 MW Steam Turbine 50 HZ NewDokument6 Seiten13 MW Steam Turbine 50 HZ Newteewee_cuteNoch keine Bewertungen

- BCP Technical & Operating DataDokument24 SeitenBCP Technical & Operating DataPradeep Srikanth50% (2)

- BPCL CYLINDER MANUFACTURINGDokument34 SeitenBPCL CYLINDER MANUFACTURINGVishalVaishNoch keine Bewertungen

- Installation, Operations & Maintenance Manual: Invertronic 3P/0-028-0009-900 Rev. FDokument99 SeitenInstallation, Operations & Maintenance Manual: Invertronic 3P/0-028-0009-900 Rev. FAlejandro Garcia MNoch keine Bewertungen

- Chapter I General Information of Pump UnitDokument42 SeitenChapter I General Information of Pump UnitRahmat Budi HartantoNoch keine Bewertungen

- Voith Turbo - BasicsDokument49 SeitenVoith Turbo - Basicssenthil031277100% (1)

- VWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Dokument20 SeitenVWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Kaushik ChakrabortyNoch keine Bewertungen

- Assembling Procedure For Framo Pump Sd200Dokument4 SeitenAssembling Procedure For Framo Pump Sd200Gonçalo CruzeiroNoch keine Bewertungen

- 15MW Steam Turbine Installation and Operation ManualDokument83 Seiten15MW Steam Turbine Installation and Operation ManualMohammed MuzzamilNoch keine Bewertungen

- Emergency Lube Oil PumpDokument28 SeitenEmergency Lube Oil Pumpdac3524Noch keine Bewertungen

- Manual High Pressure Feed Water PumpDokument16 SeitenManual High Pressure Feed Water PumpAntokNoch keine Bewertungen

- Installation OperationDokument100 SeitenInstallation OperationSV HegdeNoch keine Bewertungen

- DVC O&M Manual Axial FanDokument291 SeitenDVC O&M Manual Axial FanAmitava PalNoch keine Bewertungen

- Boiler and Aux Maintenance ManualDokument248 SeitenBoiler and Aux Maintenance Manualkeerthi dayarathnaNoch keine Bewertungen

- Rolls Royce Gas Engine of 5.255 MWDokument1 SeiteRolls Royce Gas Engine of 5.255 MWRashid Mahmood0% (1)

- Air ChillerDokument12 SeitenAir ChillerImtiaz AhmedNoch keine Bewertungen

- Cooling Water System Control Philosophy (25Mw) : ObjectiveDokument8 SeitenCooling Water System Control Philosophy (25Mw) : ObjectiveEric TaylorNoch keine Bewertungen

- Cutler-Hammer Instructions For The Installation, Operation, and Maintenance of TRITON SL 160/200/320/400 Medium Voltage Vacuum Contactors, Model ADokument16 SeitenCutler-Hammer Instructions For The Installation, Operation, and Maintenance of TRITON SL 160/200/320/400 Medium Voltage Vacuum Contactors, Model ADiego Lobos100% (1)

- CRH Drain Pot LevelDokument30 SeitenCRH Drain Pot LevelBibhash SinghNoch keine Bewertungen

- Excel ApodysDokument4 SeitenExcel ApodysjeremiahNoch keine Bewertungen

- 3 Waukesha Gas Engine Maintenance ManualDokument75 Seiten3 Waukesha Gas Engine Maintenance ManualMamunNoch keine Bewertungen

- WILO Mather and Platt Pumps Pvt. LTD: Performance ChartDokument1 SeiteWILO Mather and Platt Pumps Pvt. LTD: Performance ChartSumitBhaumikNoch keine Bewertungen

- Instruction Manual For SSP-70D-ACMEVACDokument15 SeitenInstruction Manual For SSP-70D-ACMEVACParjanya MandalNoch keine Bewertungen

- Vol III Rev 0Dokument871 SeitenVol III Rev 0Anonymous nwByj9LNoch keine Bewertungen

- Commom RailDokument21 SeitenCommom Railprueba1100% (1)

- Generator Operation ManualDokument73 SeitenGenerator Operation ManualFerdinand DescalzoNoch keine Bewertungen

- List of Part-3Dokument2.000 SeitenList of Part-3Gỗ MộcNoch keine Bewertungen

- Siemens Hydrogen-Cooled Generators With Water-Cooled Stator WindingsDokument3 SeitenSiemens Hydrogen-Cooled Generators With Water-Cooled Stator WindingsPradeep_VashistNoch keine Bewertungen

- Operation and Maintenance Manual of Hogging Vacuum Pump - 2BW5 400Dokument197 SeitenOperation and Maintenance Manual of Hogging Vacuum Pump - 2BW5 400AhmadNoch keine Bewertungen

- Boiler Operator Exam Preparation Guide pdf-1 PDFDokument27 SeitenBoiler Operator Exam Preparation Guide pdf-1 PDFEmmanuel Jesus Marquez Rea100% (1)

- LSC 54Dokument4 SeitenLSC 54pankaj tyagiNoch keine Bewertungen

- ABB Navigator 600Dokument96 SeitenABB Navigator 600lequydueu100% (1)

- Fuel Oil Meter ManualDokument89 SeitenFuel Oil Meter ManualbouguerraNoch keine Bewertungen

- WTD Test ReportDokument4 SeitenWTD Test ReportBheem NaveenNoch keine Bewertungen

- Auto Start GuidelinesDokument7 SeitenAuto Start GuidelinesBabar Priyadi Mugi HangganaNoch keine Bewertungen

- Functional Change of Sac Into Iac: Standard Field Operating ProcedureDokument7 SeitenFunctional Change of Sac Into Iac: Standard Field Operating ProcedureMithun Singh RajputNoch keine Bewertungen

- P I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsDokument2 SeitenP I F 3000 PSI B A: Recharging Nstructions OR Ladder CcumulatorsRonaldNoch keine Bewertungen

- ABB MotorsDokument22 SeitenABB MotorsKhaled HassanNoch keine Bewertungen

- How To Control Liquid Ring Vacuum PumpsDokument2 SeitenHow To Control Liquid Ring Vacuum Pumpsjdgh1986Noch keine Bewertungen

- 500 MW Turbo GeneratorDokument8 Seiten500 MW Turbo GeneratorVaishali Pandey67% (3)

- SELECTED HIGH VOLTAGE MOTOR REFERENCESDokument10 SeitenSELECTED HIGH VOLTAGE MOTOR REFERENCESqaedmahmoodNoch keine Bewertungen

- L577-User Manual For Hardware PDFDokument30 SeitenL577-User Manual For Hardware PDFLe Chi PhamNoch keine Bewertungen

- 03 - Steam Turbines Types PDFDokument49 Seiten03 - Steam Turbines Types PDFVimleshKumarSharma100% (1)

- Deluge Valve - SD-DVA PDFDokument15 SeitenDeluge Valve - SD-DVA PDFboxyfunNoch keine Bewertungen

- TechnicalDiary500MW SGTPPDokument254 SeitenTechnicalDiary500MW SGTPPJoydev Ganguly100% (2)

- Dual Plate: Installation and MaintenanceDokument28 SeitenDual Plate: Installation and MaintenanceAllen AnyayahanNoch keine Bewertungen

- BHEL CFBC ExperienceDokument31 SeitenBHEL CFBC ExperiencesprotkarNoch keine Bewertungen

- MIL control valves for process industriesDokument8 SeitenMIL control valves for process industriesGovarthanan GopalanNoch keine Bewertungen

- 4-Hour Lockout Avoidance For LM2500 and LM6000 Gas Turbines: Conversion, Modification and Upgrade OfferingDokument1 Seite4-Hour Lockout Avoidance For LM2500 and LM6000 Gas Turbines: Conversion, Modification and Upgrade OfferingabedurahmanNoch keine Bewertungen

- Actuator General KC 03 040Dokument10 SeitenActuator General KC 03 040Devendrasinh JadejaNoch keine Bewertungen

- Upgrade LMZ Turbine K-210-130 Capacity and EfficiencyDokument62 SeitenUpgrade LMZ Turbine K-210-130 Capacity and EfficiencyAnonymous gr5Pr9AVNoch keine Bewertungen

- Baa1 PDFDokument149 SeitenBaa1 PDFfebyNoch keine Bewertungen

- Commissioning Generators and Its Auxiliary SystemDokument90 SeitenCommissioning Generators and Its Auxiliary SystemSam100% (2)

- Regenerative Air PreheaterDokument19 SeitenRegenerative Air PreheaterPrakash100% (1)

- Varistor - Test (GZP)Dokument3 SeitenVaristor - Test (GZP)Hugo CiprianiNoch keine Bewertungen

- Chapter F - Cooling SystemDokument24 SeitenChapter F - Cooling SystemNigel ApilNoch keine Bewertungen

- Large Capacity Supercritical SetsDokument55 SeitenLarge Capacity Supercritical Setsbidyut100100% (5)

- CRI PumpsDokument5 SeitenCRI Pumpskumarvishal07Noch keine Bewertungen

- EEN - 499 Training SeminarDokument18 SeitenEEN - 499 Training SeminarSonu PatelNoch keine Bewertungen

- QFW Series SteamDokument8 SeitenQFW Series Steamnikon_fa50% (2)

- Shutdown Maintenance ScaffoldDokument1 SeiteShutdown Maintenance ScaffoldKrishnan SanthanarajNoch keine Bewertungen

- Unit I Divisional Superheater Coil Puncture On 10Dokument1 SeiteUnit I Divisional Superheater Coil Puncture On 10Krishnan SanthanarajNoch keine Bewertungen

- Rim and Face Shaft AlignmentDokument38 SeitenRim and Face Shaft AlignmentJaime Berry100% (2)

- NTPC Safety Rules SummaryDokument109 SeitenNTPC Safety Rules SummaryVivek Kakkoth100% (2)

- Us5282442 PDFDokument6 SeitenUs5282442 PDFKrishnan SanthanarajNoch keine Bewertungen

- Bowl Mill-Feb 2009Dokument12 SeitenBowl Mill-Feb 2009Krishnan SanthanarajNoch keine Bewertungen

- Managing Air To Improve Combustion EfficiencyDokument12 SeitenManaging Air To Improve Combustion EfficiencyKrishnan SanthanarajNoch keine Bewertungen

- 212292Dokument91 Seiten212292Jaime BerryNoch keine Bewertungen

- Instant Up Right Cat 2015Dokument40 SeitenInstant Up Right Cat 2015Krishnan SanthanarajNoch keine Bewertungen

- Review of Type IV Cracking of Weldments in 9Dokument64 SeitenReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajNoch keine Bewertungen

- NTPC Safety Rules SummaryDokument109 SeitenNTPC Safety Rules SummaryVivek Kakkoth100% (2)

- Pulverizer Fire and ExplosionDokument4 SeitenPulverizer Fire and ExplosionKrishnan SanthanarajNoch keine Bewertungen

- Thrust Bearing End PlayDokument3 SeitenThrust Bearing End PlayKrishnan SanthanarajNoch keine Bewertungen

- Sag ChartDokument1 SeiteSag ChartKrishnan SanthanarajNoch keine Bewertungen

- Turbine Operational ProblemsDokument35 SeitenTurbine Operational Problemsna2011100% (1)

- 226Dokument2 Seiten226Krishnan SanthanarajNoch keine Bewertungen

- A System For Suppressing and Inhibiting Fires in Coal Pulverizer MillsDokument25 SeitenA System For Suppressing and Inhibiting Fires in Coal Pulverizer MillsKrishnan SanthanarajNoch keine Bewertungen

- 33-1985 Evaluating Thrust Bearing Operating TemperaturesDokument7 Seiten33-1985 Evaluating Thrust Bearing Operating TemperaturesMohammad Fikri JalaludinNoch keine Bewertungen

- Plant Schematics Rev.01Dokument67 SeitenPlant Schematics Rev.01Krishnan SanthanarajNoch keine Bewertungen

- The Thrust PadDokument2 SeitenThe Thrust PadKrishnan SanthanarajNoch keine Bewertungen

- History of Hitachi Power EuropeDokument4 SeitenHistory of Hitachi Power EuropeKrishnan SanthanarajNoch keine Bewertungen

- Dry Flue Gases Losses in BoilerDokument2 SeitenDry Flue Gases Losses in BoilerKrishnan SanthanarajNoch keine Bewertungen

- Tri Sec AphDokument36 SeitenTri Sec AphKrishnan Santhanaraj100% (1)

- Tri Sec AphDokument36 SeitenTri Sec AphKrishnan Santhanaraj100% (1)

- NTPCDokument74 SeitenNTPCDilkhushMeenaNoch keine Bewertungen

- NTPC Quality InspectionDokument39 SeitenNTPC Quality InspectionPower Power60% (5)

- Operators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineDokument8 SeitenOperators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineKrishnan SanthanarajNoch keine Bewertungen

- Boilers 1Dokument29 SeitenBoilers 1Thakur Kamal Prasad50% (2)

- Governor TutorialDokument13 SeitenGovernor TutorialWalid Fattah100% (1)

- NTPL U1 Edta Prog 200214Dokument2 SeitenNTPL U1 Edta Prog 200214SethuRamalingamNoch keine Bewertungen

- TaguigDokument25 SeitenTaguigChan ReyNoch keine Bewertungen

- Chlorine Reference ManualDokument62 SeitenChlorine Reference ManualKimberly ConleyNoch keine Bewertungen

- Predicaments & DefinitionDokument32 SeitenPredicaments & DefinitionGisselle PauloNoch keine Bewertungen

- STANDS - SPONSORS & COLLABORATORS at Startup Olé 2019Dokument12 SeitenSTANDS - SPONSORS & COLLABORATORS at Startup Olé 2019Harsh BhattNoch keine Bewertungen

- William Smith: English None None NoneDokument2 SeitenWilliam Smith: English None None NoneArthur NunesNoch keine Bewertungen

- Discussion, Conclusion&Reference Practical 4Dokument2 SeitenDiscussion, Conclusion&Reference Practical 4Darzeman RaizeNoch keine Bewertungen

- Edc 1 PDFDokument18 SeitenEdc 1 PDFchetan kapoorNoch keine Bewertungen

- Liber XXVDokument14 SeitenLiber XXVTrevorReznik100% (1)

- Softcel U 1000 - en - 05494931 15528154 15528156Dokument3 SeitenSoftcel U 1000 - en - 05494931 15528154 15528156s0n1907Noch keine Bewertungen

- Manual of Instructions For Bernette Sew and Go 8Dokument80 SeitenManual of Instructions For Bernette Sew and Go 8Anna Costalonga50% (2)

- Instant Download Test Bank For Positive Psychology 4th by Lopez PDF FullDokument32 SeitenInstant Download Test Bank For Positive Psychology 4th by Lopez PDF FullAlejandraPruittarqbp100% (8)

- Arjen Kleinherenbrink - Against Continuity - Gilles Deleuze's Speculative Realism (2019, Edinburgh University Press) PDFDokument328 SeitenArjen Kleinherenbrink - Against Continuity - Gilles Deleuze's Speculative Realism (2019, Edinburgh University Press) PDFRondnelly Nunes100% (1)

- Comparison of DC and AC Container Crane Drive SystemsDokument6 SeitenComparison of DC and AC Container Crane Drive Systemsbstack10Noch keine Bewertungen

- Jovy Expenses 1Dokument1.188 SeitenJovy Expenses 1MarionAgency MimaNoch keine Bewertungen

- TCD42A10N0Dokument1 SeiteTCD42A10N0jeancharfan8353Noch keine Bewertungen

- ITP - Data & Telephone InstallationDokument6 SeitenITP - Data & Telephone InstallationGultom Juliana LiliesNoch keine Bewertungen

- Feast of Tabernacles Part 1Dokument45 SeitenFeast of Tabernacles Part 1marcdhaynesNoch keine Bewertungen

- Canal of Nuck Hernia in An Elderly Patient A Case ReportDokument8 SeitenCanal of Nuck Hernia in An Elderly Patient A Case ReportAthenaeum Scientific PublishersNoch keine Bewertungen

- Solution 4Dokument5 SeitenSolution 4askdgas50% (2)

- 5C Revision Worksheet On Vernier Calipers Answers (1E)Dokument3 Seiten5C Revision Worksheet On Vernier Calipers Answers (1E)scribduser0811972100% (3)

- 8261 ControlPanels EK00 III enDokument2 Seiten8261 ControlPanels EK00 III enAndy Kong KingNoch keine Bewertungen

- Global Regulations Affecting Copper in 2021 2023 1666654228Dokument99 SeitenGlobal Regulations Affecting Copper in 2021 2023 1666654228Leonardo Guerini MazettiNoch keine Bewertungen

- Evolution of Medical Education in Ancient Greece-1Dokument6 SeitenEvolution of Medical Education in Ancient Greece-1Elena ApostuNoch keine Bewertungen

- The Price: Twisted Sister From The Album "Stay Hungry"Dokument10 SeitenThe Price: Twisted Sister From The Album "Stay Hungry"johnny tolengoNoch keine Bewertungen

- 10th Grade Vocabulary Matching ExerciseDokument2 Seiten10th Grade Vocabulary Matching ExerciseDinara İbrahim QızıNoch keine Bewertungen

- Ancient Greek Ideas On Elements and AtomDokument23 SeitenAncient Greek Ideas On Elements and AtomEmerlyn PanganibanNoch keine Bewertungen

- Utilization of Waste Materials As A Partial Replacement of BitumenDokument65 SeitenUtilization of Waste Materials As A Partial Replacement of BitumenVenkatram PrabhuNoch keine Bewertungen

- Name: Parmar Pratik K. MSC Sem-1 Roll No.-7 Guided By-Dr. N. Y. BhattDokument29 SeitenName: Parmar Pratik K. MSC Sem-1 Roll No.-7 Guided By-Dr. N. Y. BhattPratik ParmarNoch keine Bewertungen

- Matlab Arduino PDFDokument20 SeitenMatlab Arduino PDFmekanicobucaroNoch keine Bewertungen

- Vipassana Meditation Instructions - Venerable Ashin SilanandabhivamsaDokument65 SeitenVipassana Meditation Instructions - Venerable Ashin SilanandabhivamsaBuddhaDhammaSangahNoch keine Bewertungen