Beruflich Dokumente

Kultur Dokumente

Slide BIOPOLIMER

Hochgeladen von

Jesa FradaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Slide BIOPOLIMER

Hochgeladen von

Jesa FradaCopyright:

Verfügbare Formate

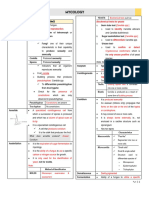

MICROBIAL BIOPOLYMER

1. Pullulan

2. Gellan Gum

3. Dextran

4. Xanthan Gum

Pullulan

Definition

Structure

Microorganism

Properties and quality parameters

Production and Downstream Process of

Pulullan

Pullulan derivatives

Application

Pullulan

Pullulan is a polysaccharide polymer

consisting of maltotriose units,

also known as -1,4- ;-1,6-glucan

Three glucose units in maltotriose are

connected by an -1,4 glycosidic bond,

whereas consecutive maltotriose units

are connected to each other by an -1,6

glycosidic bond.

Pullulan Structure

Optimum temperature : 26-28oC, pH 5 -6.5

Aureobasidium pullulan

Aureobasidium pullulan

Source of A. pullullans isolates

Wood

leather

hydrocarbons

synthetic materials

paper (paper, paper pulp)

human skin

paint (watercolours)

plants

food products (wheat, oats and bean seeds,

flours, fruits and vegetables, fruit juices)

soil

textile (cotton)

Aureobasidium pullulans

in leather (flesh)

Aureobasidium pullulans

in leather (grain)

Aureobasidium pullulans

(cotton)

Aureobasidium pullulans

in acidic paper

Growth curve of A. pullulan

On Malt-Agar growth medium

(MA) (pH 6.5)

On CYA growth medium (pH 5.5) Slimy

colonies (final pH 6).

On Czapek growth medium (initial pH

5.5 and final 5.5)

Properties and quality

parameters

1. Water soluble, insoluble in organic solvents, non

hygroscopic, aqueous solutions are stable and show a

relatively low viscosity compared to other

polysaccharides.

2. It decomposes at 250-280C. It forms easily, thermo-

stable, transparent, elastic, antistatic films, with an

extremely low oxygen permeability (compared to celofan,

polypropylene, polyesther, polyvinylchloride, etc)

3. Moldable, and spinnable, good adhesive and binder.

4. Non-toxic, edible, biodegradable and biocompatible.

Production and Downstream

Process of Pulullan in general

Submerged fermentation using carbohydrate as main media,

nitrogen source, minerals, temperature of 28o C, agitation

of 200 rpm

Downstream processing of fermentation broth includes :

biomass separation precipitation of filtrates by solvent

2- propanol concentration purification of solution

containing the pullulan-type polysaccharide ( partially

purified product or a highly-purified one modern

ultrafiltration techniques are used).

FERMENTATION STEPS

A.pululan in complex nitrogen

agar plates with 50 g/L sucrose

1

st

Media

propagation : malt

extract broth

2

nd

Media

propagation :

complex nitrogen

broth containing 50

g/L sucrose.

Fermentation

Centrifugation

and separation

of biomass

Precipitation of

pullulan by 2 propanol

followed by further

purification

Drying

Milling Packing

Examples of Pullulan Medium

Composition

Complex Nitrogen medium

5 g KH2PO4, 1 g NaCl, 0.6 g (NH4)2SO4, 0.2

g MgSO47H2O, 1 g yeast extract, 0.01 g

FeSO4, 0.01 g MnSO4 and 0.01 g ZnSO4 in

grams/liter of water

malt extract broth :20 g malt extract, 20 g

glucose and 1 g peptone per liter of water

(ATTC Medium 325).

Factors affecting pullulan

production

Media components

Strain of microorganisms

Characteristic of microorganism : the phylamentous

forms or chlamydospores are less productive than

the yeast or pigment-free blastospores (Audet et al.,

1996).

According to Shabtai and Mukmenev (1995), the

yeast-like cells did not produce much pullulan in the

presence of pigment, and the non pigmented swollen

blastospores or germinating blastospores help to

trigger the elaboration of pullulan

Commercial pullulan products

pullulan derivatives

Crosslinked pullulan microparticles

Carboxymethyl pullulan

Sulfopropyl pullulan

Pullulan acetate

Crosslinked pullulan

microparticles

Crosslinking reaction between pullulan and

epichlorohydrin followed by separation,

washing, drying

Healing of infected wounds

a b c

Treatment of a leg wound (horse) with crosslinked

pullulan microparticles: a) infected wound; b) wound

after several applications of crosslinked pullulan

microparticles; c) wound after 2 weeks of treatment.

Crosslinked pullulan microparticles in dry state

Application

edible films for food packaging

breath freshener or oral hygiene products

such as Listerine Cool Mint PocketPaks.

As a food additive, it is known by the E

number E1204 (e.g in cosmetics (hydrating

creams and gels)

filming agent in pharmaceutics (retard

tablets, capsules and microcapsules)

Entrap colours and flavours

Innovative use of pullulan film in

sugar confectionary

Effect of pullulan coating in tablet

Soft candy manufacturing

Pullulan capsules

Application (cont.)

Textiles industry (antistatic, in non-

woven)

Paper industry (coating, in composition)

Photosensible materials (emulsions)

Agriculture (low release fertilizers)

Metalurgy (foundery mold or casting)

Mining (floculant, binder).

Definition

Structure

Microorganism

Production and downstream process

Application

Gellan Gum

a water-soluble polysaccharide produced

by a bacterium Pseudomonas elodea

used primarily as a gelling agent,

alternative to agar in microbiological

culture.

MW : 500 000

Forming viscous solution, insoluble in

ethanol

Structure

The repeating unit of the polymer is a

tetrasaccharide which consists of two residues

of D-glucose and one of each residues of L-

rhamnose and D-glucuronic acid.

The tetrasacharide repeat has the following

structure:

[D-Glc(14)D-GlcA(14)D-Glc(14)L-

Rha(13)]n.

As it is evident from the formula the

tetrasacharide units are connected with each

other using an (13) glycosidic bond.

Molecular structure

Structure (cont.)

Microorganism

Pseudomonas elodea = Sphingomonas

elodea

The composition and structure of native

gellan gum produced by commercial

fermentation is identical to the naturally

occurring polysaccharide formed by

Sphingomonas elodea on plants of Lily

pad varieties.

Pseudomonas elodea

Sphingomonas

Gram-negative, rod shaped, chemo

heterotrophic,

strictly aerobic bacteria

containing glycosphingolipids (GSLs) in

their cell envelopes,

typically produce yellow-pigmented

colonies

Yellow pigmented colonies of

Sphingomonas

Properties of gellan gum

ability to suspend while contributing

minimal viscosity via the formation of a

uniquely functioning fluid gel solution

with a weak gel structure.

setting temperature, degree of structure

and thermal stability.

Water soluble

Biosynthesis

1. intracellular formation of the nucleotide-

sugar precursors, UDP-Glc, UDP-GlcA, and

dTDP-l-Rha.

2. formation of the repeat unit, with sequential

transfer of the sugar donors to an activated

lipid carrier by committed

glycosyltransferases

3. gellan polymerization

4. Export to outer of cells

Production and downstream

process in general

produced by a pure culture fermentation of

carbohydrates by Pseudomonas elodea,

purified by recovery with alcohol, dried, and

milled.

The direct fermentation of sweet cheese whey

diluted 1:5 with water resulted in production of

approximately 7 g of EPS (extra

polysaccharides Sellular ) gellan gum per liter

and in a 70% reduction in the initial BOD5

interesting valorisation of this waste of the

dairy industry and BOD reduction.

Factors affecting gellan gum

production

1. Media components

Molasses 112.5 g/L, tryptone 1 g/L,

casamino acid 1 g/L , disodium hydrogen

orthophosphate 1 g/L and manganese

chloride 0.947 g/L produced gellan

gum of 13.81 g/L

Factors affecting gellan gum

production (cont.)

2. Addition of precursor The sugar

nucleotides providing the activated

precursors for synthesis of

tetrasaccharide i.e UDP-glucose, TDP-

rhamnose and UDP-glucuronic acid.

3. Addition of amino acid triptophan

enhanced cell growth

4. pH 6.5 - 7

Factors affecting gellan gum

production (cont.)

5.Agitation rate : 250 rpm using a helical

ribbon impeller

6. Higher DOT (dissolved oxygen tension)

levels improve the viscosity and

molecular mass of the polymer

7. Temperature : 30oC

DOWNSTREAM PROCESS

Fermentation

broth

Heating 90-95oC, 10-15

min

Killed bacteria and reduced the viscosity

Dilution

Centrifugation and filtration

Separates cells and filtrates

Precipitation by alcohol

followed by centrifugation

Drying 55oC

Milling and packing of

crude gellan gum

Purification of gellan gum

After alcohol precipitation, the products are

washed repeatedly with acetone and ether,

dissolved in deionised water and dialyzed

against deionised water by using dialysis

tubing with molecular mass cut-off of 12 000

14 000.

After dialysis for 23 days with four or five

changes of deionised water, the solution was

lyophilized to formulate dry gellan powder

gel filtration chromatography (GFC) can also

be used

Application

Applications in foods : stabilizer,

emulsifier, thickener

Applications in pharmaceutical industry

Solid culture media for growth of

microorganisms and plants

Gel electrophoresis in biological

research

Cell immobilization

DEXTRAN

complex, branched glucan

(polysaccharide made of many glucose

molecules) composed of chains of

varying lengths

Dextran was first discovered by Louis

Pasteur as a microbial by product in

wine

Structure

The straight chain consists of -1,6

glycosidic linkages between glucose

molecules, while branches begin from -

1,4 linkages (and in some cases, -1,2

and -1,3 linkages as well).

molecular weights ranging from 10,000

Da to 150,000 Da.

Molecular Structure

Microorganisms

Dextran is synthesized from sucrose by

certain lactic-acid bacteria, the best-known

being Leuconostoc mesenteroides and

Streptococcus mutans, L. dextranicum , S.

salivarius, S. bovis

Dental plaque contains dextran

Leuconostoc mesenteroides Streptococcus mutans

Slimy dextran produced by Leuconostoc

mesenteroides CMG713 on sucrose

containing medium with 0.005 % sodium

azide

Production of dextran

Medium : using sucrose as carbon source, examples :

Sucrose 150.0 g., Peptone 2.5 g., Yeast extract 2.5 g.,

K2HPO4 , 5.0 g., NaCl 2.5 g., and a water extract of

sugar refining charcoal 2.0 ml.

Sucrose 150.0 g., acid hydrolyzed casein 5.0 g., Yeast

extract 1.0 g., K2HPO4 5.0 g., NaCl 2.0 g., and MgSO4

0.022 g.

(g l1): sucrose, 150.0; bacto-peptone, 5.0; yeast extract,

5.0; K2HPO4, 15.0; MnCl2.H2O, 0.01; NaCl, 0.01; CaCl2,

0.05.

Condition and downstream

process

Condition : 30 oC, 20 hours

Downstream process :

The culture medium after 20 hours was precipitated

using equal volume of chilled ethanol, shaken

vigorously, centrifuged at 10,000 rpm for 15 minutes

and the supernatant was decanted. This step was

repeated twice.

The precipitated dextran was dried under vacuum

over calcium chloride at 30C. The dextran yield was

calculated on dry weight basis.

Purification

For removal of impurities, dextran obtained

from precipitation was dissolved in distilled

water.

The dextran slurry was again precipitated with

equal volume of chilled ethanol. This

procedure of re-dissolving, precipitation and

washing was repeated three times to remove

cells debris.

Purified dextran was dried under vacuum over

calcium chloride at 30C

Factors affecting dextran

production

1. Incubation time

Factors affecting dextran

production (cont.)

2. Substrate concentration

Factors affecting dextran

production (cont.)

3. Temperature

Factors affecting dextran

production (cont.)

4. pH

Molecular weight of dextran types

using glass column chromatography

packed with Sepharose CL6B.

Remarks :

Blue Dextran, 2000,000;

Industrial dextran, 5000,000-40,000,000;

Dextran from Leuconostoc mesenteroides

CMG713, 5,000,000-20,000,000.

Application medical uses

eye drops as a lubricant

decrease vascular thrombosis.

Dextran in intravenous solution provides an

osmotically neutral fluid that once in the body is

digested by cells into glucose and free water.

It also increases blood sugar levels.

Other uses

size-exclusion chromatography matrices;

an example is Sephadex.

bead form to aid in bioreactor

applications (immobilization)

stabilizing coating to protect metal

nanoparticles from oxidation

make microcarriers for industrial cell

culture

Application (cont. )

GUM XANTHAN

ISI KULIAH :

1. Deskripsi Produk ( Sifat fisiko kimia, biosintesa ,

kegunaan dalam industri, dll)

2. Mikrooorganisme

3. Tahapan fermentasi

4. Proses Hilir (recovery)

5. Prospek Pengembangan

di Indonesia

Gum xanthan : eksopolisakarida mikrobial yang diproduksi

oleh Xanthomonas campestris dari bahan

berkarbohidrat

Sifat Fisiko Kimia :

1. Heteropolisakarida anionik yang bercabang

2. Mengandung D-glukosa (2.8 mol), D-manosa (3.0 mol),

D-glukuronat (2.0 mol), asam asetat dan asam piruvat

3. Rantai utama mirip kerangka selulosa (rantai glukosa

berikatan 1,4)

4. Rantai sisi mengandung dua unit manosa dan satu unit

asam glukuronat

5. Asetat dan piruvat berikatan pada ujung manosa

6. BM : 2-50 x 10

6

atau 3 x 10

7

dalton

Struktur molekul gum xanthan

TURUNAN KIMIA DAN KOPOLIMER CANGKOKAN GUM

XANTHAN

1. Gum Karboksimetil xanthan

2. Gum dietilaminotil xanthan

3. Ester propilenglikol xanthan

4. Gum xanthan sulfat

5. Ikatan silang aldehid gum xanthan

6. Gum deasetil xanthan

7. Gum xanthan - g poli akrilamida

Sampai saat ini tidak ada yang diproduksi secara komersil

SIFAT-SIFAT GUM XANTHAN :

1. Viskositas tinggi pada konsentrasi rendah,

2. Kekenyalan semu (pseudoplasticity) tinggi

3. Mudah larut dalam air panas maupun dingin

4. Viskositas larutan gum xanthan stabil terhadap suhu

5. Viskositas larutan gum xanthan stabil terhadap pH

6. Kelarutan dan kestabilan tinggi pada asam

7. Unggul dalam daya suspensi karena yield valuenya tinggi

8. Kesesuaian yang baik dengan berbagai garam

9. Stabilitas pada proses pelelehan dari keadaan bekunya

(freeze thaw)

SIFAT GUM XANTHAN (LANJUTAN)

10. Kompatibel terhadap beberapa pelarut seperti methanol,

ethanol, isopropanol dan aseton sampai konsentrasi 50-60

%. Konsentrasi pelarut > 60 % akan menyebabkan

gelatinisasi atau pengendapan gum xanthan

11. Tidak terdegradasi oleh enzim protease, selulase

hemiselulase, pektinase dan amilase, tetapi dapat

terdegradasi oleh pengoksidasi kuat seperti peroksida,

persulfat dan hipoklorit

12. Sinergi terhadap gum yang lain seperti gum guar, dan

gum dari biji locust (locust bean gum) serta galaktomanan

Viskositas (cp)

1000

100

0.5 1.0 1.5 2.0 2.5 3.0 Konsentrasi (%)

Pengaruh konsentrasi gum xanthan thd viskositas

Konsentrasi garam (NaCl) (%)

Viskositas (cP)

100

1000

0.01 0.05 0.1 1.0

0.1 % gum xanthan

0.25 % gum xanthan

0.5 % gum xanthan

1.0 % gum xanthan

Pengaruh konsentrasi garam thd viskositas lar gum xanthan

Temperatur (oF)

Viskositas (cP)

1000

10000

50 100 150 200

0.1 % gum xanthan

0.25 % gum xanthan

0.5 % gum xanthan

1.0 % gum xanthan

Pengaruh suhu thd viskositas lar gum xanthan

pH

Viskositas (cP)

1000

10000

1 3 5 7 9 11 13

0.1 % gum xanthan

0.25 % gum xanthan

0.5 % gum xanthan

1.0 % gum xanthan

Pengaruh pH thd viskositas lar gum xanthan

Viskositas (cP)

Laju geser detik

-1

0.1 1 10 100 1000 10 000

1

10

100

1000

10 000

100 000

1 000 000

0.5 %

1 %

2.5 %

Pengaruh laju geser terhadap viskositas larutan gum xanthan

Guar gum

Tara gum

Sifat sinergi gum xanthan dengan

polisakarida lainnya

APLIKASI DALAM INDUSTRI :

1. Industri Petroleum :

a. Sebagai cairan pelicin dalam pengeboran sumur minyak

b. Sebagai cairan untuk mengikat dan memisahkan garam-garam

dari hasil pengeboran minyak lepas pantai dari cairan petroleum

yang diinginkan

c. Sebagai cairan pemecah (fracturing fluid ) berbasis air

d. Untuk mempercepat pengambilan minyak (oil recovery)

Oil drilling

2. Industri Kimia dan lainnya

a. Pakan ternak : sebagai cairan pelengkap pakan (Liquid feed

supplements)

b. Flowable pesticides

c. Pewarnaan dan pengecatan tekstil

d. Pelapis keramik

e. Pembersih

f. Pensuspensi cairan tinta, cat dan perekat kertas

3. Industri Pharmasi dan Kosmetika :

a. Stabilizer emulsi cream untuk obat dan kosmetika

b. Pelarut cream dan lotion

c. Pensuspensi pasta gigi atau larutan pencuci gigi

4. Industri pangan :

a. Pastry filling

b. Penstabil saus dan kaldu

c. Pengemulsi dressing

d. Pengemulsi dan stabilizer dairy products

BIOSINTESA

Ada 4 jenis enzim yang terlibat :

1. Enzim untuk metabolisme awal substrat : hexokinase

2. Enzim untuk sintesis dan interkonversi nukleotida gula (UDP

glucose phosphorylase)

3. Enzim untuk pembentukan pengulangan unit polimer

(monosakarida) (transferase)

4. Enzim polimerase untuk pembentukan biopolimer

eksopolisakarida

Tahapan biosintesa :

1. Metabolisme substrat karbohidrat

2. Sintesis dan interkonversi nukleotida gula

3. Pengulangan unit monomer

4. Polimerisasi

MIKROORGANISME :

Bakteri penghasil gum xanthan :

Xanthomonas campestris

1. Gram Negatif

2. Membentuk koloni berlendir

berwarna kuning

3. Diisolasi dari daun/tanaman

yang berpenyakit,misalnya daun

kedelai yang terkena pustule,

daun kubis, tebu, dll

TAHAPAN FERMENTASI

Xanthomonas campestris

Pengembangan

inokulum

Tangki benih

Fermentasi

Pasteurisasi

dan

pemisahan

biomassa

Pengambilan

gum dengan

pelarut

Pengeringan

Penggilingan Pengemasan

Komponen media :

- Karbohidrat sbg sumber C

- Sumber N

- Mineral

- Antifoam

KONTROL PROSES

Level of control

Metabolic

Environmental Nutrients, pH, P O2, P CO2, shear, temperature, fluid properties

Equipment design

operation Nutrients, acid/base, antifoam addition, air flow, speed, over

pressure, coolant, flow rate and temperature, sparger, and fermenter

impeller geometry

Product biosynthesis

Cell environ

Other processes

Product

Waste (cells, other

products, heat)

SIFAT RHEOLOGI CAIRAN FERMENTASI GUM

XANTHAN SANGAT KHAS :

1. Pada penggunaan bioreaktor berpengaduk akan

timbul zona stagnasi

2. Masalah ini diatasi dengan penggunaan airlift

bioreactor

Air lift bioreactor

Stirred tank bioreactor

PROSES HILIR :

Cairan fermentasi

Pasteurisasi Untuk membunuh sel bakteri yang masih tersisa

Pengenceran

Untuk memudahkan pemisahan biomassa

karena kekentalannya telah diturunkan

Sentrifugasi

Untuk memisahkan sel/biomassa

Pengambilan gum dg pelarut Untuk mempresipitasikan gum , bisa dg

etanol, isopropanol, metanol, dll

Pengeringan

Penggilingan

BEBERAPA MERK GUM XANTHAN KOMERSIL :

1. Keltrol

2. Kelzan

3. Jungbunzlauer

4. Degussa

5. dll

Prospek Pengembangan di Indonesia :

1. Ketersediaan bahan baku : berbagai jenis sumber

karbon dan nitrogen

2. Ketersediaan sumber isolat

3. Aspek teknis teknologis (penggunaan teknologi

fermentasi)

4. Aspek pasar yang terbuka luas

Das könnte Ihnen auch gefallen

- Plant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterVon EverandPlant and Animal Bio-Chemistry - Including Information on Amino Acids, Proteins, Pigments and Other Chemical Constituents of Organic MatterNoch keine Bewertungen

- Microbial Biopolymer: Pullulan Gellan Gum Dextran Xanthan GumDokument93 SeitenMicrobial Biopolymer: Pullulan Gellan Gum Dextran Xanthan GumDewi WijayantiNoch keine Bewertungen

- Oonkhanond 2017Dokument37 SeitenOonkhanond 2017Gebby FebriliaNoch keine Bewertungen

- Fermentation and Recovery of L-Glutamic - Acid - FromDokument8 SeitenFermentation and Recovery of L-Glutamic - Acid - FromPrachi BhoirNoch keine Bewertungen

- Bioconversion of Posthydrolysed Autohydrolysis Liquors: An Alternative For Xylitol Production From Corn CobsDokument8 SeitenBioconversion of Posthydrolysed Autohydrolysis Liquors: An Alternative For Xylitol Production From Corn CobsMaria Victoria Ortega RamosNoch keine Bewertungen

- Xanthan Gum ProductionDokument6 SeitenXanthan Gum ProductionAleem AhmedNoch keine Bewertungen

- Verde BrilhanteDokument2 SeitenVerde BrilhanteMarcela OliveiraNoch keine Bewertungen

- Production of α-amylase using new strain of Bacillus polymyxa isolated from sweet potatoDokument7 SeitenProduction of α-amylase using new strain of Bacillus polymyxa isolated from sweet potatoInternational Organization of Scientific Research (IOSR)Noch keine Bewertungen

- Module 7 L3 Protease, Lipase, Glu OxidaseDokument4 SeitenModule 7 L3 Protease, Lipase, Glu OxidaseVIRTUOUS GAMING 4 UNoch keine Bewertungen

- Thickening and Gelling AgentsDokument10 SeitenThickening and Gelling AgentsHemasriNoch keine Bewertungen

- (Honorato Et Al., 2007) Fermentation of Cashew Apple Juice To Produce High Added Value ProductsDokument7 Seiten(Honorato Et Al., 2007) Fermentation of Cashew Apple Juice To Produce High Added Value ProductsRosane CavalcanteNoch keine Bewertungen

- Active Packaging and Role in Bio-PreservationDokument20 SeitenActive Packaging and Role in Bio-PreservationHarsh JindalNoch keine Bewertungen

- Lutein Extraction An CVDokument22 SeitenLutein Extraction An CVSacra PsyntergiaNoch keine Bewertungen

- Isolation and Characterization of Galactomannan From Sugar PalmDokument4 SeitenIsolation and Characterization of Galactomannan From Sugar PalmRafaél Berroya Navárro100% (1)

- Ethanol CalculationDokument14 SeitenEthanol CalculationMuhammad Azim Khan NiaziNoch keine Bewertungen

- Screening of Oleaginous Yeast Strains Tolerant To Lignocellulose Degradation CompoundsDokument14 SeitenScreening of Oleaginous Yeast Strains Tolerant To Lignocellulose Degradation CompoundsJuanma AlfaroNoch keine Bewertungen

- Biodegradable Films: Based On Partially Hydrolyzed Corn Starch or Potato StarchDokument2 SeitenBiodegradable Films: Based On Partially Hydrolyzed Corn Starch or Potato StarchUjak KimiaNoch keine Bewertungen

- Suppository 121004132503 Phpapp01Dokument60 SeitenSuppository 121004132503 Phpapp01نور الهدىNoch keine Bewertungen

- Appl. Environ. Microbiol. 2008 Dumbrepatil 333 5Dokument3 SeitenAppl. Environ. Microbiol. 2008 Dumbrepatil 333 5DHENADANoch keine Bewertungen

- GalactosidasaDokument8 SeitenGalactosidasaMelissa SuárezNoch keine Bewertungen

- Starch Hydrolysis by AmylaseDokument9 SeitenStarch Hydrolysis by Amylasegaurav saxenaNoch keine Bewertungen

- Introduction and Formulation: Preparation of SuppositoryDokument52 SeitenIntroduction and Formulation: Preparation of SuppositoryImam BisriNoch keine Bewertungen

- Nanoencapsulation of Passion Fruit By-Products Extracts For Enhanced Antimicrobial ActivityDokument10 SeitenNanoencapsulation of Passion Fruit By-Products Extracts For Enhanced Antimicrobial ActivityJavier R. AmayaNoch keine Bewertungen

- 4th Year Biotech Students Lab Practicals On Enzyme TechnologyDokument5 Seiten4th Year Biotech Students Lab Practicals On Enzyme TechnologyABU LoasNoch keine Bewertungen

- Gellan Gum Fermentative Production, DownstreamprocessingDokument14 SeitenGellan Gum Fermentative Production, DownstreamprocessingM KaedeNoch keine Bewertungen

- BiogumDokument11 SeitenBiogumkirshNoch keine Bewertungen

- Problem With Gelatin Containing FormulationsDokument12 SeitenProblem With Gelatin Containing FormulationsshdphNoch keine Bewertungen

- Gellan. Food Applications PDFDokument13 SeitenGellan. Food Applications PDFCamelia TincuNoch keine Bewertungen

- A Single-Host Fermentation Process For The Production of Avor Lactones From Non-Hydroxylated Fatty AcidsDokument10 SeitenA Single-Host Fermentation Process For The Production of Avor Lactones From Non-Hydroxylated Fatty Acidsoki trisnaNoch keine Bewertungen

- Jam Processing - Effect of Pectin Replacement by Locust Bean Gum On Its CharacteristicsDokument12 SeitenJam Processing - Effect of Pectin Replacement by Locust Bean Gum On Its CharacteristicsThảo PhạmNoch keine Bewertungen

- 5.Applied-Acid Tolerant - KenjiTanakaDokument8 Seiten5.Applied-Acid Tolerant - KenjiTanakaImpact JournalsNoch keine Bewertungen

- ArticleDokument12 SeitenArticleJiang ZhangNoch keine Bewertungen

- A Possible Role of Peptides in The Growth Enhancement of An Industrial Strain of Saccharomyces Sp.Dokument8 SeitenA Possible Role of Peptides in The Growth Enhancement of An Industrial Strain of Saccharomyces Sp.Albert DomingoNoch keine Bewertungen

- IJRTI2303037Dokument8 SeitenIJRTI2303037vivekNoch keine Bewertungen

- Application Potential of Grapefruit Peel As Dye Sorbent Kinetics, Equilibrium and PDFDokument9 SeitenApplication Potential of Grapefruit Peel As Dye Sorbent Kinetics, Equilibrium and PDFSaadi BadisNoch keine Bewertungen

- Gluconic AcidDokument11 SeitenGluconic AcidpalkybdNoch keine Bewertungen

- Acid WashingDokument7 SeitenAcid WashingArinaAdilaNoch keine Bewertungen

- Introduction To BioseparationsDokument5 SeitenIntroduction To BioseparationsbaanniiNoch keine Bewertungen

- Carob Bean GumDokument6 SeitenCarob Bean GumYomo OuyaneNoch keine Bewertungen

- Pectin MediaDokument2 SeitenPectin Mediasuresh_kumar16174475Noch keine Bewertungen

- Isolation, Purification and Functional Characterization of Glucansucrase From Probiotic Lactobacillus Plantarum DM5Dokument11 SeitenIsolation, Purification and Functional Characterization of Glucansucrase From Probiotic Lactobacillus Plantarum DM5NiharikaNoch keine Bewertungen

- Metodo Enzimatico para Determinacion de La Actividad CeluloliticaDokument5 SeitenMetodo Enzimatico para Determinacion de La Actividad CeluloliticaMarlom Santa CruzNoch keine Bewertungen

- Microencapsulation of Ethanol Extract Propolis by Maltodextrin and Freeze-Dried PreparationDokument7 SeitenMicroencapsulation of Ethanol Extract Propolis by Maltodextrin and Freeze-Dried Preparationridwan rahman salehNoch keine Bewertungen

- Antioxidants AOACread FileDokument4 SeitenAntioxidants AOACread FileZacariasNoch keine Bewertungen

- Industrial Production of Enzyme Protease PDFDokument25 SeitenIndustrial Production of Enzyme Protease PDFAyushman Kumar BanerjeeNoch keine Bewertungen

- AGAR CHROMOCULT Merck Rebrand - 110426 - 1906Dokument6 SeitenAGAR CHROMOCULT Merck Rebrand - 110426 - 1906Luz Katherine MartinezNoch keine Bewertungen

- Bioethanol Production From Cotton Waste Using Cellulase Extracted From SpeciesDokument9 SeitenBioethanol Production From Cotton Waste Using Cellulase Extracted From SpeciesDr-Muhammad Asim UmerNoch keine Bewertungen

- Starch Hydrolysis by AmylaseDokument13 SeitenStarch Hydrolysis by AmylaseNahusenay TewodrosNoch keine Bewertungen

- Lipase Separation Downstream ProcessDokument23 SeitenLipase Separation Downstream ProcessSonia SnowvyNoch keine Bewertungen

- Production of Ethanol From MolassesDokument5 SeitenProduction of Ethanol From MolassesKrishna PotluriNoch keine Bewertungen

- KYBGLDokument13 SeitenKYBGLWahyu Angga RizalNoch keine Bewertungen

- Extraction and Characterization of Gelatin: A Functional BiopolymerDokument4 SeitenExtraction and Characterization of Gelatin: A Functional BiopolymerTrần Thị QuỳnhNoch keine Bewertungen

- Solid-Phase Extraction Method For Patulin in Apple Juice and Unfiltered Apple JuiceDokument6 SeitenSolid-Phase Extraction Method For Patulin in Apple Juice and Unfiltered Apple JuiceLorena Gilabert GutiérrezNoch keine Bewertungen

- Andreslacueva2008 2 PDFDokument7 SeitenAndreslacueva2008 2 PDFFauziana NurhanisahNoch keine Bewertungen

- Zou Yuchun, Luo Shanshan and Li WenkuiDokument6 SeitenZou Yuchun, Luo Shanshan and Li WenkuiKumar SaurabhNoch keine Bewertungen

- Bacterii Celulozolitice PDFDokument6 SeitenBacterii Celulozolitice PDFArisitica VinilescuNoch keine Bewertungen

- Simultaneous Analysis of Glycolipids and Phospholids Molecular Species in Avocado (Persea Americana Mill) FruitDokument11 SeitenSimultaneous Analysis of Glycolipids and Phospholids Molecular Species in Avocado (Persea Americana Mill) FruitindahNoch keine Bewertungen

- Changes in The Volatile Compounds and in The Chemical and Physical Properties of Snake Fruit (Salacca Edulis Reinw) CVDokument7 SeitenChanges in The Volatile Compounds and in The Chemical and Physical Properties of Snake Fruit (Salacca Edulis Reinw) CVYulis AdrianaNoch keine Bewertungen

- Unit I Production and Application of Enzymes SN JainDokument5 SeitenUnit I Production and Application of Enzymes SN JainSuraj PatilNoch keine Bewertungen

- DssDokument12 SeitenDssJesa FradaNoch keine Bewertungen

- DssDokument12 SeitenDssJesa FradaNoch keine Bewertungen

- 71summary Karaginan June 2012 52Dokument9 Seiten71summary Karaginan June 2012 52Jesa FradaNoch keine Bewertungen

- All About IncineratorDokument11 SeitenAll About IncineratorJesa FradaNoch keine Bewertungen

- All About IncineratorDokument11 SeitenAll About IncineratorJesa FradaNoch keine Bewertungen

- +riani Telusuri Gambar Maps Youtube Gmail Documents Kalender Terjemahan LainnyaDokument7 Seiten+riani Telusuri Gambar Maps Youtube Gmail Documents Kalender Terjemahan LainnyaJesa FradaNoch keine Bewertungen

- Fermented Frutis and VegetablesDokument102 SeitenFermented Frutis and VegetablesLyant Sakowati100% (2)

- Beverages ListDokument5 SeitenBeverages ListSantiago RjverosNoch keine Bewertungen

- Isolation of Fungal EditedDokument23 SeitenIsolation of Fungal EditedEvans Timothy100% (1)

- Role of Microbes in Food and Industrial MicrobiologyDokument2 SeitenRole of Microbes in Food and Industrial MicrobiologyKunal JadhavNoch keine Bewertungen

- Nutrigenomics BookletDokument36 SeitenNutrigenomics BookletJohnny AtmanNoch keine Bewertungen

- MYCOLOGYDokument7 SeitenMYCOLOGYJeremiahNoch keine Bewertungen

- Bread Machine Basics and BeyondDokument8 SeitenBread Machine Basics and Beyondplazman30Noch keine Bewertungen

- Technical Data Sheet: Granucult™ Plate Count Skimmed Milk Agar Acc. Iso 4833 and Iso 17410Dokument4 SeitenTechnical Data Sheet: Granucult™ Plate Count Skimmed Milk Agar Acc. Iso 4833 and Iso 17410Sofia BedoyaNoch keine Bewertungen

- Beer 101 - The Basics of BeerDokument19 SeitenBeer 101 - The Basics of BeerJúlio Gabriel Queiroz dos SantosNoch keine Bewertungen

- Main Food Menu - Allergen, Ingredients and Nutrition Information - 0Dokument21 SeitenMain Food Menu - Allergen, Ingredients and Nutrition Information - 0Sponge BobNoch keine Bewertungen

- SunCoBe ShampooDokument24 SeitenSunCoBe ShampooDong YulNoch keine Bewertungen

- Ginger Garlic ExtractDokument21 SeitenGinger Garlic Extractkorki77Noch keine Bewertungen

- Chemistry XiiDokument16 SeitenChemistry XiiMohamed Aswir AswirNoch keine Bewertungen

- Commercial Applications of FungiDokument12 SeitenCommercial Applications of FungiVivek BhojwaniNoch keine Bewertungen

- Sugar Yeast FermentationDokument4 SeitenSugar Yeast FermentationLauraNoch keine Bewertungen

- Science G-8 P-I EDokument127 SeitenScience G-8 P-I EZah SchlafmützeNoch keine Bewertungen

- AP Biology Scavenger HuntDokument15 SeitenAP Biology Scavenger HuntNick EconomeNoch keine Bewertungen

- Isolation of Yeast From Soil and Different Food Samples and Its Characterization Based On FermentationDokument7 SeitenIsolation of Yeast From Soil and Different Food Samples and Its Characterization Based On FermentationZubair JuttNoch keine Bewertungen

- Biology - Pear Wine MakingDokument4 SeitenBiology - Pear Wine Makingpeach tree100% (1)

- History of BiotechnologyDokument96 SeitenHistory of BiotechnologyeskaNoch keine Bewertungen

- Biology PBL - Yeast FermentationDokument6 SeitenBiology PBL - Yeast FermentationJaida HaniNoch keine Bewertungen

- Polygala Arillata Marcha PlantDokument5 SeitenPolygala Arillata Marcha PlantParbakhar100% (2)

- How To Make Hard Cider: Yours Truly With Press, Carboys, and Winesap and Rome ApplesDokument19 SeitenHow To Make Hard Cider: Yours Truly With Press, Carboys, and Winesap and Rome Applesnicnicnic100% (1)

- Single-Cell-ProteinDokument11 SeitenSingle-Cell-ProteinKhalid AbduNoch keine Bewertungen

- Bokulich & Bamforth (2013)Dokument16 SeitenBokulich & Bamforth (2013)Cauré Barbosa PortugalNoch keine Bewertungen

- Production of Banana Alcohol and UtilizaDokument5 SeitenProduction of Banana Alcohol and UtilizaSambridhi DhakalNoch keine Bewertungen

- Questions On Alcoholic BeveragesDokument5 SeitenQuestions On Alcoholic BeveragesRahul jajoriaNoch keine Bewertungen

- Fermentation Class LectureDokument34 SeitenFermentation Class LecturenabilNoch keine Bewertungen

- Respiration (Multiple Choice) QP PDFDokument17 SeitenRespiration (Multiple Choice) QP PDFozmanNoch keine Bewertungen

- Biotechnology8 Q2 Mod3 CommonlyUsedMicrobes v1 PDFDokument29 SeitenBiotechnology8 Q2 Mod3 CommonlyUsedMicrobes v1 PDFchai chai100% (8)