Beruflich Dokumente

Kultur Dokumente

EIA 5 Industrial Air Pollutants Summer 2014

Hochgeladen von

Altaf Ur RehmanCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

EIA 5 Industrial Air Pollutants Summer 2014

Hochgeladen von

Altaf Ur RehmanCopyright:

Verfügbare Formate

Industrial Air Pollutants (Gaseous,

Noise, Electromagnetic) and

Abatement Techniques

Dr. Shahid Amjad

Institute of Business Management

(IoBM)

The Pressure Gradient Force and Other Effects on Wind

Within the atmosphere, there are several forces that

impact the speed and direction of winds. The most

important though is the Earths gravitational force. As

gravity compresses the Earths atmosphere, it creates air

pressure- the driving force of wind. Without gravity, there

would be no atmosphere or air pressure and thus, no wind.

The force actually responsible for causing the movement of

air though is the pressure gradient force. Differences in air

pressure and the pressure gradient force are caused by the

unequal heating of the Earths surface when incoming solar

radiation concentrates at the equator. Because of the

energy surplus at low latitudes for example, the air there is

warmer than that at the poles.

Warm air is less dense and has a lower barometric pressure

than the cold air at high latitudes. These differences in

barometric pressure are what create the pressure gradient

force and wind as air constantly moves between areas of

high and low pressure.

Industrial Air Quality

There are big industrial estates, and small cottage industries that

generate hazardous and toxic chemicals and Air pollutants.

The fertilizer plants, textile industry, glass industry, steel plants etc.

These industries contribute SO

2

NO

2

, smoke, volatile organic

compounds, chlorine gas, particulate matter, ammonia, CO, CO

2

,

phenol, cyanide into the atmosphere.

The human health is affected by different-sized airborne particulate

matter. Larger particles PM

10

are trapped in the nose and throat,

whereas smaller particles (PM

2.5

) penetrate the lungs and are

associated with a range of respiratory symptoms.

Traces of metals such as lead, iron, and copper are particulates as

well as plant pollen.

Primary/Secondary Air Pollutant

Sources

Secondary air pollutants derive from reactions that occur

between primary pollutants and other atmospheric chemicals

Ozone PANs (peroxyacetyl nitrates) Acids: sulfuric and nitric

There are six pollutants which have the main

contribution in creating air pollution. They are

primary pollutants like

carbon monoxide (CO),

sulphur dioxide (SO

2

),

nitrogen oxide (NO),

lead (Pb), and

particulate matters (PM),

Primary pollutants react with water molecules to

form Secondary pollutants such as weak Nitric

acid, carbonic acid, sulphuric acid etc, and ground

level ozone (O

3

).

Control Devices And Equipments (End-of-the

Pipe Cleaning)

The strategy for this method is to remove the

particulate and gaseous pollutants after they

are formed.

The cleaning devices can be broadly classified

into 2 groups

(i) Particulate Control and

(ii) Gaseous Pollutant Control.

Particulate Control

Particulate Matters (PMs) are common pollutants

present in the emission of an industry. They are

formed in wide range of sizes, diameter varying

from 0.0002 to 500 micron (1 micron = 10

6

m).

PM Control Devices can be broadly divided into 3

categories, viz.,

Internal Separators,

Wet Collection Devices and

Electrostatic Precipitators.

Internal separators. Three types of devices are

commonly in use as internal separators. They are

(i) Gravitational settling chambers, (ii) Cyclone

separators and (iii) Bag filters or fabric filters.

Gravitational settling chambers are generally

used to collect larger particles of size greater

than 50 micron. A stream of dust-laden gas at

less than 3 m/s is passed into the settling

chamber where the velocity of the gas is

further reduced.

As a result, the dust particles settle down and

collected through a hopper at the bottom.

The collection efficiency can be increased by

installing a series of settling chambers in

parallel.

Cyclone separator utilizes centrifugal force to separate

the particulate matters from the carrier gas. The particle

laden gas receives a rotating motion as it enters the

cyclone cylinder. A centrifugal force is developed due to

the vortex formed which throws the particles towards

the wall. These particles get collected at the conical

bottom of the cyclone cylinder.

High efficient cyclones are designed. A series of cyclones,

called the multiclone, are used in many industries to

increase the efficiency of collection.

The settling efficiency of cyclone separator is higher than

that of gravity separator because the centrifugal force is

added to the gravitational force to settle the particles.

An ordinary conventional cyclone can have an efficiency

of 95-99% collection for particles greater than 40 micron

diameter. At the other end, for particles of size greater

than 5 micron, the collection efficiency can be 50-80%

with cyclones of very high efficiency

Bag filters are devices by which gas is purified

through various filtering cloths (cotton, wool,

chemical filters, fibre glass, etc.) or fabric filters

(filters made of granular materials like ceramics,

porous plastics, etc).

The dusts are collected in a hopper at the bottom.

Bag filters have high efficiency but the filters are

required to be cleaned and changed in regular

intervals. The Bag filters are attached to

Mechanical shakers.

Many filters made of clothes, plastics, etc. cannot

work at high temperatures.

However though bag filters are highly efficient,

these are more expensive and require frequent

maintenance.

Wet collection devices.

In the wet collection methods, various types of

scrubbers are used by which the particulate matters

are brought into contact with the scrubbing liquid,

usually water, and the wetted particles settle down.

This is similar to the natural process of cleaning of the

atmosphere by the water cycle. Wet collections have

the advantage of collecting.

not only particulates but also gaseous impurities by

suitable choice of the scrubbing liquid (which can

absorb the gases). But wet scrubbers have the

problems of corrosion.

The scrubbed water (slurry) is required to be treated

before disposal. In this system, air pollution problem is

passed on to the water environment.

The collection efficiency of spray towers can

be increased by the use of centrifugal

scrubbers in which the water spraying nozzles

are fitted inside a conventional dry cyclone.

The water spray acts on the particles in the

outer vortex and the particulate matters are

collected at the bottom as in dry cyclones but

in the form of slurry

Packed beds and plate columns

are well-known absorbers in chemical

industries. These can also be used as wet

scrubbers. These are distinguished by their

simple design and operation, stability in

service, low hydraulic resistance and low

energy consumption.

In a simple packed bed scrubber, the polluted

air stream moving upwards comes in contact

with the scrubbing liquid stream moving

downward over the packing (Figure 5.5).

Venturi scrubber

followed by cyclone separator, the venturi

scrubber offers a high performance collection of

fine particles (2-3 micron). The polluted gas

stream is accelerated by the passage through a

narrow throttle (velocity of the order of 60-120

m/sec).

Scrubbing liquid is injected at this throttle

through low pressure nozzles. The gas-liquid

mixture then goes to the cyclone separator.

The separated slurry is removed from the bottom

(Figure 5.6). Venturi scrubbers are particularly

suitable for sticky and flammable particles.

Electrostatic precipitation. The gaseous stream is

passed through a strong electric field where the

particulate matters get electrically charged and are

attracted towards the electrode of opposite charge. In

a typical Electrostatic Precipitator (ESP), the positive

electrode (grounded) is the collecting electrode and

the negative electrode is suspended at the top.

A high voltage DC current through the electrodes

produces a corona. The gas close to the negative

electrode is ionized. The electrons produced in the

ionization process move towards the positively charged

grounded surface.

During this passage, the particulate matters also get

negatively charged by the electrons and get collected

on the positive surface (Figure 5.7).

ESPs are considered as highly efficient particulate

collecting systems and are widely used in industries.

Gaseous Pollutant Control

Two techniques are generally followed for the

control of gaseous pollutants. They are

(i) Sorption of the pollutant (absorption in a

liquid or adsorption on a solid surface

(ii) Chemical Alterations (the pollutant is

converted to innocuous substances).

Absorption by a liquid The pollutant is brought

into contact with an appropriate liquid or solution

by counter current methods whereby the gaseous

impurity is transferred from the gaseous phase to

the liquid phase.

The gas absorption devices are similar to the wet

collection devices for particulate control

(scrubbers, spray towers, Venturi scrubber, etc.)

with minor modifications wherever necessary.

The different absorbent liquids or solutions used

for various pollutant gases are shown in Table 5.1.

Adsorption on solid surface. In this method, the polluted

air is passed through a column of absorbent solid, usually

activated carbon, activated alumina, silica gel and organic

polymeric compound (molecular sieve), etc. whereby the

pollutant in the air stream is held on the solid surface. This

method, though not very common, is useful for odour

removal.

The following lists some adsorbents and their common use.

Activated carbon : Used for odour removal, purification of

industrial gases, hydrocarbons, pesticides etc.

Silica gel : Used for dehydration of gases

Activated alumina : Used for dehydration of gases and for

removal of HF in aluminum smelter

Molecular sieves : Wide application, selective adsorption of

gases like NH

3

, SO

2

, etc.

CONSTRUCTION OF HIGH STACKS/CHIMNEYS

With all the control devices, it may not be always possible to

effectively remove the pollutants from the emission. Sometimes

the available technology for complete pollutant removal may be

cost-prohibitive.

The next best approach for control of pollution is to allow the

pollutant to be diluted to the maximum and dispersed to minimize

its adverse effect. This can be done by releasing the emissions at a

high altitude with long stacks. The height and the diameter of the

stack should be designed to keep the ground level concentration

within the permissible limits.

The concentration of the pollutant at the ground level decreases

exponentially with the height of the stack and is found to be

maximum at a distance of about 5 to 10 times the stack height at

normal meteorological condition.

The coal used in thermal power plants contains sulphur, weak acid

rain can be except in small pockets.

Installation of desulphurization unit requires heavy capital

investment. The sulphur dioxide control thermal power plants is

mostly done by maintaining long stack heights

Plume rise depends on momentum and

buoyancy. Buoyancy factor is due to the

temperature difference of the stack gases and

surrounding air and the momentum due to

the molecular weight of the exhaust gases

against air.

.

Ans, We Know that

1022

Exercise

A coal power plant has a physical stack height

(chimney) height of 500 m, with an inside

diameter of 10 m. The stack gas velocity is 20

m.sec

-1

. The stack gas temperature is 200

o

C

(473 K) and the ambient air temperature is

10

o

C (283 K). The atmospheric pressure is 1

bar; average wind speed is 5m. sec

-1

.

Calculate the effective stack height.

Ans = 1150.74 m

Exercise

A power plant which runs on coal burning,

consumes 50,000 tons of coal per day. The

Sulphur content of coal is 10 percent.

Calculate the rate of emission of Sulphur

dioxide in grams. sec

-1

into the atmosphere.

(At wt of Sulphur = 32, Oxygen = 16)

Ans= 115,740 gms. sec

-1

Exercise

Before the installation of an Electrostatic

Precipitator (ESP), the Stack gas of a power

plant contained 6.0 g particulates per m

3

of

gas. The gas flow rate is 350

m

3

/minute. The

new ESP can remove 2500 kg particulates/day.

i. Calculate the emission rate of particulates

before and after pollution control in Kg/day.

ii. What is the efficiency of the new ESP

iii. Will the new system meet the particulate

emission standard of 0.7 gms/m

3

Solution: Data

a) w=6gms/m

3

; flow rate Q=350m

3

; m=2500 kg/day.

350x6=2100gms/min or 2100x10

-3

kg/min.

2100x10

-3

x24x60 = 3024 kg/day (Before).

New ESP 2500 kg/day

3024-2500=524 kg/day

b) n=Quantity of dust collection x100

Quantity of dust in flowing gas

2500 x100 =82.7%

3024

c) Total particulates at source=6gms

ESP efficiency= 82.7%

Particulates removed 6x0.827 = 4.962gms.

Particulates remain 6.0 - 4.962 = 1.038 gms/m

3

So the new ESP system cannot meet emission standard of 0.7 gms/m

3

Case Study

A survey was undertaken to monitor the levels of atmosphere Suspended

Particulate matter in the industrial area of Korangi using a high volume

sampler. The PM

monitoring was done in December and subsequently as a

follow up, the process of particulates monitoring was also repeated in

month of July.

During the December observations, the fiber glass filter paper used had an

initial weight of 7.02345 gms. After 24 hrs of sampling using a high Volume

air sampler, the filter paper weighed 8.56432 gms. The volume of air flow

(measured using a rotameter) at the start and at the end of the

experiment was recorded to be 1.2 m

3

/min and 0.8 m

3

/min. respectively.

Similarly, in monsoonal month of July. The initial and final weight of the

fiberglass filter paper was 8.00234 and 8.16012 gms. The air flow at the

start and at the end of the experiment was recorded to be 2.2 m

3

/min and

1.8 m

3

/min. The sampling time was 24 hrs. respectively.

Calculate the concentration of suspended matter in the atmosphere in

ug/m

3

at the Korangi location in December and July accordingly. Explain

variation in SPM during July and December months. Does the air quality

meet the NEQs Standards.

Procedure

1. you have the data from a 24-hour run of a Mini Volume

SPM sampler. The data include:

Weight of the filter before sampling

Weight of the filter after sampling

Total time the sampler was running

Average flow rate of the sampler

2. Using the data provided, perform the step-by-step

calculation of ambient particulate concentration.

3. Compare and explain variation in the results of particulate

matter during summer and winter to the National

Environmental Air Quality Standard (NEQs)/Air Quality

Index (AQI)

Solution

Calculate the weight of particulate matter Final

and Initial weight of the Filter paper in g

(multiply weight in gm by 1000000.)

Calculate the average air flow (from the

rotameter data) (Start +End data/2) air Volume

sampled

Calculate the sampling duration in 24 hrs (i.e total

air flow duration of sampling. (Av flow x 60 x 24).

Total Suspended Matter Weight of Particulate

matter/Volume Air flow sampled).

Guideline for Control of Air Pollution

Pollution of air in the atmosphere cannot be fully abated but can be

controlled if certain measures are taken.

Develop peoples awareness in all spheres including the

governments.

Free burning of wood, coal, wastes of forest, agriculture waste and

many other solid matters must be discouraged in the open spaces.

Vehicular emissions must me checked periodically.

Use of natural gas (CNG) or low sulphur containing fuels should be

encouraged in place of petrol and diesel.

Industry must adopt waste gas treatment facility before releasing it

into the atmosphere.

Lead free petrol should be introduced to control lead pollution.

All sorts of waste materials must be disposed properly.

Greater emphasis should be put on the use of renewable energy

sources such as hydroelectric, solar and wind energies.

Use of chlorofluorocarbons and other toxic materials must be

reduced or substituted.

Das könnte Ihnen auch gefallen

- Adc Invoice 400Dokument2 SeitenAdc Invoice 400Altaf Ur RehmanNoch keine Bewertungen

- Deputy Assistant DirectorDokument5 SeitenDeputy Assistant DirectorDanish RazaNoch keine Bewertungen

- Tariff ComparisonDokument2 SeitenTariff ComparisonAltaf Ur RehmanNoch keine Bewertungen

- Syllabus PDFDokument150 SeitenSyllabus PDFAsma SethiNoch keine Bewertungen

- Enquiry ListDokument12 SeitenEnquiry ListAltaf Ur RehmanNoch keine Bewertungen

- LC Presentation QICTDokument22 SeitenLC Presentation QICTAltaf Ur RehmanNoch keine Bewertungen

- The Drugs Act, 1976Dokument32 SeitenThe Drugs Act, 1976Dr-Usman KhanNoch keine Bewertungen

- CE-2016 Public NoticeDokument1 SeiteCE-2016 Public NoticeKenneth MillerNoch keine Bewertungen

- Custom RulesdsdsDokument279 SeitenCustom RulesdsdsAltaf Ur RehmanNoch keine Bewertungen

- Application Form Instructions To Candidates - Latest (After Adv. No. 4) 153rd Approved 30.4.2015Dokument8 SeitenApplication Form Instructions To Candidates - Latest (After Adv. No. 4) 153rd Approved 30.4.2015knight_riderrNoch keine Bewertungen

- Advt No 7-2015Dokument3 SeitenAdvt No 7-2015Waqas TayyabNoch keine Bewertungen

- Import Policy Order 2013 PakistanDokument132 SeitenImport Policy Order 2013 PakistanSher Zaman BhuttoNoch keine Bewertungen

- Assignment of DesizingDokument8 SeitenAssignment of DesizingAltaf Ur RehmanNoch keine Bewertungen

- 1) ChromatographyDokument8 Seiten1) ChromatographyAltaf Ur RehmanNoch keine Bewertungen

- SAMI Pharmaceuticals Supplier DirectoryDokument113 SeitenSAMI Pharmaceuticals Supplier DirectoryAltaf Ur RehmanNoch keine Bewertungen

- Bill of Entry Bill of Export Baggage Declaration Transshipment PermitDokument2 SeitenBill of Entry Bill of Export Baggage Declaration Transshipment PermitAltaf Ur RehmanNoch keine Bewertungen

- SCM in PharmaDokument20 SeitenSCM in PharmaAbhiNoch keine Bewertungen

- 2) Ana DiscussionDokument3 Seiten2) Ana DiscussionAltaf Ur RehmanNoch keine Bewertungen

- LC Presentation QICTDokument22 SeitenLC Presentation QICTAltaf Ur RehmanNoch keine Bewertungen

- 06 Introduction To Oceanography. TomczakDokument123 Seiten06 Introduction To Oceanography. TomczakmishazujevNoch keine Bewertungen

- Experiment # 04: ObjectDokument8 SeitenExperiment # 04: ObjectAltaf Ur RehmanNoch keine Bewertungen

- EXPERIMENT#2 (A) : Analtical Techniques COURSE#605Dokument4 SeitenEXPERIMENT#2 (A) : Analtical Techniques COURSE#605Altaf Ur RehmanNoch keine Bewertungen

- Import Docs Guide: Commercial, B/L, COO, Packing, GD FormsDokument8 SeitenImport Docs Guide: Commercial, B/L, COO, Packing, GD FormsAltaf Ur RehmanNoch keine Bewertungen

- Weboc 1Dokument30 SeitenWeboc 1Altaf Ur RehmanNoch keine Bewertungen

- Bill of Entry Bill of Export Baggage Declaration Transshipment PermitDokument2 SeitenBill of Entry Bill of Export Baggage Declaration Transshipment PermitAltaf Ur RehmanNoch keine Bewertungen

- CE-2016 Public NoticeDokument1 SeiteCE-2016 Public NoticeKenneth MillerNoch keine Bewertungen

- Salient Feature CustomsDokument3 SeitenSalient Feature CustomsAarif ShahNoch keine Bewertungen

- Syllabus PDFDokument150 SeitenSyllabus PDFAsma SethiNoch keine Bewertungen

- 1) Sales Contract 1) Sales Contract Importer or Buyer Importer or BuyerDokument5 Seiten1) Sales Contract 1) Sales Contract Importer or Buyer Importer or BuyerAltaf Ur RehmanNoch keine Bewertungen

- Advt No 7-2015Dokument3 SeitenAdvt No 7-2015Waqas TayyabNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 20 Ways To Boost Soil FertilityDokument8 Seiten20 Ways To Boost Soil FertilitymahderNoch keine Bewertungen

- YORK K OIL Material Safety Data SheetDokument5 SeitenYORK K OIL Material Safety Data SheetMunishNoch keine Bewertungen

- Reaction of TryptophanDokument2 SeitenReaction of TryptophansasmithaNoch keine Bewertungen

- Cement Technology: ReclaimerDokument17 SeitenCement Technology: ReclaimerYana Damayanti100% (1)

- Design of a Methanol Condenser ExchangerDokument3 SeitenDesign of a Methanol Condenser ExchangerIndra watiNoch keine Bewertungen

- Mandatory Appendix 41: EIH Support Plate DesignDokument5 SeitenMandatory Appendix 41: EIH Support Plate DesignHanafi BasriNoch keine Bewertungen

- CRS Resolution SheetDokument24 SeitenCRS Resolution SheetTĩnh Hồ TrungNoch keine Bewertungen

- Georgia Department of Public Health Environmental Health SectionDokument8 SeitenGeorgia Department of Public Health Environmental Health Sectionjclark13010Noch keine Bewertungen

- Dielectric Constants of MaterialsDokument68 SeitenDielectric Constants of MaterialsRUBEN DARIO BUCHELLYNoch keine Bewertungen

- Mod 2 BA PhysicsDokument412 SeitenMod 2 BA PhysicsBenitoKameloNoch keine Bewertungen

- Manage Waste & Resources with WastivityDokument21 SeitenManage Waste & Resources with WastivitybhishmNoch keine Bewertungen

- Indian Association of Chemistry Teachers: National Standard Examination in Chemistry (Nsec) 2018-19Dokument27 SeitenIndian Association of Chemistry Teachers: National Standard Examination in Chemistry (Nsec) 2018-19sankalp somaniNoch keine Bewertungen

- Elex ReviewerDokument3 SeitenElex ReviewerJhomel EberoNoch keine Bewertungen

- Damp Proofing Methods & MaterialsDokument18 SeitenDamp Proofing Methods & Materialschristelle do100% (2)

- 2011 Final AnswerDokument8 Seiten2011 Final Answerxuan1002Noch keine Bewertungen

- Nickyta Tanryan - 2106729915 - UtsgamtekDokument2 SeitenNickyta Tanryan - 2106729915 - UtsgamtekNickyta TanryanNoch keine Bewertungen

- Effects of PVC Pipes on the EnvironmentDokument9 SeitenEffects of PVC Pipes on the EnvironmentNeeraj KumarNoch keine Bewertungen

- Nde Procedure Magnetic Particle TestingDokument20 SeitenNde Procedure Magnetic Particle Testingryan.s100% (1)

- OLED Basics and Flexible DisplaysDokument18 SeitenOLED Basics and Flexible DisplaysmuaheltNoch keine Bewertungen

- Ultra FJ BrochureDokument3 SeitenUltra FJ Brochureamigofirm100% (1)

- D4B807E3B5B-Body Repairs General Body RepairsDokument54 SeitenD4B807E3B5B-Body Repairs General Body Repairsderp derpissimoNoch keine Bewertungen

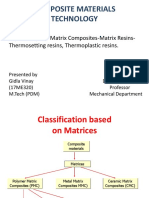

- Polymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic ResinsDokument27 SeitenPolymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic Resinsgidlavinay100% (1)

- A Powerpoint Presentaion On Ready-Mix ConcreteDokument22 SeitenA Powerpoint Presentaion On Ready-Mix ConcreteGowriSenthilNoch keine Bewertungen

- Additive and Colour Preparations: For Extruded Polystyrene FoamsDokument22 SeitenAdditive and Colour Preparations: For Extruded Polystyrene FoamsKarim HakimNoch keine Bewertungen

- STEELFORCE Welded Beam Catalogue Nov2021Dokument20 SeitenSTEELFORCE Welded Beam Catalogue Nov2021Bobby CurrieNoch keine Bewertungen

- MECH466 Lecture 4 PDFDokument28 SeitenMECH466 Lecture 4 PDFSaran ArunNoch keine Bewertungen

- Foundation Engineering-I Design of Shall PDFDokument44 SeitenFoundation Engineering-I Design of Shall PDFAhmed MohammedNoch keine Bewertungen

- Resistance Wire: Properties of Major AlloysDokument2 SeitenResistance Wire: Properties of Major Alloysyasir127Noch keine Bewertungen

- 005-Interlloy Grade 4340 Hardened and Tempered BarDokument3 Seiten005-Interlloy Grade 4340 Hardened and Tempered BarDhruv MehtaNoch keine Bewertungen

- Cold Storage SlidesDokument37 SeitenCold Storage Slidesbal singh ranaNoch keine Bewertungen