Beruflich Dokumente

Kultur Dokumente

3 Introduction To Technical Loss of Power System

Hochgeladen von

احمدعليOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3 Introduction To Technical Loss of Power System

Hochgeladen von

احمدعليCopyright:

Verfügbare Formate

1

Introduction to

Technical Loss of Power

System

The Third Country Training Course

Technology Improvement

for Transmission and Distribution in Iraq

November 2008

2

Major Factors of Power Loss

Power Plant

Losses of

Transformer

Consumers (Domestic,Industrial,Commercial etc.)

Losses of

Transmission

Line

Losses of Distribution Line

Substation

3

Transmission/Distribution Losses and Total Losses

A

B

Consumer

Substation

Distribution pole

500 kV

187 kV

66 kV 6.6 kV

100 V or 200 V

Transmission loss

Distribution loss

A

Electric

power

consumption

in P/S

Electric

power

consumption

in S/S

PS SS SS SS B

Transformer

loss (1)

Transmission

loss (1)

Transformer

loss (2)

Transmission

loss (2)

Transformer

loss (3)

Transmission

loss (3)

Distribution loss

(1)

Transformer

loss (4)

Distribution loss

(2)

Transformer

loss (5)

Watthour meter

Power station

Substation

Electric power

consumption in S/S

Electric power

consumption in P/S

Transmission

loss

Distribution

loss

Consumption

in P/S

Consumption

in S/S

Transmission

and distribution

loss

Total loss

A

m

o

u

n

t

o

f

g

e

n

e

r

a

t

e

d

/

r

e

c

e

i

v

e

d

p

o

w

e

r

A

m

o

u

n

t

o

f

d

e

m

a

n

d

e

d

p

o

w

e

r

Transmission

loss

Distribution loss

C

D

Transmission and

distribution loss

S

u

p

p

l

y

c

a

p

a

c

i

t

y

a

t

s

e

n

d

i

n

g

e

n

d

S

u

p

p

l

y

c

a

p

a

b

i

l

i

t

y

a

t

d

e

m

a

n

d

e

n

d

Total loss rate

=1-B/A

Transmission and

Distribution loss rate

=1-D/C

PS

SS

*

Excluding the consumption in P/S

Including the consumption in S/S

Substation

(for distribution)

Step-up

TR

Electric

power

consumption

in S/S

Electric

power

consumption

in S/S

4

Major Factors of Power Loss

Resistance Loss

Corona Loss

Dielectric Loss of Cable

Copper Loss & Iron Loss

of Transformer

Loss of T.L

Loss of

D.L

5

Resistance Loss (general formula)

Where

: Line Current [A]

: Resistance of one line [ /m]

: Length of the Line [m]

When current flows through T.L. or D.L. which have

Resistance, Joule heat that corresponds to

Resistance Loss generates:

Resistance Loss is as follows: ] [W w

dx r i w

L

o

x

}

=

2

i

r

L

O

6

Resistance Loss (Overhead T.L)

Where, : Charging current [A]

: Power factor

(In case of a short-distance)

L r I w =

2

3

c

I

| cos

Where, : Line Current [A]

: Resistance of one line [ /km]

: Length of the Line [km]

I

r

L

(In case of a long-distance)

O

{ }

2 2

3 / 1 cos 3 Ic Ic I I L r w + = |

7

Resistance Loss (D.L.)

Where,

: Sending-end current [A]

: Dispersal loss factor

Current is not constant except the case

Concentrating on the end of line. Therefore;

x

i

rLh I dx r i w

m

L

o

x

2 2

= =

}

m

I

h

8

Resistance Loss (D.L.)

<Load Distribution and Dispersal Loss Factor>

Concentrating on the end

of line

Dispersal loss

factor

Model of dispersal load

Distributing equally on

the line

Increasing, so that it goes

to the end of line

Becoming the maximum

in the middle of line

Decreasing, so that it

goes to the end of line

( ) % 33

3

1

~

1

( ) % 53

15

8

~

( ) % 20

5

1

=

( ) % 38

60

23

~

9

Corona Loss (Overhead T.L)

In case of a transmission line with voltage higher

than about 100kV, if the conductors which size of

diameter is too small for the specific voltage use,

voltage potential gradient on conductor surface

becomes high, and occurs partial breakdown of the

air insulation.

Corona discharge occurs, and causes corona loss.

And it is significantly affected by some external factors.

(from weather condition, such as water or snow deposit

on the conductor)

10

The losses of Overhead T.L.

A Comparison of Transmission Losses among Different Overhead Lines

Class

Yearly electric loss energy (MWh/100 kmcircuityr)

Remarks

Resistance

loss

Corona loss Core loss Total

154 kV

TACSR 610 mm

2

(1 conductor)

57,700

(99.3)

8

(Negligible)

410

(0.7)

58,118

(100)

Figures in

parentheses

are

composition

ratios (%).

275 kV

ACSR 410 mm

2

(4 conductors)

20,100

(98.8)

54

(0.3)

180

(0.9)

20,334

(100)

500 kW

TACSR 810 mm

2

(4 conductors)

11,000

(94.2)

440

(3.8)

240

(2.0)

11,680

(100)

Note: Input current: I = 1,000 (A); annual load factor: f = 0.6; loss factor: = 0.432

11

Dielectric Loss of Cables (Underground T.L./D.L. )

o |

.

|

\

|

t = tan

E

C f W

n d

2

3

2

is in proportion to the squire of voltage V .

Therefore, if the voltage is higher than 22kV, the

dielectric loss of cable cannot be disregarded.

d

W

Where, : frequency [Hz]

: Static capacity [ F/km]

: Line-to-line voltage [kV]

: Dielectric loss tangent

f

n C

E

o tan

Single-core type

Sheath

Conductor

Insulating Material

Semi-conducting

layer

12

The losses of Underground T.L.

Transmission Losses in Underground Cables

Type of

cable

Applied

voltage

(kV)

Capacity

(MW)

Yearly electric loss energy

(GWh/20 kmcircuityr)

Remarks

Resistance

loss

Dielectric

loss

Sheath

loss

Total

OF

2000

mm

2

154

100

0.44

(20)

1.68

(70)

0.09

(4)

2.21

(100)

etan

=3.40.

2%

200

1.77

(47)

1.68

(44)

0.35

(9)

3.80

(100)

275

200

0.52

(11)

4.10

(86)

0.15

(3)

4.77

(100)

400

2.09

(31)

4.10

(60)

0.61

(9)

6.80

(100)

500

400

0.64

(7)

8.57

(90)

0.27

(3)

9.48

(100)

600

1.43

(13)

8.57

(81)

0.6

(6)

10.6

(100)

o

13

Copper Loss & Iron Loss of a Transformer

Copper Loss

Eddy current loss

Winding resistance Loss

Loss

Load loss

Non-Load loss

Hysteresis loss

Iron Loss

Auxiliary equipment

loss

Cooling Fan loss

Oil pump loss

14

Copper Loss & Iron Loss of a Transformer

Iron Loss (Non-load Loss)

Loss with steady value that

generates in an energized state,

regardless of the value of the current.

Iron loss is mainly categorized to

Hysteresis loss or Eddy current

loss.

15

Copper Loss & Iron Loss of a Transformer

Iron Loss (Non-load Loss)

<Hysteresis loss>

The direction and magnitude of

magnetic flux in a coil constantly

changes due to AC current, and it

causes the friction loss between

molecules.

16

Copper Loss & Iron Loss of a Transformer

Iron Loss (Non-load Loss)

< Hysteresis loss>

: Hysteresis Loss

: Frequency

: Maximum Magnetic

Flux Density

: Proportional Constant

<Hysteresis Curve>

horizontal axis

Magnetic Field Intensity H

vertical axis

Magnetic Flux Density B

6 . 1

m h h

fB k P =

h

P

f

m

B

h

k

17

Iron Losses of a Transformer

Conventional

core

Improved Core

JIS Type

(NOTE)

35G165 35P135 35P115 30P105

Core

Loss(w/kg)

(%)

1.65

(100)

1.35

(82)

1.15

(70)

1.05

(64)

(NOTE) The first 2-digit represents the value of the thickness (mm) multiplied by 100.

G means a normal material, and P means a high-orientation material.

The last 3-digit represents the guaranteed value of core loss which is multiplied by

100.(at the 50 Hz frequency and 1.7T flux density.)

18

Copper Loss & Iron Loss of a Transformer

Iron Loss (Non-load Loss)

< Eddy current loss>

Magnetic flux change causes an electro

motive force and an eddy current is induced

within the core, causing resistive heating.

: Frequency

: Maximum Magnetic Flux Density

: Eddy current loss :Resistivity of magnetic material

: Thickness of iron plate : Proportional Constant

( )

=

2

m

e e

fB t

k P

e

P

f

m

B

e

k

t

19

Copper Loss & Iron Loss of a Transformer

Copper Loss (Load Loss)

Load current flowing through the

winding causes resistive heating of

the conductors.

Copper Loss is proportional to the

square of the load current. ( )

R I

2

20

Thank You!

21

22

Copper Loss & Iron Loss of a Transformer

Definition (IEC 60076-1*)

Copper Loss (Load Loss)

= the absorbed active power at rated

frequency at reference temperature

associated with a pair of windings when

rated current is flowing through the line

terminals of one of the windings, and

the terminals of the other winding are

short-circuited. Further windings are

open-circuited.

(*)Power Transformer General

23

Copper Loss & Iron Loss of a Transformer

Definition (IEC 60076-1)

Iron Loss (Non-load Loss)

= the active power absorbed when

rate voltage at rated frequency is

applied to the terminals of one of the

winding, other winding or winding

being open-circuited

Das könnte Ihnen auch gefallen

- Year OneDokument53 SeitenYear Oneاحمدعلي100% (1)

- Load Estimation in BuildingsDokument23 SeitenLoad Estimation in BuildingsاحمدعليNoch keine Bewertungen

- Restricted Earth Fault Relay Application Within Shunt Capacitor Bank PDFDokument115 SeitenRestricted Earth Fault Relay Application Within Shunt Capacitor Bank PDFyasadik9Noch keine Bewertungen

- CT Calculationas For 33kV SwitchgearDokument5 SeitenCT Calculationas For 33kV Switchgearjm.mankavil6230Noch keine Bewertungen

- Camtech Recommendations: Maharajpur, Gwalior - 474005Dokument20 SeitenCamtech Recommendations: Maharajpur, Gwalior - 474005ashwaniNoch keine Bewertungen

- Working Principle of Transformer: The Working Procedure On HowDokument6 SeitenWorking Principle of Transformer: The Working Procedure On HowkNoch keine Bewertungen

- MDL Number ListDokument3 SeitenMDL Number ListanjaneyulubhelNoch keine Bewertungen

- UL Standards List Latest DownloadDokument22 SeitenUL Standards List Latest DownloadDavid Kwock0% (2)

- Construction of Alternator - Electrical4uDokument5 SeitenConstruction of Alternator - Electrical4uM Kumar MarimuthuNoch keine Bewertungen

- Early Radio Receivers, Called Crystal Radios, Used A "Cat's Whisker" of Fine Wire Pressing On A Crystal ofDokument4 SeitenEarly Radio Receivers, Called Crystal Radios, Used A "Cat's Whisker" of Fine Wire Pressing On A Crystal ofPoonam bhavsarNoch keine Bewertungen

- Final DCPR 2034 COMPILED PDFDokument510 SeitenFinal DCPR 2034 COMPILED PDFAsmita84% (32)

- Power QualityDokument13 SeitenPower QualityBochiNoch keine Bewertungen

- Load Forecasting Techniques & Scheduling: Ajay Bhatnagar, NRLDCDokument44 SeitenLoad Forecasting Techniques & Scheduling: Ajay Bhatnagar, NRLDCAkshay GhotekarNoch keine Bewertungen

- Vol1 12Dokument41 SeitenVol1 12keerthi dayarathnaNoch keine Bewertungen

- Active and Reactive PowerDokument2 SeitenActive and Reactive PowerEr Mohammad SadiqueNoch keine Bewertungen

- GIS 66kV Manual PDFDokument53 SeitenGIS 66kV Manual PDFsridhar3048100% (3)

- DC DC ConvertorDokument11 SeitenDC DC ConvertorJyothiNoch keine Bewertungen

- Green Hydrogen Energy Fuel For The Future in IndiaDokument6 SeitenGreen Hydrogen Energy Fuel For The Future in IndiaResearch ParkNoch keine Bewertungen

- Types of TransformersDokument16 SeitenTypes of TransformersTahamee SHAIKHNoch keine Bewertungen

- Intro To Power Quality LEZNCHARLDokument45 SeitenIntro To Power Quality LEZNCHARLLucas De MeloNoch keine Bewertungen

- Ground (Electricity) : AustraliaDokument2 SeitenGround (Electricity) : AustraliaIngrid Juniar Adriany0% (1)

- Handbook - Energy Management For Motor Driven Systems PDFDokument123 SeitenHandbook - Energy Management For Motor Driven Systems PDFmnt6176Noch keine Bewertungen

- HP Heater Tube LKG CauseDokument4 SeitenHP Heater Tube LKG CauseDebabrata GhoshNoch keine Bewertungen

- Distribution Automation Summary Report - 09!29!16Dokument115 SeitenDistribution Automation Summary Report - 09!29!16Chetan KotwalNoch keine Bewertungen

- Reliability Evaluation of Grid-Connected Photovoltaic Power SystemsDokument32 SeitenReliability Evaluation of Grid-Connected Photovoltaic Power Systemssamsai88850% (2)

- Full WaveDokument17 SeitenFull WaveSandeep KumarNoch keine Bewertungen

- The Reduction of Total Harmonic Distortion For The Multilevel Converter Using Genetic Algorithms Optimization MethodDokument15 SeitenThe Reduction of Total Harmonic Distortion For The Multilevel Converter Using Genetic Algorithms Optimization MethodMohammad reza eesazadehNoch keine Bewertungen

- Infrared Thermography A Versatile TechnologyDokument7 SeitenInfrared Thermography A Versatile TechnologyJintotholath JjNoch keine Bewertungen

- Earthing Systems in LV - Schneider 172Dokument30 SeitenEarthing Systems in LV - Schneider 172anon_568723957Noch keine Bewertungen

- Combined Cycle Gas Turbine Gyanendra Sharma NPTI DelhiDokument148 SeitenCombined Cycle Gas Turbine Gyanendra Sharma NPTI DelhiNPTINoch keine Bewertungen

- Subestaciones Mine PowerDokument462 SeitenSubestaciones Mine PowerMellisa LewisNoch keine Bewertungen

- AREVA The Testing of TransformerDokument49 SeitenAREVA The Testing of TransformerMahmoud Moez92% (12)

- Harmonic Survey of Typical Non-Linear Loads PDFDokument5 SeitenHarmonic Survey of Typical Non-Linear Loads PDFgtgreatNoch keine Bewertungen

- TSPL GST Petition - AnnexuresDokument407 SeitenTSPL GST Petition - AnnexuresVIVEK anandNoch keine Bewertungen

- Jubran ThesisDokument128 SeitenJubran Thesisahmadove1Noch keine Bewertungen

- Department of Electrical and Computer Engineering: AdvisorDokument19 SeitenDepartment of Electrical and Computer Engineering: AdvisorSabir VeNoch keine Bewertungen

- Power Quality Improvement in Power System Using UPFCDokument6 SeitenPower Quality Improvement in Power System Using UPFCEditor IJTSRDNoch keine Bewertungen

- Fuel Cells PaperDokument20 SeitenFuel Cells PaperBig FruitNoch keine Bewertungen

- History of Desalination Cost EstimationsDokument17 SeitenHistory of Desalination Cost EstimationsGiovanniStirelliNoch keine Bewertungen

- Hvac Factsheet BasicsDokument3 SeitenHvac Factsheet BasicsAnwar SyedNoch keine Bewertungen

- English 210 Team 4 - Problem Statement First DraftDokument8 SeitenEnglish 210 Team 4 - Problem Statement First Draftapi-691625064Noch keine Bewertungen

- Synchronization Checklist PDFDokument8 SeitenSynchronization Checklist PDFAdhyartha KerafNoch keine Bewertungen

- Ecodial Advance Calcualtion IndiaDokument16 SeitenEcodial Advance Calcualtion IndiaJosé Mendes da Silva100% (1)

- Electric Power Utilisation and Energy AuditingDokument14 SeitenElectric Power Utilisation and Energy Auditingrpdmohan100% (2)

- Company Profile & Capabilties PT PJB To Badan NGLDokument68 SeitenCompany Profile & Capabilties PT PJB To Badan NGLAdi Wijaya100% (1)

- Arc Welding - Introduction and FundamentalsDokument30 SeitenArc Welding - Introduction and FundamentalsShantha Kumar G C50% (2)

- Low Voltage and LED Architectural Plug-In System by Modular InternationalDokument39 SeitenLow Voltage and LED Architectural Plug-In System by Modular InternationalLEDlightingNoch keine Bewertungen

- A.M Lec 2 AlexUniv LoadForecastingDokument26 SeitenA.M Lec 2 AlexUniv LoadForecastingWessam EssamNoch keine Bewertungen

- Electricity Demand Load Forecasting For A Remote Area of BangladeshDokument13 SeitenElectricity Demand Load Forecasting For A Remote Area of BangladeshEngidNoch keine Bewertungen

- 03 - Lectures of Load Forecasting - NnatDokument89 Seiten03 - Lectures of Load Forecasting - NnatMuhammad Yunus Nurdin0% (1)

- The Laplace TransformsDokument61 SeitenThe Laplace TransformsLouie Shaolin Lungao100% (1)

- JJ104 Workshop Technology CHAPTER9 Arc WeldingDokument14 SeitenJJ104 Workshop Technology CHAPTER9 Arc WeldingAh Tiang50% (4)

- Air BechtelDokument34 SeitenAir BechtelBhargav ChaudhariNoch keine Bewertungen

- Fuzzy Ideology Based Long Term Load ForecastingDokument6 SeitenFuzzy Ideology Based Long Term Load ForecastingCristian KlenNoch keine Bewertungen

- Motor EfficiencyDokument28 SeitenMotor EfficiencyMani KandanNoch keine Bewertungen

- K Calibration of Venturi and Orifice MetersDokument13 SeitenK Calibration of Venturi and Orifice MetersKitty VNoch keine Bewertungen

- Thermodynamic Performance Testing and MonitoringDokument3 SeitenThermodynamic Performance Testing and MonitoringNicole FelicianoNoch keine Bewertungen

- Topology Review DC DC ConvertersDokument54 SeitenTopology Review DC DC ConvertersaknuslNoch keine Bewertungen

- Nemmeli DesalDokument4 SeitenNemmeli DesalTushar NeelratanNoch keine Bewertungen

- Short Term Load Forecasting AnnDokument107 SeitenShort Term Load Forecasting AnnKishore Kumar100% (1)

- L C R C L A e Y: Grounding SystemDokument45 SeitenL C R C L A e Y: Grounding SystemAnonymous Jy6ASdQ45JNoch keine Bewertungen

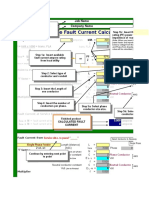

- Fault Current Calculation V7 1Dokument6 SeitenFault Current Calculation V7 1Pedro ComodoroNoch keine Bewertungen

- Od-Ops-Syst-003 Procedure For Testing and Maintenance To Avoid Excessiveover Speeding of Prime MoversDokument1 SeiteOd-Ops-Syst-003 Procedure For Testing and Maintenance To Avoid Excessiveover Speeding of Prime MoversDeepak KansalNoch keine Bewertungen

- Orifice and Venturi Meter - PrelabDokument6 SeitenOrifice and Venturi Meter - Prelableo besaNoch keine Bewertungen

- Combustion Analysis Basics: Tune-Up Procedure-Using An Electronic Combustion AnalyzerDokument19 SeitenCombustion Analysis Basics: Tune-Up Procedure-Using An Electronic Combustion AnalyzerTin Aung KyiNoch keine Bewertungen

- Power Quality TechniquesDokument9 SeitenPower Quality TechniquesS Bharadwaj ReddyNoch keine Bewertungen

- Instrumentation NotesDokument117 SeitenInstrumentation NoteshussainNoch keine Bewertungen

- SWRO - Process EngineerDokument1 SeiteSWRO - Process EngineermaniyarasanNoch keine Bewertungen

- Shielded Metal Arc Welding PrinciplesDokument23 SeitenShielded Metal Arc Welding PrinciplesSelva Kumar50% (2)

- Load ShedDokument2 SeitenLoad Shedchemical engineerNoch keine Bewertungen

- Reading Coal Flame in Tangentially Fired BoilerDokument4 SeitenReading Coal Flame in Tangentially Fired Boilerbhaskar1rkumar4092Noch keine Bewertungen

- DataCamp - ForECASTING USING R - Dynamic RegressionDokument24 SeitenDataCamp - ForECASTING USING R - Dynamic RegressionjomasoolNoch keine Bewertungen

- Dry Type Arc Welding MachineDokument11 SeitenDry Type Arc Welding MachineIsaac Honny Jnr100% (1)

- OC and SC Test On Single Phase TransformerDokument6 SeitenOC and SC Test On Single Phase TransformerGokul anandNoch keine Bewertungen

- AC Transmission Line LossesDokument8 SeitenAC Transmission Line LossesThakur YogendraNoch keine Bewertungen

- Handout 4 Losses of DC Generator and EfficiencyDokument13 SeitenHandout 4 Losses of DC Generator and EfficiencyKhate ÜüNoch keine Bewertungen

- SECTION 11 05 12 General Motor Requirements For Equipment Part 1 - General 1.1 DescriptionDokument4 SeitenSECTION 11 05 12 General Motor Requirements For Equipment Part 1 - General 1.1 DescriptionاحمدعليNoch keine Bewertungen

- SECTION 01 58 16 Temporary Interior Signage Part 1 General DescriptionDokument1 SeiteSECTION 01 58 16 Temporary Interior Signage Part 1 General DescriptionاحمدعليNoch keine Bewertungen

- Aircondition ElectDokument3 SeitenAircondition ElectاحمدعليNoch keine Bewertungen

- Pre-Wired SwitchDokument2 SeitenPre-Wired SwitchاحمدعليNoch keine Bewertungen

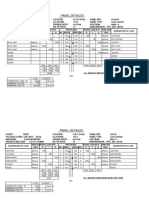

- Panel Detailes: Elpb-Ro Load Center Emdb - R Bottom 18 Elect Room 18 KADokument8 SeitenPanel Detailes: Elpb-Ro Load Center Emdb - R Bottom 18 Elect Room 18 KAاحمدعليNoch keine Bewertungen

- The Designs Principals of The Delivery Wards and Halls in The Iraqi Private HospitalsDokument16 SeitenThe Designs Principals of The Delivery Wards and Halls in The Iraqi Private HospitalsاحمدعليNoch keine Bewertungen

- Lighting Controls Terminology: A NEMA Lighting Systems Division DocumentDokument7 SeitenLighting Controls Terminology: A NEMA Lighting Systems Division DocumentاحمدعليNoch keine Bewertungen

- Rules For Wiring Single Pole SwitchDokument101 SeitenRules For Wiring Single Pole SwitchاحمدعليNoch keine Bewertungen

- Muhammad Waqas 09-EE-119 UET, Taxila Grid and The Sub StationDokument7 SeitenMuhammad Waqas 09-EE-119 UET, Taxila Grid and The Sub StationSajjad SajjadNoch keine Bewertungen

- Voltage Transformer TestingDokument19 SeitenVoltage Transformer TestingAfrin HossainNoch keine Bewertungen

- 1915 Anthracite Annual Report PDF From Univ of Scranton PDFDokument608 Seiten1915 Anthracite Annual Report PDF From Univ of Scranton PDFTavi GrigNoch keine Bewertungen

- CV MidhunDokument5 SeitenCV MidhunMidhunRameshThuvasseryNoch keine Bewertungen

- Course Title: Building Services (Electrical) : Prepared By: Olabode Oluwafemi. RDokument25 SeitenCourse Title: Building Services (Electrical) : Prepared By: Olabode Oluwafemi. ROlawale AdebesinNoch keine Bewertungen

- ANSI MV GIS SIMOSEC Substation Reference Guide enDokument16 SeitenANSI MV GIS SIMOSEC Substation Reference Guide enWasinchai KanjanapanNoch keine Bewertungen

- Traction Power Supply Infrastructure and Light Rail Vehicle InterfaceDokument19 SeitenTraction Power Supply Infrastructure and Light Rail Vehicle InterfacemoisesramosNoch keine Bewertungen

- RP - 147Dokument25 SeitenRP - 147schauhan12Noch keine Bewertungen

- Technology Procedures and ProcessesDokument24 SeitenTechnology Procedures and Processesdeion29Noch keine Bewertungen

- UntitledDokument10 SeitenUntitledKIRUBANESANNoch keine Bewertungen

- Flusarc Compact CBCC Technical Data SheetDokument6 SeitenFlusarc Compact CBCC Technical Data SheetYalem Alemayehu100% (1)

- EDS 06-0014 Secondary Substation Earthing Design PDFDokument55 SeitenEDS 06-0014 Secondary Substation Earthing Design PDFRajendra Prasad ShuklaNoch keine Bewertungen

- HTLT TenderDokument74 SeitenHTLT TenderRamesh AnanthanarayananNoch keine Bewertungen

- CEPCC SAT Distribution Transformer WisonDokument11 SeitenCEPCC SAT Distribution Transformer WisonNaveed Bin QasimNoch keine Bewertungen

- Presention - Sunil Hitech - Final PDFDokument86 SeitenPresention - Sunil Hitech - Final PDFAnonymous KzJcjGCJbNoch keine Bewertungen

- Internship Report of Hydro Power PlantDokument20 SeitenInternship Report of Hydro Power PlantSHAH RUKH KHANNoch keine Bewertungen

- 16 Samss 503Dokument42 Seiten16 Samss 503Jaikaran DanNoch keine Bewertungen

- Price Index 2015 (2) ASDDokument14 SeitenPrice Index 2015 (2) ASDAr Hanz Gerome SuarezNoch keine Bewertungen

- Keywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDokument6 SeitenKeywords Earthing Designs Substation Earthing Resistance Grid Potential Rise Mesh Voltage Step Voltage and Matlab Figures - CompressDebasish RahaNoch keine Bewertungen