Beruflich Dokumente

Kultur Dokumente

Steamthermalpowerplantpanki 121107093655 Phpapp01

Hochgeladen von

Abhishek DubeyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Steamthermalpowerplantpanki 121107093655 Phpapp01

Hochgeladen von

Abhishek DubeyCopyright:

Verfügbare Formate

Dr. B. R.

Ambedkar

National Institute of Technology, Jalandhar

Report on

Summer Training

[16

th

June to 28

th

July 2012]

Study of Electricity

Generation Through

Steam at PTPS

Ranjeet Kumar

Industrial & Production

Engineering

09113039

ranjeetnitj@gmail.com

N.I.T Jalandhar

Power Consumption In India

The energy sector holds the key in accelerating the economic

growth of India. The energy demands for developing country like

India keep on continuously growing. Energy is a driving force

behind rapid economic growth of the country. India ranks tenth in

the world in total energy consumption. It is first requirement of

energy to accelerate the development of the sector to meet its

growth aspirations.

The pattern of energy production put coal and oil again on

top. These account for 65% of the entire generation. Renewable

energy ranks bottom of the total production just before the

Nuclear energy. The distribution of energy resource like hydro

power is skewed towards North-eastern states of the country as 70

% of the total hydro potential is located in the Northern and

North-eastern region.

Figure of Power Consumption

Panki Thermal Power Station(PTPS),

Kanpur[U.P]

Panki Thermal Power Station is a Electricity Generation Station where

Electricity Generated through the steam operation on Turbine & Steam is

Generated by Coal Firing so it is a Typical Coal fired Electricity Generation

Station.

It is Located about 16 Kms Away from Kanpur Railway Station ,was

Started with two units(1

st

& 2

nd

) of 32 MW each.it was established in 1968.

After Generating Power for about 28-29 years,2*32 MW units had

completed their Rated Life So they were closed on 30

th

November 1995 &

18

th

April 1997 respectively.

So In 1976-77 ,Two Units (3

rd

& 4

th

of 2*110 MW each) Manufactured

,Installed Bharat Heavy Electronics Ltd. These units were established in

1976 & 1977 respectively.

Unit 3

rd

& 4

th

have been derated to 105 MW each by the Central

Electricity Authority(C.E.A) on 11

th

January 1990.

So Presently there are two units (3

rd

& 4

th

of 105 MW each) working at PTPS.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

About Steam Thermal Power Station

Process:-

A steam power plant is a power plant in which prime mover

is steam driven. Water is heated ,turns into steam and spins a

steam turbine(Impulse & reaction), which drives an

electrical generator. When the turbine turns, electricity is

generated and given as output by the generator, which is

then supplied to the consumers through high-voltage power

lines.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Process Diagram at Steam Power Plant

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Fossil Fuel Power Station

Previously we discussed that steam is prime driven object in steam

power plant so in the case we needed steam for power generation ;so

this steam is generated by boiling the water in boiler & this boiling is

done by burning of Fuel.

FOSSIL FUEL POWER STAION:-

a fossil fuel power station is a power station that burns fossil fuels such as

coal ,natural gas or petroleum (oil) to produce electricity.

Chemical Energy Heat Energy Mechanical Electrical

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Fuel+oil

Furnace Turbine Generator

Coal fired Steam Power Plant

Coal Fired Power Station:-

A coal Fired power station is that type of Fossil Fuel power station in

which coal is used as a Fuel. In the Steam Power Plant There is a

Separate Unit for Coal Handling System.

There are basically Five main units of a thermal power plant:

1. Coal Handling Plant (C.H.P)

2. Water Treatment Plant (W.T.P)

3. Boiler Maintenance Division (B.M.D)

4. Turbine Maintenance Division (T.M.D)

5. Generator

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Coal Handling Plant

-:COAL HANDLING & DELIVERING SYSTEM:-

In a coal Based Thermal Power Plant , the initial process in the power

generation is Coal Handling so in this article I will Discuss the overall

Process Carried out a coal handling plant in a coal based thermal

power generating station.

The huge amount of coal is usually supplied through railways. A

railway siding line is taken into the power station and the coal is

delivered in the storage yard. The coal is unloaded from the point of

delivery by means of wagon tippler. It is rack and pinion type. The coal is

taken from the unloading site to dead storage by belt conveyors. The

belt deliver the coal to 0 meter level & further moves to transfer point.

The transfer points are used to transfer coal to the next belt. The belt

elevates the coal to breaker house. It consists of a rotary machine,

which rotates the coal and separates the light dust from it through the

action of gravity and transfer this dust to reject bin house through belt.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

The belt further elevates the coal to the transfer point and it reaches the crusher

through belt. In the crusher a high-speed 3-phase induction motor is used to

crush the coal to a size of 50mm so as to be suitable for milling system. Coal rises

from crusher house and reaches the dead storage by passing through transfer

point.

Equipment used in a coal handling plant

1. Pull cord switch

Pull cord switch also known as Rope Operated Emergency Switch is used as safety

switch to stop the conveyor belt in case of an emergency by pulling the Rope. Pull

cord switch is mounted on the walkway side of the conveyor belt, Preferably at

about every 30 meters. when the rope is pulls from any side, the switch gets

operated. Unless and until the handle is reset manually position, the switch remains

in operated condition. NC contacts of all pull cord switches are wired in series and

further connected to PLC. when any switch along the belt operates, the contact

opens and conveyor is stopped.

Auxiliaries Of Coal Handling Plant

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Figure of Pull cord switch & Belt weightier

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Auxiliaries Of Coal Handling Plant

2. Vibrating feeder

The coal stored in a huge hub is collected on the belt through vibrations

created by the vibrating feeder.

3. Flap gates

These are used to channelize the route of coal through another belt in case

the former is broken or unhealthy. The flap gates open let the coal pass and

if closed stop its movement.

4. Magnetic separator

these are used to separate the ferrous impurities from the coal.

5. Metal detector

These are detect the presence of any ferrous and non-ferrous metal in the

coal and sends a signal to a relay which closes to seize the movement of

belt until the metal is removed. It basically consists of a transmitter and a

receiver.

The transmitter consists of a high frequency oscillator, which produces a.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Auxiliaries Of Coal Handling Plant

oscillations of 1500 Hz at 15V. The receiver receives this frequency signal.

If there is any presence of metal in the coal. Then this frequency is

disturbed and a tripping signal is send to relay to stop the conveyor belt

6. Belt weightier

It is used to keep an account of the tension & support on the belt

carrying coal and is moves accordingly to release tension on the belt.

7. Reclaim hopper

Reclamation is a process of taking coal from the dead storage for

preparation or further feeding to reclaim hoppers. This is accomplished

by belt conveyors

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Reclaim Hopper

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Steam Generation Process from Coal

STEAM GENERATION FROM COAL:-

1. Tipplers

Coal from the coal wagons is unloaded in the coal handling plant. This

unloading is done by the Tipplers. This coal is transported up to the raw

coal bunkers with the help of conveyor belts.

2.Coal Crushing

Although coal can be burned in solid form on grates, it is more usual to

break it up before feeding it to the combustion chamber. The treatment

depends on the nature of the coal. Some coals lend themselves to being

ground down to a very fine powder (called pulverized fuel (PF)) which is

then carried to the burners by a stream of air. Other coals are fed to

impact mills(Formally called Milling System) which use flails or hammers to

break up the material before it is propelled to the burners by an air stream.

The type of mill to be used on a particular plant will be determined by the

process

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Preparation of Fuel

engineers and it is the task of the control engineer to provide a system which

is appropriate. To do this it is necessary to have some understanding of how

the relevant type of mill operates.

Various types of pulverized-fuel mill will be encountered, but two are

most commonly used:

The Pressurized or vertical-spindle ball mill

horizontal-tube mill

AT PTPS Vertical spindle ball mill is used.

Vertical-spindle ball mills

Figure shows the operating principle of a typical ball mill, such as the

Babcock 'E' mill. In this device, the coal that is discharged from the

storage hoppers is fed down a central chute onto a table where it is crushed

by the crushing actions between the rollers and rotating tables rotating steel

balls. Air is blown into the crushed coal and carries it, via

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Preparation of Fuel

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

adjustable classifier blades, to the PF

pipes that transport it to the

burners. The air that carries the fine

particles of coal to the burners is

supplied from a fan called a 'primary-

air fan'. This delivers air to the mill,

which

therefore operates under a pressure

which is slightly positive with respect

to the atmosphere outside. Because

of this and because of its other

constructional

features, this type of mill is properly

called a 'vertical-spindle,

pressurized ball mill'.

Air supply systems for Ball mills

As stated above, the crushed coal in a pressurized ball mill is propelled to

the burners by a stream of warm air for proper drying & obtaining a particular

temperature of coal. Figure shows the arrangement

for doing this: cool air and heated air are mixed to achieve the desired temperature.

Primary Air FAN System for Ball Mill

Fuel Burning

3.Grate- It is the platform in Furnace upon which Fuel is Burnt & it is made of

Cast Iron Bars.The Bars are so arranged that air may pass on to the Fuel for

combustion.The area of the grate on which the fire rests in a coal or wood

fired boiler is called Grate surface.

4. Furnaces

It is a chamber formed by the space above the grate & below the boiler

shell,in which combustion takes place. It is also called a fire Box.

This crushed coal is taken away to the furnace through coal pipes with the

help of hot and cold air mixture from P.A Fan. P.A Fan takes atmospheric air,

a part of which is sent to Air pre-heaters for heating while a part goes

directly to the

mill for temperature control. Atmospheric air from F.D Fan is heated in the air

heaters and sent to the furnace as combustion air.

F.D(Force draught) Fan:-Force Draught Fan is main auxiliary of Furnace

which Provides Oxygen for Proper Combustioning of Fuel.It Takes Suction

From Environment. It is an Axial Flow Fan.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Oil Handling System

-:Oil Handling Plant:-

In Thermal Power Station Fuel Oil play a vital role.Oil burners besides initial

lighting up are also used to provide effective ignition of the coal

associated with P.F Burners and to stabilize the flame .The Burners can

provide enough heat to carry on boiling operation of the boilers for the

initial starting period. It can Provide 10-15% of the maximum load. At

Lean Period or when it is desired to Run the Boilers at OFF Load Condition

oil Burners are used.

Fuel oil used in Power Stations Are:-

# Heavy Furnace Oil (H.F.O)

# Light Diesel Oil (L.D.O)

# High Speed Diesel Oil (H.S.D)

# Low Sulphur High Stock Oil (L.S.H.S)

At Panki Thermal Power Station L.D.O is used as Fuel Oil

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

The Water Treatment plant is required at the water from canal cant be directly Used in

Boiler for Thermal Electricity Generator water is converted into steam at High Pressure &

It is allowed to force Turbine Rotated and the electricity is Generated. Therefore water is

the basic requirement to the thermal Power plant. Generally in the Thermal Power Plant

Is Employed to Refine the Water.

Necessity of Water Treatment:-

Natural Water Contains Solid,Liquid & Gasseous Impurities and Therefore this water cant

Be used for Generation of Steam in the Boiler ,The different Effect introduced due to use

Of Unrated Water in the boiler.So the water impurities should be removed before its used

as a stream.The following procedure is used in WTP for minimizing the hardness &

removing the impurities:-

Flocculate Plant:-

Here Alum is added is added to water to Precipitate

Dust Particles In Water.Aluminium in Alum

neutralizes Charge Dust Particle & this gives Result

to a heavy Complex Compound Which is settled

Water Treatment Plant (W.T.P)

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Auxiliaries of W.T.P

down. Bleaching Powder & limestone along with chloride is also added

in this flocculation Tank to remove temporary hardness & chloride also

removes Bacteria & Organic matter.

This is Called flocculate plant because ,all the mixing and

processing is done In flocculation plant where flocculation Mechanism is

also happens.

Sand Filter-

These Stages of sand filter are putt across the flow so as to remove other

Suspended Particle, If any.

Activated Carbon filter-

This Filter is employed for removal of Bacteria and organic material. Here

anthracite(Coal) is uses for Filter.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Auxiliaries of W.T.P

Cation Exchanger-

At this stage ions are observed by ion exchnanger method,HCl and

negative resin are principle ingredient of this chemical filter

Anion Exchanger:-

Here Negative Ions are observed by Carefully Formulated by positive

resin.

Mixed Bed Exchanger:-

Here Remaining a negative ion is removed that is extracted through

resin.

The D.M(De mineralized) water is now ready which has some properties-

Conductivity-0.03 to 0.5 (micro/cm2)

PH-6.5

Hardness-NIL

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Diagram of W.T.P at PTPS

Boiler:-

Boiler is an apparatus to produce Steam. Thermal energy Released by

Combustion of Fuel is Transferred to water ,Which Vaporizes and gets

converted water into steam at the desired temperature and pressure.It is

about 52 meter from the ground level.About its Design The boiler is a

rectangular furnace about 50 ft (15 m) on aside and 130 ft (40 m) tall. Its

walls are made of a web of high pressure steel tubes about 2.3 inches

(60 mm) in diameter. Pulverized coal is air-blown into the furnace from

fuel nozzles at the four corners and it rapidly burns, Forming

a large fireball at the center. The thermal radiation of the fireball heats

the water that circulates through the boiler tubes near the boiler

perimeter. The water circulation rate in the boiler is three to four times

the throughput and is typically driven by pumps. As the water in the

boiler circulates it absorbs heat and changes into steam at 700

0

F

(370

0

C)and 3,200psi (22.1MPa). It is separated from the water inside a

drum at the top of the furnace. The saturated steam is introduced into

superheat pendant.

Boiler Maintenance Division (B.M.D)

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

B.M.D & Its Supporting Auxiliaries

tubes that hang in the hottest part of the combustion gases as they exit the

furnace. Here the steam is superheated to 1,000F (540 C) to prepare it for

the turbine. The steam generating boiler has to produce steam at the

high purity, pressure and temperature required for the steam turbine

that drives the electrical generator. The generator includes the

economizer,

The Boiler Shell

Setting

Grate

The furnace with its steam generating tubes

Necessary safety valves are located at suitable points to avoid

excessive boiler pressure. The air and flue gas path equipment include:

Forced draft (FD) fan

Air preheater(APH)

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

B.M.D & Its Supporting Auxiliaries

boiler furnace

induced draft (ID) fan

Fly ash collectors (electrostatic precipitator or bag house) and The

flue gas stack.

The Steam produced is used for Producing Mechanical work by

expanding it in steam engine or steam turbine.

According the Process Boiler is of two type-

1.Water Tube Boiler-In water Tube boilers,Water cIrculates through the

tubes and hot products of Combustion Flow over These tubes.

2.Fire Tube Boiler In this fire flows in the tubes & tubes is surrounded by

water,Fire tube boilers have low Initial cost in compare to Water Tube

Boiler.

At PTPS Water Tube Boilers Are Used.

Boilers are also called Steam Generator

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Boiler

B.M.D & Its Supporting Auxiliaries

Boiler Shell or Boiler Drum:-The Shell or drum Consist of one or more Steel

Plates bent Into Cylinderical Form land Riveted or welded together.The shell

end are closed with the end plates.Its second or down plate made more

thicker than upper because all load applied on this.It is the main drum

which Received D.M Water from Boiler Feed Pump Passing through High

Pressure Heater & Economizer at a operating Pressure of 183kg/cm2 From

Boiler Drum.The Water Runs through the tubes.These Tubes are known as

down comers.

Setting- The Primary Function of setting is to continue Heat to the Boiler by

the Passes of gases taking From FD Fan .It is made from Brickwork.

Grate- It is the platform in Furnace upon which Fuel is Burnt & it is made of

Cast Iron Bars.The Bars are so arranged that air may pass on to the Fuel for

combustion.The area of the grate on which the fire rests in a coal or wood

fired boiler is called Grate surface.

Furnaces-It is a chamber formed by the space above the grate & below

the

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

External View of Boiler at PTPS

boiler shell,in which combustion takes place. It is also called a fire Box.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

B.M.D & Its Supporting Auxiliaries

Mountings-The Items Such as Stop Valve ,Safety valve, Water level Gauges,

Fusible Plug,Blow off cock ,Pressure Gauges,Water level Indicator etc. are

the mountings and a boiler cant work safely without these.

Path away Accessories or Integral Part of Boilers:-

Economizer:-Economizer is an important boiler accessory.The work of

Economizer is preheating of Feed water of boiler and to less Fuel

consumption Furnace. Preheating of feed Water is done by Flue Gases

which is comes from after burning of Fuel in the Combustion Chamber.

The Temperature of Feed Water at inlet of economizer is in Range of 160-

180

0

C

And after Leaving it,It becomes 210

0

C.It is located in Rear Side of Boiler.

Rotating Air Pre Heater:- The Purpose of Air Preheater is to Recover heat

of the Flue Gases Which is at a Considerably High as PA Fans

Temperature. It Rotates at the Speed of 176 rpm. The Heat of the flue

gases is absorbed by Heating Surface of air pre heaters and then transfer

to the cool air coming From P.A Fans.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

B.M.D & Its Supporting Auxiliaries

LPH(Low Pressure Heater):-it takes Extraction from Turbine & gives

these Extraction to Condensate Water Cycle for PreHeating of this

water.It is Situated at 4meter level on Turbine Side.

HPH(High Pressure Heater):- Its work same as LPH to Preheat of Feed

water by bleeding of Turbine.

Dearator:-Work of Dearator is to Dearate of Water means to Remove

Dissolve Gases from DM water & to Give Proper Suction To Boiler Feed

Pump.It is Situated at 27meter level in Boiler side.

Boiler Feed Pump:-Its work is to take suction from dearator and give

it to Boiler Drum on High Pressure(183Kg/cm2).Cycle of Dearator to

boiler drum is called Feed Water Cycle.It is situated at 0 meter level

on Turbine side.

F.D(Force draught) Fan:-Force Draught Fan is main auxiliary of

Furnace which Provides Oxygen for Proper Combustioning of Fuel. It

Takes Suction From Environment. It is an Axial Flow Fan.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

B.M.D & Its Supporting Auxiliaries

ID fan(Induced Draft Fan):-basically pulls out flue gas from the furnace

of boiler. It is located between dust precipitators(ESPs) and Chimney.

Obviously it handles hot air/dust. Whereas, FD fan(Forced Draft

Fan)supplies the required air into the furnace for combustion of fuel. It

handles air at normal temperature. The capacity/power rating of ID fan

will be more than that of FD fan.

Chimney:-When Coal burns in Furnace then Produce Smoke, Flew

Gases which content NO,SO2,CO,C etc. that ash is send in to Electro

Static precipitation and ash comes out with water but some Ash is

sucked by I.D fan which send into chimney with the smoke so the some

which is passing through Chimney is Black.

Super Heater:-The Function of a super heater is to Increase the

Temperature of Steam above Its Saturation point.The Super heater is very

important accessory of a Boiler & used in both in Fire Tube & Water Tube

Boiler.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Turbine Maintenance Division(T.M.D)

Steam Turbine

Steam turbines are used in all of our major coal fired power stations to

drive the generators or alternators, which produce electricity. The turbines themselves

are driven by steam generated in 'Boilers' or 'Steam Generators' as

they are sometimes called.Energy in the steam after it leaves the boiler is

converted into rotational energy as it passes through the turbine. The turbine normally

consists of several stages with each stage consisting of a stationary blade (or nozzle)

and a rotating blade. Stationary blades convert the potential

energy of the steam (temperature and pressure) into kinetic energy (velocity)

And direct the flow onto the rotating blades. The rotating blades convert the kinetic

energy into forces, caused by pressure drop, which results in the rotation

of the turbine shaft. The turbine shaft is connected to a generator, which

produces the electrical energy. The rotational speed is 3000 rpm for

Indian System (50 Hz)systems and 3600 for American (60 Hz) systems.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

T.M.D

In a typical larger power stations, the steam turbines are split into three

separate stages, the first being the High Pressure (HP), the second the

Intermediate Pressure (IP) and the third the Low Pressure (LP) stage, where

high, intermediate and low describe the pressure of the steam.

After the steam

has passed through the HP stage, it is returned to the boiler to be re-heated

to its original temperature although the pressure remains greatly

reduced. The reheated steam then passes through the IP stage and finally

to the LP stage of the turbine.

A distinction is made between "impulse" and "reaction turbine designs

based on the relative pressure drop across the stage. There are two

measures for pressure drop, the pressure ratio and the percent reaction.

Pressure ratio is the pressure at the stage exit divided by the pressure at the

stage entrance. Reaction is the percentage is entropic enthalpy drop

across the rotating blade or bucket compared to the total stage enthalpy

drop. Some manufacturers utilize percent pressure drop across stage to

define reaction.

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Steam Properties

At High Pressure (H.P) Turbine:-

Entrance Pressure-535

0

C-540

0

C

Entrance Temperature-130Kg/cm

2

Exit Pressure - 26Kg/cm

2

Exit Temperature-340

0

C

At Intermediate Pressure(I.P) Turbine:-

Entrance Pressure-24Kg/cm

2

Entrance Temperature-535

0

C

Exit Pressure-1.02 Kg/cm

2

Exit Temperature-140

0

C

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Steam Turbine

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Generator

Generator:-

An electric Generator is a machine which converts Mechanical Energy

(or Power) into Electrical Energy. This Energy Conversion is based on the

principle of the production of dynamically induced e.m.f is Produced in

it according to faradays law, Whenever a conductor is moving in a

magnetic Field then it cuts Magnetic Flux and there were an

E.M.F(Electro magnetic Force) Produced ,which is Called Induced

E.M.F.

e=N*d/dt

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Overall Process

Thank You !

by ranjeetnitj@gmail.com (N.I.T Jalandhar)

Das könnte Ihnen auch gefallen

- Calculation KersDokument3 SeitenCalculation KersAbhishek DubeyNoch keine Bewertungen

- WhisperPower - Genverter - Variable Speed GeneratorDokument2 SeitenWhisperPower - Genverter - Variable Speed GeneratorAbhishek DubeyNoch keine Bewertungen

- 24 Volt DC Generator, 24 Volt DC Generator Suppliers and Manufacturers at AlibabaDokument10 Seiten24 Volt DC Generator, 24 Volt DC Generator Suppliers and Manufacturers at AlibabaAbhishek DubeyNoch keine Bewertungen

- Home - QuoraDokument2 SeitenHome - QuoraAbhishek DubeyNoch keine Bewertungen

- Project NTPCDokument45 SeitenProject NTPCAbhishek DubeyNoch keine Bewertungen

- Iffco Aonla - Google SearchDokument2 SeitenIffco Aonla - Google SearchAbhishek DubeyNoch keine Bewertungen

- Amit Kakkar Chotu - Google SearchDokument1 SeiteAmit Kakkar Chotu - Google SearchAbhishek DubeyNoch keine Bewertungen

- NTPC TandaDokument11 SeitenNTPC TandaAbhishek Dubey0% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Chapter 3 - Well Completion Practices PDFDokument138 SeitenChapter 3 - Well Completion Practices PDFchft100% (1)

- Nexus 1262 & 1272 CatalogueDokument12 SeitenNexus 1262 & 1272 CataloguenaveenNoch keine Bewertungen

- Kristian Tlangau - November, 2016 PDFDokument52 SeitenKristian Tlangau - November, 2016 PDFMizoram Presbyterian Church SynodNoch keine Bewertungen

- Falcon 7X CommunicationsDokument105 SeitenFalcon 7X Communicationsjunmech-1Noch keine Bewertungen

- Energy Cable Accessories Epp1984 EngDokument156 SeitenEnergy Cable Accessories Epp1984 EngSathiyanathan ManiNoch keine Bewertungen

- 7ML19981GC61 1Dokument59 Seiten7ML19981GC61 1Andres ColladoNoch keine Bewertungen

- The Essentials of Directional Protection and SelectivityDokument27 SeitenThe Essentials of Directional Protection and SelectivityMarcus Figueroa100% (1)

- HL780 9SDokument583 SeitenHL780 9SAnonymous yjK3peI7100% (3)

- Interview MemoDokument3 SeitenInterview Memoapi-285542299Noch keine Bewertungen

- 1 Chapter1 Introduction V5.5a1Dokument13 Seiten1 Chapter1 Introduction V5.5a1Alejandro LaraNoch keine Bewertungen

- Long+term+storage+procedure 1151enDokument2 SeitenLong+term+storage+procedure 1151enmohamadhakim.19789100% (1)

- Community Needs Assessments and Sample QuestionaireDokument16 SeitenCommunity Needs Assessments and Sample QuestionaireLemuel C. Fernandez100% (2)

- ICT Css NotesDokument11 SeitenICT Css NotesWinnie OoiNoch keine Bewertungen

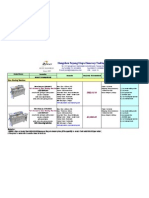

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Dokument1 SeiteQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargNoch keine Bewertungen

- Toshiba NB520 Compal LA-6859PDokument38 SeitenToshiba NB520 Compal LA-6859Pash thonNoch keine Bewertungen

- k2601 enDokument12 Seitenk2601 enRobert MasaNoch keine Bewertungen

- ASSA ABLOY - Digital Cam LocksDokument12 SeitenASSA ABLOY - Digital Cam LocksSales Project 2 VCPNoch keine Bewertungen

- 中国铁路客运枢纽发展回顾与展望 王昊Dokument9 Seiten中国铁路客运枢纽发展回顾与展望 王昊qiqiaorongNoch keine Bewertungen

- Micronta 12VDC Power Adapter 273-1653A InstructionsDokument2 SeitenMicronta 12VDC Power Adapter 273-1653A Instructions240GL guyNoch keine Bewertungen

- Assign#1Dokument2 SeitenAssign#1Edrielle ValdezNoch keine Bewertungen

- Android VersionsDokument7 SeitenAndroid VersionsEdna Mae Salas GarciaNoch keine Bewertungen

- Wireless Body Area Networks: A SurveyDokument29 SeitenWireless Body Area Networks: A Surveyabdul hananNoch keine Bewertungen

- NHD Works Cited 2015Dokument9 SeitenNHD Works Cited 2015miakellerNoch keine Bewertungen

- A Neural Network Model For Electric PDFDokument6 SeitenA Neural Network Model For Electric PDFR Adhitya ArNoch keine Bewertungen

- PL54 PeugeotDokument3 SeitenPL54 Peugeotbump4uNoch keine Bewertungen

- Regional VP Sales Director in USA Resume Margo PappDokument2 SeitenRegional VP Sales Director in USA Resume Margo PappMargoPappNoch keine Bewertungen

- InternshipDokument14 SeitenInternshipMohammed Shaheeruddin0% (1)

- Xenon Xenalight Surgical Lighting SystemsDokument2 SeitenXenon Xenalight Surgical Lighting SystemsQasim AliNoch keine Bewertungen

- Company Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Dokument2 SeitenCompany Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Kumaran GopalNoch keine Bewertungen

- PESTLE Analysis Patanjali Ayurved LTDDokument7 SeitenPESTLE Analysis Patanjali Ayurved LTDvaidehi50% (2)